Maintenance strategies are an essential facet of operational performance in any asset-reliant industry. The right maintenance approach can reduce downtime, save costs, and extend the life of equipment. However, choosing the appropriate strategy is often a complex task that requires a deep understanding of various methodologies and their impacts. In this blog, we explore the different types of maintenance strategies and provide insights on selecting the most suitable one for your business needs.

Understanding the Spectrum of Maintenance Strategies

Before diving into selection criteria, it's crucial to understand the different maintenance strategies available.

Reactive Maintenance (Breakdown Maintenance)

Reactive Maintenance occurs when repairs are made after a piece of equipment has failed or when its performance has degraded significantly enough to impact operations. This approach does not involve preventative measures or scheduled checks but rather a response-based action triggered by equipment malfunction or breakdown.

Preventive Maintenance (Scheduled Maintenance)

Preventive Maintenance involves scheduled maintenance tasks that are performed on equipment at predetermined intervals to ensure it continues to operate efficiently and to minimize the possibility of unplanned downtime due to equipment failure. These tasks are typically outlined based on time intervals (e.g., monthly, quarterly) or usage milestones (e.g., every 1,000 hours of operation).

Predictive Maintenance (Condition-Based Maintenance)

Predictive Maintenance (PdM) utilizes various diagnostic tools and techniques, such as vibration analysis, thermal imaging, and acoustic inspections, to monitor the condition and performance of equipment during its normal operation. By continuously collecting and analyzing data from equipment sensors, this strategy allows maintenance teams to identify potential issues before they lead to failure.

Reliability-Centered Maintenance (RCM)

RCM is an advanced maintenance strategy that revolves around the reliability of system components and prioritizes maintenance actions based on the risk and consequences of failure. This maintenance philosophy was originally developed for the aviation industry but has since been adopted widely across various sectors that require high reliability, such as manufacturing, energy, and transportation.

Total Productive Maintenance (TPM)

TPM is a maintenance philosophy developed in Japan in the 1970s, derived from the preventive maintenance strategies of the United States. It emphasizes proactive and preventive maintenance to maximize the operational efficiency of equipment. TPM aims to empower all employees to take part in maintenance activities through continuous improvement and problem-solving efforts based on teamwork.

Choosing the Right Maintenance Strategy

Selection of a maintenance strategy depends on several factors:

Assessing Equipment Criticality: Determine how crucial each piece of equipment is to your operations. High-criticality assets might require more robust strategies like RCM or predictive maintenance.

Understanding Asset Lifecycle: Analyze where each asset is in its lifecycle. Older equipment might benefit more from preventive maintenance, while newer technology can be monitored effectively with predictive approaches.

Calculating Cost Implications: Consider both direct costs (such as repairs) and indirect costs (such as downtime). Predictive and RCM strategies may require higher upfront investment but can offer savings over time.

Evaluating Technical Capabilities: Do you have the technical resources to implement sophisticated strategies like predictive maintenance, or would a preventive approach be more realistic?

Compliance and Safety Requirements: For certain industries, regulations may dictate maintenance strategies to ensure safety and compliance.

Training and Culture: TPM requires a cultural shift and training at all levels. Assess if your organization is ready for such an approach.

Implementing Your Chosen Maintenance Strategy

Once you select a strategy, implementation involves:

Creating a Detailed Plan: Outline all tasks, schedules, and responsibilities.

Investing in Training: Ensure all relevant personnel are trained for the new maintenance regime.

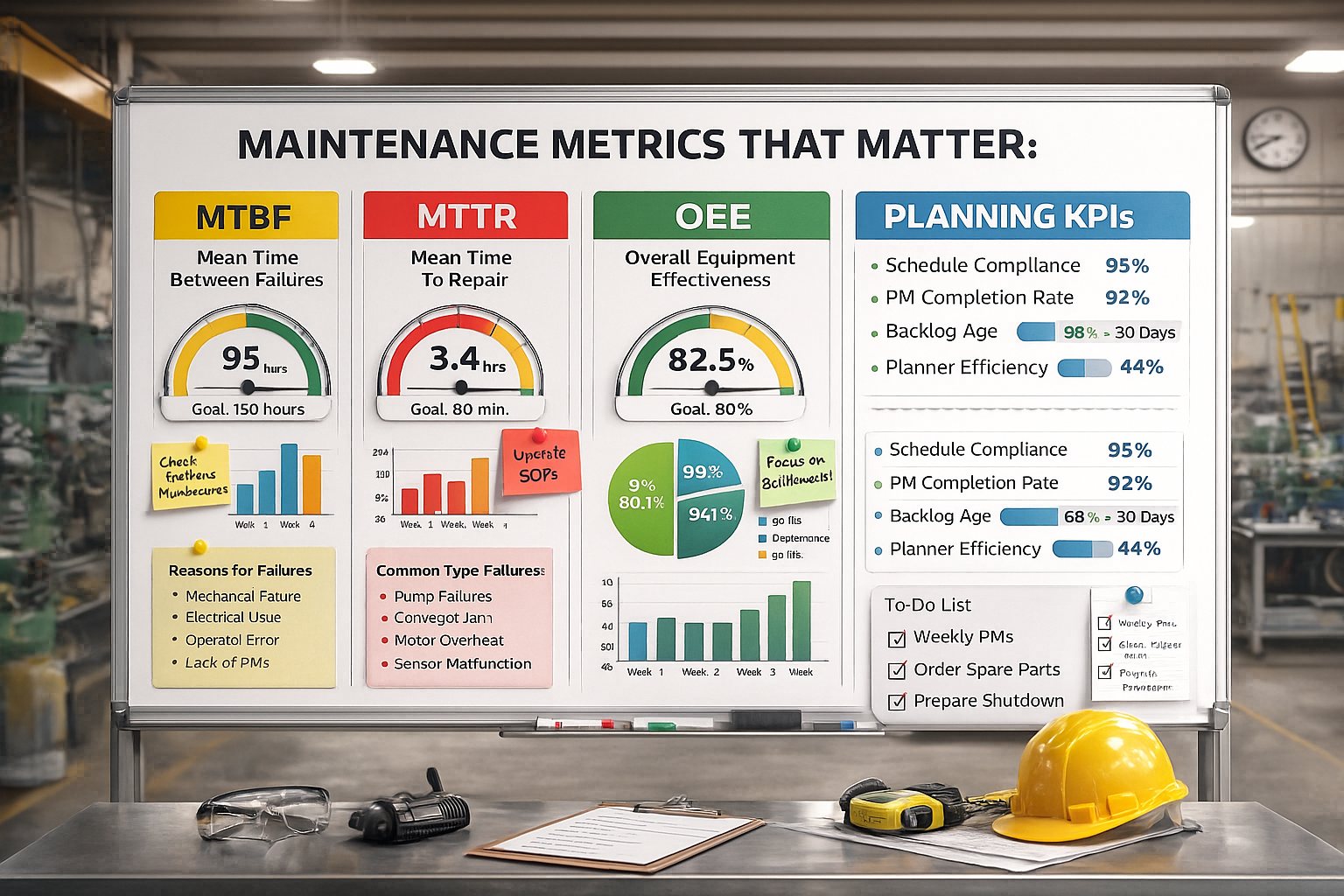

Monitoring and Adjusting: Use KPIs to track the effectiveness of your maintenance strategy and be prepared to adjust as necessary.

Conclusion

There is no one-size-fits-all approach to maintenance. The right strategy for your organization will align with your operational needs, asset criticality, and organizational capabilities. By carefully evaluating your unique circumstances and making informed decisions, you can choose a maintenance strategy that enhances reliability, efficiency, and profitability.

If you're ready to develop a tailored maintenance strategy that aligns with your business goals and maximizes asset uptime, click the button below to get in touch with our experts today.

➤ Optimize Your Maintenance

FAQs

What are the main types of maintenance strategies?

The main types of maintenance strategies include reactive maintenance, preventive maintenance, predictive maintenance, reliability-centered maintenance (RCM), and total productive maintenance (TPM).

How do I choose the right maintenance strategy for my business?

Choosing the right maintenance strategy depends on various factors, including the criticality of your equipment, the complexity and age of your assets, cost considerations, your technical capacity to implement the strategy, and your industry's safety and compliance regulations.

Can I combine different maintenance strategies?

Yes, many organizations use a hybrid approach, combining elements from various maintenance strategies to meet their specific operational needs.

Is preventive maintenance better than reactive maintenance?

While preventive maintenance is generally more cost-effective in the long run compared to reactive maintenance, the best choice depends on the nature and use of the equipment in question. Some non-critical assets may be suitable for a reactive approach, while critical assets often require preventive measures.

What is predictive maintenance, and how does it work?

Predictive maintenance is a strategy that relies on equipment condition monitoring and data analysis to predict when maintenance should be performed. It prevents unnecessary maintenance tasks and can reduce the likelihood of unexpected equipment failures.

Why is reliability-centered maintenance considered to be comprehensive?

Reliability-centered maintenance is considered comprehensive because it looks beyond the equipment itself and focuses on maintaining system functionality. It involves detailed analysis to determine the most effective maintenance actions based on reliability and criticality.

What are the benefits of total productive maintenance (TPM)?

TPM benefits include improved equipment effectiveness, increased productivity, a culture of continuous improvement, and enhanced employee morale, as it involves everyone in the organization from operators to senior management.

How often should I review and adjust my maintenance strategy?

Your maintenance strategy should be reviewed regularly, at least annually, or whenever there are significant changes in your operating environment, equipment, or business objectives.

What kind of training is needed to implement a new maintenance strategy?

The training needed will vary depending on the strategy you choose. It could range from basic instruction on routine inspection techniques to comprehensive training on advanced predictive maintenance technologies.

Are there any software tools that can help with maintenance management?

Yes, there are various Computerized Maintenance Management Systems (CMMS) and Enterprise Asset Management (EAM) software tools available that can help plan, track, and optimize maintenance activities.