At 3:47 AM, your most critical production line shuts down. A bearing failure in the main drive motor brings $500,000 worth of hourly production to a grinding halt. By the time you source replacement parts and complete repairs, you've lost two full production days, missed customer deliveries, and racked up $75,000 in emergency maintenance costs.

This scenario plays out in manufacturing facilities across America every single day. Equipment failures aren't just maintenance problems—they're business killers that can determine whether your operation thrives or struggles to survive. The average manufacturing facility experiences equipment failures every 3-4 days, with each major failure costing between $50,000 to $250,000 in direct and indirect costs.

But here's what separates industry leaders from the pack: top-performing facilities don't just respond to failures faster—they prevent 85-90% of potential failures from ever occurring. The difference lies in understanding why equipment fails and implementing systematic prevention strategies that address root causes rather than symptoms.

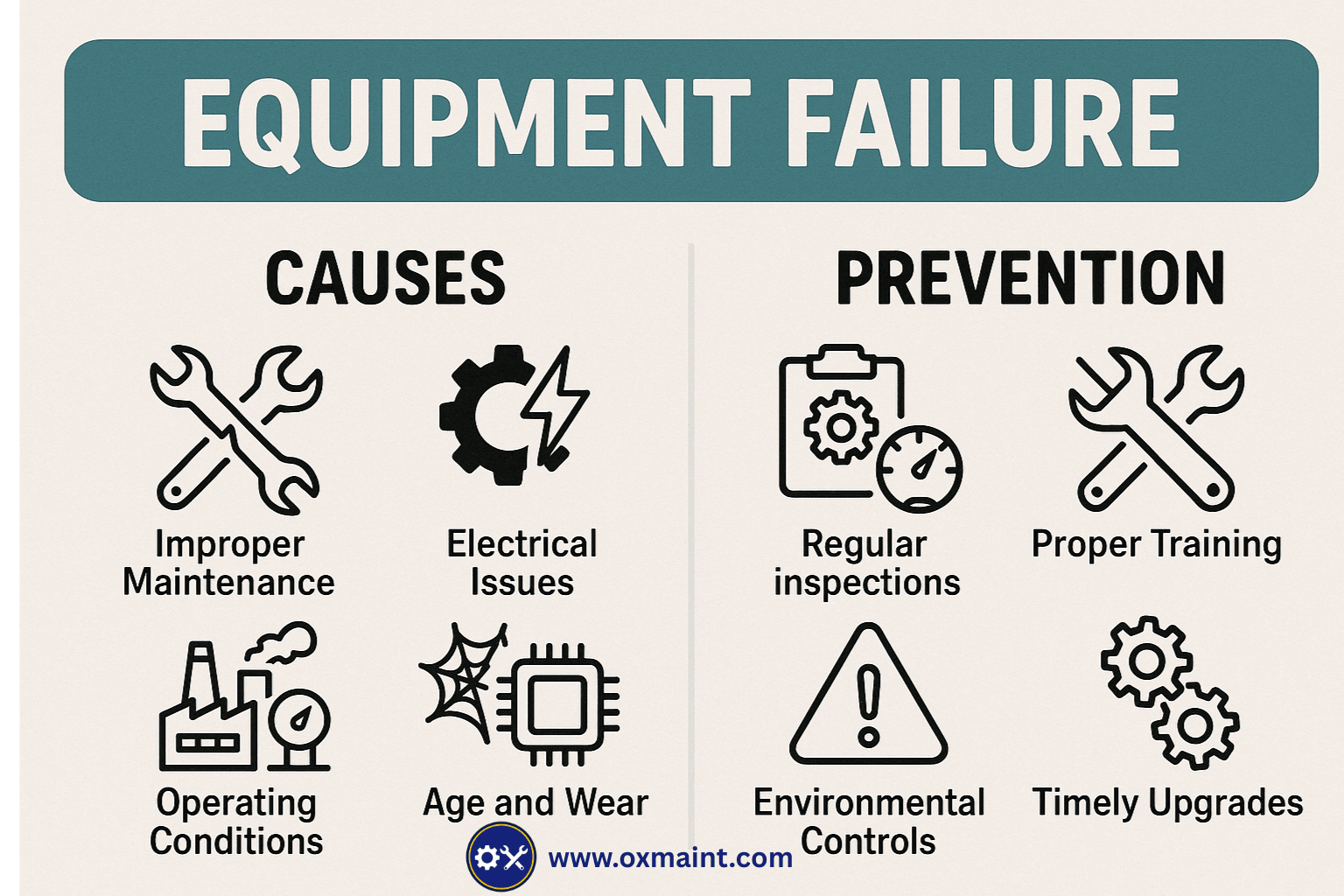

Understanding Failure Types and Root Causes

Equipment failures aren't random events—they follow predictable patterns that can be anticipated and prevented. Understanding these patterns provides the foundation for developing effective prevention strategies that address specific failure mechanisms rather than applying generic maintenance approaches.

The majority of equipment failures fall into five primary categories, each with distinct characteristics and prevention requirements. Recognizing these failure types enables targeted prevention strategies that maximize reliability while optimizing maintenance resources.

Wear-Related Failures

Gradual degradation from normal use. Predictable and preventable through proper maintenance timing.

Fatigue Failures

Stress-induced cracking from repeated loading cycles. Detectable through condition monitoring.

Corrosion Failures

Environmental degradation from moisture, chemicals, or temperature extremes.

Overload Failures

Sudden failures from operating beyond design limits or improper loading conditions.

Random Failures

Unpredictable events from manufacturing defects, installation errors, or external factors.

Wear-related failures account for 60-70% of equipment problems and offer the greatest prevention opportunities. These failures develop gradually over months or years, providing ample warning through condition monitoring and inspection programs. Components like bearings, seals, belts, and filters follow predictable wear patterns that enable optimized replacement scheduling.

Fatigue failures represent 15-20% of equipment problems but often cause the most catastrophic consequences. Metal fatigue from repeated stress cycles creates micro-cracks that eventually propagate to complete failure. These failures can be detected early through vibration analysis, ultrasonic testing, and visual inspection programs.

The root causes behind equipment failures often extend beyond the failed component itself. Poor lubrication practices cause 40-50% of bearing failures, contamination accounts for 30% of hydraulic system problems, and improper installation creates 25% of new equipment issues. Understanding these underlying causes enables prevention strategies that address the source rather than symptoms.

Operating conditions significantly influence failure patterns. Equipment running at high utilization rates, in harsh environments, or beyond design specifications will experience accelerated wear and more frequent failures. Environmental factors like temperature extremes, humidity, vibration, and contamination can reduce equipment life by 50-75% if not properly managed.

The Hidden Costs of Equipment Failures

Equipment failures cost far more than the obvious repair bills. The true financial impact includes cascading effects that ripple throughout operations, affecting everything from customer relationships to long-term competitive position. Understanding these hidden costs provides the business case for investing in comprehensive prevention strategies.

Production losses represent the largest cost component for most facilities. When critical equipment fails, entire production lines may shut down, affecting not just the failed machine but all downstream processes. A single conveyor failure can idle dozens of operators and multiple production lines, creating losses that far exceed the repair cost itself.

Emergency maintenance premiums multiply direct repair costs by 3-5 times normal rates. Emergency labor commands premium wages, expedited parts delivery adds 100-500% cost premiums, and emergency contractors charge substantially higher rates than planned maintenance providers. These premiums quickly add tens of thousands of dollars to major repairs.

Quality impacts create long-term costs that extend far beyond immediate production losses. Equipment operating outside normal parameters produces inconsistent output, higher defect rates, and increased rework requirements. These quality issues can damage customer relationships and require expensive corrective actions that continue long after equipment repairs are completed.

Supply chain disruptions multiply failure impacts throughout the entire operation. Missed production schedules create shortages that affect downstream manufacturing, delay customer deliveries, and require expensive expediting to recover. These disruptions can take weeks to fully resolve even after equipment is repaired.

Safety risks increase dramatically during failure events and emergency repairs. Rushed repairs under pressure create opportunities for accidents, and failed equipment may create hazardous conditions for operators. The human and financial costs of safety incidents far exceed equipment repair costs and can have permanent consequences for both individuals and organizations.

Proven Prevention Strategies That Work

Effective failure prevention requires systematic implementation of multiple strategies that work together to address different failure mechanisms. The most successful facilities don't rely on single approaches but build comprehensive prevention programs that create multiple layers of protection against equipment failures.

Preventive maintenance forms the foundation of any effective prevention program. However, generic PM schedules based solely on manufacturer recommendations often miss the mark. Effective programs customize schedules based on actual operating conditions, failure history, equipment criticality, and specific failure modes.

Start with failure mode analysis to understand how each piece of equipment can fail and what maintenance activities prevent each failure mode. This analysis reveals that different components require different approaches: time-based schedules work well for consumable items, condition-based strategies excel for rotating equipment, and inspection-based approaches suit structural components.

Condition monitoring technologies provide early warning of developing problems weeks or months before failure occurs. Vibration analysis detects bearing and alignment issues, oil analysis reveals internal wear patterns, thermal imaging identifies electrical problems, and ultrasonic testing finds leaks and friction issues. The key is matching monitoring technologies to specific failure modes and establishing clear action thresholds.

Lubrication management deserves special attention since poor lubrication causes 40-50% of equipment failures. Implement proper lubricant selection, storage, handling, and application procedures. Use filtration systems to maintain lubricant cleanliness, establish regular sampling and analysis programs, and train personnel in proper lubrication practices.

Operator-driven reliability programs leverage frontline knowledge to prevent failures. Train operators to perform basic inspections, recognize abnormal conditions, and report developing problems before they cause downtime. Simple daily checks can identify 60-70% of potential failures while they're still preventable.

Environmental control addresses external factors that accelerate equipment degradation. Maintain proper temperature and humidity levels, implement contamination control measures, provide vibration isolation, and protect equipment from corrosive environments. These measures can extend equipment life by 50-100% in harsh operating conditions.

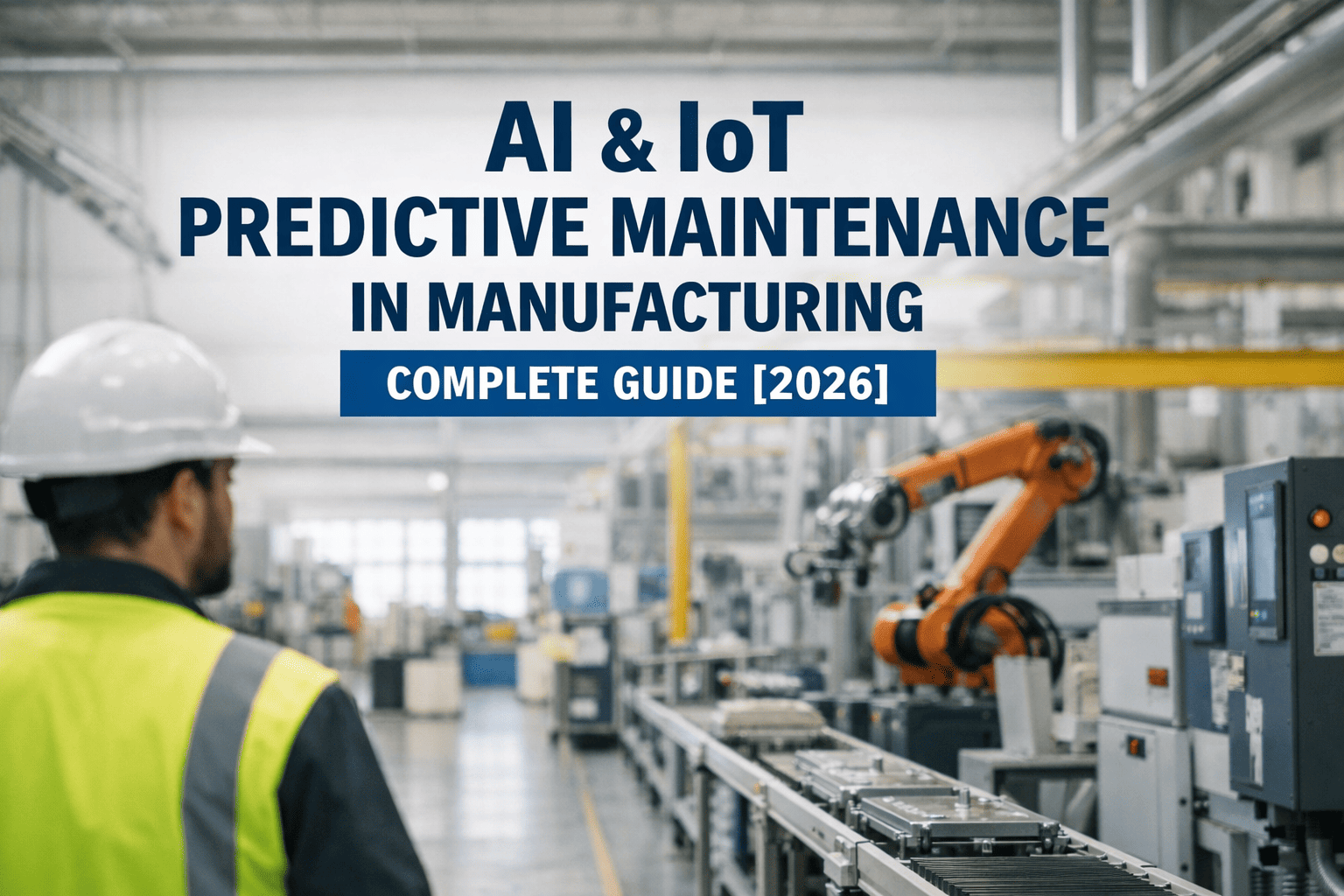

Technology Solutions for Failure Prevention

Modern technology platforms transform failure prevention from reactive maintenance into predictive intelligence. Advanced systems can identify developing problems months in advance, optimize maintenance timing, and enable intervention before failures occur. The right technology investments typically deliver 3-5 times ROI through prevented failures and optimized maintenance activities.

Predictive maintenance systems use machine learning algorithms to analyze equipment data and predict failure probability. These systems continuously monitor vibration patterns, temperature trends, power consumption, and other parameters to identify developing problems. Advanced systems can predict specific failure modes 60-90 days in advance with 85-95% accuracy.

Internet of Things (IoT) sensors provide continuous monitoring of critical equipment parameters without human intervention. Wireless sensors can track everything from motor temperatures and bearing vibrations to hydraulic pressures and electrical loads. When parameters exceed normal ranges, automatic alerts enable immediate intervention before minor problems become major failures.

Digital twin technology creates virtual replicas of physical equipment that enable simulation of different operating scenarios and maintenance strategies. This capability allows testing of optimization approaches without risking actual production equipment, accelerating improvement while reducing implementation risks.

Computerized Maintenance Management Systems (CMMS) integrate all prevention activities into a single platform. Advanced systems can automatically schedule maintenance based on equipment condition, optimize resource allocation, manage spare parts inventory, and track performance metrics. Integration with other plant systems enables holistic optimization of maintenance and production activities.

Artificial intelligence platforms analyze vast amounts of operational data to identify patterns that human analysis might miss. These systems can correlate equipment conditions with production parameters, environmental factors, and operational practices to provide insights that enable more effective prevention strategies.

Building a Culture of Reliability

Technology and procedures provide the tools for failure prevention, but sustainable success requires building an organizational culture that prioritizes reliability over short-term production pressures. The most reliable facilities create environments where prevention is valued, rewarded, and continuously improved.

Leadership commitment starts with recognizing that reliability is a competitive advantage rather than just a cost center. When leadership demonstrates genuine commitment to prevention over reaction, it creates organizational alignment that enables sustained improvement. This commitment must be visible through resource allocation, performance metrics, and daily decision-making priorities.

Cross-functional collaboration breaks down silos between maintenance, operations, engineering, and quality teams. Equipment reliability affects all these functions, and sustainable improvement requires coordinated effort. Regular reliability meetings, shared performance metrics, and collaborative problem-solving approaches create alignment around common objectives.

Continuous improvement processes ensure that prevention strategies evolve with changing conditions and new knowledge. Implement regular failure analysis procedures, share lessons learned across the organization, and systematically update prevention strategies based on actual experience. The most reliable facilities treat every failure as a learning opportunity that strengthens future prevention efforts.

Training and development build the knowledge and skills needed for effective prevention. Provide technical training on equipment operation and maintenance, develop problem-solving and analytical skills, and create career development paths that reward reliability expertise. Skilled, motivated personnel are essential for sustaining long-term improvement.

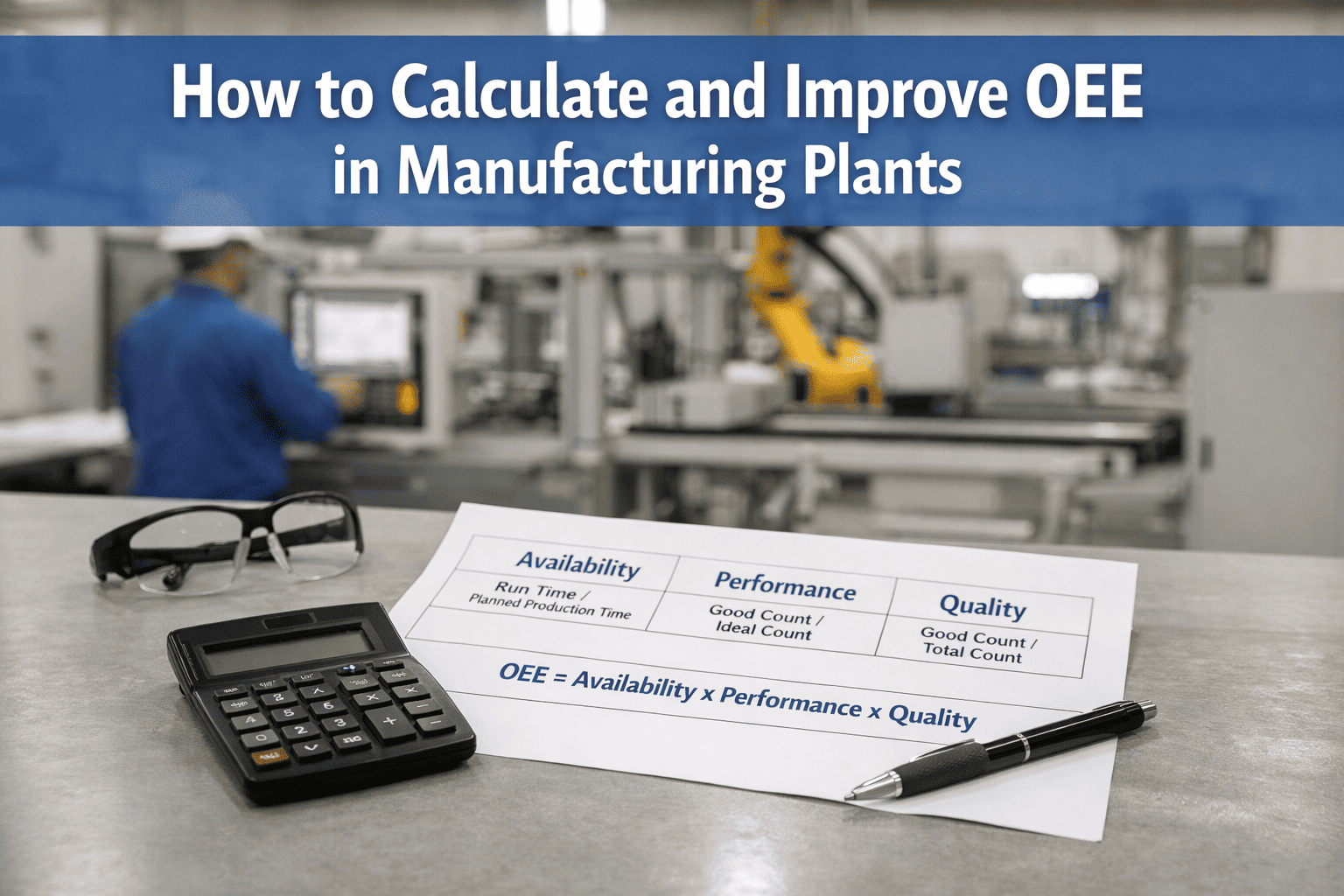

Performance measurement and recognition reinforce reliability priorities through daily operations. Track and communicate reliability metrics regularly, recognize teams and individuals who contribute to prevention success, and ensure that performance management systems align with reliability objectives rather than conflicting short-term production goals.

Conclusion

Equipment failures aren't inevitable costs of manufacturing—they're preventable events that can be eliminated through systematic understanding of failure mechanisms and implementation of targeted prevention strategies. The facilities that excel in reliability don't just fix problems faster; they prevent 85-90% of potential failures from ever occurring.

Success requires a comprehensive approach that addresses the multiple factors contributing to equipment failures. Technical solutions like condition monitoring and predictive maintenance provide the early warning systems, while systematic maintenance practices address the underlying causes of degradation. Cultural factors ensure that prevention remains a priority even under production pressure.

The business case for failure prevention continues strengthening as competitive pressures intensify and customer expectations rise. Facilities that master prevention achieve sustainable competitive advantages through superior reliability, predictable operations, and optimized costs. The investment in prevention typically pays for itself within 6-12 months while building capabilities that deliver value for years.

Start with systematic failure analysis to understand your specific patterns and highest-impact opportunities. Implement targeted prevention strategies based on actual failure modes rather than generic approaches. Build organizational capabilities gradually while demonstrating value through measurable improvements in reliability and cost performance.

Remember that failure prevention is a journey requiring sustained commitment and continuous improvement. The most successful facilities continuously evolve their approaches based on changing equipment, operational requirements, and available technologies. This commitment to excellence in reliability creates competitive advantages that compound over time and become increasingly difficult for competitors to match.