Small business maintenance management represents one of the most critical operational challenges facing growing companies, with unorganized maintenance approaches costing an average of $5,000 per breakdown per facility. Industry data reveals that 68% of small businesses still rely on reactive maintenance approaches that create unexpected failures, missed maintenance schedules, and emergency repair costs. Systematic CMMS implementation can reduce emergency repairs by 80%, extend equipment life by 35% and decrease maintenance costs by 65% while ensuring operational continuity, and maximum asset utilization across small business environments.

Modern small businesses depend on efficient equipment operations and systematic maintenance approaches, where even minor oversight can escalate into complete system failures that halt operations and devastate tight budgets. Maintenance management inefficiencies cascade throughout small organizations, affecting productivity, equipment availability, and total operational costs in ways that large enterprises can absorb but small businesses cannot.

The Hidden Crisis: Critical Maintenance Challenges in Small Business Operations

Reactive Maintenance Trap

72% of small businesses operate in reactive mode, addressing equipment issues only after failures occur, resulting in 3x higher repair costs and extended downtime periods.

Poor Documentation Systems

85% of small businesses lack systematic maintenance records, making warranty claims difficult and preventing optimal maintenance scheduling that could save $10,000+ annually.

Resource Management Issues

Small businesses struggle with maintenance resource allocation, with 60% reporting inefficient technician scheduling and parts inventory management causing project delays.

Budget Unpredictability

Maintenance cost unpredictability affects 78% of small businesses, with emergency repairs consuming 45% of annual maintenance budgets without providing preventive value.

Skilled Labor Shortage

Limited maintenance expertise in small businesses leads to improper repairs, delayed responses, and equipment mismanagement costing $15,000+ in preventable expenses.

Compliance and Safety Risks

Regulatory compliance challenges affect 65% of small businesses, with inadequate maintenance documentation creating safety risks and potential penalty exposures.

The Financial Impact of Poor Maintenance Management

Before implementing systematic CMMS solutions, small business operations experience significant inefficiencies that disproportionately impact their limited resources and operational flexibility:

- Emergency repair premiums consuming 45% of maintenance budgets while providing no preventive value or operational improvement

- Equipment downtime averaging 20-25% of available hours due to reactive maintenance and poor scheduling coordination

- Maintenance cost volatility making budget planning extremely difficult and affecting cash flow predictability

- Regulatory compliance risks with 35% of small businesses facing potential penalties due to inadequate documentation

- Lost productivity from equipment failures averaging $20,000+ annually for typical small business operations

Foundation Elements: Comprehensive CMMS Framework for Small Businesses

Professional CMMS solutions provide the organizational framework necessary for systematic maintenance management, incorporating asset tracking, preventive scheduling, and cost optimization into unified platforms designed specifically for small business operational requirements and resource constraints.

Core CMMS Components and Architecture

Effective CMMS frameworks integrate multiple operational streams and management criteria to create comprehensive maintenance systems that balance functionality with operational simplicity suitable for small business environments.

Asset Management Database

Comprehensive asset tracking including equipment specifications, maintenance history, warranty information, and performance metrics that enable precise condition assessment and lifecycle planning.

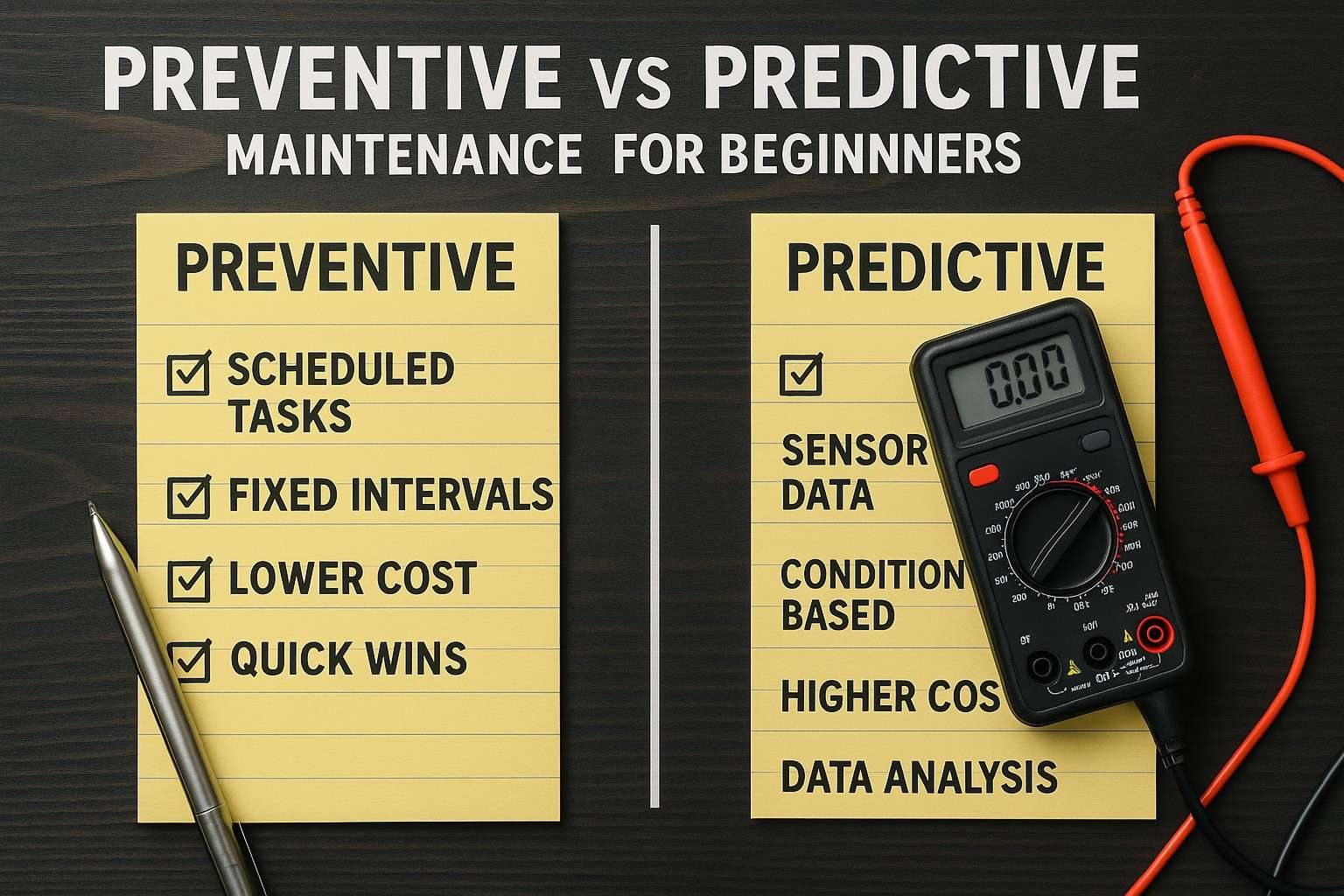

Preventive Maintenance Scheduling

Automated scheduling systems, maintenance task libraries, resource allocation, and notification protocols that ensure systematic maintenance execution and optimal timing.

Work Order Management System

Digital work order creation, assignment tracking, completion documentation, and cost accounting that streamlines maintenance operations and ensures accountability.

Inventory and Parts Management

Parts inventory tracking, automatic reorder points, vendor management, and cost optimization to ensure maintenance continuity while minimizing inventory carrying costs.

Advanced Integration and Automation Capabilities

Smart CMMS Features and Predictive Analytics

Modern CMMS solutions transcend basic scheduling to incorporate real-time monitoring, automated workflows, and data analytics that optimize maintenance operations for maximum efficiency and cost-effectiveness in small business environments.

Automated Work Order Generation

System-generated maintenance tasks based on time, usage, or condition triggers that eliminate scheduling oversight and ensure consistent preventive maintenance execution.

Mobile Accessibility and Updates

Mobile-responsive interfaces enabling technicians to access work orders, update status, and document completion from any location, improving communication and efficiency.

Cost Tracking and Budget Management

Comprehensive cost accounting including labor, parts, and contractor expenses with budget tracking and variance analysis for optimal financial control.

Vendor and Contractor Integration

Vendor management systems that coordinate external maintenance services, track performance, and optimize contractor relationships for maximum value and reliability.

Implementation Methodology and Best Practices

Phased Deployment Strategy for Small Business CMMS

Successful CMMS implementation requires systematic deployment approaches that minimize operational disruption while maximizing adoption success across small business teams with limited technical resources and implementation experience.

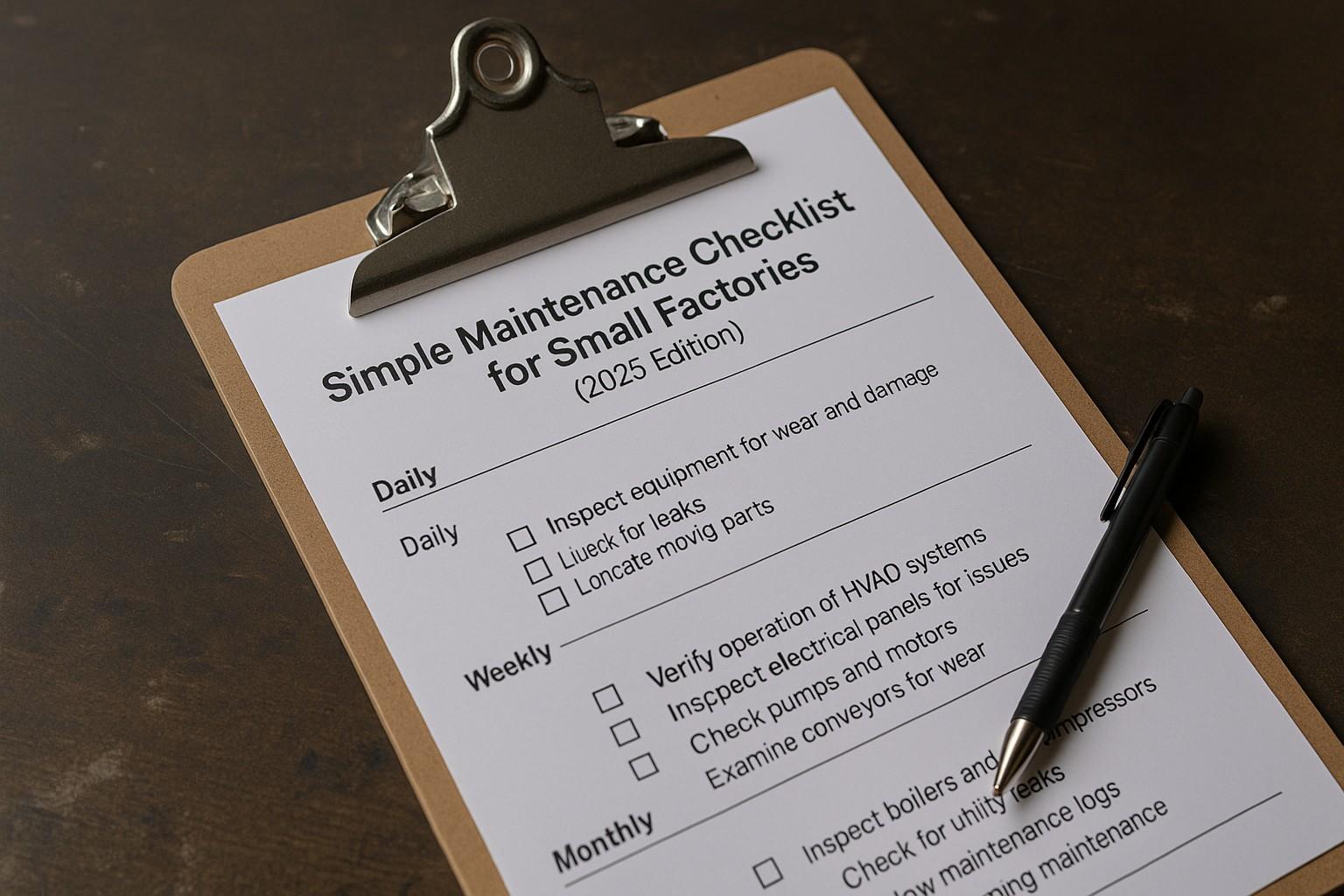

Phase 1: Asset Discovery and Setup

Complete asset inventory, equipment specification gathering, maintenance history compilation, and initial system configuration tailored to specific business operational requirements.

Phase 2: Process Standardization

Maintenance procedure documentation, preventive schedule development, work order template creation, and workflow optimization based on business-specific operational patterns.

Phase 3: Team Training and Adoption

Comprehensive user training, system orientation, process familiarization, and change management support to ensure successful adoption across all organizational levels.

Phase 4: Optimization and Scaling

Performance monitoring, process refinement, advanced feature adoption, and system expansion based on operational feedback and business growth requirements.

Change Management and User Adoption Strategies

CMMS implementation success depends heavily on user adoption and process transformation, requiring comprehensive training programs and change management approaches that address small business team dynamics and resource constraints.

Role-Based Training Programs

Customized training for managers, technicians, and administrators covering system usage, process workflows, and best practices for maximum operational effectiveness.

Process Integration Support

Workflow integration assistance, standard operating procedure development, and process optimization guidance to ensure seamless CMMS adoption.

Ongoing Technical Support

Dedicated support channels, system troubleshooting, user assistance, and continuous improvement consultation to maintain operational momentum.

Performance Monitoring and Feedback

Regular performance reviews, user feedback collection, system optimization recommendations, and success measurement to ensure continuous improvement.

Analytics and Performance Monitoring Capabilities

Advanced CMMS Analytics and KPI Tracking

CMMS analytics capabilities transform maintenance data into actionable insights that enable continuous improvement, cost optimization, and performance enhancement across small business operations with limited analytical resources.

Real-Time Dashboard Analytics

Executive and operational dashboards providing immediate visibility into maintenance performance, cost trends, and equipment health across all business assets.

Cost Analysis and Budget Tracking

Comprehensive cost analysis covering labor, parts, and contractor expenses with budget variance tracking and optimization recommendations for financial control.

Equipment Performance Metrics

Asset performance tracking including uptime, reliability, and lifecycle analysis that support replacement decisions and optimization strategies.

Compliance and Documentation Reports

Automated compliance reporting ensuring maintenance activities meet regulatory requirements, safety standards, and warranty obligations with exception tracking.

ROI and Operational Excellence Outcomes

Quantifiable Financial Benefits and Cost Optimization

Systematic CMMS implementation delivers measurable financial returns through multiple value streams that extend beyond direct maintenance savings to encompass operational efficiency, equipment longevity and business growth enablement benefits.

Operational Efficiency and Competitive Advantages

Comprehensive CMMS implementation creates operational advantages that enhance competitive positioning through improved equipment reliability, predictable maintenance costs, and enhanced service delivery capabilities.

- Improved operational reliability with predictable equipment availability and minimal maintenance-related disruptions to business operations

- Enhanced productivity averaging 85%+ equipment uptime compared to 70% with reactive maintenance approaches

- Better customer service delivery through reliable operations and reduced service interruptions that affect customer satisfaction

- Increased business scalability with systematic processes that support growth without proportional maintenance management complexity

- Improved cash flow predictability through planned maintenance budgets and eliminated emergency repair surprises

Compliance and Regulatory Alignment

Regulatory compliance requirements make systematic maintenance documentation essential for small businesses, with safety standards, environmental regulations, and insurance requirements demanding organized maintenance records and systematic asset management programs.

Safety Standard Compliance

OSHA and safety regulations requiring systematic equipment maintenance and documentation, with CMMS systems ensuring compliance and reducing violation risks that can cost $10,000+ per incident.

Environmental Regulation Adherence

Environmental protection standards demanding proper equipment maintenance to ensure compliance with emission controls and environmental safety requirements.

Insurance and Risk Management

Insurance carrier requirements for documented maintenance programs, with CMMS systems reducing premiums and claim exposures through systematic risk management.

Warranty Protection and Claims

Manufacturer warranty requirements for proper maintenance documentation, with CMMS systems protecting warranty coverage and supporting claim processes effectively.

Future Outlook and Technology Integration

The CMMS landscape continues evolving with emerging technologies that promise enhanced automation, predictive capabilities, and integration possibilities that will further improve maintenance efficiency and cost-effectiveness for small businesses.

IoT Integration Capabilities

Internet of Things technologies enabling automatic data collection and condition monitoring integration with CMMS systems for enhanced predictive maintenance.

Artificial Intelligence Analytics

AI-powered analytics providing enhanced pattern recognition, optimization recommendations, and automated decision support for maintenance planning and execution.

Cloud-Based Scalability

Cloud infrastructure providing unlimited scalability, automatic updates, and reduced IT overhead that enable small businesses to access enterprise-level capabilities.

Mobile Technology Enhancement

Advanced mobile capabilities including offline functionality, voice commands, and augmented reality features that improve field technician productivity and accuracy.