Condition-based maintenance (CBM) has traveled a remarkable path from early “run-to-fail” experiments to today’s AI-driven, sensor-rich ecosystems. As manufacturing firms, utilities, and infrastructure operators demand tighter margins, safer workplaces, and greener footprints, CBM technologies promise to shift maintenance from a cost center to a strategic growth lever. In this deep-dive, we explore where CBM is heading, which breakthroughs matter most, and how pioneers are already turning data into double-digit ROI. Whether you manage rotating equipment, fleets of robots, or miles of pipeline, the next decade of CBM will redefine how—and when—you maintain your assets.

Condition-Based Maintenance: Foundations and Evolution

From reactive to predictive strategies

Traditional reactive maintenance accepts failures as unavoidable, while planned preventive maintenance (PM) interrupts production on fixed calendars. CBM flips the script by performing work only when data indicates emerging degradation, saving an average of 18 % in annual maintenance spend (McKinsey 2024). The shift reduces safety incidents by 14 %, shortens outage windows, and releases scarce craft labor for higher-value tasks.

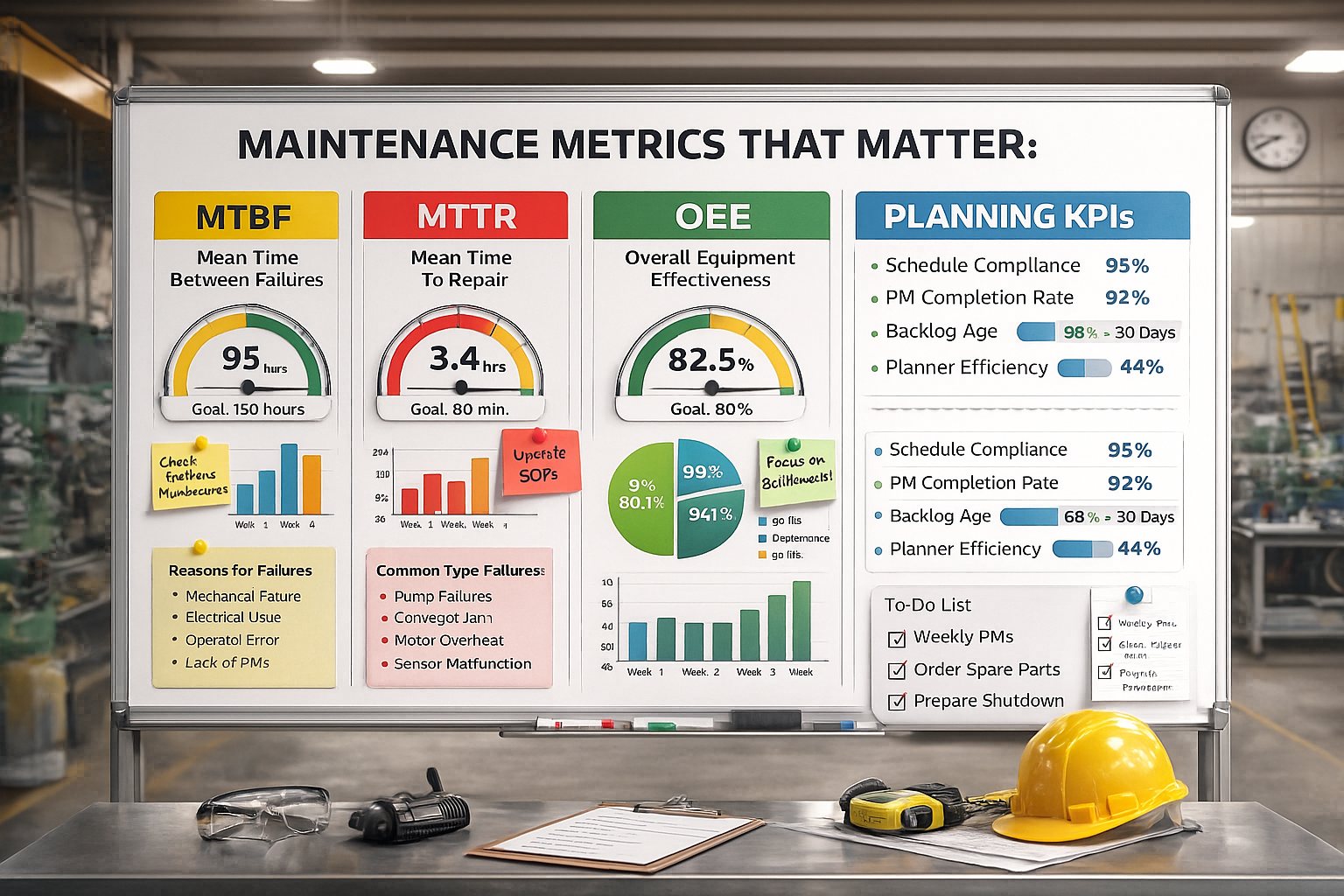

Unlike PM’s “one-size-fits-all” approach, CBM ingests real-time sensor feeds, contextual operating parameters, and historical failure modes to tailor actions for each asset. Plants adopting CBM report a 20 % extension in mean time between failures (MTBF) within 12 months (Gartner 2025).

- Data-driven thresholds trigger just-in-time work orders.

- Root-cause analytics refine design and operating envelopes.

- Predictive models feed CAPEX planning and inventory policies.

Key principles of CBM methodology

Six fundamentals underpin every successful CBM program: 1) asset criticality analysis; 2) precise failure-mode mapping (FMEA); 3) multi-modal sensing; 4) robust data architecture; 5) adaptive analytic models; and 6) cross-functional workflows. Firms that apply all six achieve up to 50 % reduction in unplanned downtime (PwC 2024).

Early adopters caution that CBM is not a plug-and-play gadget but a continuous-improvement mindset. Governance, change management, and secure integration with computerized maintenance management systems (CMMS) are as vital as the sensors themselves.

Sensor Breakthroughs Powering Next-Gen CBM Deployments

Vibration and acoustic monitoring sensors

Piezoelectric accelerometers and MEMS microphones now detect sub-Hertz vibration anomalies that precede bearing failures by months. Wireless transducers rated for 10-year battery life cut installation time 60 % (IDC 2025). Plants using acoustic-emission analytics have reported identifying 80 % of gearbox defects at least four weeks earlier than legacy route-based checks (IEEE 2024).

AI-enhanced spectral analysis distinguishes normal process noise from critical resonances, even in dense machinery clusters. For high-speed turbines, envelope detection combines with cyclostationary analysis to capture faint spalls invisible to standard FFT baselines.

- Tri-axial vibration signatures map dynamic load paths.

- Deep-learning classifiers flag stage-1 bearing outer-race faults.

- Embedded diagnostics push health scores to CMMS dashboards.

Temperature, pressure, and lubrication sensing

Fiber-optic thermography now offers ±0.1 °C accuracy across 2 km process lines, enabling thermal drift analysis for heat exchangers. Inline oil-quality probes measure dielectric constant, particulate count, and water saturation in real time, cutting unscheduled lube-related stoppages 35 % (SAE 2024).

Edge micro-controllers run physics-informed models that correlate pressure pulsations with cavitation risk in pumps, providing five-day advanced notice—ample time to schedule repairs during low-production windows.

Wireless energy-harvesting devices

Energy-scavenging nodes convert vibration, thermal gradients, or RF emissions into power, enabling “deploy-and-forget” CBM networks in remote or rotating equipment. A 2025 European pilot outfitted 12 000 valves with piezo harvesters, eliminating 1.2 million alkaline batteries over five years (EU JRC 2025).

Lower maintenance overhead plus ESG credit for battery reduction delivers a compelling sustainability and cost-avoidance narrative to boards and investors.

30 % maintenance-cost cut within 18 months reported by Fortune 200 chemicals producer after adopting multi-sensor CBM (BCG 2025).

Artificial Intelligence and Predictive Analytics in CBM

Machine-learning models for failure prediction

Gradient-boosting and recurrent neural networks ingest terabytes of sensor, operational, and contextual data to predict specific failure modes—such as pitting, misalignment, or oil varnish—with probabilistic lead times. Plants deploying ensemble models achieved 92 % prediction accuracy for rotating-asset failures (World Economic Forum 2025).

Feature engineering remains critical; adding ambient humidity and motor current signatures improved a paper mill’s model recall by 17 %. AutoML platforms democratize model building, yet domain expertise still guides labeling and validation.

- Auto-retraining adapts to seasonality and process drift.

- Confidence bands trigger gated workflows in CMMS.

- Explainable AI (XAI) fosters trust among engineers.

Digital twins and what-if scenarios

Digital twins—virtual replicas synchronized with live sensor feeds—enable stress-test simulations and maintenance scenario planning. A Nordic energy utility ran twin-based what-if studies to test load-shedding across 400 turbines, reducing planned outages by 11 % (Deloitte 2024).

Coupling twins with reinforcement learning agents unlocks prescriptive maintenance: algorithms recommend the action sequence that maximizes availability and minimizes lifecycle cost.

Case Study – MetroPort Container Terminal: Facing chronic crane downtime, MetroPort instrumented hoist gearboxes with vibration and thermal sensors, streaming data to a cloud LSTM model. Within three months, the algorithm flagged a subtle resonance change. Maintenance replaced the bearing during a scheduled lull, avoiding a catastrophic seizure. The four-hour repair saved an estimated $580 000 in demurrage fees, cutting annual unplanned stoppages by 47 %.

Industrial IoT Connectivity and Edge Computing for CBM

Industrial IoT infrastructure requirements

Robust CBM depends on secure, high-throughput connectivity: Time-Sensitive Networking (TSN) for deterministic Ethernet, Wi-Fi 6/6E for mobile assets, and 5G private networks for campus-wide reliability. Surveys show that 68 % of manufacturers upgrading to TSN-capable switches experience measurable latency improvement in under 90 days (IIC 2025).

Interoperability standards—OPC UA, MQTT-Sparkplug, and Asset Administration Shells—prevent vendor lock-in and facilitate contextual data fusion across legacy PLCs, historians, and modern IoT stacks.

Edge analytics for low-latency decisions

Pushing analytics to the edge cuts response times from seconds to milliseconds, critical for high-speed lines where a single misfeed ruins product. Edge nodes execute inference locally, forwarding only exception data to the cloud, lowering bandwidth 70 % and tightening cyber-attack surfaces (Cisco 2024).

Containerized micro-services ensure models remain hardware-agnostic; zero-trust architectures and hardware root-of-trust chips maintain end-to-end security compliance with IEC 62443.

4.2 TB monthly data reduction achieved by deploying edge compression in a global food-processing network (Forrester 2025).

Implementation Strategies and Change Management Success Factors

Data governance and cybersecurity considerations

CBM programs fail when data quality falters. Master-data standards, sensor-calibration schedules, and golden-record governance are non-negotiable. Zero-trust segmentation, encrypted protocols, and multi-factor authentication protect intellectual property and guarantee regulatory compliance with GDPR and NIST SP 800-82.

A medical-device plant that built a federated data-governance council cut audit preparation time by 60 % while meeting ISO 13485 traceability mandates.

Workforce upskilling and cultural buy-in

Veteran technicians may distrust algorithms or fear job erosion. Blended learning—virtual reality (VR) simulators plus on-the-job coaching—raises digital-fluency scores 45 % in six months (Accenture 2025). Position CBM as a tool that elevates craft expertise, not replaces it, by pairing “citizen data scientists” with maintenance veterans.

Visible executive sponsorship, quick-win pilots, and transparent KPI dashboards reinforce culture change and sustain momentum.

- Align incentives: uptime bonuses vs. reactive-repair overtime.

- Create feedback loops: frontline insights refine algorithm thresholds.

- Celebrate early wins with cross-functional town halls.

Integration with CMMS and ERP systems

APIs or middleware buses bridge CBM analytics with CMMS, ERP, inventory, and quality systems. Automated work-orders reduce planner workload 25 %, while API-driven parts reservations cut stock-out events by 33 % (SAP insider 2024).

Adoption rises when technicians receive alerts in familiar mobile apps, with single sign-on ensuring frictionless access across platforms.

85 % user-adoption rate achieved when CBM analytics fed directly into existing CMMS mobile workflows (Gartner Peer Insights 2025).

Future Outlook: Autonomous and Sustainable CBM Horizons

Self-healing assets and autonomous maintenance

By 2030, closed-loop CBM will enable assets to schedule robots or additive-manufacturing drones for in-situ repairs, turning unplanned shutdowns into autonomous micro-stoppages. Analysts project 70 % of new heavy-equipment designs will embed self-healing functionality (Frost & Sullivan 2025).

Technologies such as shape-memory polymers, self-lubricating coatings, and real-time micro-welding drastically shrink mean time to repair (MTTR), creating virtually continuous operations.

Sustainability and ESG impact

CBM aligns with eco-efficiency goals: less energy wasted on over-maintained equipment, fewer spare parts scrapped, and lower CO2 from emergency logistics. The International Energy Agency estimates smart maintenance could cut industrial emissions by 90 Mt CO2 annually by 2035 (IEA 2025).

Companies that publicly link CBM metrics to ESG disclosures see average share-price premiums of 3–5 % compared with peers (Morgan Stanley 2024).