Request Maintenance

Empower anyone to submit maintenance requests with a simple QR code scan. Track requests, prioritize issues, and resolve problems 60% faster with OxMaint's intelligent request management system.

Trusted by over 1000+ clients across the world

Simple Request Process

6-Step Request Workflow

From QR scan to resolution, streamline your entire maintenance request process with OxMaint.

Scan QR Code

Public AccessSubmit Request

Fill DetailsAuto Assign

Route to TeamPrioritize

Set UrgencyCreate WO

Generate OrderResolve

Complete & CloseFeature Spotlight

External Request QR Code

Share a single QR code to allow anyone—employees, contractors, or visitors—to submit maintenance requests instantly. No login required, no app download needed. Just scan and report.

Public Access

No login or account required to submit requests.

Mobile Friendly

Works on any smartphone with camera access.

Copy Link

Share request link via email, SMS, or chat.

Print & Post

Download and print QR codes for your facility.

Auto Dashboard

Requests appear in your dashboard automatically.

Share Options

Share via social media or embed on intranet.

External Request QR Code

Quick accessShare this QR code to allow external users to submit maintenance requests

Easy Submission

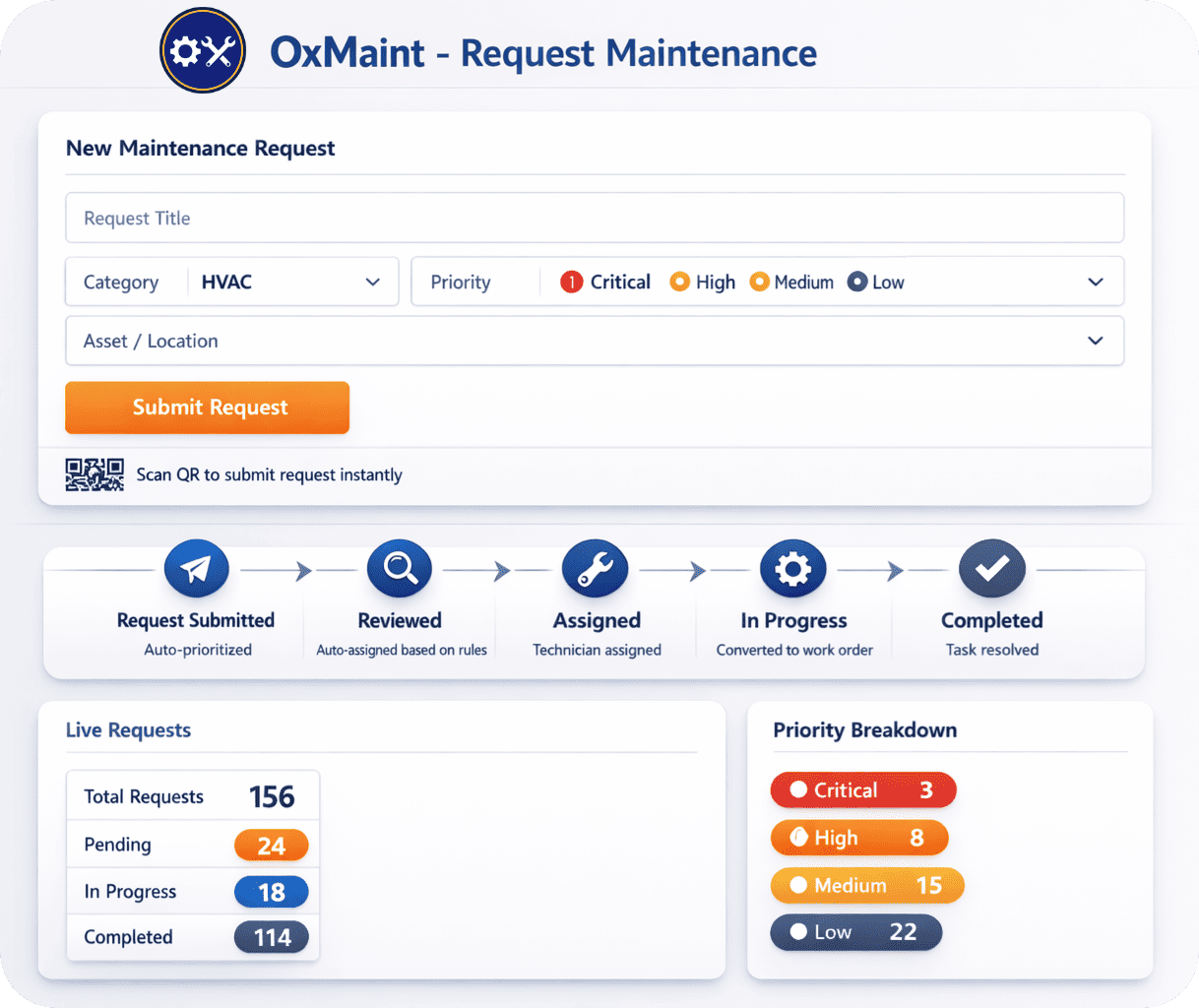

Create Maintenance Request

Simple, intuitive form that captures all essential information. Requesters can describe issues, set priority, attach photos, and link to specific assets or locations.

Title & Description

Brief issue title with detailed description field.

Priority Selection

Choose Critical, High, Medium, or Low priority.

Photo Attachments

Upload up to 4 images (JPG, PNG, GIF) per request.

Asset Selection

Link request to specific equipment or asset.

Location Tagging

Specify where the issue is located in your facility.

Auto-Fill Requester

Name and email auto-filled from user profile.

Create Maintenance Request

Real-Time Tracking

Request Status Overview

Monitor all maintenance requests in one dashboard. Track status from submission to completion, see pending items, and identify requests in progress.

Total Requests

See all requests submitted to your organization.

Pending Queue

Requests awaiting review and assignment.

In Progress

Requests currently being worked on by your team.

Completed

Successfully resolved and closed requests.

Status Filters

Filter by status, priority, or custom criteria.

Search Requests

Quickly find specific requests by keyword.

Request Status Overview

156

Total Requests24

Pending18

In Progress114

CompletedUrgency Control

Priority Breakdown

Categorize requests by urgency level. Ensure critical issues get immediate attention while lower priority items are scheduled appropriately.

Critical Priority

Safety hazards, production stoppage, emergencies.

High Priority

Significant impact on operations or safety concerns.

Medium Priority

Standard issues that need attention but aren't urgent.

Low Priority

Minor issues that can be scheduled when convenient.

Auto Escalation

Escalate unresolved requests automatically.

SLA Tracking

Monitor response times by priority level.

Priority Breakdown

Critical

Requires immediate attentionHigh

Significant impactMedium

Standard priorityLow

Can be scheduledPerformance Analytics

Key Metrics & Quick Insights

Get instant visibility into your maintenance request performance. Track completion rates, pending backlogs, and active requests with real-time metrics.

Completion Rate

Percentage of requests completed successfully.

Pending Rate

Requests awaiting attention in the queue.

Active Requests

Currently in progress by your maintenance team.

Most Urgent

High-priority requests needing immediate action.

Backlog Tracking

Monitor pending requests to prevent buildup.

Success Rate

Track overall maintenance success percentage.

Key Metrics

73%

Complete 114 of 15615%

Pending 24 awaiting18

Active In progressQuick Insights

Getting Started

How to Use QR Request System

Setting up and using the QR code request system is simple. Follow these steps to enable anyone in your facility to report maintenance issues.

Print and Post QR Code

Download and print the QR code. Post it in visible locations throughout your facility.

Workers Scan with Mobile

Anyone can scan the QR code with their smartphone camera—no app required.

Fill Maintenance Request Form

They'll be directed to a simple form to describe the issue and add photos.

Request Appears in Dashboard

Requests will appear in your dashboard automatically for review and assignment.

How to use:

Print and post this QR code in your facility

Workers can scan with their mobile devices

They'll be directed to a maintenance request form

Requests will appear in your dashboard automatically

Pro Tip

Post QR codes near equipment, in break rooms, and at facility entrances for maximum visibility.Integrated Modules

Requests Connected to Your Workflow

Maintenance requests seamlessly integrate with work orders, assets, inventory, and your entire CMMS ecosystem.

Work Orders

Convert to WOAssets

Link to equipmentLocations

Tag facility areasTeam

Auto-assign techsInventory

Reserve partsNotifications

Instant alertsReports

Request analyticsScheduling

Plan workWe are proud of our results

We bring solutions to make maintenance requests easier for everyone.

60%

Faster Response Time

85%

Completion Rate

99.5%

Customer Satisfaction

"The QR code system is brilliant. Anyone in our facility can report issues instantly. Response time improved by 60% since implementation."

Metro Facilities Inc.

Facilities Management

"Our maintenance team loves how requests come in with photos and location details. No more playing phone tag to understand the issue."

Industrial Solutions Co.

Manufacturing

"Priority-based routing ensures critical issues get immediate attention. Our SLA compliance improved dramatically."

HealthCare Plus

Healthcare

"External contractors can now submit requests without needing system access. It's streamlined our entire maintenance workflow."

Campus Solutions

Education

FAQ

Frequently Asked Questions

Everything you need to know about OxMaint's request maintenance system.

OxMaint generates a unique QR code for your organization. When anyone scans this code with their smartphone camera, they're directed to a simple web form where they can describe the maintenance issue, set priority, attach photos, and specify the location. No app download or login is required. The request automatically appears in your OxMaint dashboard for review and assignment.

Yes! The QR code request system is specifically designed for public access. Employees, contractors, visitors, or anyone in your facility can scan the QR code and submit a request without needing an OxMaint account or login credentials. This makes it easy for anyone to report issues.

Yes, requesters can upload up to 4 images per request in JPG, PNG, or GIF format (max 5MB per image). Photo attachments help maintenance teams understand the issue better and come prepared with the right tools and parts.

Requests can be set to Critical, High, Medium, or Low priority. Critical requests are for safety hazards or production stoppages requiring immediate attention. High priority is for significant operational impact. Medium is for standard issues, and Low is for minor problems that can be scheduled. Your team can also adjust priority levels after review.

Yes, maintenance requests can be easily converted to work orders with a single click. When you convert a request, all the information—including description, photos, priority, asset, and location—transfers to the work order automatically. This streamlines your workflow from request to resolution.

Simplify your maintenance requests today.

Enable anyone to report issues with a simple QR scan. Track requests, prioritize work, and resolve problems faster than ever.

OxMaint is available to download from both App Store and Google Play Store.