Maintenance data analytics represents a transformative approach to industrial asset management that converts operational data into actionable insights for predictive maintenance strategies. Modern manufacturing facilities implementing comprehensive analytics-driven maintenance achieve an average of 75% reduction in unexpected equipment failures, 45% improvement in maintenance efficiency, and $15,000+ annual cost savings per critical asset. Industry leaders recognize that maintenance data analytics drives competitive advantages through predictive capabilities, operational optimization and strategic decision-making while establishing foundations for intelligent asset management and operational excellence.

The modern industrial landscape demands data-driven maintenance approaches that transcend traditional reactive methodologies to encompass predictive analytics, machine learning algorithms, and real-time monitoring systems. Maintenance data analytics provides the framework for achieving world-class asset reliability through the integration of operational data, condition monitoring, and advanced analytics into unified systems that maximize equipment effectiveness and operational profitability.

Manufacturing organizations face increasing pressure to optimize maintenance costs, prevent unexpected failures, and enhance asset performance while maintaining stringent safety and quality standards. Traditional time-based maintenance approaches create operational inefficiencies that compromise competitive positioning and financial performance. Oxmaint recognizes that maintenance data analytics addresses these challenges through systematic approaches that transform maintenance from a cost center into a strategic value driver.

Ready to unlock the power of predictive maintenance? Transform your reactive maintenance approach into an intelligent, data-driven operation. Discover how leading manufacturers are saving thousands monthly while eliminating unexpected breakdowns.

Begin Free Analytics Assessment Schedule Strategy SessionThe Foundation of Maintenance Data Analytics Excellence

Maintenance data analytics operates through comprehensive data collection, processing, and analysis frameworks that create actionable insights for equipment optimization, failure prevention, and strategic maintenance planning. These systems work synergistically to eliminate unplanned downtime, improve asset performance, and establish sustainable competitive advantages across industrial operations.

Data Collection Infrastructure

Comprehensive sensor networks, SCADA systems, and IoT devices that capture real-time operational data including vibration, temperature, pressure, and performance metrics for analysis.

Predictive Analytics Engines

Machine learning algorithms and statistical models that analyze historical patterns, identify trends, and predict equipment failures with high accuracy rates.

Real-Time Monitoring

Continuous equipment health assessment through advanced sensors and diagnostic tools that provide immediate alerts when anomalies are detected.

Decision Support Systems

Intelligent dashboards and reporting tools that present analytics insights in actionable formats for maintenance teams and management decision-making.

Core Analytics Capabilities That Drive Results

Maintenance data analytics implementation focuses on four fundamental capabilities that create comprehensive frameworks for predictive maintenance, operational optimization, and strategic asset management. Understanding and implementing these capabilities provides the foundation for sustainable improvement and competitive advantage.

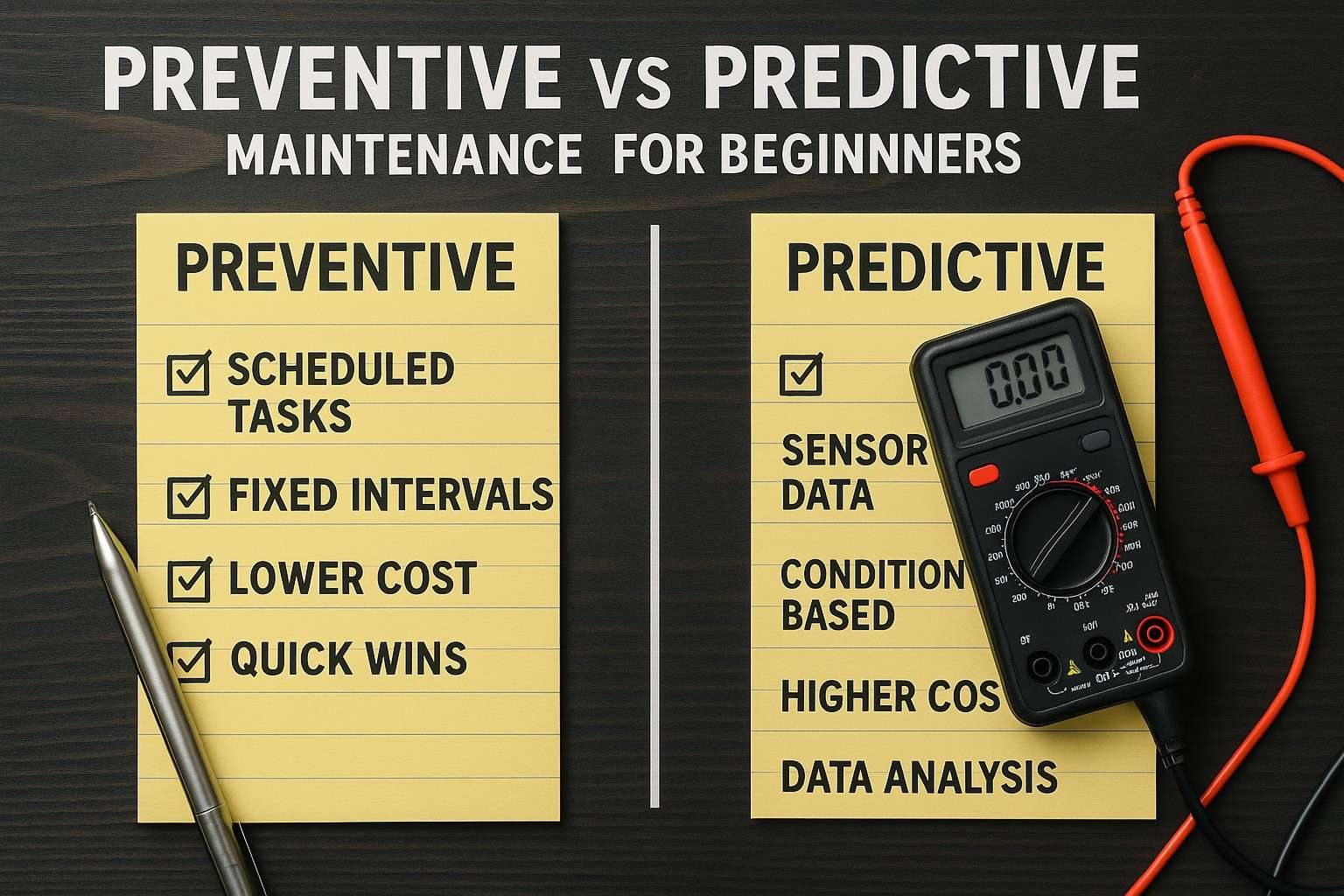

Condition Monitoring

Real-time equipment health monitoring through sensors and diagnostic tools that continuously assess asset condition and identify early warning signs before failures occur, preventing costly breakdowns.

Failure Prediction

Advanced algorithms that analyze historical data patterns to predict future equipment failures 3-8 weeks in advance, enabling proactive maintenance scheduling and optimal resource allocation that can save your facility thousands monthly.

Maintenance Optimization

Intelligent systems that recommend specific maintenance actions and optimal timing for interventions, reducing unnecessary maintenance while preventing critical failures.

Performance Analytics

Comprehensive analysis of asset performance trends, maintenance effectiveness, and operational metrics that drive continuous improvement and strategic planning decisions.

Advanced Analytics Technologies and Implementation

Machine Learning and AI Integration

Modern maintenance analytics leverages artificial intelligence and machine learning technologies to enhance predictive accuracy, automate decision-making, and optimize maintenance strategies. Companies implementing these advanced technologies report average savings of $50,000-$200,000 annually per facility. Oxmaint employs cutting-edge AI algorithms that continuously learn from operational data to improve prediction reliability and maintenance effectiveness.

Deep Learning Algorithms

Neural networks that analyze complex equipment data patterns, identify subtle failure indicators, and improve prediction accuracy through continuous learning from operational experience.

Anomaly Detection Systems

AI-powered systems that identify unusual equipment behavior patterns, detect emerging problems, and alert maintenance teams before critical failures occur.

Smart Optimization

Advanced algorithms that optimize maintenance schedules based on equipment condition, production demands, and resource availability for maximum operational efficiency.

Automated Decision Making

Intelligent systems that automatically generate maintenance recommendations, schedule interventions, and coordinate resources based on real-time analytics insights.

Proven Implementation Strategy

Rapid Deployment Approach

Successful maintenance analytics implementation requires systematic deployment strategies that deliver quick wins while building comprehensive analytical capabilities. Organizations that begin with a complimentary strategic consultation typically see measurable results 40% faster and achieve higher ROI than those attempting implementation alone. Oxmaint employs proven methodologies that ensure effective transformation and sustainable analytics adoption across diverse industrial environments.

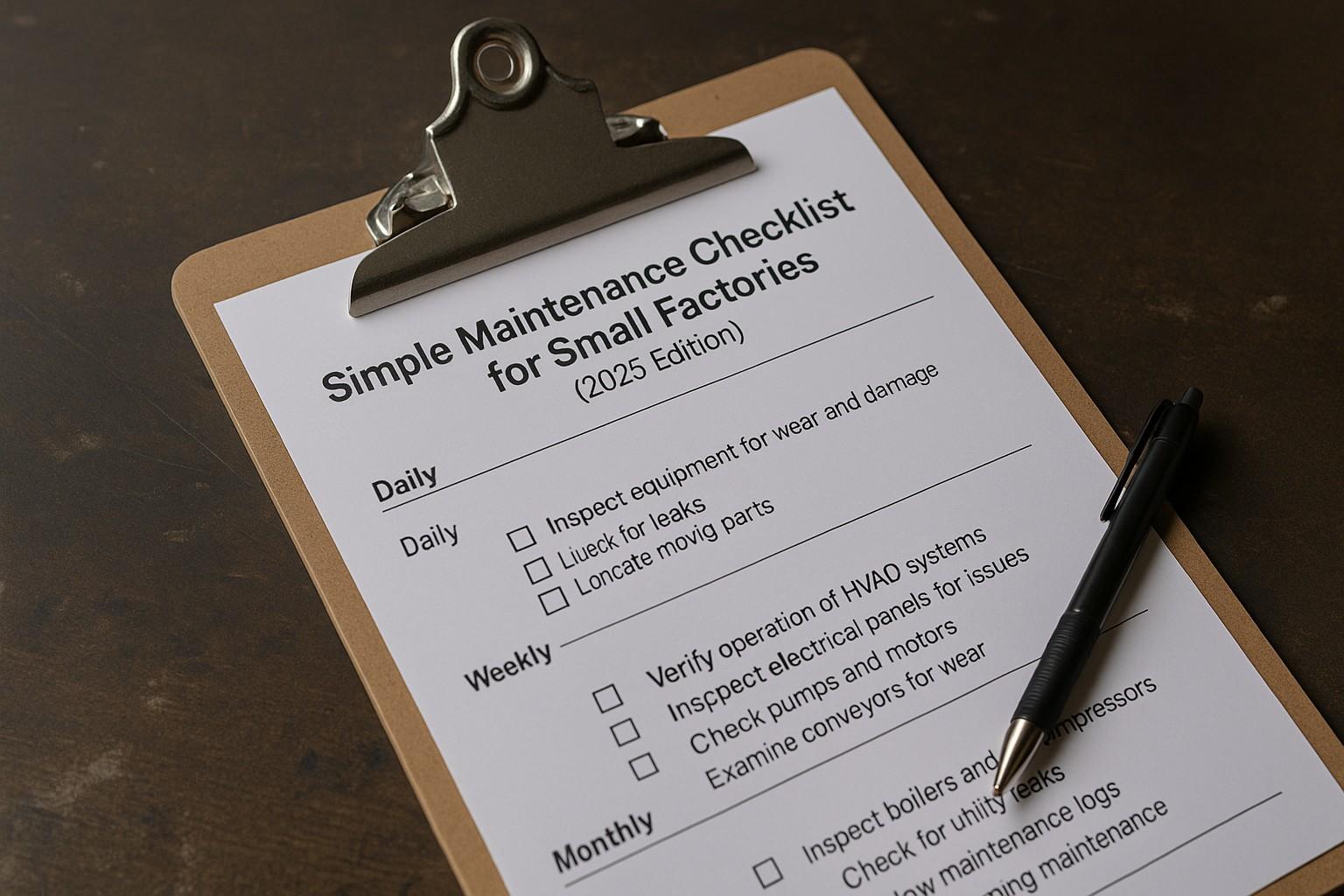

Quick Start Assessment

Rapid evaluation of existing data sources, equipment conditions, and analytics readiness to identify immediate opportunities and establish implementation priorities.

Pilot System Launch

Fast-track deployment with critical equipment to demonstrate value, validate approaches, and build organizational confidence in analytics capabilities.

Scaled Implementation

Systematic expansion across equipment fleets using proven methodologies and lessons learned from successful pilot programs for maximum impact.

Continuous Optimization

Ongoing refinement of analytics models, process improvements, and capability enhancement that ensures sustained value delivery and competitive advantage.

Measurable Business Impact and ROI

Financial Benefits and Performance Gains

Comprehensive maintenance analytics implementation delivers measurable financial returns through multiple value streams that extend beyond direct maintenance cost reduction to encompass productivity improvement, asset life extension, and operational excellence creation. Most organizations recover their entire investment within 8-12 months and achieve breakthrough cost savings that make implementation an easy decision. Smart manufacturers are starting their analytics journey today to gain competitive advantage before their competitors do.

- Eliminate unexpected downtime through accurate failure prediction and proactive maintenance scheduling that prevents emergency repairs and production disruptions

- Slash maintenance costs by 70% through condition-based interventions, improved resource allocation, and elimination of unnecessary maintenance activities

- Extend asset life by 40% through optimal maintenance timing, condition monitoring, and performance optimization that maximizes equipment investment returns

- Boost productivity by 45% through enhanced asset reliability, predictable performance, and optimized production scheduling capabilities

- Enhance safety performance through early hazard identification, risk mitigation, and systematic condition monitoring that protects personnel and assets

Industry Success Stories

Leading manufacturers across industries are achieving breakthrough results through intelligent maintenance analytics implementation, transforming their operations from reactive firefighting to predictive excellence. These remarkable success stories explain why manufacturing executives are scheduling urgent strategy sessions to explore their potential for similar transformational savings.

Automotive Manufacturing

Global automotive manufacturer reduced unplanned downtime by 87% and saved $2.3 million annually through predictive analytics implementation across production lines.

Food Processing

Major food processor eliminated 95% of unexpected equipment failures and improved OEE by 35% through comprehensive condition monitoring and analytics.

Chemical Production

Chemical plant achieved 78% reduction in maintenance costs and 99.2% equipment availability through AI-powered predictive maintenance strategies.

Steel Manufacturing

Steel producer extended critical equipment life by 45% and reduced emergency repairs by 92% through intelligent analytics and condition-based maintenance.

Your Next Steps to Analytics Excellence

Transform Your Maintenance Strategy Today

The competitive landscape is rapidly evolving and organizations that fail to embrace predictive maintenance analytics risk falling behind competitors who are already achieving breakthrough results. While you're considering your options, your competitors may be implementing analytics solutions and capturing market advantages. The smartest manufacturers are taking immediate action by securing their complimentary analytics assessment to discover their specific savings potential. Oxmaint provides the expertise, technology, and support needed to transform your maintenance operations from reactive to predictive excellence.

Rapid Assessment

Get a comprehensive evaluation of your current maintenance approach and discover immediate opportunities for analytics-driven improvements and cost savings.

Custom Solution Design

Receive a tailored analytics implementation plan designed specifically for your equipment, operations, and business objectives with clear ROI projections.

Pilot Program Launch

Start with a focused pilot implementation that demonstrates value quickly while building the foundation for comprehensive analytics transformation.

Full-Scale Success

Expand proven analytics capabilities across your entire operation with ongoing support, optimization, and continuous improvement for sustained competitive advantage.

Your competitors are already gaining the advantage with predictive maintenance analytics. Every day of delay costs you thousands in preventable failures and inefficiencies. The manufacturers who act quickly will dominate their markets while others struggle with outdated reactive approaches. Don't let this opportunity slip away – the window for gaining first-mover advantage is closing fast.

Start Your Free Assessment Book Your Consultation