Work order tracking inefficiencies represent one of the most significant operational challenges facing maintenance organizations, with poor tracking systems costing an average of $12.3 lakhs per facility annually in lost productivity. Industry research reveals that 68% of organizations still rely on manual or fragmented tracking approaches that create missed deadlines, resource conflicts, and operational blind spots. Comprehensive work order tracking solutions can reduce task completion times by 75%, improve resource utilization by 60%, and decrease administrative overhead by 80% while ensuring accountability, and maximum operational efficiency across all maintenance activities.

Modern maintenance operations depend on coordinated task execution across multiple teams, locations, and priorities, where inefficient work order tracking creates cascading delays that impact entire operational schedules. Work order management inefficiencies extend throughout organizations, affecting maintenance completion rates, resource optimization, and overall facility performance.

The Hidden Crisis: Work Order Tracking Challenges in Maintenance Operations

Contemporary maintenance environments require sophisticated coordination systems that track work orders from creation through completion, where inadequate tracking capabilities lead to missed priorities, resource conflicts and operational inefficiencies that compromise facility performance and increase operational costs.

Task Priority Management

67% of maintenance delays stem from unclear priority assignments and conflicting work order scheduling that creates resource bottlenecks costing $8+ lakhs monthly in productivity losses.

Timeline Accountability Issues

Manual tracking systems fail to provide real-time progress visibility, with 45% of work orders exceeding planned completion times due to coordination failures and status reporting gaps.

Resource Allocation Conflicts

Insufficient tracking capabilities create technician scheduling conflicts and inventory shortages that delay 40% of maintenance activities and increase emergency response requirements.

Documentation and Compliance

Fragmented tracking systems compromise audit trails and compliance documentation, creating regulatory risks and warranty claim challenges that cost $15+ lakhs annually.

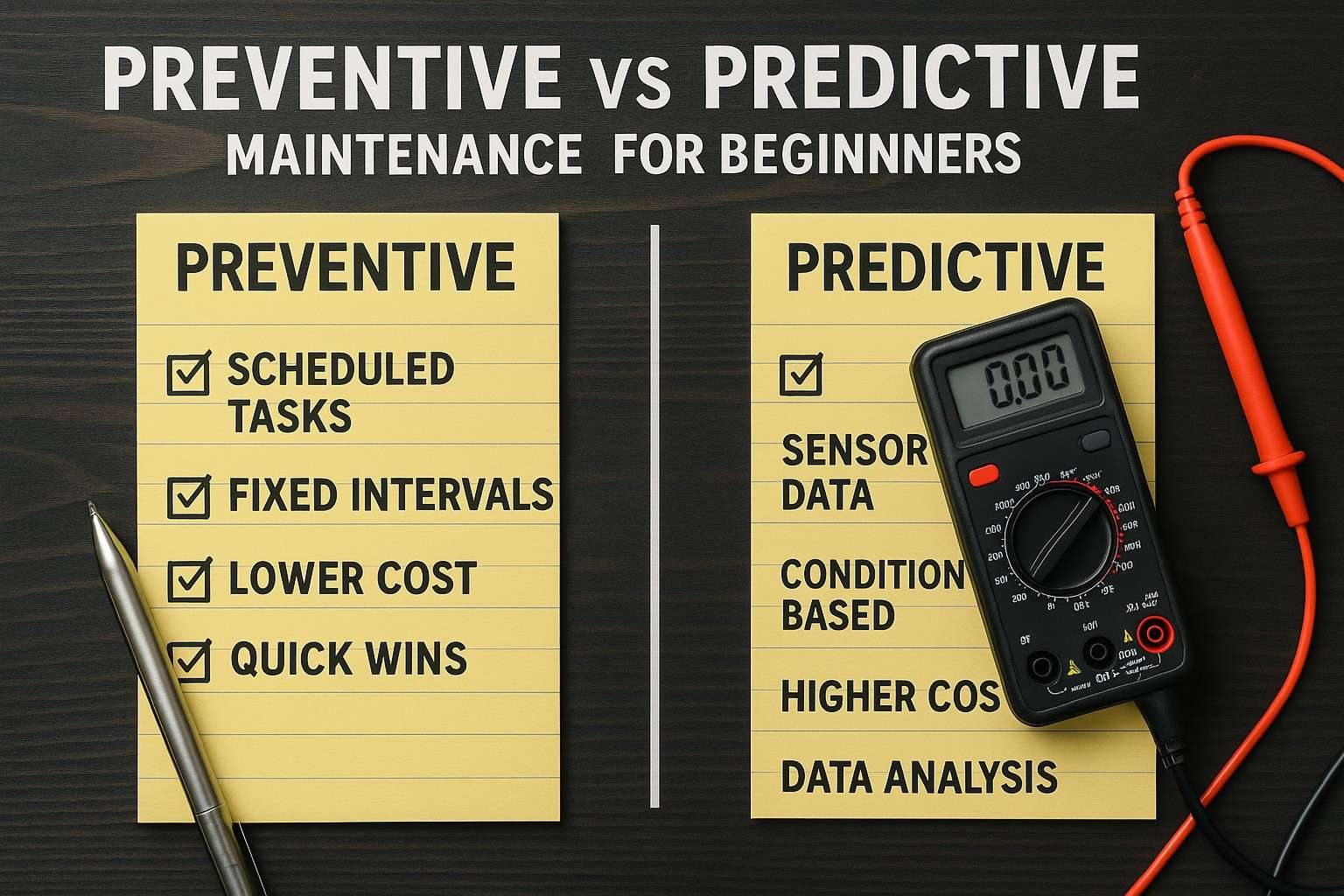

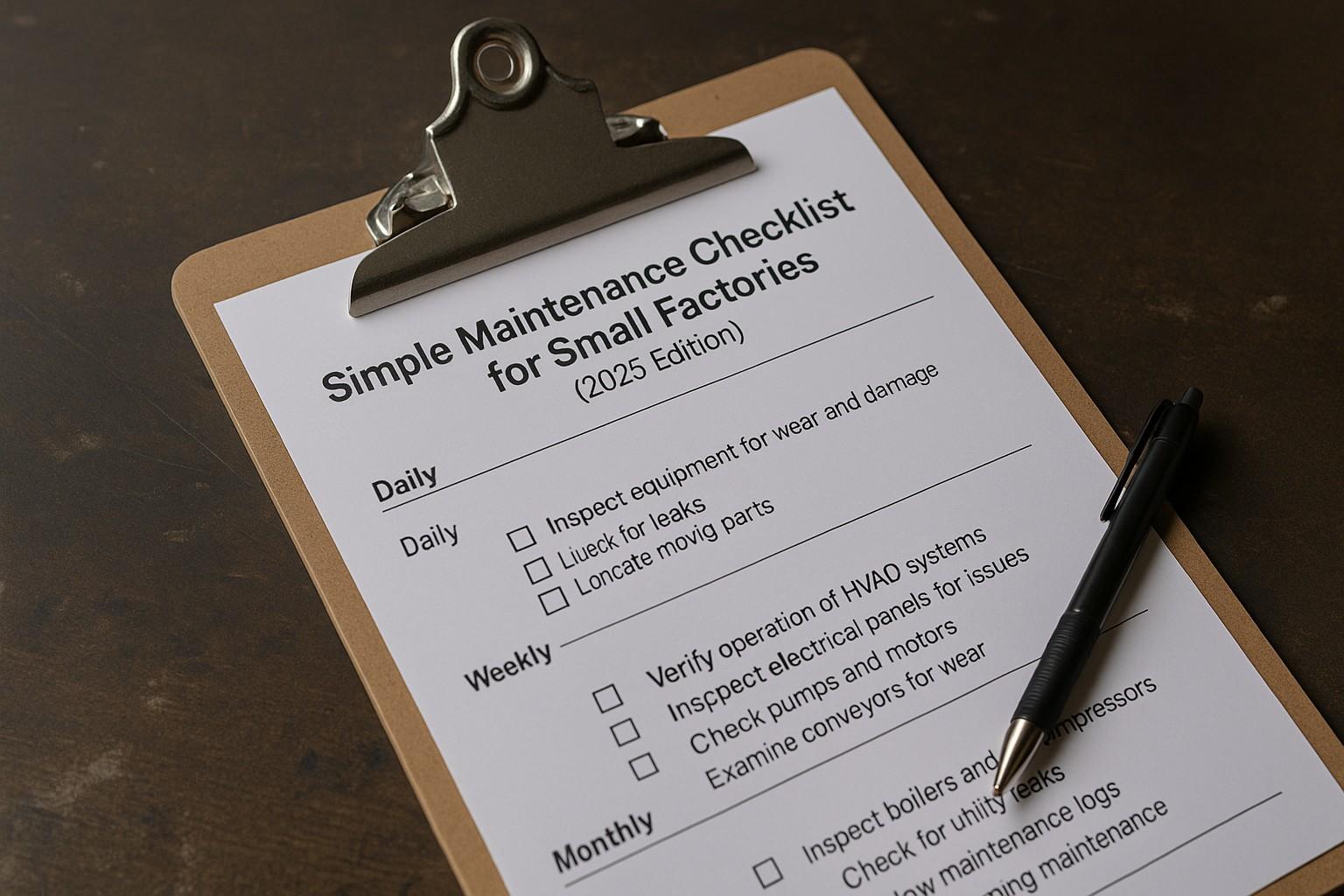

Preventive Maintenance Coordination

Poor work order tracking disrupts preventive maintenance schedules, with 35% of planned activities delayed or missed, leading to equipment failures and increased reactive maintenance costs.

Performance Analytics Limitations

Manual tracking provides insufficient data for performance analysis, preventing optimization opportunities worth $12+ lakhs in operational improvements and efficiency gains.

The Financial Impact of Inefficient Work Order Tracking

Before implementing systematic work order tracking with Oxmaint, maintenance organizations experience significant operational inefficiencies that impact both productivity metrics and financial performance:

- Administrative overhead consuming 35% of technician time through manual paperwork and status reporting requirements

- Task completion delays averaging 40-50% beyond planned timelines due to coordination failures and resource conflicts

- Maintenance cost unpredictability making budget planning difficult with emergency repairs and priority conflicts

- Resource utilization inefficiencies with 30% of technician capacity lost to scheduling conflicts and task prioritization issues

- Compliance documentation gaps creating audit risks and regulatory violations costing $25+ lakhs in penalties

Foundation Elements: Comprehensive Work Order Tracking Architecture

Professional work order tracking systems provide the operational framework necessary for systematic maintenance coordination, incorporating priority management, resource allocation, and progress monitoring into unified tracking platforms that optimize task execution and organizational efficiency.

Core Tracking Components and System Architecture

Effective work order tracking frameworks integrate multiple management streams and coordination criteria to create comprehensive operational visibility that balances efficiency with accountability across all maintenance activities.

Work Order Creation and Assignment

Streamlined request processing including priority classification, resource requirements analysis, and technician assignment based on skills, availability, and workload optimization.

Progress Monitoring and Updates

Real-time status tracking, milestone progression, and completion documentation that provides instant visibility into work order progress and potential delays.

Resource Coordination Integration

Inventory management connections, parts ordering automation, and contractor coordination systems that ensure resource availability and task completion efficiency.

Analytics and Performance Metrics

Comprehensive reporting capabilities including completion rates, cost analysis, technician productivity, and operational KPIs that enable continuous improvement and optimization.

Advanced Digital Integration and Automation Capabilities

Smart Tracking and Predictive Coordination Integration

Modern work order tracking with Oxmaint transcends manual coordination to incorporate automated workflows, intelligent scheduling, and predictive analytics that optimize resource allocation and task prioritization across complex operational environments.

Automated Work Order Generation

Intelligent system triggers that automatically create work orders based on equipment conditions, scheduled maintenance, and operational requirements, eliminating manual request processing delays.

Dynamic Priority Management

Smart prioritization algorithms that continuously evaluate work order urgency based on equipment criticality, safety requirements, and operational impact to optimize task sequencing.

Mobile Workforce Integration

Field technician mobile applications providing instant work order access, real-time updates, photo documentation, and completion reporting that eliminate paperwork delays.

Predictive Scheduling Optimization

Advanced algorithms that analyze historical data, technician skills, and resource availability to automatically optimize work order scheduling and minimize completion times.

Implementation Methodology and Best Practices

Phased Deployment Strategy for Work Order Tracking Systems

Successful tracking system implementation with Oxmaint requires systematic deployment approaches that minimize operational disruption while maximizing adoption rates and operational benefits across diverse maintenance environments and organizational structures.

Phase 1: Current State Assessment

Existing process evaluation, workflow analysis, tracking requirement identification, and system customization planning based on organizational needs and operational complexity.

Phase 2: System Configuration

Work order templates creation, priority matrices development, user role configuration, and integration planning with existing maintenance management and operational systems.

Phase 3: Pilot Testing

Limited deployment with selected departments, user training execution, workflow validation, and system optimization based on initial user feedback and operational performance.

Phase 4: Organization-Wide Deployment

Complete system rollout, comprehensive training programs, change management support, and ongoing optimization based on usage analytics and operational requirements.

Change Management and User Adoption Strategies

Tracking system implementation success depends heavily on user adoption and workflow integration, requiring comprehensive training programs and change management strategies that encourage systematic work order management practices across all organizational levels.

Role-Based Training Development

Customized training programs for technicians, supervisors, planners, and managers covering system functionality, workflow integration, and operational best practices for maximum adoption.

Performance Incentive Integration

KPI alignment and reward systems that recognize efficient work order completion, system utilization, and operational improvements to encourage consistent platform usage.

Communication and Support Systems

Regular system updates, user feedback collection, and technical support channels that ensure continuous system optimization and user satisfaction throughout deployment.

Champion Network Establishment

Power user identification and development programs that create internal expertise and peer-to-peer support networks for ongoing system adoption and optimization.

Analytics and Performance Monitoring Capabilities

Advanced Tracking Analytics and KPI Management

Work order tracking analytics with Oxmaint transform operational data into actionable insights that enable continuous improvement, performance optimization, and strategic planning across maintenance operations and organizational objectives.

Real-Time Operational Dashboards

Executive and operational dashboards providing immediate visibility into work order status, completion rates, resource utilization, and performance trends across all organizational levels.

Predictive Performance Analysis

Advanced analytics identifying efficiency patterns, resource optimization opportunities, and operational bottlenecks based on historical tracking data and real-time performance metrics.

Cost and ROI Analytics

Comprehensive analysis covering operational savings, efficiency improvements, and productivity gains that quantify tracking system value and organizational impact measurement.

Compliance and Audit Support

Automated compliance tracking ensuring work order activities meet regulatory requirements, safety standards, and audit documentation standards with comprehensive reporting capabilities.

ROI and Operational Excellence Outcomes

Quantifiable Financial Benefits and Efficiency Gains

Systematic work order tracking with Oxmaint delivers measurable financial returns through multiple value streams that extend beyond administrative savings to encompass operational efficiency, resource optimization, and maintenance excellence benefits.

Operational Efficiency and Competitive Advantages

Comprehensive work order tracking creates operational advantages that enhance competitive positioning through improved maintenance reliability, predictable operational costs, and enhanced service delivery capabilities across all facility operations.

- Enhanced maintenance reliability with predictable task completion and minimal operational disruptions through systematic coordination

- Improved resource productivity achieving 85%+ technician utilization compared to 65% with manual coordination approaches

- Reduced operational costs through optimized workflows and eliminated administrative inefficiencies worth $35+ lakhs annually

- Better compliance documentation with comprehensive audit trails and regulatory compliance support reducing violation risks

- Enhanced decision-making capabilities through real-time operational visibility and predictive analytics for strategic planning

Compliance and Regulatory Alignment

Regulatory compliance requirements make systematic work order tracking essential for maintenance operations, with safety standards, audit requirements, and documentation standards demanding comprehensive tracking systems and detailed operational records for risk management and regulatory adherence.

Safety and Audit Compliance

Comprehensive tracking ensuring systematic maintenance documentation and audit trail capabilities that satisfy regulatory requirements and reduce compliance violation risks worth $18+ lakhs per incident.

Quality Management Standards

ISO and quality standard requirements for systematic work management and documentation, with tracking systems supporting certification maintenance and operational excellence initiatives.

Insurance and Risk Management

Insurance carrier requirements for systematic maintenance documentation and risk management protocols, with tracking systems reducing premiums and liability exposures significantly.

Warranty and Service Documentation

Equipment warranty requirements for proper maintenance documentation and service records, with systematic tracking protecting warranty coverage and reducing replacement costs.

Future Outlook and Innovation Roadmap

The work order tracking landscape continues evolving with emerging technologies that promise enhanced automation, predictive capabilities, and integrated maintenance management that will further improve operational efficiency and organizational effectiveness across all maintenance activities.

Artificial Intelligence Integration

Advanced AI algorithms providing intelligent work order prioritization, predictive scheduling, and automated resource allocation based on complex operational data analysis and pattern recognition.

IoT and Sensor Integration

Internet of Things technologies enabling automatic work order generation based on equipment conditions and performance parameters that eliminate manual request creation processes.

Augmented Reality Support

AR-enabled technician tools providing real-time work order information, visual guidance, and documentation capabilities that enhance field productivity and accuracy.

Blockchain Documentation

Immutable work order records and maintenance documentation providing enhanced audit capabilities, compliance verification, and operational transparency for regulatory requirements.

Frequently Asked Questions

Ready to streamline your work order tracking with professional CMMS solutions?

Getting Started Book a Demo

.jpeg)