Your facility manager confidently reports that "operations are running smoothly" during the monthly review. But when the CEO asks for specifics—What's our equipment utilization rate? How much are we spending on maintenance per asset? Are we improving our energy efficiency?—the room falls silent. Without clear facility management KPIs, "smooth operation" becomes meaningless optimism rather than verifiable operational excellence.

This scenario repeats itself in manufacturing facilities across America every day. Teams work hard, spend millions on facility operations and maintenance, but lack the KPI framework needed to understand whether their efforts are delivering results. The absence of defined performance metrics doesn't just create reporting problems—it undermines the ability to make informed decisions, identify cost reduction opportunities and justify investments.

Yet facilities with well-defined KPI systems achieve 30% cost reduction and 25% improvement in equipment reliability compared to those operating without clear measurement frameworks. The difference isn't luck or superior equipment—it's the power of systematic measurement to focus efforts, validate results, and drive continuous improvement.

Ready to implement KPIs that drive measurable cost reduction and performance improvement?

Stop operating blind with vague performance reports. Track the 12 essential KPIs that deliver 30% cost reduction and 25% reliability improvement through data-driven facility management.

Why Facility Management KPIs Matter More Than Ever in 2025

Facility management KPIs aren't just numbers on a dashboard—they're the language of operational success that connects facility activities to strategic business objectives. Without clear KPIs, manufacturing organizations operate in a fog of assumptions, intuition, and hope rather than data-driven facility management.

The modern manufacturing environment demands precise measurement because margins continue tightening, energy costs keep rising, and competitive pressures intensify. Facilities that can't measure their performance accurately struggle to identify inefficiencies early, optimize resource allocation, or demonstrate value to stakeholders who control budgets and strategic decisions.

Effective facility management KPIs serve multiple critical functions that extend far beyond basic reporting. They provide early warning systems that alert teams to developing problems before they become costly crises, enable objective evaluation of improvement initiatives, and create accountability that drives consistent execution of operational plans.

| Operational Aspect | With Defined KPIs | Without Defined KPIs |

|---|---|---|

| Maintenance Planning | Data-driven, proactive, scheduled | Reactive, crisis-based, unplanned |

| Cost Control | Measured, optimized spending | Uncontrolled, reactive expenses |

| Equipment Performance | Monitored reliability metrics | Unknown until failure occurs |

| Energy Management | Tracked efficiency improvements | Rising costs without explanation |

| Resource Allocation | Performance-based decisions | Historical patterns and assumptions |

12 Essential Facility Management KPIs for Manufacturing Excellence

Not all KPIs provide equal value for driving manufacturing facility success. The most effective measurement systems focus on essential KPIs that directly connect to business outcomes while avoiding information overload that paralyzes decision-making.

These 12 critical facility management KPIs provide comprehensive visibility into operational efficiency, maintenance effectiveness, and cost optimization opportunities. The key is selecting KPIs that balance comprehensiveness with actionable insights.

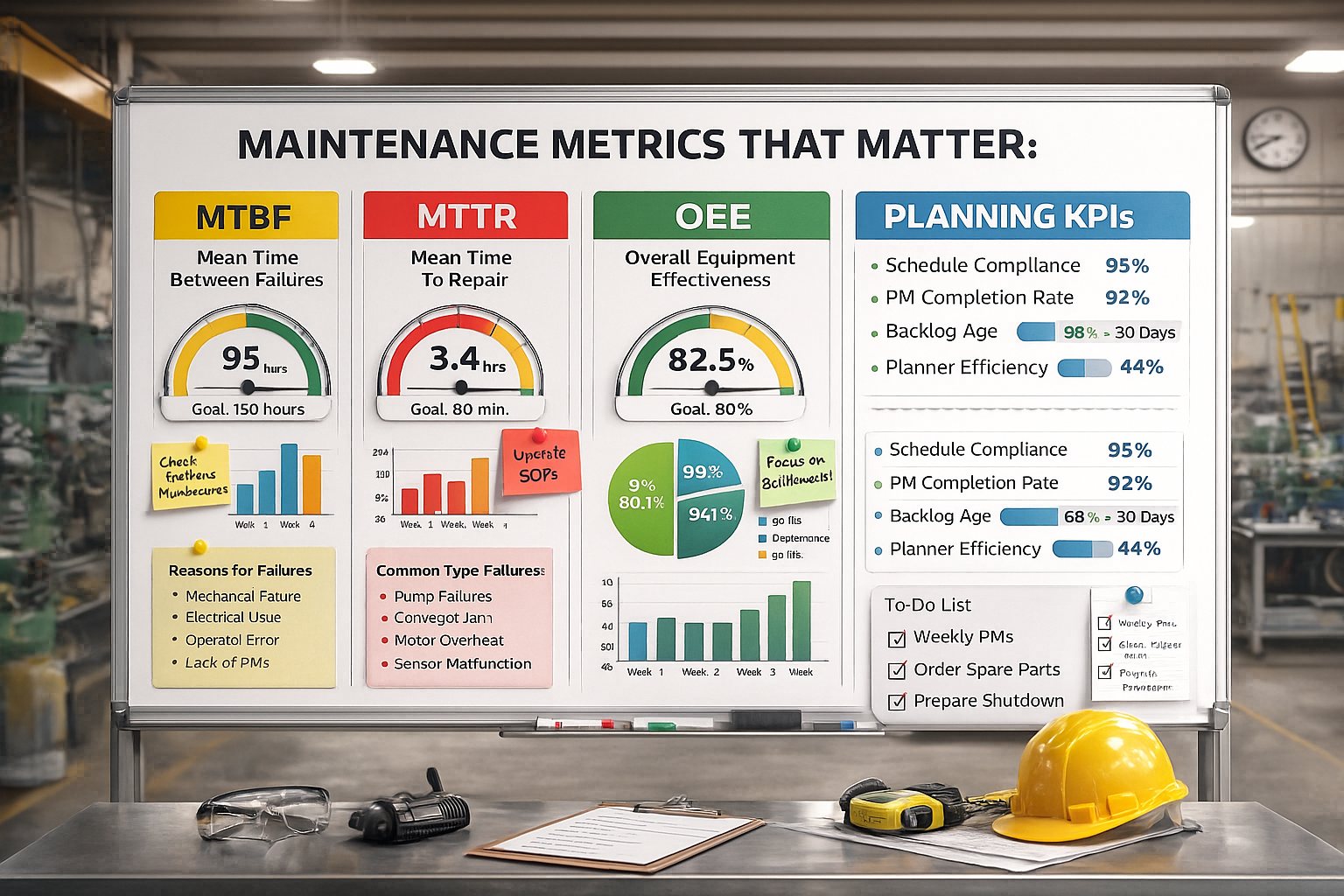

Equipment Performance KPIs

Measure equipment reliability and efficiency

- Overall Equipment Effectiveness (OEE) - Target 85%

- Mean Time Between Failures (MTBF) - 200+ hours

- Mean Time to Repair (MTTR) - Under 2 hours

- Equipment Utilization Rate - 85%+

Maintenance KPIs

Track maintenance efficiency and effectiveness

- Preventive Maintenance Compliance - 95%+

- Planned vs. Unplanned Maintenance Ratio - 80:20

- Work Order Completion Rate - 95%+

- Emergency Repair Frequency - Minimize

Cost Management KPIs

Monitor spending efficiency and profitability

- Energy Cost per Square Foot - $1.50-$3.00

- Maintenance Cost as % of Asset Value - 2-5%

- Facility Utilization Rate - 85%+

- Vendor Performance Score - Optimize costs

Safety & Compliance KPIs

Ensure workplace safety and regulatory compliance

- Safety Incident Rate - Below 2.0 per 100 employees

- Environmental Compliance Rate - 100%

- Safety Training Completion - 100%

- Near Miss Reporting Rate - Proactive metric

Implementation Strategies for Effective KPI Management

Successful KPI implementation requires systematic approaches that address both technical requirements and organizational factors. The most effective strategies start with clear objectives and build measurement capabilities gradually rather than attempting comprehensive systems overnight.

Stakeholder alignment provides the foundation for successful KPI implementation. Different organizational levels need different types of KPIs—executives require strategic cost indicators, managers need operational efficiency metrics, and frontline teams benefit from real-time performance feedback.

KPI Implementation Timeline

Critical Success Factors

- Assign clear ownership for each KPI's accuracy and improvement initiatives

- Provide real-time dashboards for instant access and rapid decision-making

- Implement predictive analytics combining KPI data with machine learning

- Establish integration capabilities connecting legacy equipment with modern systems

- Design automated data collection reducing manual effort and improving accuracy

- Create actionable alerts and thresholds triggering immediate response protocols

Quantified Benefits of Tracking Facility Management KPIs

Implementing comprehensive facility management KPIs delivers measurable benefits that drive significant cost reduction and operational excellence for US manufacturing facilities. These benefits compound over time, creating sustainable competitive advantages.

Reduced downtime costs represent one of the most significant benefits of KPI tracking. Proactive monitoring cuts unplanned downtime by 35%, saving manufacturing facilities $50,000-$300,000 annually per production line. This improvement comes from early problem detection and preventive maintenance scheduling.

| Benefit Category | Typical Improvement | Annual Savings | Implementation Time |

|---|---|---|---|

| Maintenance Cost Reduction | 25-30% decrease | $100K-$500K | 6-12 months |

| Unplanned Downtime | 35% reduction | $50K-$300K per line | 3-6 months |

| Energy Efficiency | 15-25% improvement | $25K-$150K | 6-9 months |

| Equipment Lifespan | 20% extension | Deferred capex | 12-24 months |

Common Pitfalls and How to Avoid Them

Facility management KPI initiatives fail more often than they succeed, usually due to predictable mistakes that can be avoided through awareness and proper planning. Understanding these common pitfalls enables proactive strategies that dramatically improve success probability.

Data collection complexity represents a major challenge as gathering accurate, real-time data from multiple systems and sources requires robust integration capabilities and standardized processes. Legacy equipment integration with modern KPI tracking systems demands significant investment in sensors, software, and networking infrastructure.

Common KPI Implementation Pitfalls

- Selecting too many KPIs without clear priorities or adequate resources

- Focusing on easy-to-measure items rather than important business outcomes

- Ignoring data quality and accuracy issues in automated collection systems

- Failing to connect KPIs to actionable maintenance and operational decisions

- Setting unrealistic targets that demotivate facility teams and stakeholders

- Neglecting to update KPIs as equipment and operational conditions change

- Using KPIs for punishment rather than continuous improvement and learning

Technology integration challenges require careful planning and phased implementation. Start with critical assets that have the highest impact on production and maintenance costs to demonstrate immediate ROI before expanding to comprehensive facility-wide systems.

Building a Culture of KPI-Driven Excellence

Sustainable success with facility management KPIs requires more than just collecting data—it demands building organizational cultures that value measurement, use data for decision-making, and continuously improve based on objective feedback. This cultural transformation often determines whether KPI systems deliver lasting value or become abandoned administrative exercises.

Leadership commitment must be visible and consistent, demonstrated through resource allocation, decision-making processes, and performance management systems. When leaders consistently use KPIs to guide facility decisions and hold teams accountable for results, it signals that measurement is a priority rather than just a reporting requirement.

Recognition and rewards should align with KPI achievement while maintaining focus on underlying performance rather than just numbers. Celebrate improvements in equipment reliability, maintenance efficiency, energy performance, and cost reduction that KPIs reveal, but ensure that recognition systems don't inadvertently encourage gaming behaviors.

The most successful organizations treat facility management KPI tracking as a core competency that provides sustainable competitive advantage. They invest in measurement capabilities, develop internal expertise, and continuously refine their approaches based on results rather than treating KPIs as a one-time implementation project.

Conclusion

Defining clear facility management KPIs isn't just about creating better reports—it's about building the measurement foundation that enables manufacturing excellence. Organizations that master KPI tracking gain the ability to make faster decisions, optimize resource allocation, and demonstrate value in ways that create sustained competitive advantage.

Success requires understanding that effective KPIs serve multiple purposes: they provide early warning systems, enable objective evaluation of improvement efforts, create accountability, and connect facility activities to strategic objectives. The most valuable KPIs are those that drive behavior toward desired outcomes rather than just measuring historical performance.

Implementation success depends on systematic approaches that address both technical requirements and organizational factors. Start with clear objectives, select essential KPIs that provide actionable insights, establish accurate baselines, and build measurement capabilities gradually rather than attempting comprehensive systems overnight.

Building a KPI-driven culture creates the foundation for sustained excellence that extends far beyond initial implementation. Organizations that treat facility management KPI tracking as a core competency develop capabilities that compound over time, creating competitive advantages that become increasingly difficult for competitors to match.

Ready to implement the 12 essential KPIs that deliver 30% cost reduction and operational excellence?

Every day without systematic KPI tracking is another day of missed cost reduction opportunities and operational inefficiency. Implement proven measurement frameworks that drive measurable performance improvements.