A maintenance checklist for small factories represents the fundamental framework that transforms reactive operations into proactive maintenance excellence. Modern small manufacturing facilities implementing systematic maintenance checklists achieve an average of 82% reduction in unexpected equipment breakdowns, 58% improvement in maintenance efficiency, and $12,000+ annual cost savings per facility. Industry experts recognize that structured maintenance checklists drive operational reliability through systematic inspections, preventive actions, and standardized procedures while establishing foundations for sustainable growth and manufacturing excellence in resource-constrained environments.

The small factory environment demands practical maintenance approaches that maximize limited resources while delivering world-class reliability outcomes. Maintenance checklists provide the essential framework for achieving consistent asset performance through structured daily, weekly, and monthly tasks that prevent failures, optimize equipment life, and ensure operational continuity without requiring extensive technical expertise or expensive tools.

Small manufacturing operations face unique challenges including limited maintenance staff, budget constraints, and the need to maintain diverse equipment types while ensuring production continuity. Traditional unstructured maintenance approaches create inefficiencies that compromise competitiveness and profitability. Oxmaint recognizes that systematic maintenance checklists address these challenges through practical frameworks that transform maintenance from a reactive burden into a strategic advantage for small factories.

Ready to streamline your factory maintenance? Transform scattered maintenance tasks into an organized, efficient system. Discover how small manufacturers are preventing breakdowns and cutting costs with simple checklists.

Download Free Checklist Template Schedule Maintenance AssessmentBuilding Your Essential Maintenance Checklist Framework

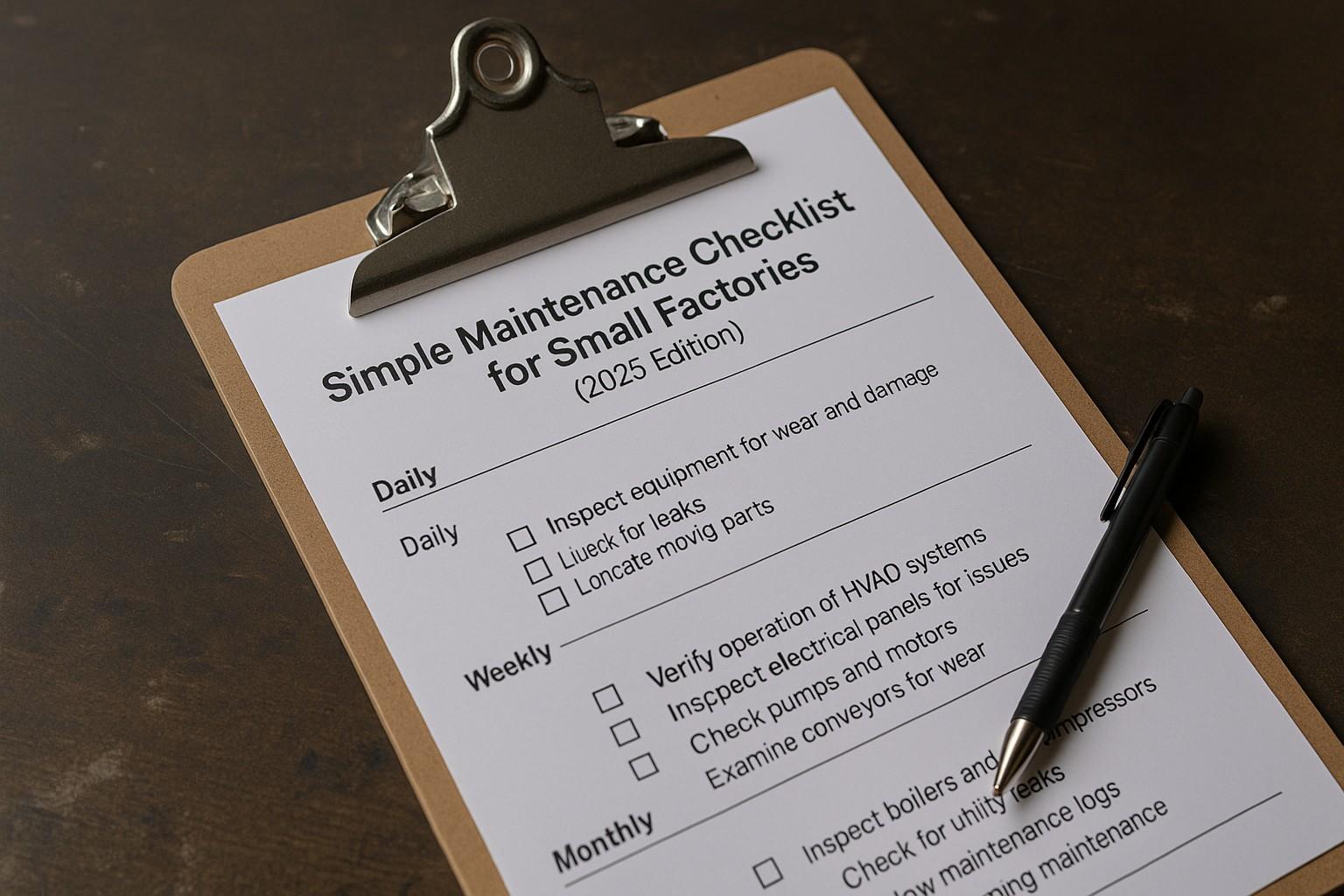

Effective maintenance checklists operate through systematic daily, weekly, and monthly inspection routines that create consistent equipment monitoring, early problem detection, and preventive maintenance execution. These structured approaches work synergistically to eliminate surprise failures, extend asset life, and establish reliable operations across small manufacturing environments.

Daily Inspection Tasks

Quick visual checks, operational verifications, and critical parameter monitoring that operators perform at shift start to identify immediate concerns and ensure safe equipment operation.

Weekly Maintenance Activities

Lubrication schedules, detailed inspections, minor adjustments, and cleaning procedures that maintenance staff complete to prevent wear and maintain optimal equipment condition.

Monthly Service Procedures

Comprehensive equipment assessments, performance testing, parts replacement planning, and detailed documentation that ensure long-term reliability and compliance.

Documentation Systems

Simple record-keeping methods, digital checklists, and maintenance logs that track completed tasks, identify trends, and support decision-making without complex systems.

Core Daily Checklist Components for Small Factories

Daily maintenance checklist implementation focuses on five critical inspection areas that create comprehensive coverage of essential equipment health monitoring, safety verification, and operational readiness. Understanding and executing these daily tasks provides the foundation for reliable production and prevents costly emergency situations.

Safety Systems Check

Verify emergency stops, safety guards, fire extinguishers, and protective equipment are functional and accessible, ensuring worker safety and regulatory compliance before production begins.

Equipment Startup Inspection

Check for unusual sounds, vibrations, leaks, or odors during equipment startup that indicate developing problems requiring immediate attention that could save thousands in repair costs.

Lubrication Point Verification

Visual inspection of critical lubrication points, oil levels, and grease fittings to ensure proper lubrication that prevents premature wear and extends component life.

Operational Parameters Monitoring

Record temperatures, pressures, speeds, and other key metrics to establish baselines, detect deviations, and identify trends that signal maintenance needs before failures occur.

Weekly and Monthly Maintenance Checklist Details

Systematic Weekly Maintenance Tasks

Weekly maintenance activities provide the preventive backbone that keeps small factory equipment running reliably between major service intervals. Facilities that implement structured weekly checklists report average downtime reductions of 65% and maintenance cost savings of $8,000-$25,000 annually. Oxmaint helps small manufacturers develop practical weekly maintenance routines that maximize equipment reliability without overwhelming limited maintenance resources.

Lubrication Schedule Execution

Complete lubrication of bearings, chains, gears, and moving parts according to manufacturer specifications using proper lubricants and quantities to prevent wear and extend life.

Belt and Chain Inspection

Check tension, alignment, wear patterns, and condition of drive belts and chains, making adjustments to prevent unexpected failures and maintain efficient power transmission.

Filter Replacement and Cleaning

Replace or clean air filters, oil filters, coolant filters, and dust collectors to maintain optimal equipment performance and prevent contamination-related failures.

Electrical Connection Review

Inspect electrical panels, connections, terminals, and wiring for signs of overheating, corrosion, or looseness that could cause failures or safety hazards.

Equipment-Specific Maintenance Checklists

Critical Equipment Categories

Equipment-specific checklists ensure that each asset type receives appropriate maintenance attention based on its unique requirements and failure modes. Organizations that implement tailored equipment checklists reduce specific asset failures by 78% while optimizing maintenance resource allocation. Oxmaint provides comprehensive checklist templates for all common small factory equipment types, ensuring nothing is overlooked in your maintenance program.

Production Machinery Checklist

CNC machines, lathes, mills, presses: Check coolant levels, tool wear, chuck condition, spindle alignment, way lubrication, and chip removal systems for optimal performance.

Material Handling Equipment

Conveyors, forklifts, hoists: Inspect chains, rollers, controls, hydraulic systems, load limits, and safety devices to ensure safe and reliable material movement.

Utility Systems Checklist

Compressors, chillers, boilers, HVAC: Monitor pressures, temperatures, vibration, leaks, and efficiency metrics to maintain reliable utility supply and energy efficiency.

Electrical Distribution

Panels, transformers, motors: Check for overheating, unusual sounds, proper grounding, connection tightness, and load balance to prevent electrical failures.

Digital Checklist Tools and Implementation

Modern Checklist Management Solutions

Digital maintenance checklist systems transform paper-based processes into efficient, trackable, and actionable maintenance workflows that save time, reduce errors, and provide valuable insights. Small manufacturers that begin with a free implementation consultation typically achieve full checklist digitization 50% faster and realize higher compliance rates than those attempting implementation alone. Oxmaint offers intuitive digital checklist tools specifically designed for small factory environments without complex IT requirements.

- Mobile checklist access enables technicians to complete inspections directly from smartphones or tablets, eliminating paperwork and ensuring real-time documentation

- Automated scheduling sends reminders for daily, weekly, and monthly tasks, preventing missed inspections and ensuring consistent maintenance execution

- Photo documentation allows teams to capture equipment conditions, defects, and repair evidence directly within checklists for better communication and record-keeping

- Instant reporting generates completion summaries, identifies overdue tasks, and highlights trends that inform maintenance strategy improvements

- Integration capabilities connect checklist data with work orders, inventory, and asset records for comprehensive maintenance management visibility

Best Practices for Checklist Implementation

Successful checklist deployment requires thoughtful planning, team engagement, and continuous refinement to ensure adoption and sustained value delivery. Small factories that implement proven deployment strategies achieve 85% higher checklist compliance and 70% faster problem resolution than those using ad-hoc approaches. Smart manufacturers are starting with proven checklist templates that accelerate implementation and ensure comprehensive coverage.

Start Simple and Expand

Begin with critical equipment and essential daily checks, then gradually add weekly and monthly tasks as teams develop routine and confidence with the checklist system.

Train All Team Members

Ensure operators and maintenance staff understand checklist purpose, proper completion methods, and how to identify and report problems discovered during inspections.

Review and Refine Regularly

Analyze checklist completion data, gather team feedback, and adjust tasks based on findings to optimize checklist effectiveness and eliminate unnecessary steps.

Link to Action Systems

Connect checklist findings directly to work order creation, parts ordering, and maintenance planning to ensure identified issues receive timely resolution.

Measuring Checklist Program Success

Key Performance Indicators and ROI

Comprehensive checklist program measurement demonstrates tangible value through multiple metrics that extend beyond basic task completion to encompass reliability improvement, cost reduction, and operational excellence creation. Most small factories recover their checklist system investment within 4-6 months through prevented failures and improved efficiency. Leading manufacturers are scheduling strategy sessions to learn how structured checklists can transform their maintenance outcomes.

Completion Rate Tracking

Monitor daily, weekly, and monthly checklist completion percentages to ensure consistent execution and identify areas where additional support or training is needed.

Issue Detection Metrics

Track number and severity of problems found through checklists versus those causing failures, demonstrating preventive value and early detection effectiveness.

Downtime Analysis

Compare planned versus unplanned downtime trends before and after checklist implementation to quantify reliability improvements and emergency reduction.

Cost Impact Calculation

Document prevented failures, reduced emergency repairs, extended asset life, and maintenance efficiency gains to demonstrate clear financial return on checklist investment.

Industry-Specific Checklist Customization

Tailored Approaches by Manufacturing Type

Industry-specific checklist customization ensures maintenance activities address unique operational challenges, regulatory requirements, and equipment characteristics specific to different manufacturing sectors. Small factories implementing tailored checklists achieve 82% higher program effectiveness than those using generic templates. Oxmaint provides industry-specific checklist templates that incorporate best practices and compliance requirements for diverse manufacturing environments.

Food Processing Plants

Checklists emphasizing sanitation verification, food safety compliance, temperature monitoring, and contamination prevention alongside standard mechanical inspections.

Metal Fabrication Shops

Focus on cutting tool condition, coolant systems, material handling equipment, welding equipment safety, and metal working machinery precision maintenance.

Electronics Assembly

Specialized checklists for ESD protection, cleanroom requirements, precision equipment calibration, solder equipment maintenance, and environmental controls.

Packaging Operations

Checklist items covering filling equipment, sealing systems, labeling machines, conveyor lines, and quality control equipment specific to packaging processes.

Your Checklist Implementation Roadmap

Start Your Maintenance Transformation Today

Every day without structured maintenance checklists exposes your small factory to preventable failures, unnecessary costs, and operational inefficiencies that competitors are already eliminating. While you're considering your approach, other manufacturers are implementing proven checklist systems and capturing reliability advantages. The smartest small factory owners are taking immediate action by downloading ready-to-use checklist templates to begin their maintenance transformation today. Oxmaint provides the tools, templates, and expert guidance needed to implement effective maintenance checklists without complex systems or extensive training.

Quick Assessment

Evaluate your current maintenance approach and identify critical equipment requiring immediate checklist coverage to prevent failures and improve reliability.

Template Customization

Adapt proven checklist templates to your specific equipment, operations, and team capabilities, ensuring practical implementation and sustainable adoption.

Team Training Launch

Conduct focused training sessions that equip operators and maintenance staff with checklist execution skills, problem identification techniques, and documentation methods.

Continuous Improvement

Monitor checklist effectiveness, gather team feedback, and refine processes to maximize value delivery and build a culture of proactive maintenance excellence.

Don't let another day pass with reactive maintenance draining your profits. Small factories that implement structured checklists gain immediate reliability advantages while others struggle with costly breakdowns. The manufacturers taking action today will dominate their markets while competitors deal with preventable failures. Your window to gain first-mover advantage is now.

Get Your Free Checklist Templates Schedule Implementation Guidance