Asset management best practices represent the cornerstone of operational excellence in modern industrial environments, with organizations implementing comprehensive lifecycle management strategies achieving an average of 40% reduction in total cost of ownership and 35% improvement in equipment reliability. Industry leaders recognize that strategic asset management drives sustainable competitive advantages through optimized performance, extended equipment lifecycles and data-driven decision making while establishing foundations for predictive maintenance and operational efficiency across diverse industrial sectors.

Modern industrial operations demand sophisticated asset management approaches that extend beyond traditional maintenance practices to encompass holistic lifecycle optimization, performance monitoring, and strategic resource allocation. Asset management provides the framework for maximizing return on investment while minimizing operational risks through integrated systems that balance performance, cost and reliability objectives across complex equipment portfolios.

Manufacturing and industrial organizations face increasing pressure to optimize asset utilization, extend equipment lifecycles, and reduce operational costs while maintaining stringent safety and performance standards. Traditional reactive asset management approaches create inefficiencies that compromise competitive positioning and financial performance. Oxmaint recognizes that comprehensive asset management addresses these challenges through systematic approaches that transform asset management from a cost center into a strategic value driver.

Stop losing thousands to inefficient asset management and equipment failures. Join over 750+ industrial companies who've transformed their operations and achieved remarkable cost savings of $75,000+ annually. Don't let your competitors gain the advantage while you struggle with reactive asset strategies. The time to optimize is now.

Optimize Your Assets Schedule Asset ReviewFoundation Elements: Comprehensive Asset Lifecycle Management Framework

Strategic asset management operates through integrated lifecycle phases that create comprehensive frameworks for asset performance, cost optimization, and risk management. These phases work synergistically to maximize asset value, extend operational lifecycles, and establish sustainable competitive advantages across industrial operations.

Asset Planning and Acquisition

Strategic asset planning incorporating lifecycle cost analysis, performance requirements, and operational integration considerations that optimize acquisition decisions and long-term value creation.

Installation and Commissioning

Systematic installation procedures and commissioning protocols ensuring optimal asset performance from day one while establishing baseline performance metrics and operational parameters.

Operational Performance Management

Continuous performance monitoring, optimization activities, and efficiency improvements that maximize asset productivity while minimizing operational costs and resource consumption.

Maintenance and Reliability

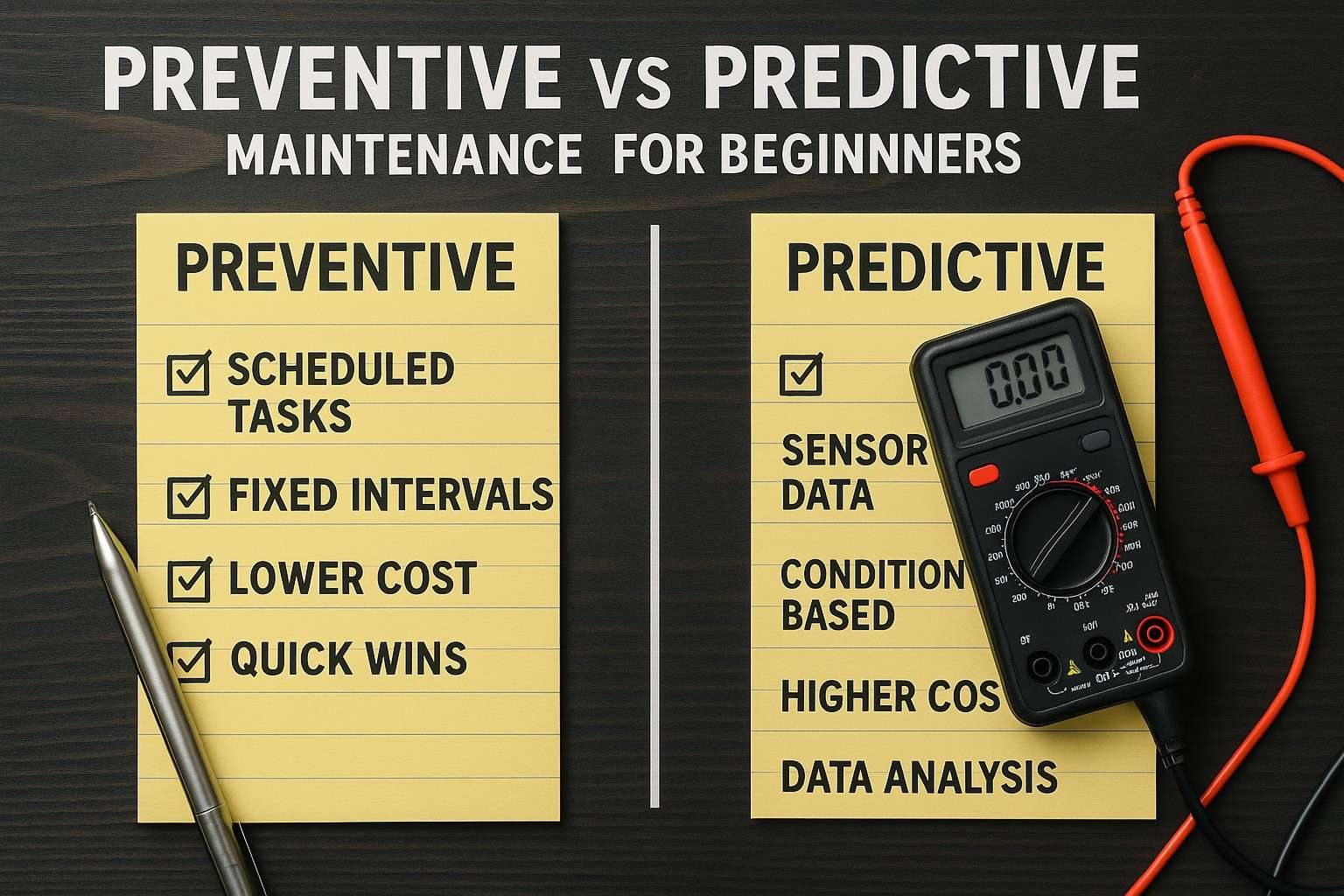

Integrated maintenance strategies incorporating predictive, preventive, and condition-based approaches that optimize asset availability while controlling maintenance costs and extending useful life.

Performance Analytics and Monitoring

Advanced analytics platforms providing real-time asset performance insights, trend analysis, and predictive modeling that enable proactive decision-making and optimization opportunities.

Risk Management and Compliance

Comprehensive risk assessment and mitigation strategies ensuring regulatory compliance, safety performance, and operational continuity while minimizing liability exposure.

Asset Modernization and Upgrades

Strategic upgrade planning and modernization initiatives that enhance asset capabilities, improve efficiency, and extend operational lifecycles through technology integration and performance enhancements.

End-of-Life Planning and Disposal

Systematic retirement planning, disposal strategies, and replacement optimization that maximize residual value while ensuring environmental compliance and smooth operational transitions.

Asset Performance Optimization Strategies

Effective asset performance optimization requires systematic approaches that balance operational efficiency, cost control, and reliability objectives while leveraging data analytics and performance monitoring to identify improvement opportunities and optimize resource allocation.

Performance Monitoring Systems

Real-time monitoring platforms tracking key performance indicators, operational efficiency metrics, and performance trends that enable proactive optimization and early problem detection.

Predictive Maintenance Integration

Advanced predictive technologies including vibration analysis, thermal imaging, and oil analysis that predict maintenance needs and optimize intervention timing for maximum cost-effectiveness.

Data Analytics and Intelligence

Comprehensive data analytics platforms that transform asset performance data into actionable insights for continuous improvement, optimization planning, and strategic decision-making.

Reliability Centered Maintenance

Systematic reliability analysis and maintenance optimization strategies that focus resources on critical asset functions while optimizing maintenance costs and operational availability.

Energy Efficiency Optimization

Energy management systems and efficiency improvement programs that reduce operational costs, enhance sustainability performance, and optimize resource consumption across asset portfolios.

Continuous Improvement Programs

Structured improvement methodologies that systematically identify optimization opportunities, implement performance enhancements, and measure improvement results for sustainable gains.

Digital Asset Management and Industry 4.0 Integration

Smart Asset Management Technologies

Modern asset management leverages digital technologies and Industry 4.0 capabilities to enhance traditional methodologies with real-time monitoring, predictive analytics, and automated decision-making that amplify performance results and operational effectiveness. Oxmaint employs cutting-edge digital platforms that transform asset management through intelligent automation and data-driven insights.

IoT Sensor Networks

Internet of Things technologies providing continuous asset monitoring, real-time condition assessment, and automated data collection that enhances traditional inspection and monitoring activities.

Predictive Analytics Platforms

Advanced analytics systems that analyze asset performance patterns, predict maintenance needs, and optimize intervention timing for maximum effectiveness and cost efficiency.

Digital Twin Technology

Virtual asset representations enabling simulation, scenario analysis, and optimization modeling that improve decision-making and performance prediction capabilities.

Mobile Asset Management

Mobile applications enabling real-time asset tracking, work order management, and field data collection that improve response times and information accuracy.

Asset Tracking and Inventory Management

Comprehensive asset tracking systems provide complete visibility into asset locations, conditions, and performance status while optimizing inventory management, resource allocation, and operational planning across complex industrial environments.

RFID and Barcode Systems

Automated identification technologies that enable accurate asset tracking, location monitoring, and inventory management while reducing manual data entry errors and improving efficiency.

Asset Registry Management

Centralized asset databases containing comprehensive asset information, specifications, maintenance history, and performance data that support informed decision-making and planning.

Spare Parts Optimization

Intelligent inventory management systems that optimize spare parts availability, reduce carrying costs, and ensure critical components are available when needed for maintenance activities.

Asset Utilization Analytics

Comprehensive utilization analysis tools that identify underutilized assets, optimization opportunities, and resource reallocation possibilities for improved operational efficiency.

Risk Management and Compliance Strategies

Asset Risk Assessment and Mitigation

Strategic risk management represents a critical component of effective asset management, requiring systematic approaches to identify, assess, and mitigate operational risks while ensuring regulatory compliance and maintaining operational continuity across diverse industrial environments.

Risk Assessment Methodologies

Systematic risk evaluation processes including failure mode analysis, criticality assessments, and impact analysis that identify potential risks and prioritize mitigation efforts for maximum effectiveness.

Regulatory Compliance Management

Comprehensive compliance tracking systems ensuring adherence to safety regulations, environmental standards, and industry requirements while maintaining audit trails and documentation.

Business Continuity Planning

Contingency planning and backup strategies that ensure operational continuity during asset failures, emergencies, or unexpected events while minimizing business disruption and financial impact.

Insurance and Liability Management

Insurance optimization and liability management strategies that protect against asset-related risks while minimizing premium costs and ensuring adequate coverage for operational exposures.

Financial Optimization and Cost Management

Lifecycle Cost Analysis and Optimization

Total cost of ownership optimization requires comprehensive analysis of all asset-related costs throughout the complete lifecycle, enabling informed decisions that balance initial investment, operational costs, and long-term value creation for maximum financial performance.

- Capital Investment Optimization through comprehensive lifecycle cost analysis, ROI evaluation, and strategic timing that maximizes asset value and financial returns

- Operational Cost Reduction through efficiency improvements, maintenance optimization, and resource allocation strategies that minimize ongoing expenses while maintaining performance

- Maintenance Cost Control through predictive strategies, planned interventions, and condition-based approaches that reduce emergency repairs and extend asset lifecycles

- Energy and Resource Optimization through efficiency programs, consumption monitoring, and optimization initiatives that reduce operational costs and environmental impact

- Replacement and Upgrade Planning through strategic timing analysis, technology evaluation, and financial modeling that optimize modernization investments and asset transitions

Performance Measurement and Analytics

Key Performance Indicators and Metrics

Asset performance measurement requires comprehensive KPI systems that track efficiency, reliability, and cost-effectiveness while providing insights for continuous improvement and strategic decision-making across complex asset portfolios and operational environments.

Asset Reliability Metrics

Comprehensive reliability measurement including mean time between failures, availability rates, and performance consistency that track asset reliability and identify improvement opportunities.

Cost Performance Indicators

Financial metrics including maintenance costs per unit, lifecycle costs, and cost avoidance measurements that track financial performance and optimization effectiveness.

Efficiency and Utilization Metrics

Operational efficiency measurements including utilization rates, throughput performance, and resource optimization that identify improvement opportunities and operational gaps.

Sustainability Performance Tracking

Environmental and sustainability metrics including energy consumption, emissions tracking, and resource utilization that support environmental objectives and regulatory compliance.

Implementation Methodology and Best Practices

Phased Asset Management Deployment

Successful asset management implementation requires systematic deployment approaches that minimize operational disruption while maximizing organizational engagement and sustainable improvement results. Oxmaint employs proven methodologies that ensure effective transformation and long-term success across diverse industrial environments.

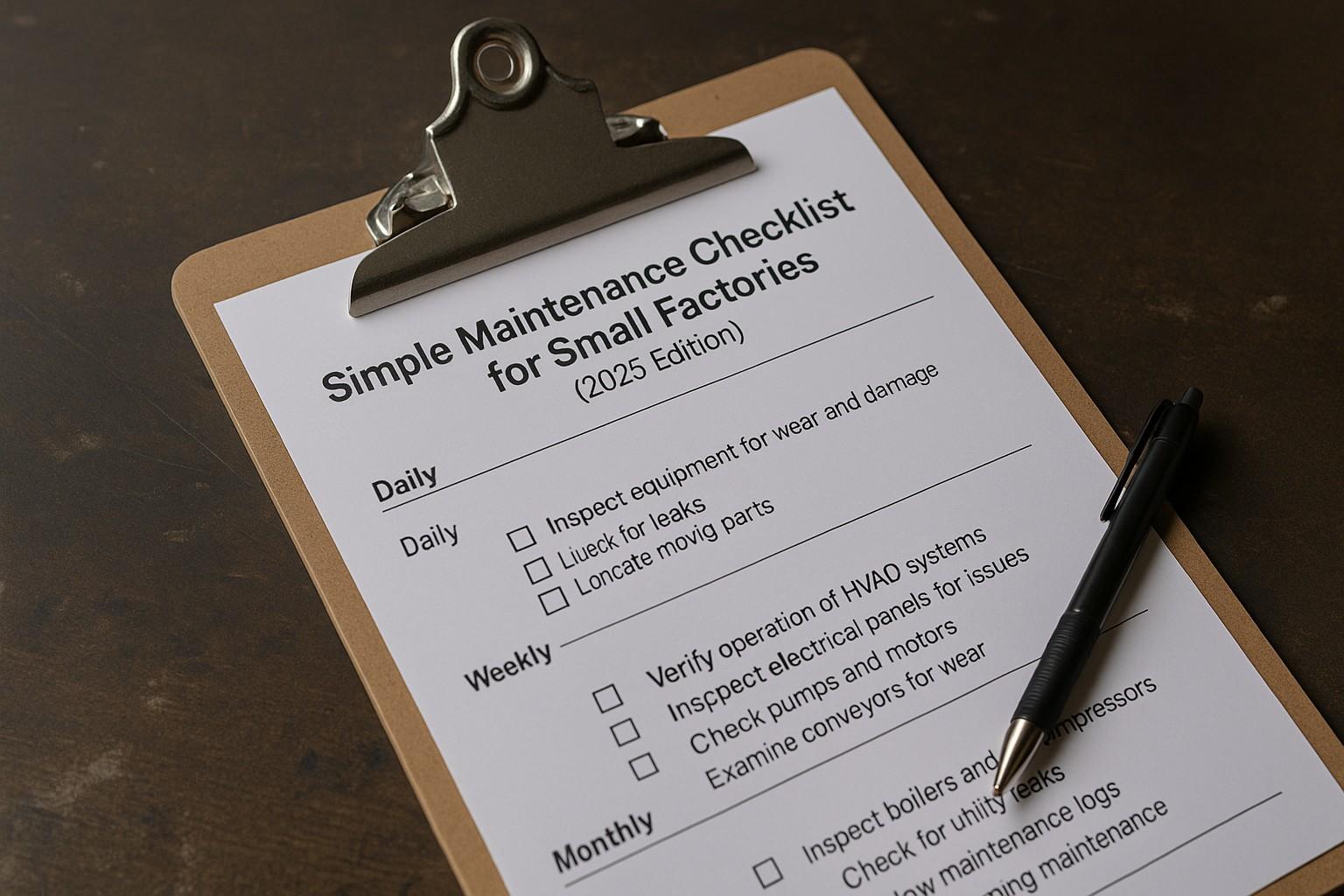

Phase 1: Asset Assessment and Planning

Comprehensive asset inventory, condition assessment, criticality analysis, and strategic planning that establish implementation foundations and priorities for maximum impact.

Phase 2: System Development and Integration

Technology platform deployment, system integration, data migration, and process development that create operational frameworks for comprehensive asset management.

Phase 3: Process Implementation and Training

Process rollout, team training, procedure development, and performance monitoring that ensure effective adoption and operational proficiency across all stakeholder groups.

Phase 4: Optimization and Continuous Improvement

Performance analysis, process refinement, technology enhancement, and continuous improvement that ensure sustained benefits and ongoing optimization results.

Change Management and Organizational Development

Asset management transformation success depends heavily on organizational culture change, requiring comprehensive change management programs that address both technical implementation and cultural transformation for sustainable improvement results.

Leadership Development and Engagement

Executive training and engagement programs that develop asset management leadership competencies while ensuring sustained commitment and strategic support for transformation initiatives.

Employee Training and Development

Comprehensive training programs that develop asset management competencies, technical skills, and continuous improvement capabilities across all organizational levels and functions.

Communication and Feedback Systems

Structured communication channels that ensure stakeholder awareness, progress visibility, and feedback integration throughout implementation and ongoing operations.

Performance Recognition and Incentives

Recognition programs and incentive structures that reward asset management contributions, celebrate achievements, and reinforce behaviors that support optimization objectives.

Industry Applications and Sector-Specific Solutions

Asset management best practices adapt effectively across diverse industrial sectors, with industry-specific applications that address unique operational challenges, regulatory requirements, and competitive dynamics while delivering sector-appropriate benefits and improvements.

Manufacturing and Production

Manufacturing asset management focusing on production efficiency, quality consistency, and operational reliability while optimizing maintenance costs and extending equipment lifecycles.

Energy and Utilities

Utility asset management emphasizing reliability, regulatory compliance, and infrastructure resilience while managing aging infrastructure and optimizing capital investments.

Transportation and Logistics

Transportation asset management optimizing fleet performance, route efficiency, and service reliability while controlling operational costs and ensuring safety compliance.

Healthcare and Facilities

Healthcare facility management ensuring medical equipment reliability, regulatory compliance, and operational continuity while optimizing lifecycle costs and patient safety.

Future Trends and Emerging Technologies

Asset management continues evolving with emerging technologies and industry trends that promise enhanced effectiveness, automated capabilities, and intelligent decision-making that will further improve asset performance, reduce costs, and create competitive advantages across industrial sectors.

Artificial Intelligence and Machine Learning

AI-powered analytics providing advanced pattern recognition, predictive optimization, and automated decision-making that enhance asset management effectiveness and operational efficiency.

Augmented Reality and Virtual Training

AR-enabled maintenance procedures, remote expert support, and immersive training systems that improve maintenance quality and reduce skill development requirements.

Blockchain and Distributed Ledgers

Immutable asset records, maintenance documentation, and compliance tracking that enhance accountability, transparency, and regulatory compliance capabilities.

Sustainable Asset Management

Environmental optimization, circular economy integration, and sustainability performance tracking that align asset management with environmental objectives and regulatory requirements.

Don't let inefficient asset management drain your profits and compromise your competitive position. While you're considering your options, your competitors are already implementing advanced asset management strategies and gaining significant operational advantages. Every day of delay costs thousands in lost efficiency, unnecessary maintenance expenses, and shortened asset lifecycles. Take decisive action now and join industry leaders who've revolutionized their operations through strategic asset management. Our proven methodology has helped over 750+ companies achieve breakthrough results and substantial cost savings within just 4-6 months.

Transform Your Asset Strategy Get Asset Management Consultation