CMMS implementation on a budget represents a strategic approach for small and mid-sized manufacturers to achieve world-class maintenance management without enterprise-level investments. Modern SMEs implementing cost-effective CMMS solutions achieve an average of 65% reduction in maintenance planning time, 50% improvement in asset uptime, and $25,000+ annual savings per facility. Industry research confirms that budget-conscious CMMS implementation delivers enterprise-grade results through lean methodologies, phased deployment, and smart resource allocation while establishing foundations for scalable maintenance excellence and long-term operational success.

Small and mid-sized manufacturing organizations face unique challenges when implementing maintenance management systems - limited budgets, small teams, minimal IT resources, and pressure to deliver immediate results. Traditional enterprise CMMS implementations requiring six-figure investments and year-long deployments are simply not feasible for most SMEs. The good news is that modern cloud-based CMMS platforms enable rapid, low-risk implementations that deliver measurable results within weeks, not months, at a fraction of traditional costs.

The key to successful budget CMMS implementation lies in adopting a lean, phased approach that prioritizes quick wins, minimizes disruption, and builds momentum through early successes. Rather than attempting to implement every feature simultaneously, successful SMEs start with core functionality, prove value quickly, and expand systematically based on demonstrated ROI. Oxmaint recognizes that smart implementation planning transforms limited budgets into competitive advantages through focused execution and strategic prioritization.

Ready to implement a CMMS without breaking the bank? Discover how SMEs are achieving enterprise-level maintenance management at small-plant prices. Get your custom implementation roadmap and budget analysis in minutes.

Get Free Implementation Plan Schedule Budget ConsultationThe Foundation: Pre-Implementation Planning on a Budget

Successful budget CMMS implementation begins with thorough yet efficient planning that identifies critical requirements, prioritizes must-have features, and establishes realistic timelines without expensive consulting engagements. Smart SMEs complete comprehensive planning in 2-4 weeks using internal resources and vendor-provided templates, avoiding the costly mistakes that plague rushed implementations.

Current State Assessment

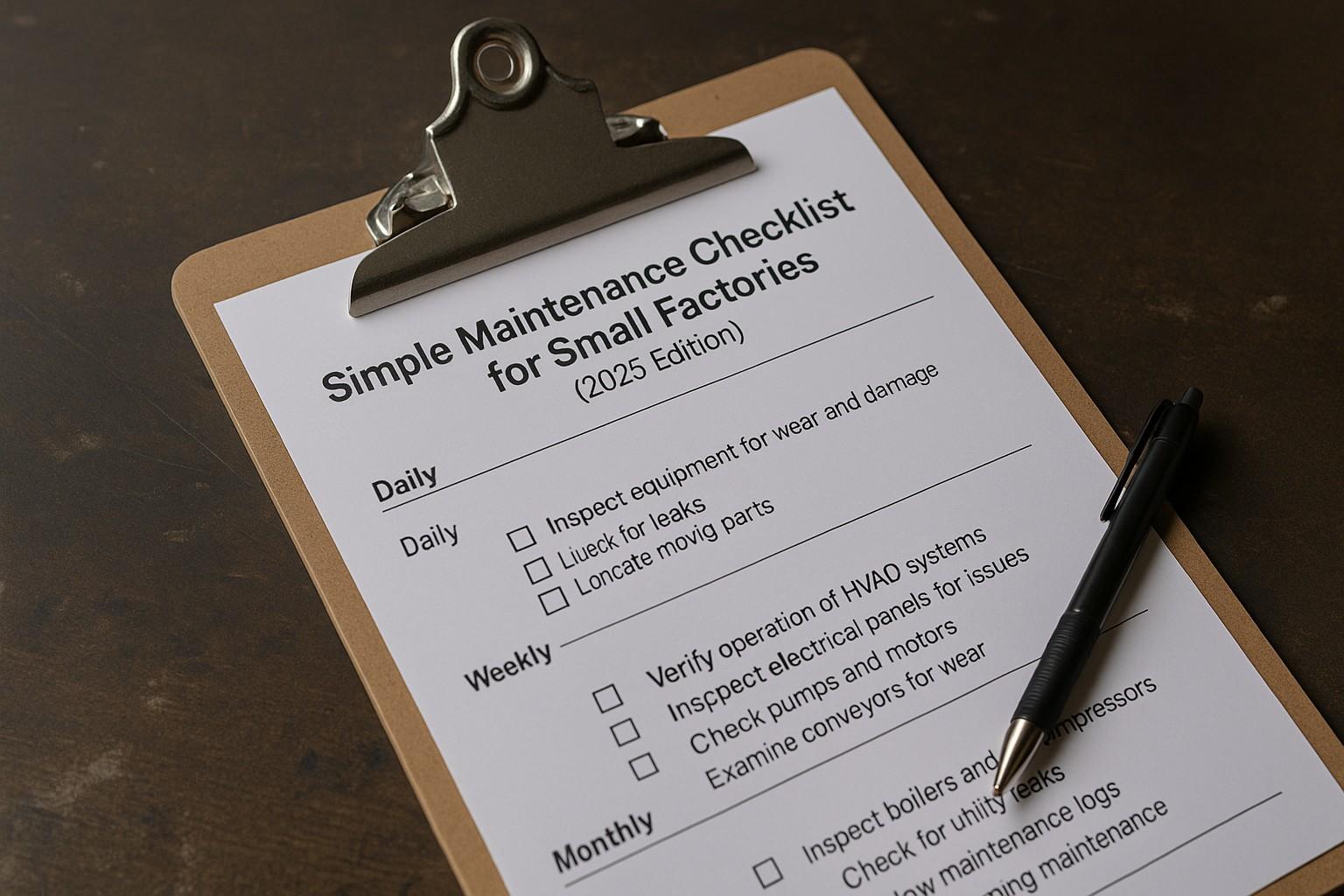

Document existing maintenance processes, pain points, and data sources using simple spreadsheets and team interviews. Identify what's working and what needs improvement without expensive audits.

Requirements Definition

Define must-have versus nice-to-have features focusing on solving your top 3 maintenance challenges. Avoid feature bloat that increases costs and complexity without delivering proportional value.

Vendor Selection Strategy

Evaluate cloud-based CMMS options with free trials, transparent pricing, and no implementation fees. Prioritize vendors offering self-service tools and comprehensive documentation over expensive professional services.

Resource Allocation

Assign a part-time implementation champion (10-15 hours/week) and establish a small core team with representatives from maintenance, operations, and leadership for decision-making and validation.

Critical Success Factors for Budget Implementation

Budget CMMS implementation success depends on five fundamental factors that maximize value while minimizing costs and risks. Understanding and addressing these factors from day one ensures smooth deployment and rapid return on investment that justifies continued investment.

Executive Sponsorship

Secure visible support from plant leadership who communicate implementation importance, remove obstacles, and hold teams accountable. Executive buy-in costs nothing but dramatically increases success probability.

Realistic Scope

Start with core work order management and PM scheduling rather than attempting complete asset management, inventory control, and advanced analytics simultaneously. Phase additional features over time as you prove value and build momentum.

Clean Data Approach

Import only active, accurate equipment and maintenance data. Resist the temptation to migrate decades of historical records that add complexity without proportional value to daily operations.

User-Centric Design

Configure workflows that match how technicians actually work rather than forcing process changes. Minimize clicks, maximize mobile access, and eliminate unnecessary data entry that creates resistance.

Phase 1: Data Preparation and Migration

Building Your Asset Foundation

Data preparation represents the most critical phase of budget CMMS implementation, yet it's where most SMEs make costly mistakes that delay deployment and frustrate users. The key is focusing on essential data only - active equipment, critical spare parts, and recurring maintenance tasks - while deliberately excluding historical baggage that adds no operational value. Oxmaint provides streamlined data templates and import tools that enable SMEs to complete data preparation in days rather than weeks, eliminating the need for expensive data cleansing services.

Asset Hierarchy Setup

Create a simple 3-level structure (Location > System > Equipment) that matches your facility layout. Avoid complex taxonomies that confuse users and complicate reporting without adding practical value.

Equipment Data Import

Include only essential fields: asset ID, description, location, manufacturer, model, and criticality rating. Skip optional fields initially - you can always add details later as needed.

Parts Catalog Creation

Start with your top 100 critical spare parts using simple part numbers and descriptions. Build comprehensive catalog over time based on actual usage rather than attempting complete inventory from day one.

PM Library Development

Convert your top 20 recurring maintenance tasks into CMMS templates with clear instructions, required parts, and estimated duration. Expand library gradually as you identify additional standardization opportunities.

Phase 2: Core System Configuration

Essential Setup for Immediate Value

System configuration focuses on essential settings that enable your team to start managing work orders and preventive maintenance immediately. Budget implementations prioritize out-of-the-box functionality over extensive customization, leveraging proven best practices built into modern CMMS platforms rather than expensive custom development.

Work Order Types

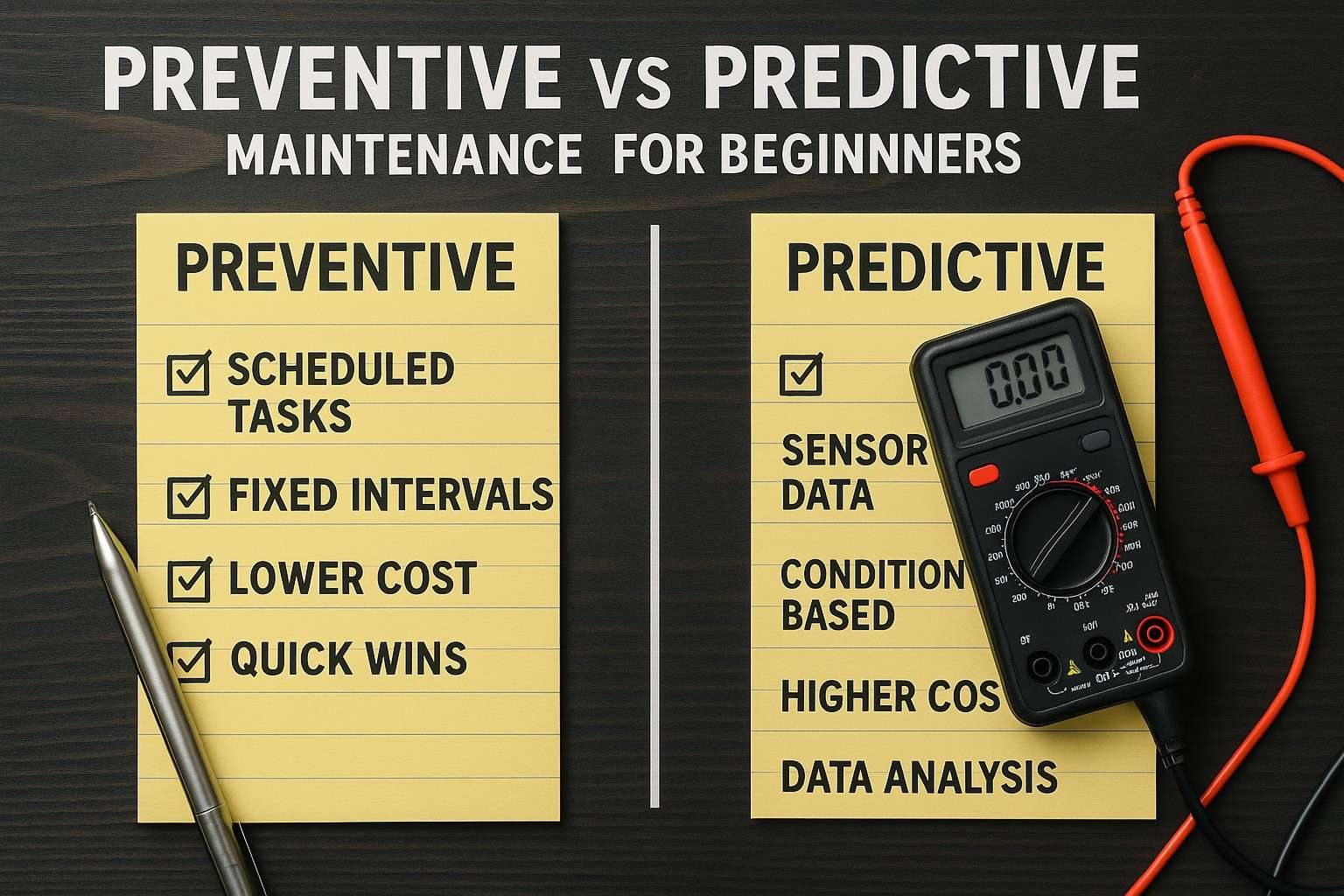

Configure 4-5 basic work order types (Corrective, Preventive, Predictive, Project, Safety) with simple approval workflows. Avoid complex routing that delays responses and frustrates technicians seeking quick approvals.

Priority Levels

Establish clear priority definitions (Emergency, Urgent, Normal, Low) with response time targets. Train teams on consistent priority assignment to ensure appropriate resource allocation and response.

Failure Codes Library

Create a focused failure coding system covering your most common issues (Electrical, Mechanical, Hydraulic, Pneumatic, Controls) with 3-5 subcategories each. Detailed failure analysis comes later after building data history.

User Roles Setup

Define 3-4 basic roles (Technician, Planner, Supervisor, Administrator) with appropriate permissions. Keep security simple initially - you can refine access controls as you understand actual usage patterns.

Mobile Deployment Strategy

Mobile access represents the single most important factor in achieving high user adoption rates among maintenance technicians. Budget implementations leverage vendor-provided mobile apps rather than custom mobile development, delivering enterprise-grade mobile functionality at zero additional cost. Organizations enabling mobile access from day one achieve 85% technician adoption versus 40% for desktop-only implementations.

Offline Capability

Ensure technicians can access work orders, update status, and record time even without network connectivity. Offline-first mobile apps eliminate connectivity as a barrier to adoption.

Barcode Integration

Print simple barcode labels for critical equipment using standard laser printers and free barcode fonts. Enable technicians to scan assets for instant work order creation and history access.

Photo Documentation

Allow technicians to capture equipment condition photos directly in the mobile app. Visual documentation improves troubleshooting and provides valuable failure analysis data over time.

Simplified Data Entry

Configure mobile screens to show only essential fields and use dropdown lists wherever possible. Reduce typing to absolute minimum to maximize field usability and data quality.

Phase 3: Pilot Program and Validation

Proving Value Before Full Deployment

Pilot programs enable SMEs to validate their CMMS configuration and processes with a small group before committing to full deployment, minimizing risk and building organizational confidence without additional investment. Smart manufacturers run 2-4 week pilots with their most capable technicians and critical equipment, identifying and fixing issues before they impact the entire organization. Leading companies that complete structured pilot programs achieve 70% faster full deployment and 90% user adoption versus those attempting immediate facility-wide rollout.

Pilot Team Selection

Choose technically strong, change-positive technicians who will provide honest feedback and help champion the system. Include mix of experience levels to validate usability across user spectrum.

Scope Definition

Focus pilot on one production line or critical equipment group with 30-50 assets. Run all maintenance activities through CMMS while maintaining parallel paper system as backup during validation.

Daily Check-ins

Conduct brief daily stand-ups with pilot team to identify issues, gather feedback, and make rapid adjustments. Address problems immediately rather than waiting until pilot completion.

Success Metrics

Track work order completion rates, data quality, mobile app usage, and user satisfaction. Establish clear go/no-go criteria for proceeding to full deployment based on pilot performance.

Phase 4: Training and Change Management

Building Adoption Without Expensive Training Programs

Effective training on a budget leverages peer-to-peer learning and vendor-provided resources rather than expensive external training programs. Oxmaint provides comprehensive video tutorials, quick reference guides, and in-app help that enable SMEs to train their entire maintenance team for $0 additional cost beyond standard subscription fees.

- Train-the-trainer approach where pilot team members become champions who train peers through hands-on demonstrations and job shadowing rather than classroom sessions

- Just-in-time learning using short (2-3 minute) video tutorials that technicians watch when they need to perform specific tasks, maximizing retention and minimizing time away from work

- Quick reference cards for common tasks (creating work orders, updating status, recording time) that technicians keep at their workstations or on mobile devices for instant guidance

- Gamification elements tracking usage metrics and recognizing top users to create positive competition and reinforce desired behaviors without additional incentive costs

- Regular lunch-and-learns where power users share tips, tricks, and time-saving techniques while building community and collective expertise across the maintenance team

Overcoming Resistance and Building Momentum

Change management on a budget focuses on communication and early wins rather than expensive change consulting engagements. The most effective approach involves identifying and addressing specific concerns, celebrating successes loudly, and demonstrating tangible benefits that matter to frontline technicians.

Address the "Why"

Communicate clear business reasons for CMMS implementation and specific benefits for technicians (easier work assignment, better parts availability, reduced paperwork, job security through improved plant performance).

Quick Wins Strategy

Identify and solve 2-3 painful manual processes immediately (PM scheduling, parts requests, work history access). Broadcast successes widely to build momentum and demonstrate tangible value.

Feedback Loops

Establish regular channels for users to suggest improvements and report issues. Respond quickly to feedback and implement reasonable requests to demonstrate that user input shapes the system.

Management Accountability

Ensure supervisors and planners use CMMS exclusively for all maintenance activities. Leadership modeling desired behavior drives adoption faster than any training program or incentive system.

Phase 5: Go-Live and Optimization

Executing Smooth Full Deployment

Go-live execution determines whether months of preparation translate into operational success or frustrating false starts that damage credibility and adoption. Budget implementations succeed through careful planning, comprehensive checklists, and dedicated support during the critical first weeks when users form lasting impressions about system value and usability.

Pre-Launch Checklist

Validate all system configurations, user accounts, mobile access, and data accuracy. Conduct final system walkthrough with key users to confirm readiness and address last-minute concerns before launch.

Cutover Strategy

Schedule go-live for beginning of week when support resources are fully available. Maintain paper backup system for first 48 hours as safety net while building user confidence in digital processes.

Intensive Support Period

Provide on-floor support during first week with implementation champion available for immediate assistance. Resolve issues in real-time rather than allowing frustrations to build and undermine adoption.

Daily Performance Reviews

Monitor key metrics daily (work orders created, completion rates, mobile usage) and address adoption barriers immediately. First 30 days establish usage patterns that persist long-term.

Continuous Improvement and Expansion

Post-implementation optimization transforms good implementations into great ones through systematic refinement based on actual usage patterns and user feedback. Smart SMEs schedule monthly reviews to identify improvement opportunities, eliminate friction points, and gradually expand functionality as users master core capabilities.

Usage Analytics Review

Analyze which features see high adoption versus low utilization. Double down on successful capabilities while reconsidering or simplifying underutilized features that may be too complex or unnecessary.

Process Refinement

Streamline workflows based on observed usage patterns. Remove unnecessary approval steps, consolidate redundant fields, and optimize mobile screens to match how technicians actually work in practice.

Capability Expansion

Add advanced features (inventory management, predictive analytics, vendor management) incrementally after mastering core functionality. Phase expansion based on demonstrated value and organizational readiness rather than arbitrary timelines.

Best Practice Sharing

Document power user techniques and efficient workflows. Create internal knowledge base of tips and tricks that accelerates new user onboarding and improves overall system utilization across the team.

Measuring Success and Demonstrating ROI

Budget-Friendly Metrics That Matter

ROI measurement on a budget focuses on simple, meaningful metrics that demonstrate value to leadership without expensive business intelligence tools or complex analytics. The most impactful approach tracks 5-7 key indicators that directly link CMMS usage to operational improvements and cost savings that justify continued investment.

- Work order completion rate tracking percentage of planned maintenance completed on schedule, demonstrating improved planning discipline and execution capability

- Preventive vs. corrective ratio measuring shift from reactive firefighting to proactive maintenance that prevents failures before they occur

- Mean time to repair (MTTR) showing reduced downtime through better parts availability, improved work instructions, and faster technician response enabled by mobile access

- Equipment availability demonstrating reduced unplanned downtime and improved production uptime directly attributable to better maintenance execution

- Parts inventory turnover indicating optimized spare parts stocking levels based on actual usage data rather than guesswork and hoarding

- Maintenance cost per unit produced providing clear financial metric that connects maintenance efficiency improvements to bottom-line business impact

Building the Business Case for Continued Investment

Successful budget implementations create foundation for expanded capabilities by demonstrating clear value that justifies additional investment in advanced features, integrations, and expanded deployment. Organizations that document and communicate wins effectively secure ongoing support and resources to maximize their CMMS investment returns. Forward-thinking manufacturers are starting with lean implementations that prove value quickly, then expanding systematically based on demonstrated ROI and organizational readiness.

Financial Impact Documentation

Calculate and report hard savings (reduced overtime, lower parts costs, decreased contractor expenses) and soft benefits (improved safety, better compliance, enhanced decision-making) with specific dollar values and percentages.

Success Story Development

Document 3-5 specific examples where CMMS directly prevented equipment failures, reduced downtime, or enabled significant cost savings. Quantify impact and share broadly with leadership and stakeholders.

Expansion Roadmap

Present phased plan for additional capabilities (predictive maintenance, vendor management, multi-site deployment) with projected ROI for each phase. Link expansion to business objectives and strategic priorities.

Benchmark Comparisons

Compare your facility's maintenance KPIs against industry standards and peers to demonstrate performance improvements and identify remaining opportunities. Use vendor-provided benchmarking data to establish context.

Common Pitfalls and How to Avoid Them

Learning From Others' Mistakes

Budget CMMS implementations fail when organizations attempt to do too much too quickly, underestimate change management requirements, or select inappropriate software for their needs. Understanding and avoiding these common pitfalls dramatically increases success probability while protecting limited budgets from costly mistakes and delays.

Scope Creep

Pitfall: Attempting to implement every feature simultaneously. Solution: Start with work orders and PM scheduling only. Add inventory, analytics, and integrations after mastering core functionality.

Perfect Data Syndrome

Pitfall: Delaying go-live to achieve 100% data accuracy. Solution: Launch with 80% accurate data for critical equipment. Clean and enhance data over time based on actual usage.

Training Shortcuts

Pitfall: Skipping proper training to save time and money. Solution: Invest in thorough training using free vendor resources. Poor adoption from inadequate training costs far more than training investment.

Wrong Software Selection

Pitfall: Choosing complex enterprise systems requiring extensive customization. Solution: Select cloud-based CMMS designed for SMEs with out-of-box functionality and simple, transparent pricing.

Vendor Selection and Contract Negotiation Tips

Smart vendor selection saves thousands annually and dramatically impacts implementation success. Budget-conscious SMEs focus on vendors offering transparent pricing, self-service implementation tools, free trials, and inclusive support rather than those requiring expensive professional services and long-term contracts. Key factors to evaluate include total cost of ownership, implementation requirements, user limits, feature restrictions, and contract terms that protect your investment.

Transparent Pricing Model

Avoid vendors with hidden fees, per-user charges that escalate rapidly, or expensive mandatory services. Choose all-inclusive pricing with unlimited users and clear upgrade paths as your needs grow.

Self-Service Implementation

Select vendors providing comprehensive DIY tools, templates, and documentation rather than requiring costly implementation services. Best vendors enable SMEs to implement successfully using internal resources only.

Flexible Contracts

Negotiate month-to-month or annual contracts rather than multi-year commitments. Ensure ability to export data easily if you need to switch vendors. Avoid platforms that lock in your data.

Included Support

Verify that phone, email, and chat support are included at no additional cost. Understand response time commitments and availability hours. Test support quality during trial period before committing.

Your Roadmap to Budget CMMS Success

Taking Action Without Overspending

The best time to implement CMMS was yesterday - the second best time is today. Every day without structured maintenance management costs your facility money through inefficiency, unplanned downtime, and reactive firefighting. The good news is that modern cloud-based CMMS enables you to get started immediately with minimal investment and risk. Oxmaint specializes in helping SMEs implement world-class maintenance management on small-plant budgets through proven methodologies, comprehensive self-service tools, and expert guidance when you need it.

Week 1-2: Planning

Document current state, define requirements, evaluate vendors, and create implementation plan. Complete planning using internal resources and vendor-provided templates without consulting fees.

Week 3-4: Setup

Prepare and import data, configure system, create user accounts, and establish mobile access. Leverage vendor expertise and documentation to complete setup efficiently without external help.

Week 5-6: Pilot

Run focused pilot program with small group, gather feedback, make adjustments, and validate readiness. Use pilot success to build momentum and organizational confidence for full deployment.

Week 7-8: Deploy

Execute go-live with intensive support, monitor adoption metrics, address issues immediately, and celebrate wins. Establish foundation for continuous improvement and capability expansion over time.

Stop letting budget constraints prevent you from achieving maintenance excellence. Your competitors are gaining advantages through better maintenance management while you struggle with spreadsheets and reactive firefighting. Modern CMMS implementation costs less than one major equipment failure, yet delivers returns for years to come. The question isn't whether you can afford CMMS - it's whether you can afford to delay any longer.

Start Your Free CMMS Trial Get Implementation Roadmap