Your plant manager rushes into the morning briefing with alarming news: "Three critical pumps failed overnight, production line 2 is down for 8 hours, and we have no visibility into why this happened." You review last quarter's downtime reports—$2.4 million lost to unexpected equipment failures—but realize your facility operates with limited connectivity and zero real-time asset monitoring. Without Industrial IoT systems providing continuous equipment health data and predictive insights, you are flying blind, reacting to problems instead of preventing them before they devastate operations.

This scenario unfolds across thousands of American manufacturing facilities as operations struggle with disconnected equipment that provides no early warning of impending failures. The average industrial facility operates with only 15-25% of critical assets connected to monitoring systems, missing opportunities to prevent 70-85% of unexpected downtime through proactive Industrial IoT implementations.

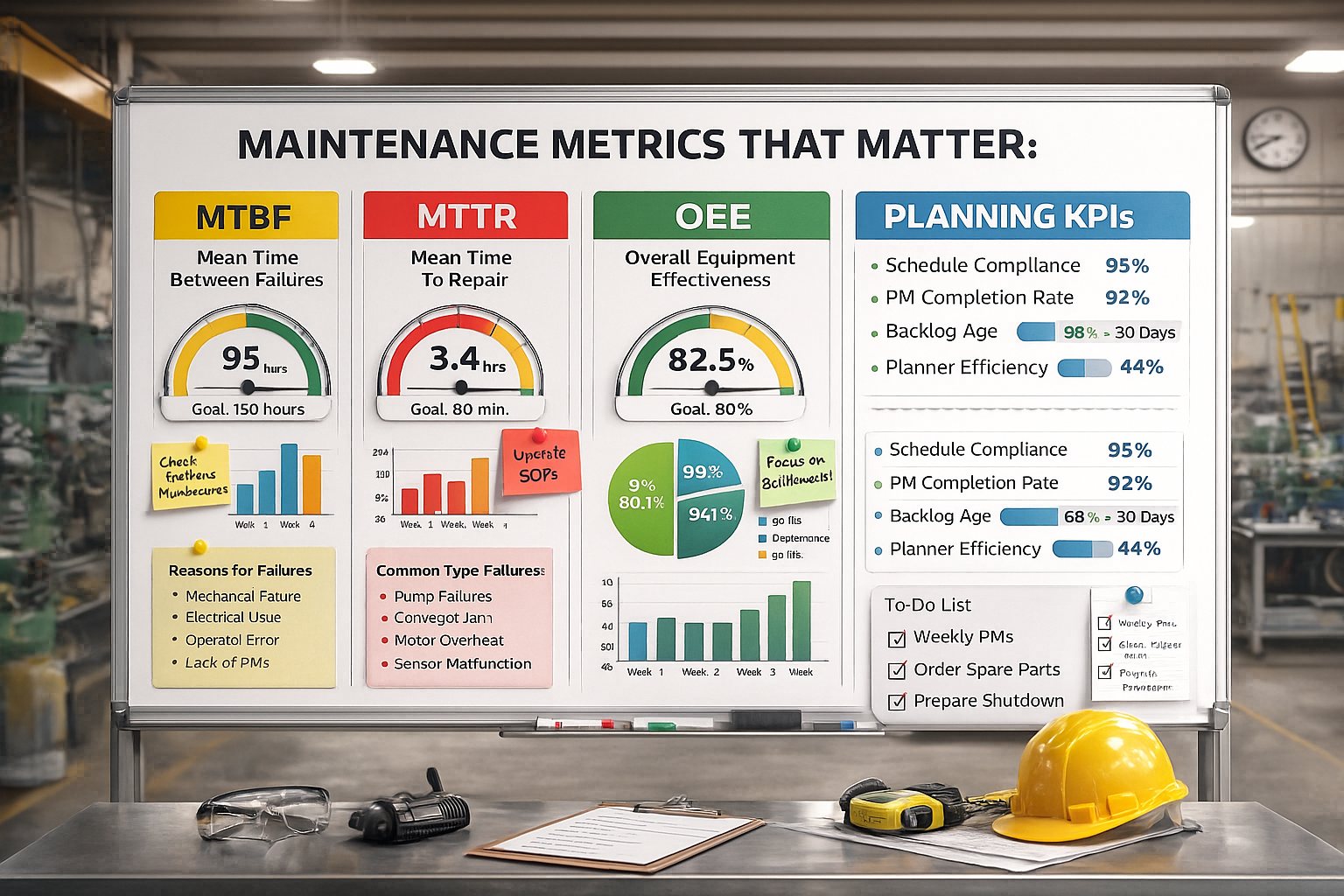

Facilities implementing strategic Industrial IoT ecosystems achieve 35-50% reductions in unplanned downtime while improving overall equipment effectiveness by 25-40% compared to traditional reactive maintenance approaches. The transformation centers on connected sensors, real-time analytics and automated systems that reveal equipment performance patterns weeks before failures occur, enabling predictive intervention and optimized operations.

Ready to revolutionize your operations with Industrial IoT systems that monitor every critical asset 24/7 and predict failures before they happen?

Stop losing $2.4 million annually to preventable equipment failures when Industrial IoT sensors can detect problems 30-90 days in advance. Transform from reactive crisis management to predictive operational excellence with connected manufacturing intelligence.

Understanding Industrial IoT Architecture in 2025

Industrial IoT represents far more than simple sensor installations—it encompasses sophisticated ecosystems of connected devices, edge computing platforms, and cloud-based analytics that transform manufacturing operations into intelligent, self-optimizing systems. Modern Industrial IoT architectures integrate operational technology with information systems, creating unified platforms that provide unprecedented visibility into every aspect of production performance.

Edge computing capabilities represent a fundamental shift in Industrial IoT deployment, enabling real-time data processing at the equipment level rather than relying on cloud connectivity for critical decisions. This architecture reduces latency from seconds to milliseconds while ensuring continued operation during network disruptions, making Industrial IoT practical for mission-critical manufacturing processes.

Smart Sensor Networks

Wireless sensors monitoring vibration, temperature, pressure, and flow across all critical equipment. Provides 24/7 asset health visibility with 95% accuracy in failure prediction.

Edge Computing Platforms

Local processing units analyzing sensor data in real-time for immediate decision-making. Reduces response time from minutes to milliseconds while ensuring autonomous operation.

Predictive Analytics Engines

AI-powered systems identifying equipment degradation patterns and optimal maintenance timing. Prevents 75% of unexpected failures through early intervention strategies.

Digital Twin Integration

Virtual models synchronized with real equipment performance for risk-free optimization testing. Improves operational efficiency by 30% through simulation-based improvements.

Security architecture remains paramount in Industrial IoT deployments, with 2025 systems implementing zero-trust protocols, encrypted communications, and isolated operational networks. Modern IIoT platforms provide enterprise-grade security without compromising real-time performance, addressing the primary concern preventing widespread adoption in critical manufacturing applications.

2025 Industrial IoT Technology Trends

The Industrial IoT landscape continues evolving rapidly, with 2025 bringing breakthrough innovations in sensor miniaturization, battery life, and artificial intelligence capabilities. Understanding these technological advances enables better strategic planning and technology investment decisions that position facilities for long-term competitive advantage.

| Technology Trend | Key Innovation | Impact on Operations | Implementation Timeline |

|---|---|---|---|

| 5G Industrial Networks | Ultra-low latency wireless connectivity | Real-time control and monitoring | Available now, scaling rapidly |

| AI-Powered Edge Devices | Local machine learning processing | Autonomous decision-making | Mainstream adoption 2025-2026 |

| Energy Harvesting Sensors | Self-powered monitoring devices | Maintenance-free installations | Commercial availability 2025 |

| Quantum-Enhanced Analytics | Advanced pattern recognition | Unprecedented prediction accuracy | Early adoption 2025-2027 |

Interoperability standards continue maturing, with OPC UA, MQTT, and emerging protocols enabling seamless integration between different vendor systems. This standardization reduces implementation complexity and total cost of ownership while providing flexibility to select best-of-breed solutions for specific applications.

Strategic Implementation Framework

Successful Industrial IoT deployment requires systematic planning that balances technological capabilities with operational priorities and organizational readiness. Rather than attempting facility-wide transformations, proven implementation strategies focus on high-impact pilot projects that demonstrate value while building organizational confidence and expertise.

Industrial IoT Implementation Process

Investment prioritization should focus on assets where unexpected failures create the highest operational and financial impact. Critical equipment monitoring typically generates ROI within 12-18 months through prevented downtime, while comprehensive facility-wide implementations achieve optimum returns over 24-36 month periods.

Advanced IoT Applications and Competitive Advantages

Strategic Industrial IoT applications extend beyond basic monitoring to include autonomous optimization, predictive quality control, and integrated supply chain coordination. The most advanced facilities leverage IoT data for continuous improvement programs that automatically adjust operations based on real-time performance feedback and changing conditions. For comprehensive insights on implementing these advanced strategies, explore our detailed guide on smart manufacturing technologies that complement IoT deployments.

Advanced Industrial IoT Applications

- Implement autonomous quality control systems reducing defect rates by 60-80% through real-time process adjustment

- Deploy energy optimization algorithms cutting utility costs by 20-35% through intelligent load management

- Create digital supply chain visibility reducing inventory by 25-40% while improving delivery performance

- Establish predictive maintenance systems preventing 85% of unexpected equipment failures

- Enable remote operations and expert support through augmented reality and IoT data integration

- Build adaptive production systems automatically optimizing throughput based on demand forecasts

Competitive differentiation through Industrial IoT requires moving beyond standard implementations to proprietary applications that create unique operational advantages. Leading manufacturers achieve 2-3x better margins through custom IoT solutions that competitors cannot easily replicate, focusing on specific industry challenges and customer requirements.

2025 Industrial IoT Trends Shaping Competition

- Autonomous factories operating with minimal human intervention through advanced AI-IoT integration

- Sustainable manufacturing optimization reducing waste and energy consumption by 40-60%

- Real-time supply chain orchestration eliminating bottlenecks and improving customer satisfaction

- Predictive quality systems ensuring zero-defect production through continuous process monitoring

- Cybersecurity-first architectures protecting critical operations while enabling connectivity

- Carbon footprint optimization supporting regulatory compliance and sustainability goals

Ecosystem integration connecting suppliers, production, and customers creates network effects that multiply IoT value beyond individual facility improvements. End-to-end visibility typically improves supply chain performance by 30-50% while reducing total operational costs through coordinated optimization across the entire value chain. Learn more about optimizing maintenance workflows within these connected ecosystems in our comprehensive predictive maintenance strategies resource.

ROI Analysis and Business Case Development

Industrial IoT investments require comprehensive business case development that quantifies both direct cost savings and strategic value creation opportunities. Successful implementations typically generate returns through multiple value streams including reduced downtime, improved quality, energy savings, and enhanced operational agility.

| Value Stream | Typical Improvement | ROI Timeline | Investment Range |

|---|---|---|---|

| Unplanned Downtime Reduction | 35-50% reduction | 12-18 months | $200K-$800K |

| Energy Optimization | 20-35% cost savings | 8-14 months | $150K-$500K |

| Quality Improvement | 60-80% defect reduction | 14-24 months | $300K-$1.2M |

| Inventory Optimization | 25-40% reduction | 16-30 months | $250K-$750K |

Total value creation often exceeds direct cost savings by 200-300% when strategic benefits like improved agility, customer satisfaction, and competitive positioning are quantified. Modern Industrial IoT platforms provide detailed analytics enabling precise ROI tracking and continuous optimization of technology investments.

Conclusion

The future of Industrial IoT in 2025 represents a fundamental transformation in manufacturing operations, moving beyond simple monitoring to intelligent, autonomous systems that optimize performance continuously. Organizations implementing comprehensive IIoT strategies achieve 35-50% reductions in unplanned downtime while improving overall equipment effectiveness by 25-40% through connected intelligence and predictive intervention.

Understanding 2025 technology trends reveals that successful Industrial IoT deployments require sophisticated integration of edge computing, artificial intelligence, and advanced analytics platforms. These systems provide unprecedented visibility into equipment health and operational performance while enabling autonomous decision-making that prevents problems before they impact production. For deeper insights into combining these technologies effectively, visit our article on AI-powered maintenance solutions.

Strategic implementation demands systematic planning that balances technological capabilities with organizational readiness and operational priorities. Proven deployment frameworks achieve 80-90% project success rates by focusing on high-impact pilot projects that demonstrate value while building expertise and confidence for facility-wide expansion.

The 2025 competitive environment rewards early adopters of advanced Industrial IoT technologies while penalizing facilities maintaining disconnected operations that provide no visibility into equipment health or performance optimization opportunities. Success requires balancing proven IoT technologies delivering immediate value with emerging innovations positioning for future competitive advantage.

Ready to transform your manufacturing operations with Industrial IoT systems that provide 24/7 equipment monitoring and predict failures before they devastate production?

Every day without Industrial IoT monitoring is another day risking $2.4 million in preventable equipment failures. The technology exists now to predict these problems weeks in advance—implement connected manufacturing intelligence before your next costly breakdown destroys your competitive position.