Preventive and predictive maintenance represent two fundamental approaches to equipment management that every maintenance beginner must understand to build reliable industrial operations. Organizations starting their maintenance journey achieve an average of 40% reduction in equipment failures through proper preventive maintenance implementation, while those progressing to predictive strategies see an additional 30% improvement in uptime and $12,000+ annual savings per critical asset. Maintenance professionals recognize that understanding preventive versus predictive maintenance provides the foundation for building world-class maintenance programs through systematic implementation, data-driven decision-making, and strategic capability development.

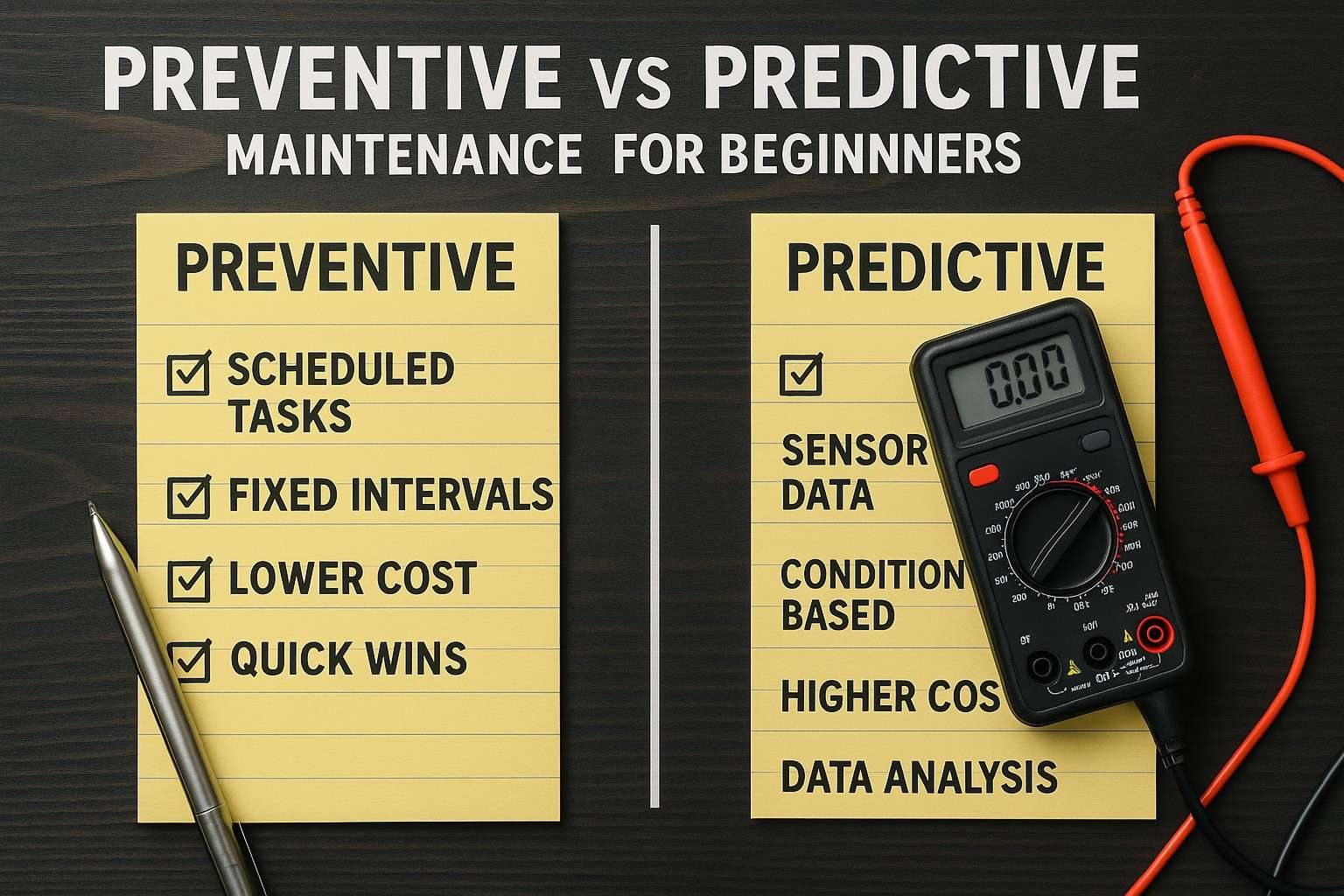

The maintenance landscape can seem overwhelming for beginners, with numerous approaches, technologies, and methodologies competing for attention. However, understanding the fundamental difference between preventive and predictive maintenance provides the essential foundation for building effective maintenance programs. Preventive maintenance operates on scheduled intervals regardless of equipment condition, while predictive maintenance uses real-time data to determine optimal intervention timing based on actual asset health.

Manufacturing organizations beginning their maintenance transformation face critical decisions about where to invest limited resources, which technologies to adopt, and how to build sustainable improvement programs. Starting with the wrong approach creates wasted investments, employee frustration, and missed improvement opportunities. Oxmaint recognizes that beginners need clear guidance on preventive versus predictive maintenance to make informed decisions that align with organizational readiness, resource availability, and business objectives while building capabilities systematically for long-term success.

Ready to build your maintenance foundation the right way? Start with a clear roadmap that matches your current capabilities and grows with your organization. Discover which maintenance approach delivers the fastest wins for your facility.

Start Your Maintenance Assessment Book Expert Guidance SessionUnderstanding Preventive Maintenance Fundamentals

Preventive maintenance (PM) represents the foundational maintenance strategy that performs scheduled maintenance activities at predetermined intervals regardless of equipment condition. This time-based approach provides the essential framework for beginners to establish maintenance discipline, build organizational capabilities, and achieve immediate improvements over reactive maintenance approaches that only fix equipment after breakdowns occur.

Time-Based Scheduling

Maintenance activities performed at fixed intervals (weekly, monthly, quarterly) based on calendar time or equipment runtime hours, providing predictable maintenance routines.

Standardized Tasks

Predetermined checklists and procedures for inspections, lubrication, adjustments, and component replacements that ensure consistent maintenance execution.

Lower Technology Requirements

Minimal sensor or monitoring technology needed - relies primarily on visual inspections, basic tools, and manual data collection accessible to all facilities.

Predictable Resource Planning

Known maintenance schedules enable straightforward labor planning, parts inventory management, and budget forecasting for maintenance operations.

Core Preventive Maintenance Benefits

Preventive maintenance implementation delivers immediate and measurable improvements that establish the foundation for more advanced maintenance strategies. Understanding these benefits helps beginners recognize why PM represents the essential first step in maintenance excellence, even before considering predictive technologies.

Dramatic Failure Reduction

Organizations moving from reactive to preventive maintenance reduce unexpected breakdowns by 40-50% through regular inspections and timely interventions that catch problems early.

Extended Equipment Life

Scheduled maintenance activities like lubrication, cleaning, and adjustments extend asset lifespan by 20-30% through consistent care that prevents accelerated wear and deterioration.

Improved Safety

Regular equipment inspections identify safety hazards before accidents occur, creating safer work environments and reducing injury risks through proactive hazard elimination.

Lower Implementation Cost

PM requires minimal technology investment - typically $2,000-$10,000 to start compared to $50,000+ for predictive systems, making it accessible for organizations beginning their maintenance journey.

Understanding Predictive Maintenance Fundamentals

Condition-Based Monitoring Approach

Predictive maintenance (PdM) leverages real-time equipment condition monitoring through sensors and diagnostic technologies to predict failures before they occur and optimize maintenance timing based on actual asset health rather than arbitrary schedules. This data-driven approach represents the evolution beyond preventive maintenance, delivering significantly higher performance but requiring greater technological capability and organizational maturity. Oxmaint provides beginners with scalable predictive solutions that grow with organizational capabilities.

Vibration Analysis

Sensors detect abnormal vibration patterns indicating bearing wear, misalignment, or imbalance, enabling intervention 4-8 weeks before failure with 85%+ accuracy.

Thermal Imaging

Infrared cameras identify hot spots indicating electrical problems, insulation breakdown, or mechanical friction before catastrophic failures occur.

Oil Analysis

Laboratory testing of lubricant samples reveals wear particles, contamination, and degradation patterns that predict equipment problems weeks in advance.

Ultrasonic Monitoring

High-frequency sound detection identifies compressed air leaks, electrical arcing, and bearing problems invisible to other monitoring methods.

Side-by-Side Comparison for Beginners

Key Differences That Matter

Understanding the practical differences between preventive and predictive maintenance helps beginners make informed decisions about implementation priorities, resource allocation, and capability development strategies. Organizations that begin with a structured implementation roadmap achieve results 50% faster than those attempting to implement advanced strategies before building foundational capabilities. Oxmaint provides beginners with clear guidance on phasing maintenance evolution for optimal results.

Implementation Complexity

Preventive: Simple - requires basic scheduling and checklists. Predictive: Complex - requires sensors, data systems, and analytical expertise for effective deployment.

Cost to Start

Preventive: $2,000-$10,000 for CMMS and training. Predictive: $50,000-$200,000 for sensors, software, and specialist training initially.

Time to Results

Preventive: 1-3 months to see failure reduction. Predictive: 6-12 months to achieve reliable predictions and optimize interventions.

Maintenance Reduction

Preventive: May increase maintenance initially through scheduled activities. Predictive: Reduces maintenance by 30-50% through condition-based optimization.

When to Start With Preventive Maintenance

Ideal Starting Conditions

Preventive maintenance represents the optimal starting point for most organizations beginning their maintenance transformation journey. Understanding when PM provides the best foundation helps beginners avoid the common mistake of attempting advanced predictive strategies before establishing basic maintenance discipline and organizational readiness.

Currently Reactive

Organizations operating in reactive "run-to-failure" mode should start with PM to establish scheduled maintenance discipline, reduce chaos, and build foundational capabilities before considering predictive.

Limited Budget

Facilities with maintenance budgets under $100,000 annually benefit from PM's lower cost while achieving 40-50% failure reduction, building business case for future predictive investment.

Basic Equipment

Operations with standard equipment lacking connectivity or sensor compatibility achieve better results focusing on systematic PM rather than forcing predictive on unsuitable assets.

Building Foundations

Teams new to structured maintenance need PM experience to develop data collection habits, work order discipline, and analytical skills that enable predictive success later.

When to Progress to Predictive Maintenance

Readiness Indicators

Predictive maintenance delivers breakthrough results for organizations that have established strong preventive foundations and achieved the organizational maturity required for data-driven maintenance. Companies implementing comprehensive predictive strategies after building PM capabilities achieve average savings of $75,000-$300,000 annually per facility. Oxmaint helps organizations assess predictive readiness and implement scalable condition monitoring strategies that maximize ROI.

Strong PM Foundation

Achieving 80%+ preventive maintenance compliance with disciplined scheduling, consistent execution, and reliable data collection demonstrates readiness for predictive strategies.

High-Value Assets

Critical equipment where downtime costs $10,000+ per hour or replacement exceeds $100,000 justifies predictive investment through clear ROI from failure prevention.

Data Collection Maturity

Teams consistently collecting maintenance data, analyzing trends, and making data-driven decisions possess skills needed for successful predictive implementation.

Budget for Technology

Available capital of $50,000+ for sensors, software, and training enables proper predictive deployment rather than underfunded attempts that fail to deliver results.

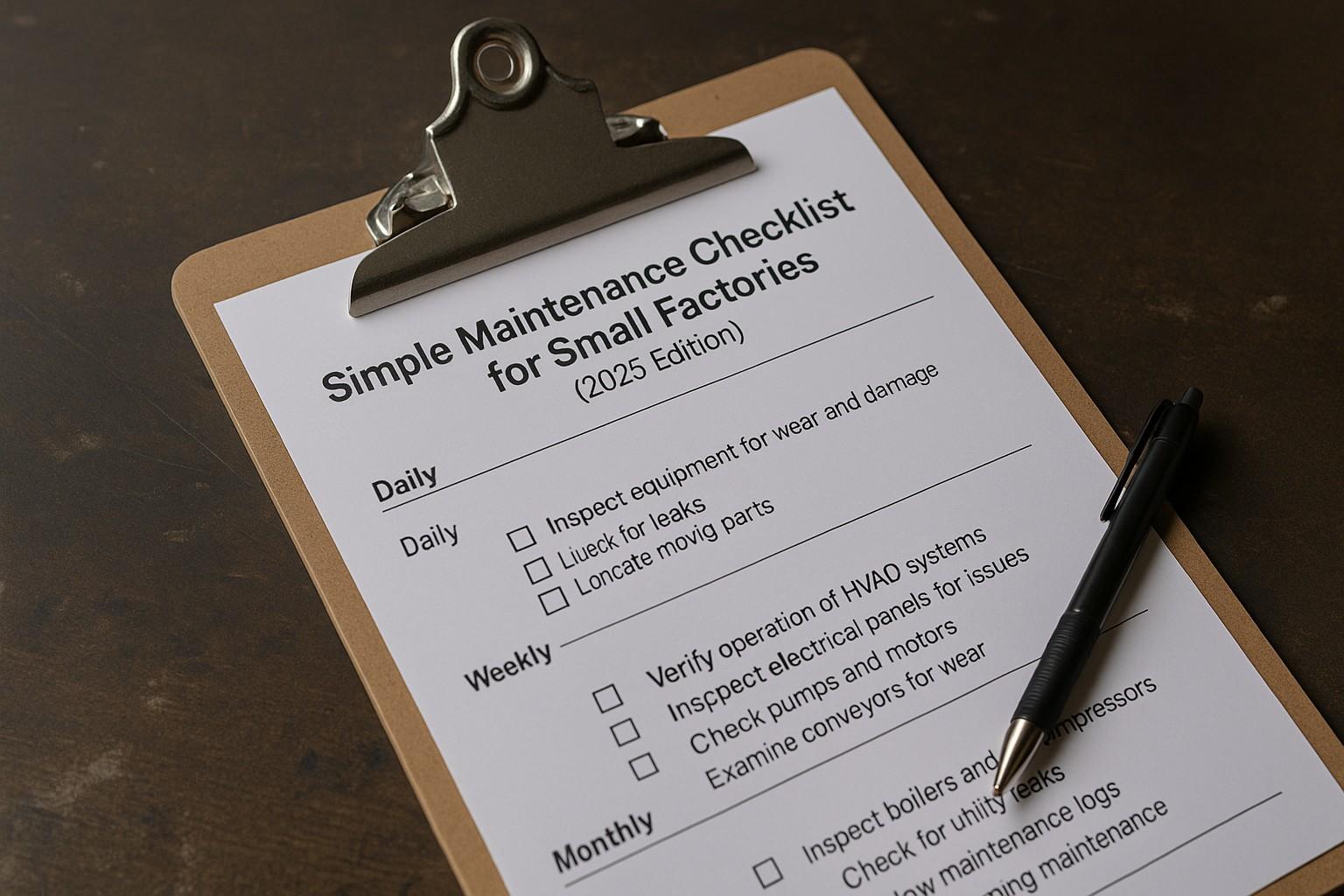

Step-by-Step Implementation Roadmap

Phased Approach for Beginners

Successful maintenance transformation follows a systematic progression that builds capabilities progressively rather than attempting to implement advanced strategies without foundational readiness. Organizations following structured roadmaps achieve breakthrough results 70% faster and with 90% higher ROI than those skipping foundational steps. Smart maintenance teams are securing expert guidance to accelerate their journey while avoiding common pitfalls. Oxmaint provides proven methodologies that ensure sustainable maintenance evolution.

Phase 1: PM Foundation (Months 1-6)

Implement basic preventive maintenance with CMMS, develop PM procedures, train teams, and achieve 80%+ compliance to establish maintenance discipline and data collection habits.

Phase 2: PM Optimization (Months 7-12)

Analyze failure data, optimize PM intervals, eliminate unnecessary tasks, and refine procedures based on actual equipment performance patterns and failure history.

Phase 3: Predictive Pilot (Months 13-18)

Deploy predictive monitoring on 3-5 critical assets, validate prediction accuracy, demonstrate ROI, and build team expertise before broader implementation.

Phase 4: Scaled Predictive (Months 19-24)

Expand predictive across high-value equipment using proven technologies and processes, integrate with PM program, and achieve world-class maintenance performance.

Cost and ROI Comparison

Financial Investment Required

Understanding the financial commitment and return potential helps beginners make informed decisions about maintenance strategy implementation based on available resources, asset criticality, and business objectives. Most preventive maintenance programs deliver positive ROI within 6-12 months, while predictive strategies require 12-18 months to achieve full financial returns.

Preventive Maintenance Costs

Initial Investment: $2,000-$10,000 for basic CMMS, training, and procedures. Ongoing: $500-$2,000 monthly for labor and materials. ROI Timeline: 6-12 months payback.

Predictive Maintenance Costs

Initial Investment: $50,000-$200,000 for sensors, software, training, and integration. Ongoing: $3,000-$10,000 monthly for monitoring and analysis. ROI Timeline: 12-18 months payback.

Preventive Maintenance Returns

Annual Benefits: $25,000-$100,000 through 40% failure reduction, 20% maintenance efficiency gains, and extended asset life for typical manufacturing facilities.

Predictive Maintenance Returns

Annual Benefits: $100,000-$500,000 through 75% failure prevention, 50% maintenance reduction, and optimized intervention timing for facilities with critical assets.

Common Beginner Mistakes to Avoid

Critical Implementation Pitfalls

Learning from common mistakes accelerates maintenance transformation by helping beginners avoid pitfalls that derail programs, waste resources, and damage organizational confidence in maintenance improvement initiatives. Understanding these challenges enables proactive risk mitigation and increases implementation success rates dramatically.

- Skipping preventive foundation by jumping directly to predictive creates organizational chaos, wasted technology investment, and poor prediction accuracy due to lack of basic maintenance discipline

- Over-maintenance with PM through excessively conservative intervals wastes resources and creates unnecessary work - optimize based on actual failure data after 6-12 months

- Under-investment in predictive by deploying incomplete monitoring systems produces unreliable predictions that undermine confidence rather than demonstrating value

- Ignoring data quality by failing to validate sensor accuracy, clean data, and verify predictions leads to false alarms and missed failures that destroy trust

- Lack of training investment by attempting implementation without proper team education creates execution failures regardless of strategy quality or technology capability

Success Stories Across Industries

Real-world implementation examples demonstrate how beginners successfully navigate the preventive-to-predictive journey, achieving breakthrough results through systematic capability building and strategic technology adoption. These success patterns help organizations understand what's possible and build confidence in their maintenance transformation initiatives.

Small Manufacturer Success

50-person facility started with basic PM, achieved 45% failure reduction in 6 months, then added predictive to 3 critical assets, reaching 80% total downtime elimination and $180,000 annual savings.

Food Processing Plant

Reactive operation implemented PM program achieving 90% compliance, then progressed to vibration monitoring on packaging lines, preventing $500,000 in potential line failures annually.

Distribution Center

Warehouse operation built PM foundation over 8 months, then deployed thermal imaging on electrical systems, identifying 23 critical issues before failure at $15,000 implementation cost.

Metal Fabrication Shop

Job shop established PM discipline reducing breakdowns by 50%, then added oil analysis to CNC machines, extending tool life 30% and saving $85,000 annually in maintenance costs.

Your Personalized Maintenance Roadmap

Take Action With Expert Guidance

Every facility's maintenance journey is unique based on equipment types, organizational maturity, budget constraints, and business objectives. While general principles apply universally, achieving optimal results requires personalized strategy development that aligns technology investment, capability building, and implementation timing with specific operational realities. Organizations that begin with professional assessment achieve results 60% faster and avoid costly mistakes that derail self-guided implementations. Oxmaint provides beginners with clear roadmaps, proven methodologies, and ongoing support that accelerates maintenance transformation while maximizing ROI.

Free Readiness Assessment

Comprehensive evaluation of current maintenance maturity, organizational capabilities, and equipment criticality to determine optimal starting strategy - preventive, predictive, or hybrid approach.

Custom Implementation Plan

Detailed roadmap specifying exact steps, timelines, resource requirements, and expected outcomes based on your facility's unique conditions and business objectives.

Technology Selection Guidance

Expert recommendations on CMMS platforms, predictive technologies, and monitoring systems that match your budget, technical capabilities, and equipment requirements.

Ongoing Success Support

Continuous guidance throughout implementation ensuring smooth deployment, rapid problem resolution, and optimization based on actual performance data and results achieved.

Stop guessing about where to start your maintenance journey. Every month of confusion costs you thousands in preventable failures and wasted resources. The most successful facilities begin with clear roadmaps and expert guidance that accelerate results while avoiding expensive mistakes. Your competitors are already building maintenance advantages - don't fall behind because of uncertainty.

Get Your Free Roadmap Assessment Schedule Strategy Consultation