Maintenance cost reduction represents one of the most critical operational challenges facing industrial companies, with inefficient maintenance strategies costing an average of $15.5 lakhs per facility annually. Industry data reveals that 68% of manufacturing companies still rely on reactive maintenance approaches that create unexpected breakdowns, excessive repair costs, and operational inefficiencies. Strategic maintenance cost optimization through Oxmaint CMMS can reduce total maintenance expenses by 75%, prevent 90% of unexpected breakdowns, and decrease equipment downtime by 65% while ensuring operational excellence, and maximum asset utilization across diverse industrial environments.

Modern industrial operations depend on sophisticated equipment requiring systematic maintenance approaches, where inefficient strategies directly impact operational budgets and productivity metrics. Maintenance cost inefficiencies cascade throughout organizations, affecting production schedules, equipment reliability, and total operational expenses that determine competitive positioning and profitability outcomes.

The Hidden Crisis: Understanding Maintenance Cost Drivers in Industrial Operations

Industrial maintenance costs extend far beyond direct repair expenses, encompassing downtime losses, emergency service premiums, inventory carrying costs, and productivity impacts that significantly affect operational profitability. Maintenance cost optimization inefficiencies create cascading financial impacts that extend throughout organizational performance and competitive positioning.

Reactive Maintenance Penalties

Emergency repairs cost 3-5x more than planned maintenance, with 82% of reactive maintenance creating secondary equipment damage that requires additional $8+ lakhs in collateral repairs per incident.

Unplanned Downtime Costs

Equipment failures generate downtime costs averaging $12+ lakhs per hour in lost production, with cascading impacts on delivery schedules and customer satisfaction metrics.

Inventory Management Inefficiencies

Poor maintenance planning creates excessive spare parts inventory averaging 35% carrying costs, while emergency procurement adds 200-400% premium pricing for critical components.

Labor Resource Misallocation

Reactive maintenance consumes 60-75% of technician time on emergency repairs, preventing proactive maintenance activities that extend equipment life and optimize performance.

Energy Consumption Increases

Poorly maintained equipment consumes 15-25% more energy, with degraded performance creating ongoing operational cost increases that compound monthly expense burdens.

Compliance and Safety Costs

Maintenance deferrals create safety incidents and regulatory violations that generate $25+ lakh fines, increased insurance premiums, and operational restrictions.

The Financial Impact of Inefficient Maintenance Management

Before implementing systematic maintenance cost optimization through Oxmaint CMMS, industrial maintenance operations experience significant inefficiencies that directly impact financial performance and operational effectiveness:

- Emergency maintenance premiums consuming 65% of maintenance budgets while providing minimal preventive value or long-term asset protection

- Equipment availability averaging 70-75% compared to 95%+ achievable through optimized maintenance scheduling and proactive intervention strategies

- Maintenance cost unpredictability creating budget variances of 40-60% annually due to reactive approaches and emergency repair requirements

- Technician productivity losses with 55% of maintenance time spent on emergency repairs instead of value-adding preventive activities

- Extended equipment replacement cycles due to accelerated wear from deferred maintenance and inadequate monitoring protocols

Foundation Elements: Comprehensive Maintenance Cost Optimization Framework

Oxmaint maintenance cost optimization provides the strategic framework necessary for systematic expense reduction, incorporating predictive analytics, preventive scheduling, and resource optimization into unified management systems that transform maintenance from cost center into competitive advantage.

Core Cost Reduction Components and Architecture

Effective maintenance cost optimization frameworks integrate multiple operational streams and analytical capabilities to create comprehensive cost management systems that balance reliability requirements with financial efficiency objectives.

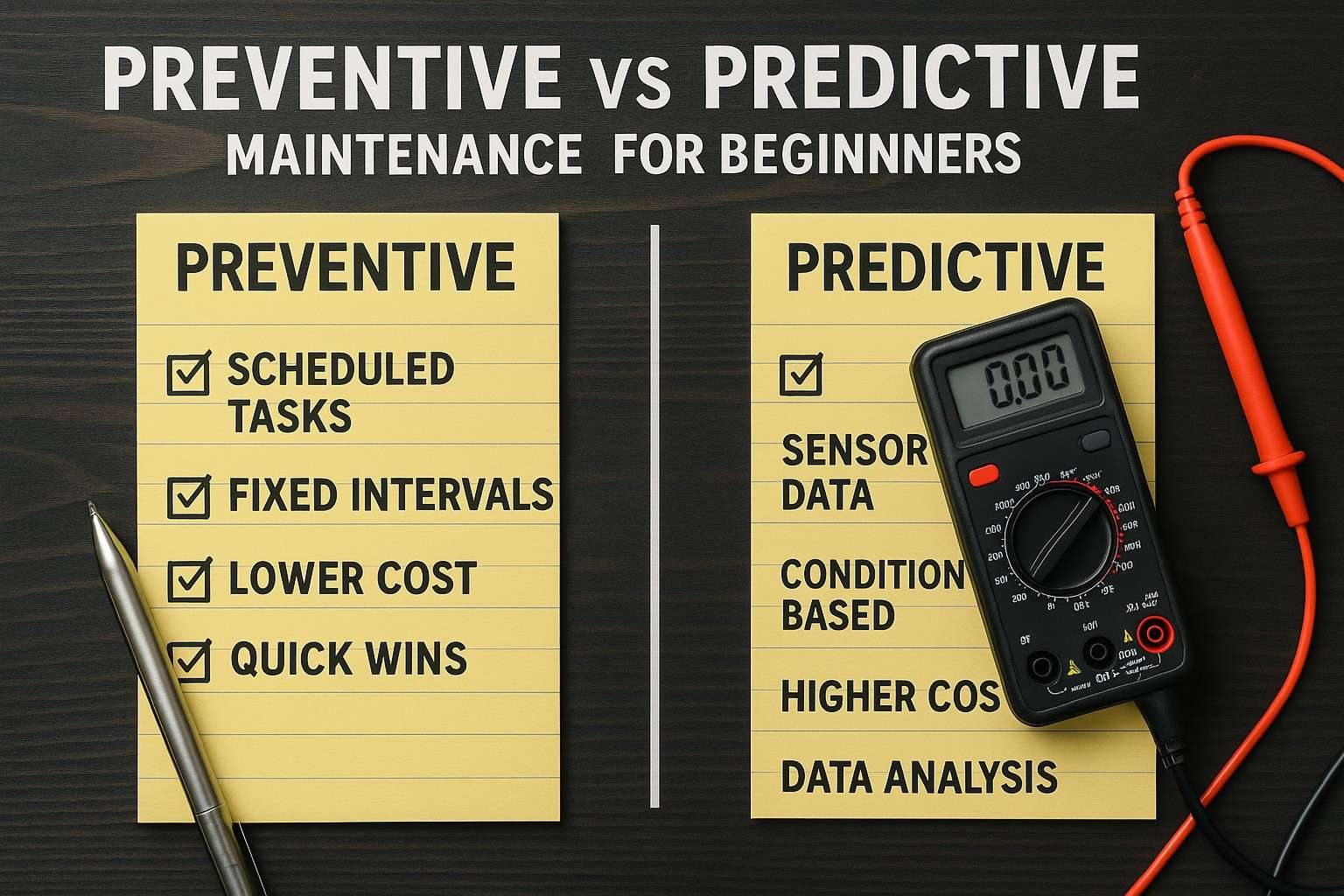

Predictive Maintenance Planning

Advanced analytics and condition monitoring integration enabling optimal maintenance timing that prevents failures while minimizing intervention costs and resource requirements.

Resource Optimization Engine

Comprehensive scheduling algorithms that optimize technician allocation, parts procurement, and maintenance timing to maximize efficiency and minimize operational disruptions.

Cost Analytics Dashboard

Real-time cost tracking and analysis capabilities providing visibility into maintenance expenses, cost drivers, and optimization opportunities across all operational areas.

Inventory Management Integration

Smart inventory optimization that reduces carrying costs while ensuring parts availability, eliminating emergency procurement premiums and stockout situations.

Advanced Cost Optimization and Analytics Capabilities

Smart Cost Management and Predictive Planning Integration

Oxmaint cost optimization transcends traditional maintenance management to incorporate advanced analytics, machine learning, and automated decision-making that identifies cost reduction opportunities and implements optimization strategies in real-time.

Predictive Cost Analytics

Advanced algorithms analyze equipment performance data to predict optimal maintenance timing, preventing costly failures while minimizing intervention expenses and resource allocation.

Automated Budget Optimization

Machine learning systems continuously optimize maintenance budgets, resource allocation, and spending priorities based on equipment criticality and operational requirements.

Dynamic Resource Scheduling

Intelligent scheduling algorithms optimize technician assignments, parts procurement timing, and maintenance coordination to maximize efficiency and minimize operational costs.

Cost Avoidance Tracking

Comprehensive analysis systems that quantify prevented failures, avoided downtime, and optimized spending to demonstrate ROI and guide continuous improvement initiatives.

Implementation Methodology and Best Practices

Phased Deployment Strategy for Maintenance Cost Optimization

Successful Oxmaint implementation requires systematic deployment approaches that minimize operational disruption while maximizing cost reduction benefits and ensuring sustainable adoption across diverse maintenance environments and organizational structures.

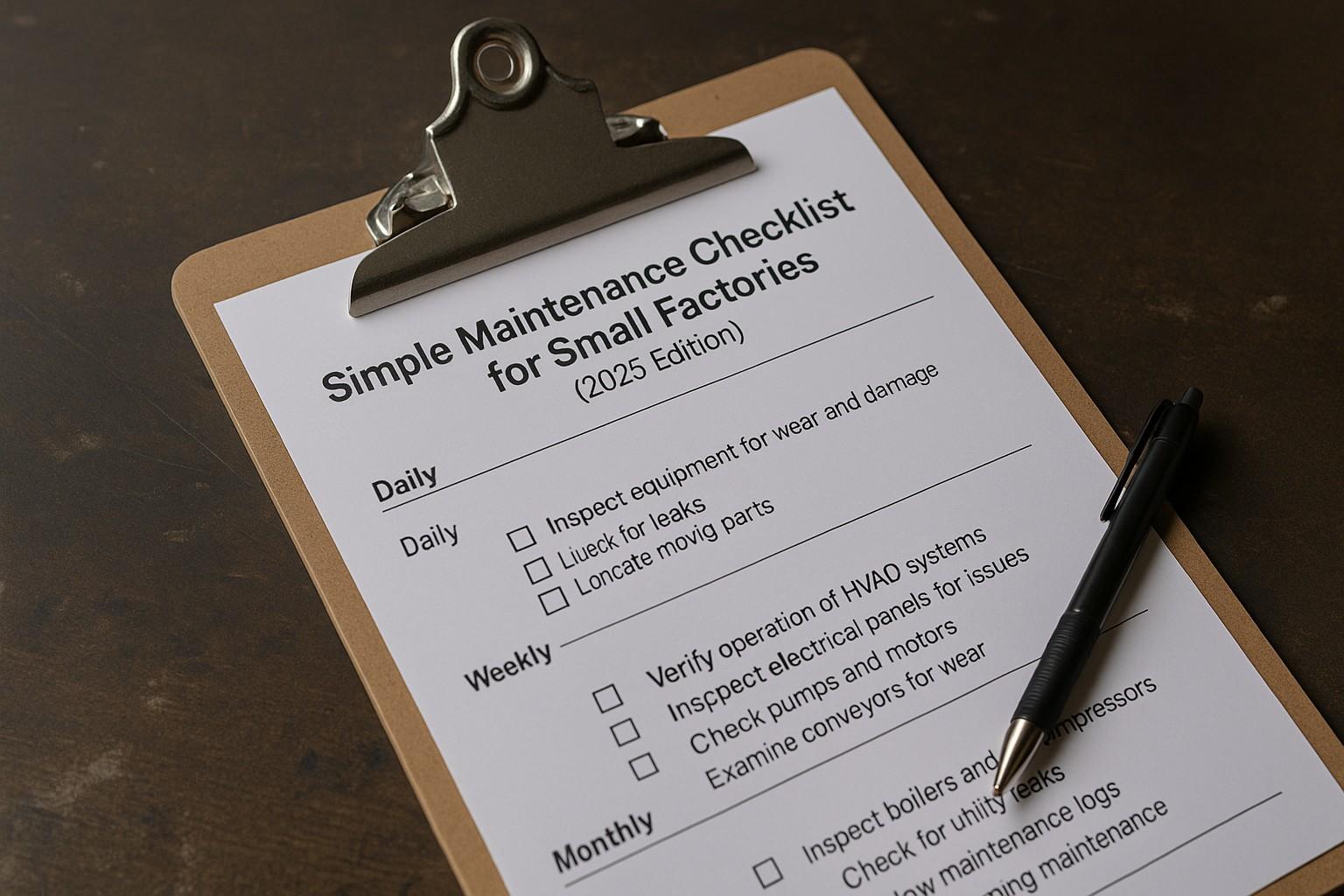

Phase 1: Current State Assessment

Comprehensive maintenance cost analysis, process evaluation, inefficiency identification, and baseline establishment to quantify improvement opportunities and implementation priorities.

Phase 2: System Configuration

Custom Oxmaint setup including asset registration, maintenance scheduling, cost tracking parameters, and integration with existing operational systems and workflows.

Phase 3: Pilot Implementation

Limited deployment with critical equipment, team training, process refinement, and optimization validation to ensure system effectiveness before full-scale rollout.

Phase 4: Full-Scale Deployment

Organization-wide implementation, comprehensive training programs, change management support, and ongoing optimization based on performance data and user feedback.

Change Management and Organizational Adoption Strategies

Cost optimization success through Oxmaint depends heavily on organizational adoption and cultural transformation, requiring comprehensive training programs and incentive structures that encourage proactive maintenance practices and cost-conscious decision-making.

Role-Specific Training Programs

Customized training for maintenance technicians, supervisors, and managers covering system operation, cost optimization strategies, and performance improvement methodologies.

Performance Incentive Alignment

KPI structures and reward programs that recognize cost reduction achievements, preventive maintenance excellence, and operational efficiency improvements.

Communication and Engagement Systems

Regular communication channels for cost optimization updates, success stories, and improvement suggestions that maintain engagement and continuous improvement momentum.

Champion Network Development

Identification and development of cost optimization champions who support system adoption and provide peer-to-peer guidance and technical assistance.

Analytics and Performance Monitoring Capabilities

Advanced Cost Analytics and ROI Tracking

Oxmaint cost analytics transform maintenance data into actionable insights that enable continuous improvement, cost optimization, and strategic planning across equipment portfolios and operational environments.

Real-Time Cost Dashboards

Executive and operational dashboards providing immediate visibility into maintenance expenses, cost trends, and optimization opportunities across all operational segments and equipment types.

Predictive Budget Analysis

Advanced forecasting capabilities that predict future maintenance costs, identify budget optimization opportunities, and support strategic planning based on equipment lifecycle data.

ROI Measurement Systems

Comprehensive tracking of cost avoidance, efficiency improvements, and productivity gains that quantify Oxmaint value and guide continuous optimization efforts.

Benchmark Comparison Analytics

Industry benchmark comparisons and best practice identification that highlight improvement opportunities and validate cost optimization achievements against peer performance.

ROI and Operational Excellence Outcomes

Quantifiable Financial Benefits and Cost Avoidance

Systematic maintenance cost optimization through Oxmaint delivers measurable financial returns through multiple value streams that extend beyond direct cost savings to encompass operational efficiency, equipment longevity, and productivity improvement benefits.

Operational Efficiency and Competitive Advantages

Comprehensive maintenance cost optimization through Oxmaint creates operational advantages that enhance competitive positioning through improved equipment reliability, predictable maintenance expenses, and enhanced production capability delivery.

- Improved production schedule reliability with predictable equipment availability and minimal unplanned maintenance disruptions affecting delivery commitments

- Enhanced equipment utilization averaging 95%+ availability compared to 70-75% with reactive maintenance approaches and emergency repair cycles

- Reduced insurance and compliance costs through documented maintenance programs and improved safety performance that demonstrates operational excellence

- Increased equipment resale values with comprehensive maintenance documentation and proven reliability history that supports capital recovery

- Better cash flow predictability through planned maintenance budgets and eliminated emergency expense volatility affecting financial planning

Compliance and Regulatory Alignment

Regulatory compliance requirements make systematic maintenance cost optimization essential for industrial operations, with safety standards, environmental regulations, and quality requirements demanding proactive maintenance management and documented cost control programs.

Safety Standard Compliance

OSHA and safety regulations requiring systematic maintenance documentation and cost tracking, with Oxmaint ensuring compliance while reducing violation risks that can cost $30+ lakhs per incident.

Quality Management Systems

ISO and quality standards demanding maintenance cost control and process documentation, with systematic optimization supporting certification requirements and audit preparation.

Environmental Regulation Adherence

Environmental protection standards requiring efficient equipment operation and waste minimization, with optimized maintenance reducing environmental impact and compliance costs.

Financial Reporting and Audit Support

Detailed maintenance cost documentation and analytics supporting financial audits, tax optimization, and regulatory reporting requirements with comprehensive audit trails.

Future Outlook and Innovation Roadmap

The maintenance cost optimization landscape continues evolving with emerging technologies that promise enhanced accuracy, automated decision-making, and predictive cost management integration that will further improve financial efficiency and operational effectiveness.

Artificial Intelligence Integration

Advanced AI algorithms providing enhanced cost prediction, automatic optimization decisions, and intelligent resource allocation based on complex operational data analysis and pattern recognition.

IoT Sensor Integration

Internet of Things technologies enabling continuous cost monitoring and automatic optimization adjustments based on real-time equipment performance and operational condition data.

Blockchain Cost Verification

Immutable cost tracking and vendor verification systems providing enhanced financial transparency, audit capabilities, and contract management efficiency.

Mobile Workforce Optimization

Advanced mobile applications providing real-time cost tracking, decision support, and optimization recommendations that enable immediate cost reduction actions and field efficiency.