Your maintenance strategy looks impressive on paper. Detailed preventive maintenance schedules, comprehensive equipment lists, perfectly calibrated intervals based on manufacturer recommendations and failure analysis. The plan promises 25% fewer breakdowns, 30% lower maintenance costs, and 95% equipment availability. Six months later, you're still fighting the same chronic equipment problems, emergency repairs consume 60% of your maintenance budget, and your CEO is asking why the expensive PM program isn't delivering promised results.

This scenario haunts manufacturing facilities across America. Industry surveys reveal that 70-80% of facilities have documented preventive maintenance strategies, yet only 40-50% achieve their intended outcomes. The gap between strategy and execution isn't just an operational inconvenience—it's a competitive disadvantage that costs millions in lost productivity, emergency repairs, and missed opportunities.

The facilities that successfully bridge this gap don't just have better plans—they've mastered the art of turning maintenance intentions into consistent daily actions. They achieve the promised benefits of preventive maintenance: 35-50% fewer unplanned failures, 25-40% lower maintenance costs, and equipment availability rates exceeding 95%. The difference lies in addressing the hidden barriers that prevent good strategies from becoming great results.

Ready to transform maintenance strategy into unstoppable execution?

Don't let another quarter pass watching great plans fail. Join facilities achieving 90%+ PM compliance and 40% cost reductions through systematic execution excellence.

Understanding the Strategy-Execution Gap

The disconnect between preventive maintenance strategy and execution manifests in predictable ways that reveal fundamental misalignments between planning and operational reality. Understanding these manifestations provides the foundation for developing targeted solutions that address root causes rather than symptoms.

Strategy documents typically present idealized scenarios where equipment operates predictably, resources are always available and competing priorities don't interfere with maintenance schedules. Reality involves production pressure, parts shortages, staffing constraints, and the thousand daily decisions that determine whether planned maintenance actually happens.

Strategy (What's Planned)

- Optimized PM schedules based on analysis

- Comprehensive equipment coverage

- Predictable resource requirements

- Standardized procedures and checklists

- Clear performance targets and metrics

- Integrated maintenance and operations

Execution (What Actually Happens)

- Deferred maintenance due to production pressure

- Incomplete PM tasks and shortcuts

- Parts unavailable when needed

- Inconsistent procedure compliance

- Reactive crisis management mode

- Maintenance-operations conflicts

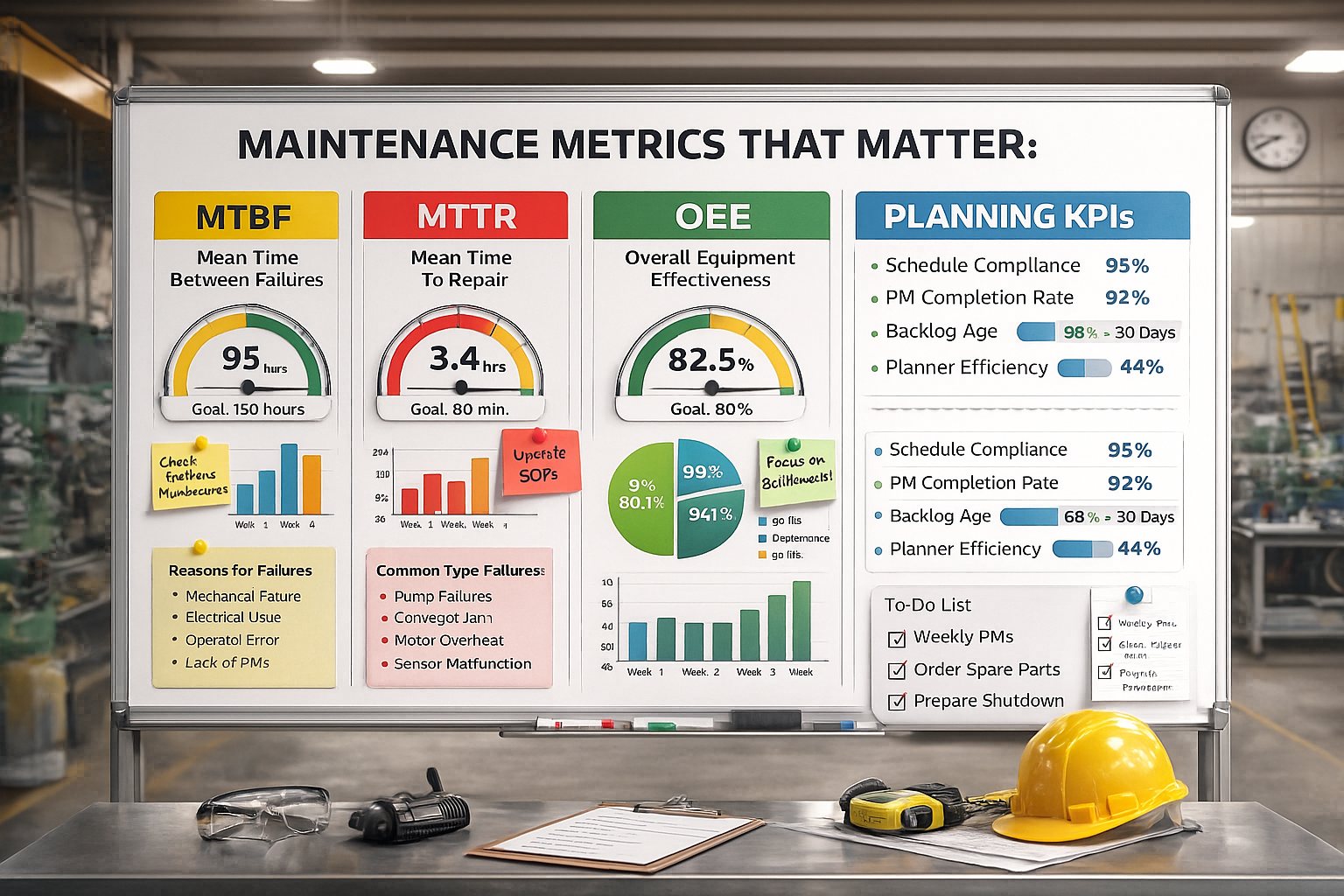

Schedule compliance serves as the most visible indicator of execution gaps. World-class facilities achieve 90-95% compliance with preventive maintenance schedules, while struggling operations may see compliance rates below 70%. This gap directly correlates with reliability outcomes and maintenance cost effectiveness.

The quality of executed maintenance often deteriorates even when compliance appears acceptable. Time pressure leads to shortcuts, incomplete inspections, and superficial task completion that provides false confidence without delivering intended benefits. A PM task may be marked "complete" while critical steps were skipped due to resource constraints.

Root Causes of Implementation Failures

Successful gap-closing requires systematic understanding of why well-intentioned maintenance strategies fail during implementation. These root causes often interact and reinforce each other, creating execution barriers that persist despite repeated improvement efforts.

Resource constraints represent the most common implementation barrier, but the problem extends beyond simple budget limitations. Inadequate staffing, skill gaps, competing priorities, and poor resource planning create conditions where maintenance teams understand requirements but lack the capacity to execute consistently.

Planning Disconnects

Strategies developed without sufficient input from execution teams, unrealistic time estimates, and failure to account for operational variability create plans that look good on paper but fail in practice.

Cultural Resistance

Maintenance teams comfortable with reactive approaches, operations prioritizing production over maintenance, and leadership that doesn't consistently support preventive practices.

System Limitations

Inadequate CMMS functionality, poor integration between systems, and tools that create administrative burden rather than enabling efficient execution.

Skill Gaps

Technicians lacking knowledge needed for complex PM tasks, supervisors unable to manage preventive programs effectively, and planners without practical execution experience.

Communication failures between strategy development and execution teams create fundamental misalignments. Strategies developed in isolation from operational realities often contain assumptions that prove incorrect when implementation begins. The result is maintenance plans that seem reasonable to planners but appear unrealistic to technicians responsible for execution.

Building Bridges: Technology and Process Solutions

Closing the strategy-execution gap requires systematic solutions that address both technical capabilities and organizational processes. The most effective approaches combine technology enablers with process improvements and cultural changes that support consistent execution.

Modern CMMS platforms provide the foundation for execution excellence by automating scheduling, tracking compliance, and providing real-time visibility into maintenance activities. However, technology success depends on proper configuration, user training, and integration with existing workflows rather than just software deployment.

| Solution Type | Implementation Time | Compliance Impact | Key Benefits |

|---|---|---|---|

| Mobile Execution | 2-4 weeks | 15-25% improvement | Real-time updates, paperless workflow |

| Workflow Automation | 6-8 weeks | 20-30% improvement | Automatic scheduling, resource allocation |

| Resource Planning | 4-6 weeks | 25-35% improvement | Parts availability, skill matching |

| Performance Analytics | 3-5 weeks | 10-20% improvement | Execution quality tracking, optimization |

Proven Execution Solutions

- Implement mobile work order systems reducing administrative time by 40%

- Deploy automated resource planning ensuring parts availability for 95% of scheduled work

- Create standardized procedures with quality checkpoints preventing shortcuts

- Establish real-time performance dashboards enabling immediate corrective action

- Build collaborative planning processes involving both strategy and execution teams

- Enable predictive analytics identifying execution bottlenecks before they impact schedules

Creating Sustainable Execution Excellence

Sustainable execution excellence requires more than initial implementation success—it demands building organizational capabilities that maintain execution quality over time despite changing conditions, personnel turnover, and competing priorities.

Organizational maturity development follows predictable stages that build execution capabilities systematically. Understanding these stages helps facilities develop realistic implementation plans while setting appropriate expectations for improvement timelines and resource requirements.

Execution Excellence Roadmap

2025 Execution Excellence Trends

- AI-powered scheduling optimizing resource allocation and execution timing

- Augmented reality work instructions reducing execution errors by 60%

- Predictive analytics identifying execution risks before schedule impacts

- Digital twin technology enabling virtual execution rehearsals

- Automated compliance monitoring ensuring quality without administrative burden

Conclusion

Closing the gap between preventive maintenance strategy and execution isn't about having perfect plans—it's about building organizational capabilities that consistently transform maintenance intentions into reliable results. The facilities that excel in this transformation don't just prevent equipment failures; they create competitive advantages through superior reliability, predictable operations, and optimized costs.

Understanding the strategy-execution gap requires recognizing that good intentions and detailed plans aren't sufficient for success. Execution occurs in complex environments with competing priorities, resource constraints, and organizational pressures that can undermine even the best-designed strategies without proper support systems.

Technology and process solutions provide the tools for execution excellence, but success depends on proper implementation that addresses both technical capabilities and organizational factors. The most effective approaches combine CMMS platforms, mobile execution, workflow automation, and performance analytics with process standardization and collaborative planning.

Sustainable execution excellence requires building organizational maturity that maintains performance quality over time despite changing conditions and personnel turnover. This maturity development follows predictable stages that build capabilities systematically while creating cultures that value preventive maintenance over reactive heroics.

Ready to eliminate the strategy-execution gap and achieve 90%+ PM compliance?

Every day without execution excellence costs you reliability, productivity, and competitive advantage. Transform your maintenance effectiveness with proven solutions that bridge strategy and reality.