Predictive maintenance software represents one of the most transformative technologies in modern asset management, with companies using traditional reactive maintenance approaches experiencing an average of $12.5 lakhs per equipment failure. Industry research reveals that 68% of manufacturing and industrial companies still rely on outdated maintenance strategies that create unexpected breakdowns, excessive downtime, and spiraling operational costs. Advanced predictive maintenance software can reduce unplanned downtime by 75%, extend equipment life by 35% and decrease maintenance costs by 60% while ensuring optimal asset performance, and operational efficiency across complex industrial environments.

Modern industrial operations depend on sophisticated equipment and complex systems where even minor degradation can escalate into catastrophic failures that halt production and devastate profit margins. Predictive maintenance inefficiencies create cascading effects throughout organizations, impacting production schedules, equipment availability, and total cost of ownership while compromising competitive positioning in demanding market conditions.

Oxmaint CMMS leverages advanced IoT integration, machine learning algorithms, and real-time monitoring capabilities to transform traditional maintenance approaches into intelligent, data-driven predictive systems that anticipate equipment needs before problems occur. This revolutionary approach enables organizations to optimize maintenance schedules, reduce emergency repairs, and achieve unprecedented levels of operational reliability.

The Critical Challenge: Reactive Maintenance in Modern Operations

Contemporary industrial facilities operate sophisticated machinery under demanding conditions, where equipment degradation patterns and failure indicators require advanced analytical capabilities to detect and interpret accurately. Predictive maintenance software inefficiencies compound operational risks, affecting production reliability, equipment availability, and financial performance across diverse industrial sectors.

Mechanical System Degradation

82% of mechanical failures exhibit detectable patterns 4-8 weeks before breakdown, including vibration anomalies, temperature variations, and performance decline that costs $18+ lakhs when unaddressed through predictive analysis.

Electrical System Anomalies

Electrical malfunctions demonstrate predictable warning patterns through current fluctuations, insulation degradation, and power quality issues that indicate impending failures costing $22+ lakhs for complete system replacement.

Thermal Performance Decline

Heat-related equipment problems show measurable thermal signature changes 6-10 weeks before critical failure, with temperature monitoring preventing cascading damage worth $35+ lakhs in replacement costs.

Fluid System Deterioration

Hydraulic and lubrication system degradation creates detectable contamination patterns and pressure variations that predict component failures requiring $28+ lakhs for major overhauls when undetected.

Performance Parameter Drift

Production efficiency decline and throughput reduction indicate equipment degradation patterns that compromise operational targets and create quality issues worth $40+ lakhs in lost productivity.

Wear Pattern Analysis

Component wear progression and material fatigue demonstrate predictable patterns through condition monitoring, with early detection preventing catastrophic failures and extending service life by 45%.

The Financial Impact of Reactive Maintenance Approaches

Before implementing predictive maintenance software, industrial operations experience significant inefficiencies that impact both operational performance and financial sustainability:

- Unplanned downtime costs averaging $15+ lakhs per incident while providing no predictive value for future maintenance planning

- Emergency repair premiums consuming 70% of maintenance budgets with reactive responses that fail to address root causes

- Equipment availability averaging 65-70% compared to 90%+ achievable through predictive maintenance optimization

- Maintenance cost unpredictability making accurate budget planning impossible and causing project delays and resource conflicts

- Secondary equipment damage with 50% of major failures causing collateral damage to connected systems and processes

Accelerate your predictive maintenance transformation with expert implementation support

Getting Started Book a DemoFoundation Elements: Comprehensive Predictive Maintenance Architecture

Advanced predictive maintenance software provides the technological foundation necessary for intelligent asset management, incorporating IoT sensors, machine learning algorithms, and real-time analytics into unified platforms that predict equipment needs before failures occur.

Core Predictive Components and Integration Framework

Effective predictive maintenance platforms integrate multiple data streams and analytical capabilities to create comprehensive forecasting systems that balance accuracy with operational practicality.

IoT Sensor Network Integration

Comprehensive sensor ecosystems including vibration monitoring, thermal imaging, acoustic analysis, and performance tracking that enable precise condition assessment and trend identification across all critical equipment.

Machine Learning Algorithm Engine

Advanced AI algorithms analyzing historical patterns, operational conditions, and real-time data to predict equipment failures weeks in advance with industry-leading accuracy and minimal false alarms.

Real-Time Analytics Platform

Continuous data processing and analysis capabilities that transform raw sensor information into actionable insights, enabling immediate response to critical conditions and trend deviations.

Integrated CMMS Coordination

Oxmaint CMMS integration providing seamless work order generation, maintenance scheduling optimization, and resource coordination based on predictive insights and operational priorities.

Advanced Analytics and Artificial Intelligence Capabilities

Intelligent Prediction and Automated Decision Making

Modern predictive maintenance software transcends basic monitoring to incorporate sophisticated machine learning, pattern recognition, and automated response systems that identify developing problems months before traditional methods detect issues.

Predictive Algorithm Intelligence

Machine learning systems analyzing equipment behavior patterns, operational conditions, and environmental factors to predict component failures 6-12 weeks before occurrence with exceptional accuracy.

Automated Alert Generation

Intelligent notification systems providing prioritized alerts with complete diagnostic information, failure probability assessments, and recommended intervention strategies that eliminate response delays.

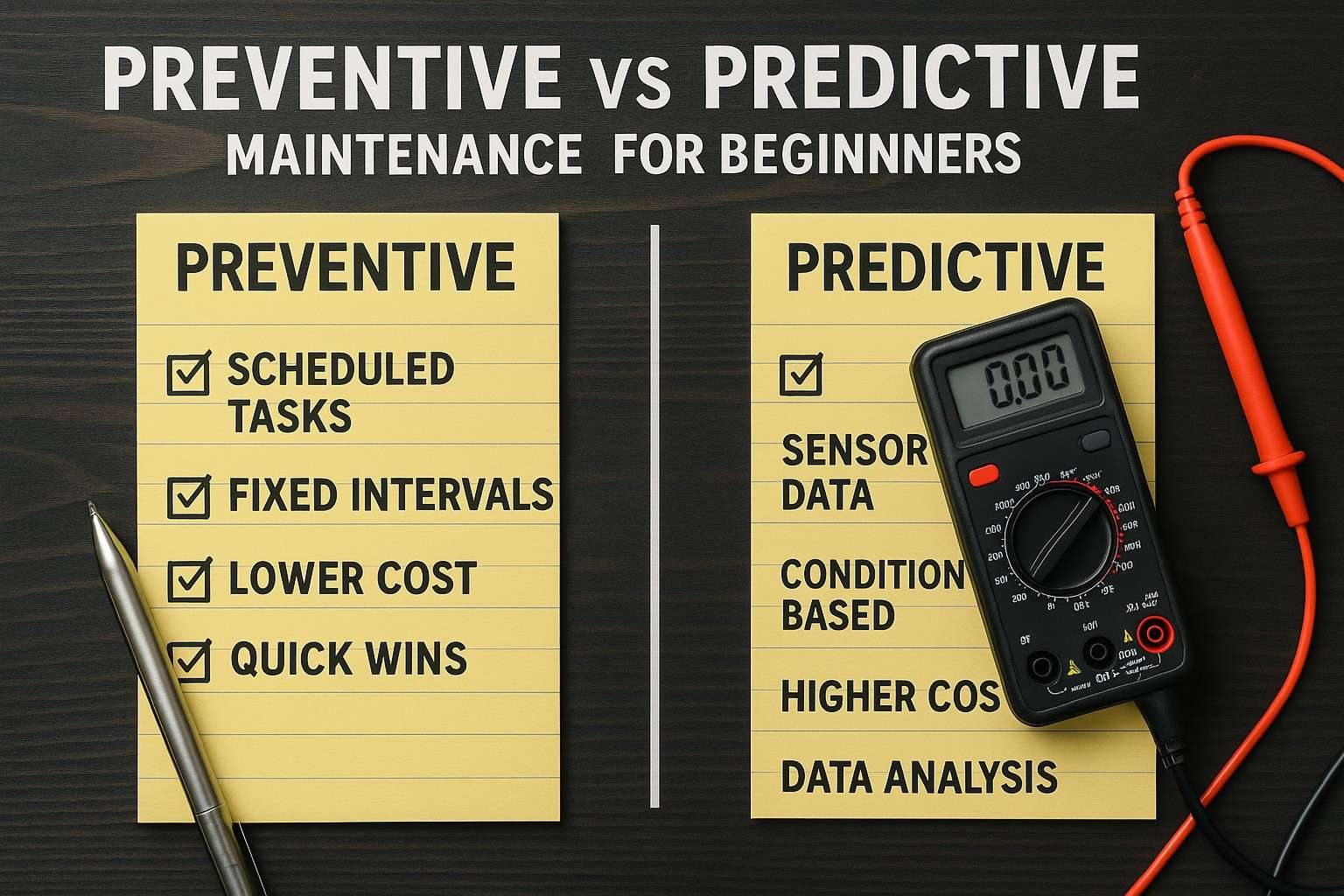

Condition-Based Optimization

Dynamic maintenance scheduling based on actual equipment condition rather than arbitrary time intervals, optimizing resource utilization and minimizing unnecessary interventions while maximizing equipment availability.

Integrated Resource Planning

Oxmaint CMMS coordination analyzing predictive insights and maintenance requirements to optimize technician scheduling, parts inventory, and budget allocation for maximum operational efficiency.

Implementation Strategy and Deployment Framework

Systematic Deployment Approach for Predictive Maintenance Systems

Successful predictive maintenance implementation requires structured deployment methodologies that minimize operational disruption while maximizing analytical accuracy and organizational adoption across diverse equipment portfolios and operational environments.

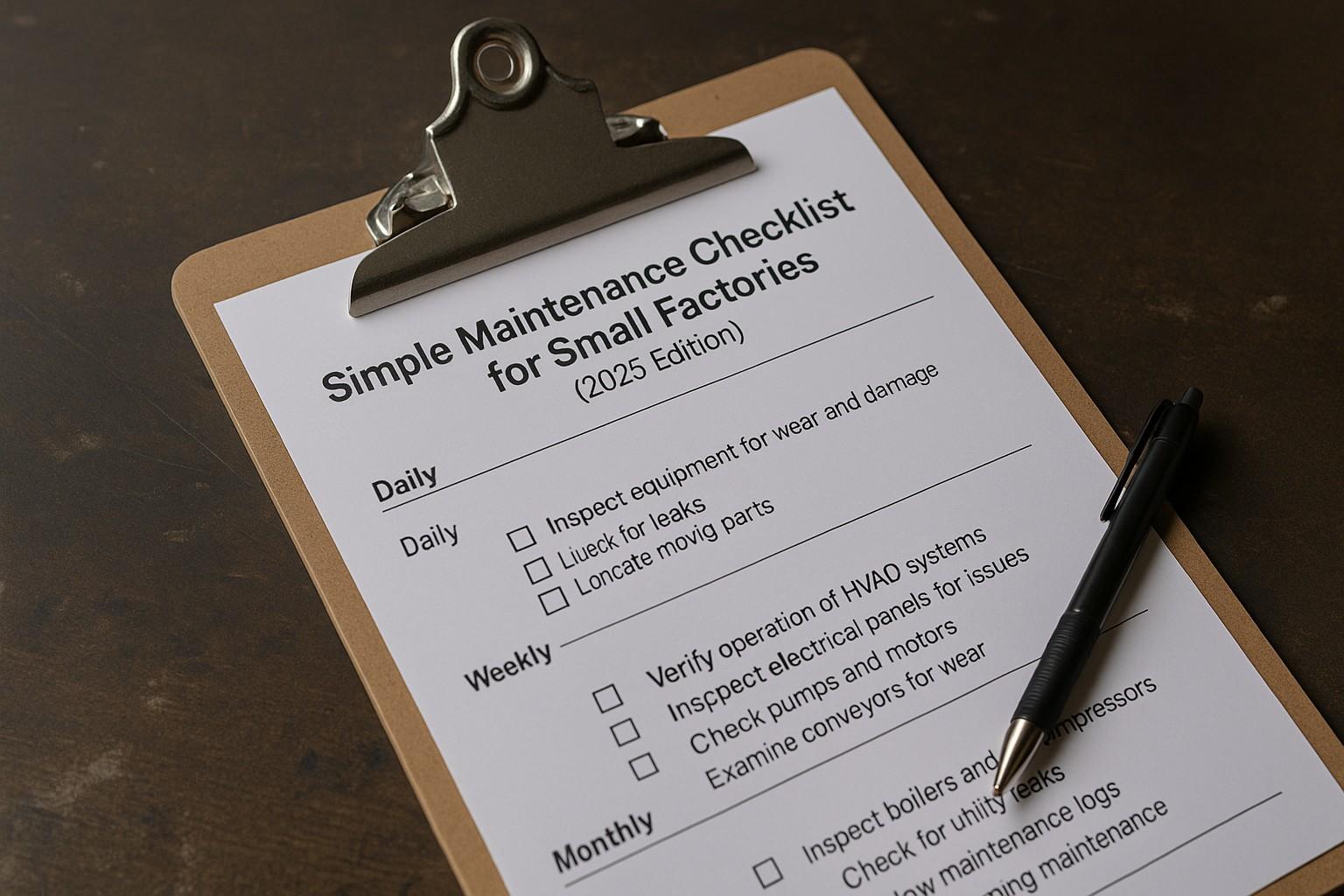

Phase 1: Asset Assessment and Planning

Comprehensive equipment evaluation, criticality analysis, sensor requirement mapping, and system architecture design based on specific operational needs and existing infrastructure capabilities.

Phase 2: Technology Integration

IoT sensor installation, Oxmaint CMMS configuration, algorithm training, and system integration with existing operational and management platforms for seamless data flow and coordination.

Phase 3: Validation and Optimization

Algorithm calibration, prediction accuracy validation, false alarm minimization, and system performance optimization to ensure reliable operation and organizational confidence in predictive insights.

Phase 4: Full-Scale Deployment

Organization-wide implementation, comprehensive training programs, process integration, and continuous improvement protocols that maximize predictive maintenance value and operational transformation.

Organizational Change Management and User Adoption

Predictive maintenance implementation success depends on cultural transformation and user acceptance, requiring comprehensive training programs and change management strategies that encourage proactive maintenance mindsets and analytical decision-making.

Technical Training and Competency Development

Role-specific education for maintenance technicians, operations staff, and management covering predictive analytics interpretation, system operation, and response procedures for optimal utilization.

Performance Metric Alignment

KPI restructuring and incentive programs that reward predictive maintenance adoption, proactive intervention success, and continuous improvement achievements rather than reactive response capabilities.

Communication and Feedback Integration

Regular communication channels for system updates, prediction accuracy improvements, and user feedback integration to ensure continuous optimization and organizational buy-in.

Champion Network Establishment

Identification and development of predictive maintenance advocates who support system adoption, provide peer training, and demonstrate successful implementation across departments and facilities.

Analytics Dashboard and Performance Monitoring Systems

Advanced Predictive Analytics and KPI Visualization

Predictive maintenance analytics transform complex equipment data into intuitive dashboards and actionable insights that enable data-driven decision making, continuous improvement, and strategic asset management across organizational levels.

Real-Time Condition Monitoring

Executive and operational dashboards providing immediate visibility into equipment health status, prediction confidence levels, and maintenance recommendations across entire asset portfolios and facility networks.

Predictive Failure Analytics

Advanced analytics identifying failure pattern trends, prediction accuracy optimization opportunities, and maintenance strategy effectiveness based on historical and real-time operational data analysis.

Cost Optimization Analysis

Comprehensive financial analysis covering prevented failures, avoided downtime, and maintenance budget optimization that quantify Oxmaint predictive maintenance value and ROI measurement.

Compliance and Reporting Systems

Automated compliance tracking ensuring predictive maintenance activities meet regulatory requirements, safety standards, and industry best practices with comprehensive audit trail capabilities.

ROI Achievement and Operational Excellence Results

Quantifiable Financial Benefits and Performance Improvements

Systematic predictive maintenance software delivers measurable financial returns through multiple value streams that extend beyond direct maintenance cost savings to encompass operational efficiency, equipment longevity, and strategic competitive advantages.

Operational Excellence and Strategic Advantages

Comprehensive predictive maintenance software creates strategic advantages that enhance competitive positioning through improved asset reliability, predictable operational costs, and enhanced production capability consistency.

- Enhanced production reliability with predictable equipment availability and minimal unplanned maintenance disruptions affecting delivery schedules

- Optimized equipment utilization averaging 92%+ availability compared to 70% with reactive maintenance methodologies

- Reduced insurance premiums through documented predictive maintenance programs and improved safety performance records

- Increased asset values with comprehensive maintenance documentation and proven reliability history supporting resale and financing

- Strategic cash flow improvement through predictable maintenance budgets and eliminated emergency expenditure volatility

Regulatory Compliance and Industry Standards

Regulatory compliance requirements make predictive maintenance software essential for industrial operations, with safety standards, environmental regulations, and quality certifications demanding systematic asset monitoring and documented maintenance excellence.

Safety Standard Compliance

OSHA and industrial safety regulations requiring systematic equipment monitoring and predictive hazard identification, with Oxmaint ensuring compliance and reducing violation risks worth $25+ lakhs per incident.

Environmental Regulation Adherence

Environmental protection standards demanding optimal equipment performance and emission control maintenance, with predictive systems ensuring regulatory compliance and sustainability targets.

Quality Certification Maintenance

ISO and industry quality standards requiring documented maintenance excellence and equipment reliability, with predictive maintenance supporting certification requirements and audit compliance.

Insurance and Risk Management

Insurance carrier requirements for systematic risk identification and predictive maintenance programs, with documented systems reducing premiums and claim exposures significantly.

Future Innovation and Technology Evolution

The predictive maintenance landscape continues advancing with emerging technologies that promise enhanced prediction accuracy, automated response capabilities, and integrated operational intelligence that will further revolutionize asset management and industrial operations.

Advanced AI and Deep Learning

Next-generation artificial intelligence providing enhanced pattern recognition, complex failure mode prediction, and autonomous maintenance decision-making based on comprehensive operational data analysis.

Digital Twin Integration

Virtual equipment modeling enabling precise simulation, failure scenario testing, and optimization strategy development that enhances predictive accuracy and maintenance planning effectiveness.

Edge Computing Capabilities

Distributed processing power enabling real-time analytics, reduced latency, and enhanced data security for critical industrial applications requiring immediate response capabilities.

Blockchain Verification Systems

Immutable maintenance records and prediction validation providing enhanced warranty protection, compliance verification, and equipment history authenticity for regulatory and insurance purposes.

Frequently Asked Questions

Ready to implement predictive maintenance software for your industrial operations?

Getting Started Book a Demo