Your forklift breaks down in the middle of a critical shipment, stranding pallets of finished goods and delaying customer deliveries. The cause? A hydraulic leak that could have been caught during routine inspection—if you had an effective maintenance checklist in place. Instead, you're facing $8,000 in emergency repairs, two days of production delays, and an unhappy customer threatening to switch suppliers.

This scenario repeats daily across manufacturing facilities nationwide. Fleet vehicles and material handling equipment are the unsung heroes of operations, quietly moving materials, products, and people until they suddenly don't. Poor fleet maintenance costs the average manufacturing facility $250,000-500,000 annually through unplanned downtime, emergency repairs, and safety incidents.

Yet facilities with systematic fleet maintenance programs achieve 40-60% fewer breakdowns, 25-35% longer equipment life, and 30-50% lower maintenance costs. The difference lies in having comprehensive maintenance checklists that catch problems early, ensure consistent care, and maintain detailed records that guide optimization efforts.

Understanding Fleet Maintenance Fundamentals

Effective fleet maintenance checklists aren't just lists of tasks—they're systematic tools that ensure nothing critical gets overlooked while making inspections efficient enough that they actually get completed. The best checklists balance thoroughness with practicality, providing clear guidance that works for both experienced technicians and newer operators.

Fleet maintenance in manufacturing environments encompasses diverse equipment types, each with specific requirements. Forklifts need hydraulic system checks and load testing, delivery trucks require DOT compliance inspections, utility vehicles need basic safety verifications, and specialized equipment like crane trucks demand detailed structural assessments.

The most effective checklists organize tasks by frequency rather than equipment type, creating daily, weekly, monthly, and annual inspection routines that build comprehensive care over time. This frequency-based approach prevents inspection overload while ensuring that critical safety and operational items receive appropriate attention.

Regulatory compliance adds another layer of complexity, particularly for commercial vehicles and material handling equipment. OSHA requirements, DOT inspections, and industry-specific standards must be integrated into maintenance checklists to avoid costly violations and ensure worker safety.

Documentation requirements vary by equipment type and usage patterns. Commercial vehicles need detailed records for compliance purposes, while internal material handling equipment requires less formal documentation but benefits from systematic tracking that identifies trends and optimization opportunities.

Essential Checklist Components by Equipment Type

Different types of fleet equipment require tailored inspection approaches that address their specific failure modes, safety risks, and operational requirements. Understanding these differences enables creation of focused checklists that maximize effectiveness while minimizing inspection time.

Forklifts & Material Handling

- Hydraulic fluid levels and leaks

- Fork condition and alignment

- Overhead guard integrity

- Brake system function

- Warning devices and lights

- Load capacity verification

- Tire condition and pressure

Delivery & Commercial Vehicles

- Engine oil and coolant levels

- Brake system inspection

- DOT compliance items

- Tire tread and pressure

- Lighting and electrical systems

- Emergency equipment check

- Cargo securing mechanisms

Utility & Service Vehicles

- Basic safety equipment

- Fluid levels verification

- Tool and equipment security

- Communication systems

- First aid kit contents

- Vehicle cleanliness

- Fuel system condition

Hydraulic systems require special attention in material handling equipment, as hydraulic failures can create both safety hazards and operational disruptions. Checklists should include visual leak inspections, fluid level checks, and operational testing of lifting and tilting functions. Document any unusual noises, slow operation, or inconsistent performance.

Electrical systems in modern fleet equipment include complex safety interlocks, warning systems, and operational controls. Effective checklists verify that all warning lights function properly, safety systems engage correctly, and charging systems maintain appropriate battery levels. Include checks for loose connections, damaged wiring, and proper grounding.

Structural integrity becomes increasingly important for aging fleet equipment. Include visual inspections for cracks, excessive wear, and component looseness. Pay special attention to mounting points, welds, and high-stress areas that could fail catastrophically if not caught early.

Environmental factors specific to your operation should be reflected in checklist design. Equipment operating in dusty conditions needs more frequent filter checks, while vehicles exposed to chemicals require additional corrosion inspections and protective equipment verification.

Establishing Inspection Frequencies and Schedules

Effective maintenance checklists use frequency-based scheduling that balances thorough care with operational efficiency. The key is matching inspection intervals to actual failure patterns, usage intensity, and regulatory requirements rather than using generic manufacturer recommendations.

Daily pre-shift inspections form the foundation of effective fleet maintenance, focusing on safety-critical items and basic operational readiness. These inspections should be quick enough to complete in 5-10 minutes while covering items that could create immediate safety hazards or operational failures.

| Frequency | Focus Areas | Typical Duration |

|---|---|---|

| Daily | Safety items, fluid levels, obvious damage | 5-10 minutes |

| Weekly | Detailed visual inspection, basic testing | 15-30 minutes |

| Monthly | Comprehensive inspection, service items | 45-90 minutes |

| Quarterly | Detailed systems testing, compliance items | 2-4 hours |

| Annual | Complete overhaul, certification renewals | 4-8 hours |

Weekly inspections provide opportunities for more detailed examination without disrupting daily operations. Focus on items that develop gradually over time: tire wear patterns, belt condition, filter status, and early signs of component wear. These inspections often reveal problems while they're still preventable.

Monthly comprehensive inspections enable thorough examination of all systems and components. Include items that require measurement or testing equipment: brake adjustments, alignment checks, load testing, and detailed fluid analysis. These inspections provide data for trending and optimization efforts.

Usage-based scheduling provides more accurate maintenance timing for equipment with variable utilization patterns. High-usage equipment may require weekly inspections that other units receive monthly, while seasonal equipment needs adjusted schedules based on activity periods.

Regulatory compliance schedules must be integrated with operational maintenance frequencies to avoid duplication while ensuring nothing gets missed. DOT inspections, OSHA compliance checks, and industry-specific requirements should be built into the frequency structure rather than treated as separate activities.

Digital Tools and Implementation Strategies

Modern fleet maintenance checklists benefit enormously from digital tools that streamline inspections, ensure consistency, and provide data for optimization efforts. The right technology platforms eliminate paperwork, reduce inspection time, and create valuable historical records automatically.

Mobile applications enable field inspections without requiring technicians to return to offices for documentation. Quality mobile platforms work offline, synchronize when connectivity is available, and provide photo capabilities for documenting issues. Look for apps that can generate automatic follow-up work orders when problems are identified.

Integrated CMMS platforms connect fleet maintenance checklists with broader maintenance management systems, enabling comprehensive tracking of costs, trends, and optimization opportunities. This integration eliminates duplicate data entry while providing management visibility into fleet performance and maintenance effectiveness.

Implementation Success Tips:

- Start with pilot equipment groups before facility-wide rollout

- Train inspectors thoroughly on both checklist content and technology usage

- Establish clear escalation procedures for identified problems

- Create feedback mechanisms for continuous checklist improvement

- Integrate with parts inventory systems for automatic reorder triggers

- Use data analytics to identify patterns and optimization opportunities

Barcode or QR code systems can eliminate identification errors while speeding up inspection processes. Each piece of equipment gets a unique identifier that links directly to its specific maintenance checklist, service history, and parts requirements. This automation reduces errors while providing instant access to relevant information.

Workflow automation creates seamless connections between inspection results and corrective actions. When checklists identify problems, the system can automatically generate work orders, order necessary parts, and schedule appropriate technicians. This automation ensures that identified issues receive prompt attention rather than getting lost in administrative processes.

Analytics capabilities transform routine inspection data into actionable insights about fleet performance, cost optimization, and reliability improvement opportunities. Look for platforms that can identify trends, predict maintenance needs, and optimize scheduling based on actual usage patterns rather than generic recommendations.

Measuring Effectiveness and Continuous Improvement

Effective fleet maintenance checklists require systematic measurement and continuous refinement to ensure they deliver intended benefits while adapting to changing operational requirements. The right metrics provide early warning of problems while validating improvement efforts.

Inspection compliance rates serve as the primary indicator of checklist effectiveness. Target completion rates above 90% for daily inspections and 95% for weekly and monthly inspections. Low compliance typically indicates checklist design problems, inadequate training, or competing operational priorities that require attention.

Problem identification rates measure how well checklists catch developing issues before they cause failures. Track the percentage of maintenance needs identified through routine inspections versus emergency breakdowns. Effective checklists should identify 70-80% of maintenance requirements proactively.

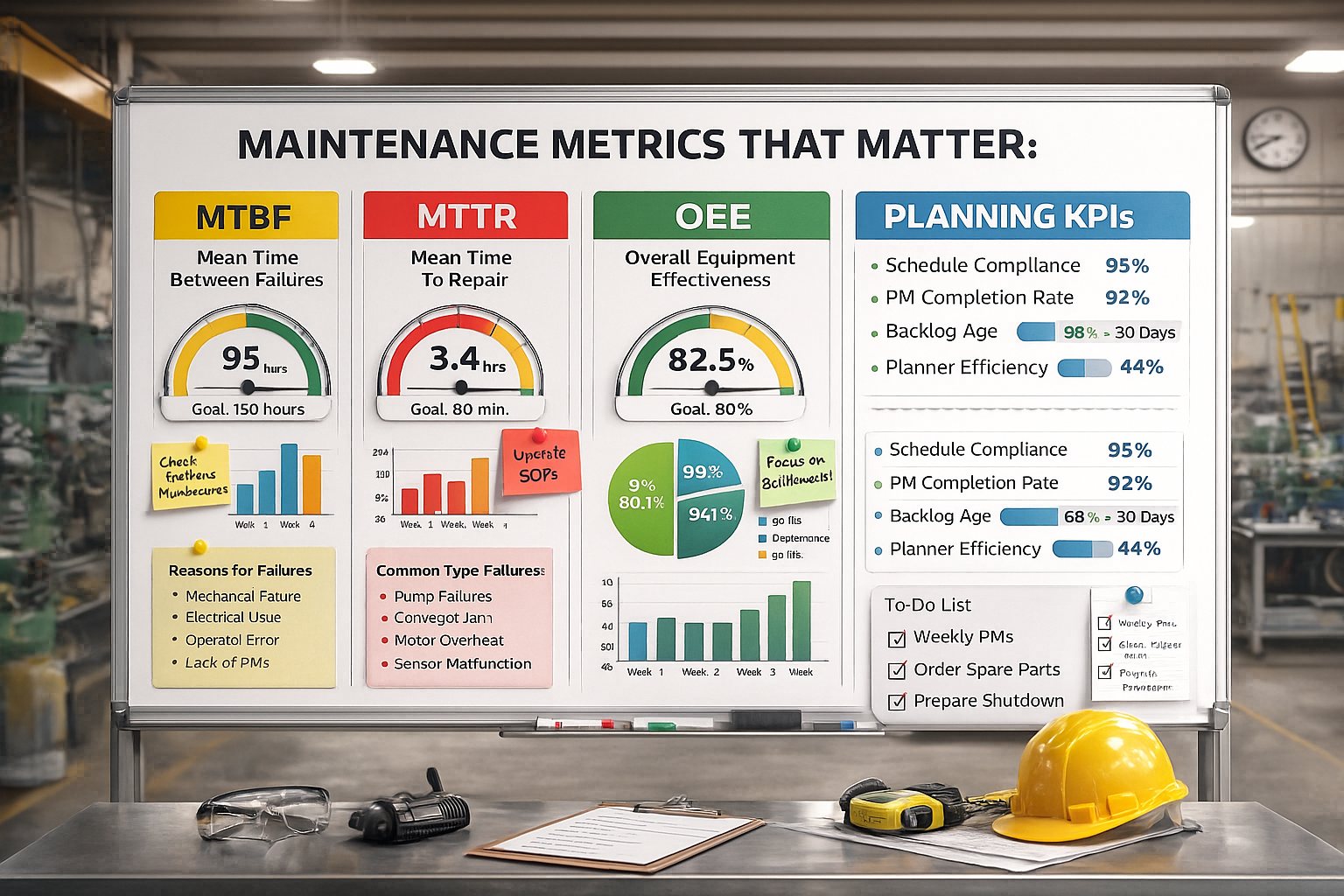

Equipment availability improvements demonstrate checklist value through reduced unplanned downtime. Monitor mean time between failures (MTBF), availability percentages, and emergency maintenance frequency. Well-designed inspection programs typically improve availability by 15-25% within the first year.

Cost optimization metrics include both direct maintenance savings and avoided costs from prevented failures. Track maintenance cost per operating hour, parts consumption patterns, and emergency repair frequency. Document how inspection findings enable planned maintenance during convenient times rather than emergency repairs during production periods.

Continuous improvement processes should systematically review checklist effectiveness and identify optimization opportunities. Analyze failure patterns to identify missing inspection items, review inspection times to eliminate unnecessary tasks, and gather feedback from operators to improve usability and compliance.

Checklist evolution should be data-driven rather than based on assumptions or generic recommendations. Use actual failure history, inspection findings, and cost data to refine inspection frequencies, add or remove checklist items, and optimize the balance between thoroughness and efficiency.

Conclusion

Effective fleet maintenance checklists represent far more than administrative requirements—they're strategic tools that prevent costly breakdowns, ensure regulatory compliance, and optimize equipment performance. The facilities that excel in fleet reliability treat checklists as living documents that evolve with equipment needs and operational experience.

Success requires understanding that different equipment types need tailored approaches while maintaining consistency in inspection frequencies and documentation standards. The most effective programs balance thoroughness with practicality, ensuring that inspections are comprehensive enough to catch problems early but efficient enough that they actually get completed consistently.

Digital tools transform checklist effectiveness by eliminating paperwork, ensuring consistency, and providing data for continuous improvement. However, technology success depends on having well-designed checklists and trained personnel who understand both the inspection requirements and the systems that support them.

Measuring effectiveness and continuously improving checklist design ensures that inspection programs deliver sustained value rather than becoming stale administrative exercises. The most successful facilities treat every failure as a learning opportunity that strengthens future prevention efforts.

Remember that fleet maintenance checklists are investments in operational reliability that compound over time. Start with basic inspection frameworks, implement digital tools that support rather than complicate the process, and continuously refine approaches based on actual results rather than theoretical ideals.