Your maintenance supervisor rushes into the Monday meeting with alarming news: "Line 3 went down unexpectedly at 2 AM, and we're looking at 8 hours of downtime with parts costs hitting $45,000." You review last month's unplanned maintenance report—$380,000 in emergency repairs and 72 hours of lost production—but struggle to predict when the next failure might occur. Without intelligent maintenance systems and predictive capabilities, you are essentially playing equipment roulette with your facility's profitability.

This scenario unfolds across industrial facilities nationwide as manufacturers grapple with aging equipment, skilled technician shortages, and mounting pressure to minimize downtime. The average industrial facility now loses $50,000 per hour during unplanned equipment failures, with maintenance costs consuming 15-40% of total production budgets.

Facilities leveraging artificial intelligence for industrial maintenance achieve 25-30% reductions in maintenance costs while improving equipment reliability by 70-75% compared to traditional reactive maintenance approaches. The key lies in understanding AI applications, implementing smart monitoring systems, and building predictive maintenance capabilities that transform maintenance from cost center to competitive advantage.

Ready to revolutionize your maintenance operations with AI technology?

Start AI-Powered MaintenanceBook Your AI Demo

Understanding AI-Powered Industrial Maintenance Systems

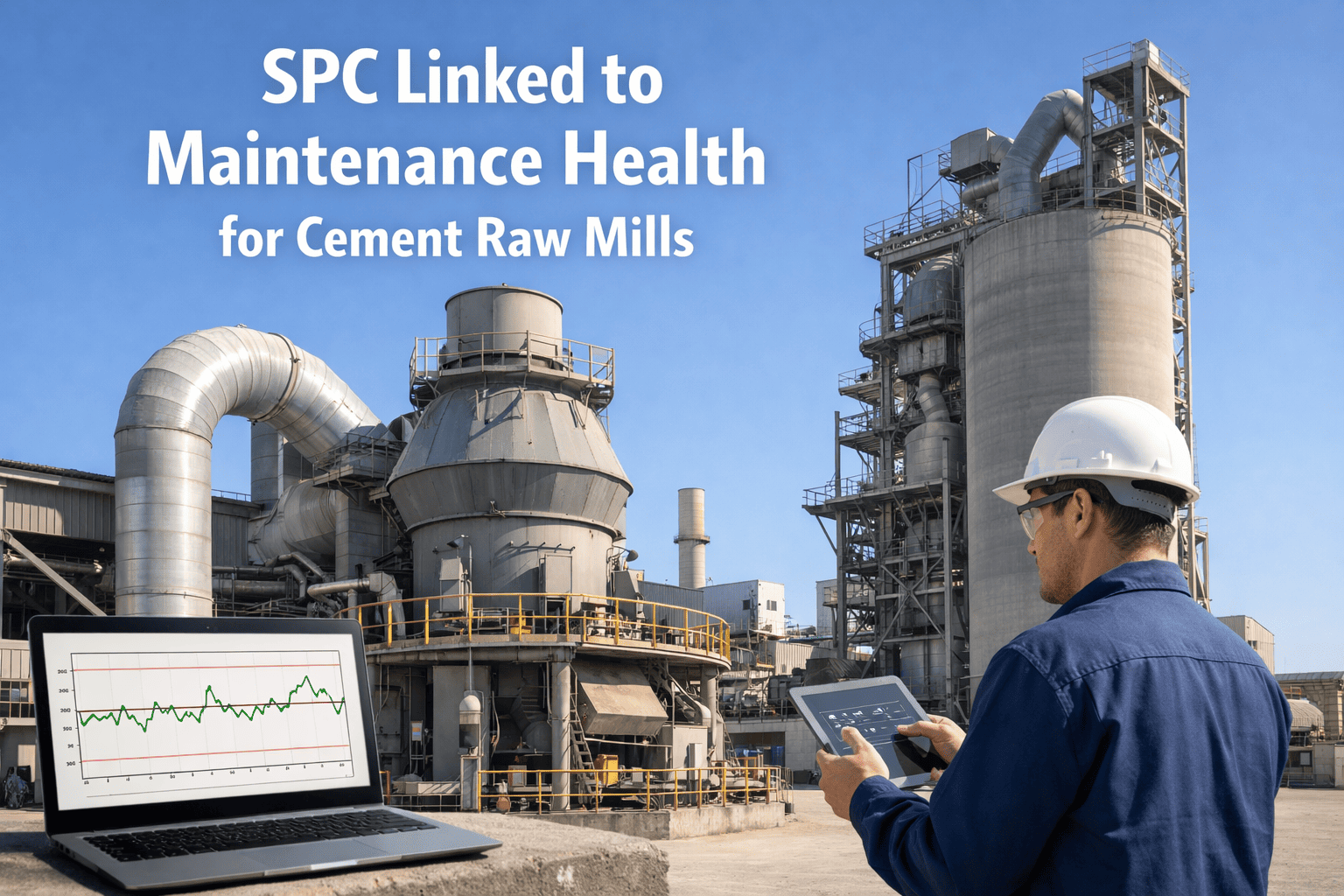

Artificial intelligence in industrial maintenance encompasses machine learning algorithms, predictive analytics, computer vision, and automated decision-making systems that collectively transform how facilities monitor, diagnose, and maintain critical equipment. These technologies extend far beyond simple sensors to include sophisticated analysis platforms that learn equipment patterns and predict failures before they occur.

Traditional maintenance approaches rely on scheduled intervals or reactive responses to breakdowns. AI-powered systems continuously analyze equipment data, identifying subtle patterns and anomalies that human technicians cannot detect. This shift from reactive to predictive maintenance typically reduces emergency repairs by 60-80% while extending equipment life 20-40%.

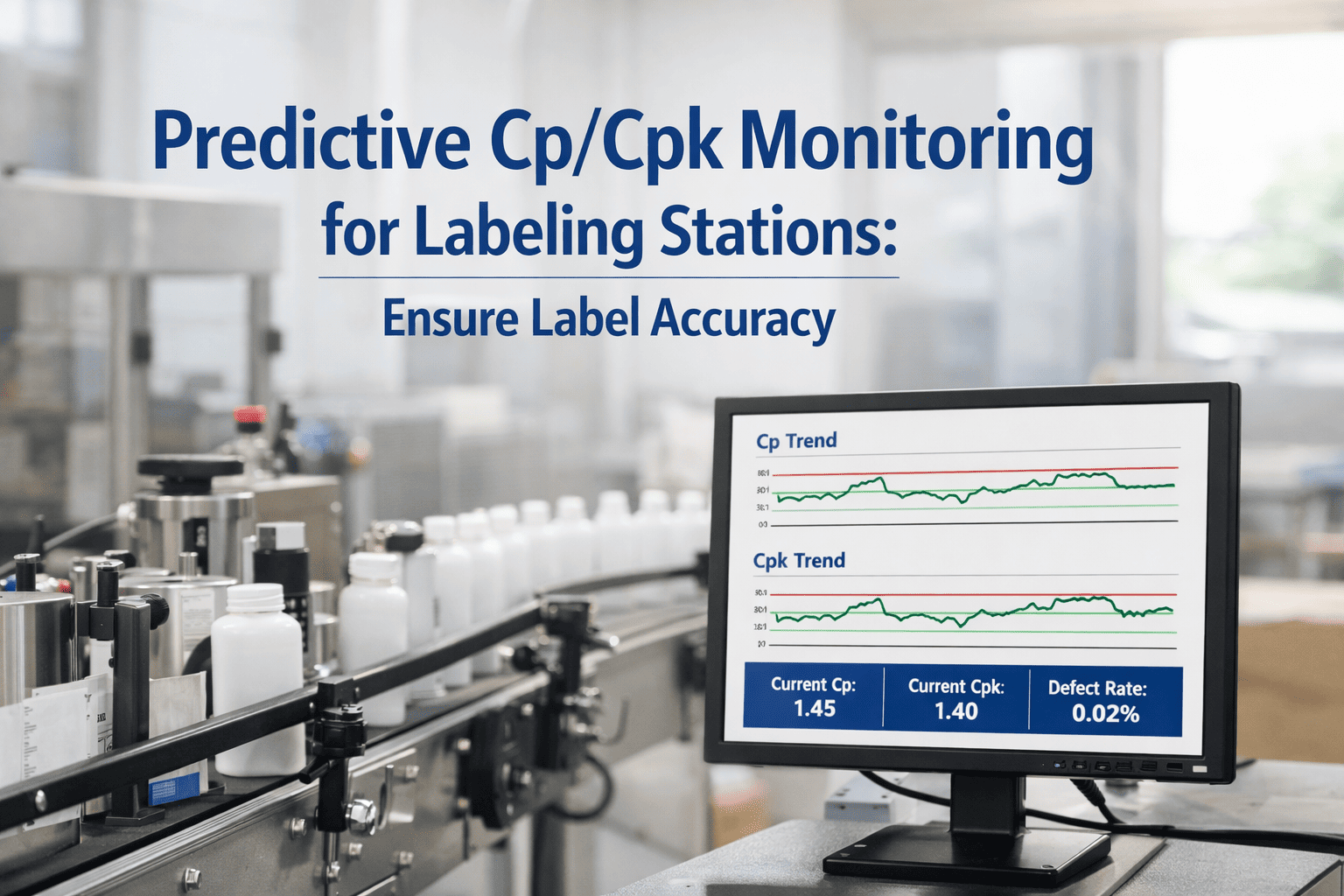

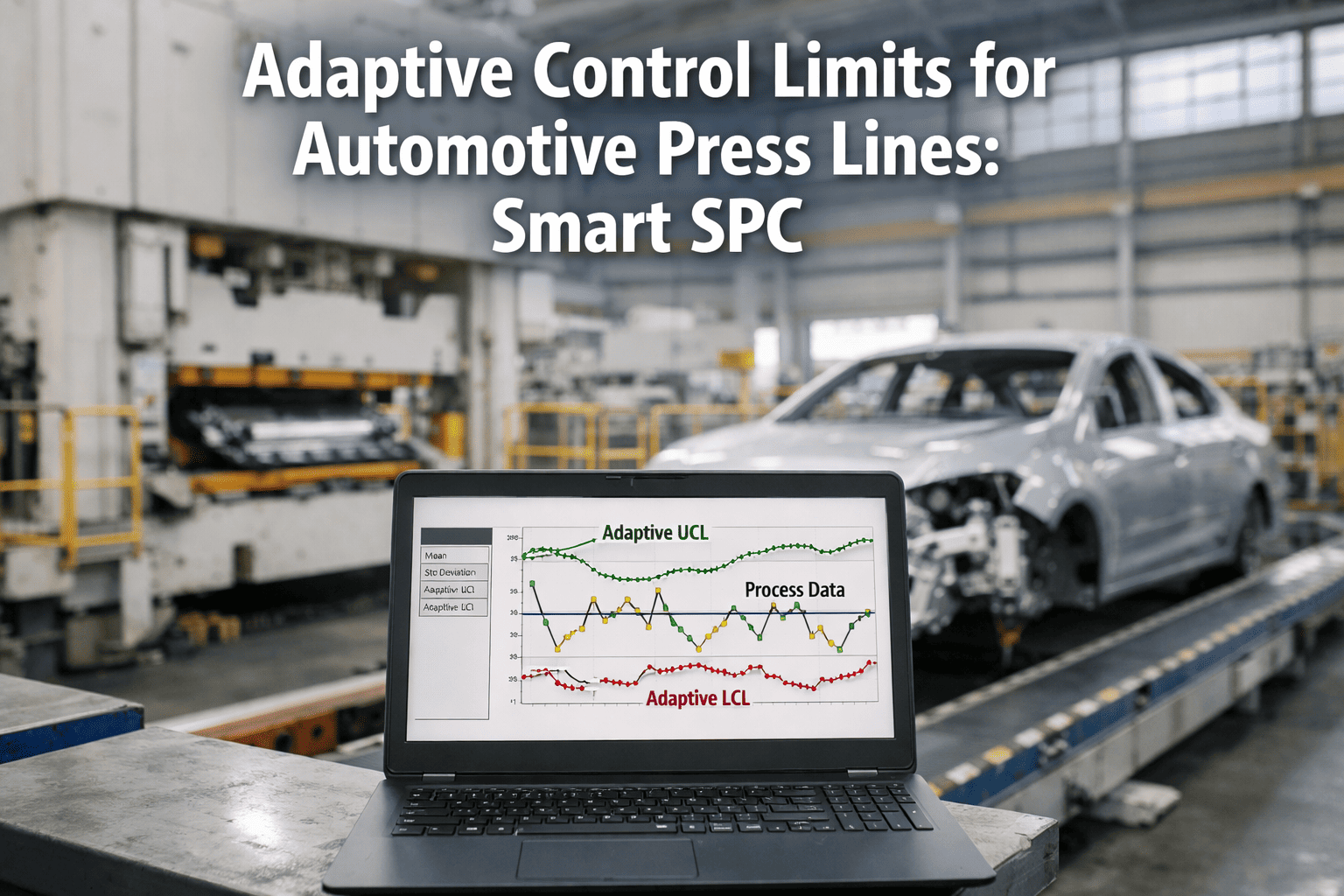

Predictive Analytics AI

Machine learning algorithms analyzing vibration, temperature, and performance data to predict failures 2-8 weeks in advance. Enables proactive parts ordering and scheduled repairs during planned downtime.

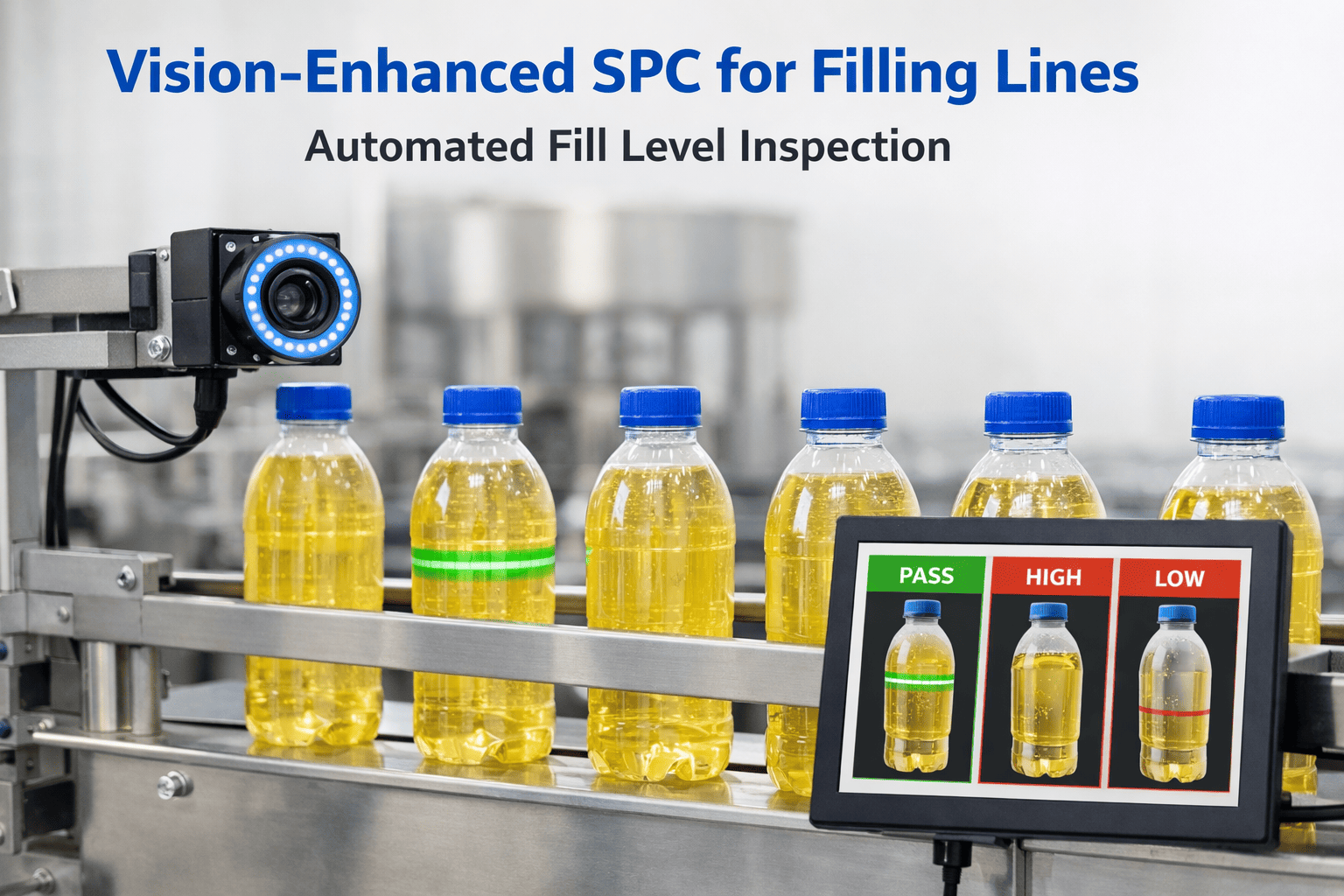

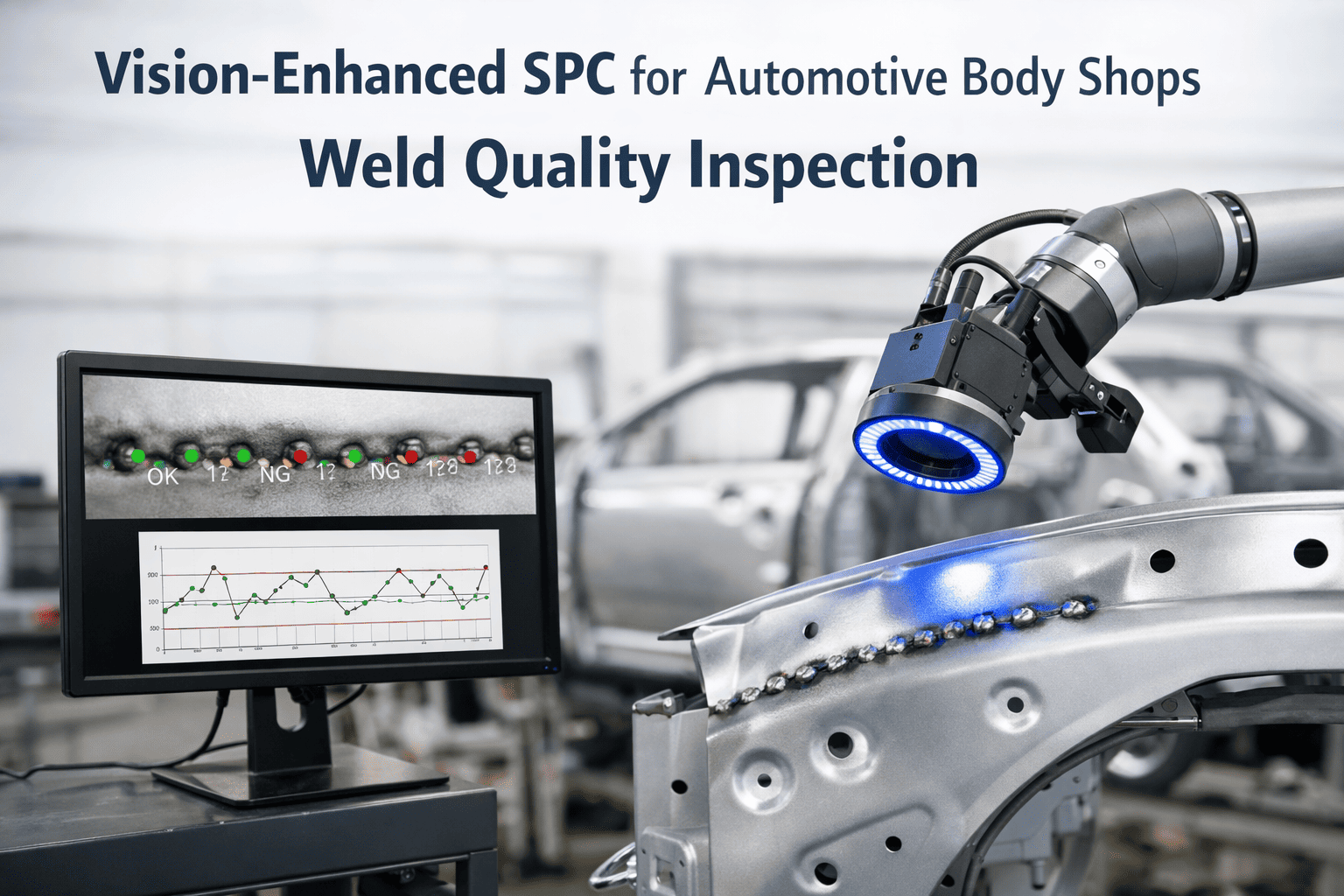

Computer Vision Systems

AI-powered cameras detecting equipment wear, oil leaks, corrosion, and safety hazards through visual inspection. Identifies issues invisible to routine inspections with 95% accuracy rates.

IoT Sensor Networks

Smart sensors monitoring equipment health in real-time, feeding data to AI systems for continuous analysis. Provides 24/7 equipment monitoring without human intervention.

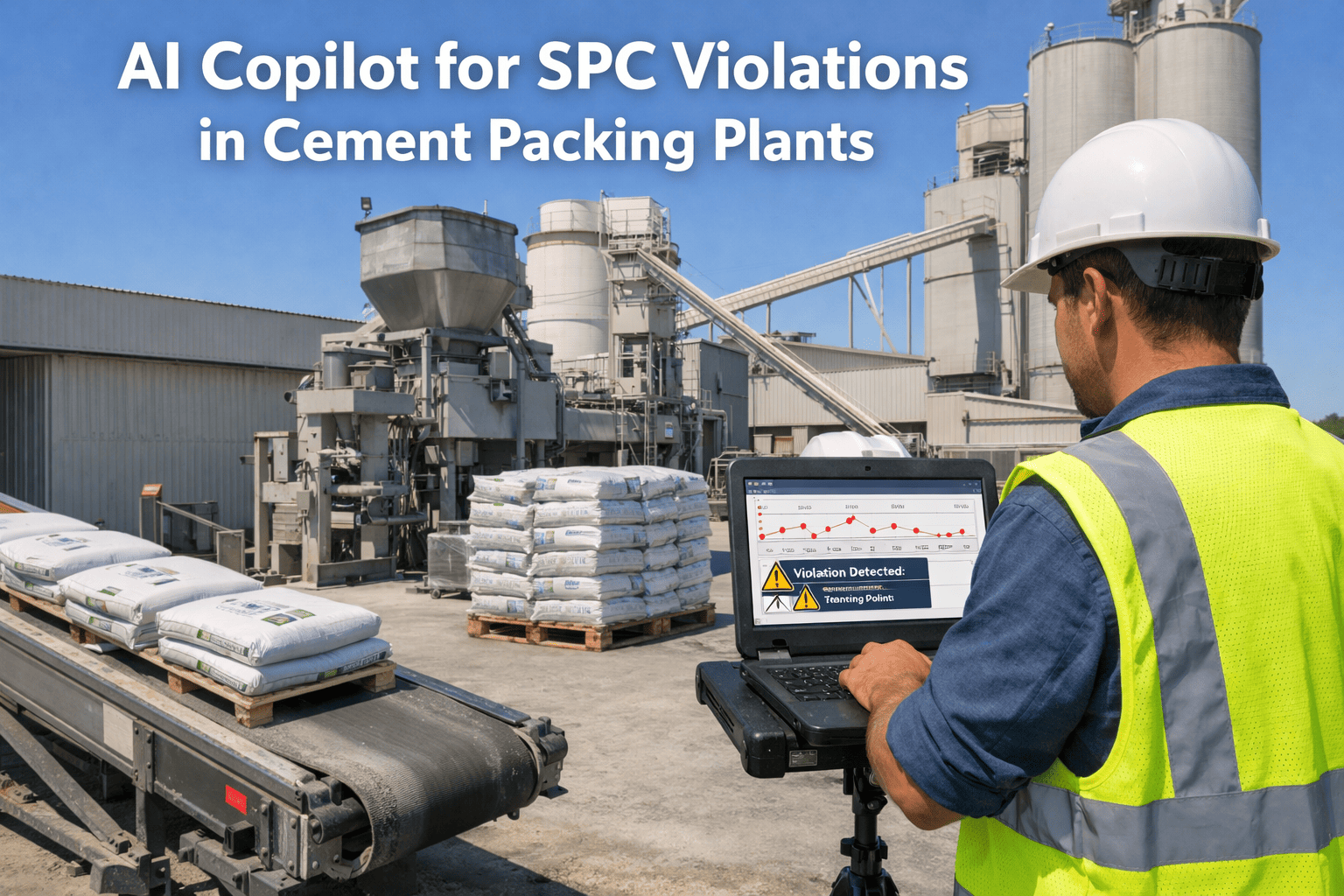

Automated Diagnostics

AI systems identifying root causes of equipment problems and recommending specific repair actions. Reduces troubleshooting time by 70% and improves repair accuracy.

Maintenance Optimization

AI algorithms optimizing maintenance schedules based on production demands, parts availability, and technician skills. Maximizes uptime while minimizing maintenance costs.

Digital Twin Technology

Virtual equipment models powered by AI enabling risk-free testing of maintenance strategies and failure scenario planning without production disruption.

Integration between AI systems and existing maintenance management software creates comprehensive platforms that not only predict failures but automatically generate work orders, order parts, and schedule technicians. This level of automation typically reduces maintenance administrative time by 40-60% while improving response speed.

Data quality and sensor placement significantly impact AI system effectiveness. Successful implementations require strategic sensor deployment, robust data collection protocols, and initial training periods where AI systems learn normal equipment behavior patterns before achieving reliable predictive accuracy.

2025 AI Maintenance Technology Benchmarks and ROI Analysis

Understanding AI maintenance technology investment requirements and return potential enables better planning and vendor selection. Implementation costs, training requirements, and value realization timelines vary significantly based on facility size, equipment complexity and current maintenance maturity levels.

AI maintenance solutions span from simple predictive analytics platforms to comprehensive integrated systems managing entire facility operations. Investment levels and capabilities increase substantially across different solution categories, requiring careful matching of technology sophistication to organizational needs and capabilities.

| AI Solution Category | Investment Range | Implementation Timeline | Expected ROI | Key Capabilities |

|---|---|---|---|---|

| Basic Predictive Analytics | $25,000 - $75,000 | 3-6 months | 300-500% in 24 months | Failure prediction, trend analysis |

| Computer Vision Systems | $50,000 - $150,000 | 4-8 months | 250-400% in 18 months | Visual inspection, defect detection |

| Comprehensive AI Platform | $150,000 - $500,000 | 8-18 months | 400-700% in 36 months | Full predictive suite, automation |

| Digital Twin Integration | $200,000 - $750,000 | 12-24 months | 350-600% in 42 months | Virtual modeling, scenario planning |

| Enterprise AI Suite | $500,000 - $2,000,000 | 18-36 months | 500-900% in 48 months | Facility-wide AI, full automation |

High-complexity industrial environments with multiple production lines and diverse equipment types may require 40-50% higher investment levels due to integration challenges and customization requirements. However, these facilities also typically achieve proportionally higher returns through greater automation potential.

Geographic factors influence both implementation costs and vendor availability. Established industrial regions offer 15-25% cost advantages through competitive vendor markets and local expertise availability compared to isolated facilities requiring extensive travel and support costs.

Technology maturity and vendor ecosystem development have dramatically improved AI maintenance accessibility. Cloud-based solutions now enable smaller facilities to access enterprise-level capabilities for 50-70% less than traditional on-premise implementations while providing superior scalability and automatic updates.

Building Your AI Maintenance Strategy: Implementation Roadmap

Successful AI maintenance implementation requires systematic planning that aligns technology capabilities with operational priorities and organizational readiness. Generic AI solutions provide limited value without careful customization to specific equipment types, failure modes, and operational contexts.

Baseline assessment establishes current maintenance practices, data availability, and organizational capabilities essential for AI system success. Many implementations fail because organizations underestimate the data infrastructure and process changes required for effective AI deployment.

Strategic AI Implementation Process

Pilot project selection critically impacts initial AI system success and organizational buy-in. Target equipment with clear failure patterns, significant downtime costs, and adequate historical data for algorithm training. Success with initial pilots creates momentum for broader AI adoption across facility operations.

Hardware & Sensors

25-35% of budget for IoT sensors, edge computing devices, and networking infrastructure enabling data collection

AI Software Platform

30-45% for predictive analytics software, machine learning algorithms, and integration capabilities

Data Infrastructure

15-25% for data storage, processing systems, and cybersecurity measures supporting AI operations

Training & Change Management

10-15% for workforce development, process redesign, and organizational change support

Integration Services

8-12% for system integration, customization, and initial algorithm development

Ongoing Support

5-10% for maintenance, updates, and continuous improvement activities

Data governance and cybersecurity requirements add complexity but are essential for sustainable AI maintenance operations. Industrial AI systems handling critical equipment data require robust security protocols, regular updates, and backup systems ensuring continued operation during network disruptions.

Organizational change management often determines AI implementation success more than technology quality. Successful deployments invest heavily in technician training, process redesign, and clear communication about AI's role in enhancing rather than replacing human expertise.

Advanced AI Applications and Competitive Advantages

Leading manufacturers are deploying sophisticated AI applications that extend beyond basic predictive maintenance to encompass autonomous maintenance operations, supply chain optimization, and intelligent resource allocation. These advanced implementations create sustainable competitive advantages through operational capabilities competitors cannot easily replicate.

Autonomous maintenance systems powered by AI can diagnose problems, order parts, schedule repairs, and in some cases, initiate self-healing responses without human intervention. These systems typically reduce maintenance response times by 80-90% while ensuring optimal repair timing and resource utilization.

Next-Generation AI Maintenance Capabilities

- Self-diagnosing equipment systems identifying and communicating specific repair needs automatically

- AI-powered parts inventory optimization reducing carrying costs 30-40% while ensuring 99%+ availability

- Intelligent technician scheduling matching skills, availability, and proximity for optimal response

- Predictive supply chain management anticipating parts needs 2-6 months in advance

- Automated compliance monitoring ensuring regulatory adherence without manual inspection

- AI-driven energy optimization reducing facility power consumption 15-25% through equipment efficiency

- Real-time production optimization balancing equipment health with production demands

- Augmented reality maintenance guidance providing technicians with AI-generated repair instructions

Integration with enterprise resource planning (ERP) and manufacturing execution systems (MES) enables AI maintenance platforms to consider production schedules, inventory levels, and business priorities when making maintenance recommendations. This holistic approach typically improves overall facility efficiency by 20-35%.

Continuous learning capabilities distinguish advanced AI systems from basic predictive tools. Machine learning algorithms continuously refine their predictions based on new data and maintenance outcomes, achieving prediction accuracy improvements of 10-15% annually as systems mature.

Collaborative AI ecosystems connecting multiple facilities enable knowledge sharing and benchmarking that accelerates improvement across entire manufacturing networks. Organizations with multiple facilities report 25-40% faster AI optimization through shared learning and best practice transfer.

2025 AI Maintenance Trends Shaping Industrial Competition

- Generative AI creating custom maintenance procedures and troubleshooting guides instantly

- Quantum computing enabling complex optimization calculations previously impossible

- 5G networks supporting real-time AI processing and remote maintenance operations

- Edge AI reducing latency and enabling autonomous responses in milliseconds

- Sustainable AI optimizing equipment operations for carbon footprint reduction

- Human-AI collaboration platforms augmenting technician capabilities rather than replacing them

Competitive differentiation through AI maintenance requires moving beyond vendor-standard implementations to develop proprietary capabilities and unique applications. Leaders invest 10-15% of AI budgets in custom algorithm development and innovation projects that create distinctive operational advantages.

Performance measurement evolution accompanies advanced AI adoption, with leading facilities tracking AI-specific metrics like prediction accuracy, false positive rates, and autonomous response success alongside traditional maintenance KPIs. This comprehensive measurement enables continuous AI system optimization and value maximization.

Conclusion

Artificial intelligence is fundamentally transforming industrial maintenance from reactive cost centers to proactive value drivers that enhance equipment reliability, reduce costs, and improve operational competitiveness. The most successful facilities achieve 25-30% maintenance cost reductions while improving equipment reliability 70-75% through strategic AI implementation that balances technology sophistication with practical operational needs.

Understanding AI maintenance technology reveals that predictive analytics, computer vision, and automated diagnostics work synergistically to create comprehensive equipment health monitoring and management capabilities. Success requires moving beyond isolated point solutions to integrated platforms that leverage multiple AI technologies collaboratively.

Investment benchmarks provide guidance for different AI solution categories, from basic predictive analytics delivering 300-500% ROI to comprehensive enterprise platforms achieving 500-900% returns. However, success depends equally on implementation quality, organizational readiness, and sustained commitment to continuous improvement.

Building effective AI maintenance capabilities requires structured implementation combining technology deployment with organizational change management, workforce development, and process optimization. The most successful approaches prioritize pilot projects, validate results, and scale proven applications systematically.

Advanced AI applications create sustainable competitive advantages through autonomous maintenance operations, intelligent resource optimization, and continuous learning capabilities that improve performance over time. Leading manufacturers invest in custom capabilities and innovation projects that differentiate their operations from standard vendor implementations.

The 2025 industrial landscape rewards early AI adopters while penalizing facilities maintaining traditional reactive maintenance approaches. Success requires balancing proven AI technologies delivering immediate value with emerging innovations positioning for future competitive advantage in an increasingly AI-driven manufacturing environment.

Ready to transform your maintenance operations with cutting-edge AI technology?

Launch AI MaintenanceSchedule AI Consultation