Manufacturing leaders face a critical challenge: how to balance the structured approach of preventive maintenance, the intelligence of condition-based monitoring, and the strategic framework of reliability-centered maintenance (RCM) into a cohesive strategy that maximizes equipment reliability while optimizing costs.

The traditional approach of treating these maintenance philosophies as separate, competing strategies is giving way to a more sophisticated understanding: the most successful manufacturing operations integrate all three approaches into a unified reliability strategy that leverages the strengths of each method while minimizing their individual limitations.

This integration isn't just about using multiple maintenance techniques—it's about creating a systematic approach that applies the right maintenance strategy to the right equipment at the right time, based on criticality, failure modes, and operational context. When done correctly, this integrated approach can deliver dramatic improvements in equipment reliability, maintenance efficiency, and operational costs.

Understanding the Three Maintenance Approaches: Building Your Foundation

Before diving into integration strategies, it's essential to understand how preventive maintenance, condition-based maintenance, and reliability-centered maintenance complement each other when properly aligned within a comprehensive reliability strategy.

Preventive Maintenance (PM) forms the backbone of any reliability program with its time-based or usage-based approach to maintenance activities. While often criticized as potentially wasteful, preventive maintenance provides crucial benefits: predictable scheduling, regulatory compliance, and protection against catastrophic failures. The key is knowing when and where to apply PM most effectively.

Condition-Based Maintenance (CBM) leverages real-time data from sensors, inspections, and monitoring systems to trigger maintenance activities only when equipment condition indicates the need. This approach maximizes equipment utilization while minimizing unnecessary maintenance, but requires sophisticated monitoring capabilities and technical expertise to interpret condition data effectively.

Reliability-Centered Maintenance (RCM) provides the systematic framework for making these decisions. RCM analyzes equipment functions, potential failure modes, and failure consequences to determine the most appropriate maintenance strategy for each asset. It's not a maintenance technique itself, but rather a decision-making process that determines when to use PM, CBM, or other maintenance approaches.

The power of integration lies in using RCM as the strategic framework while deploying PM and CBM as tactical tools. This approach ensures that maintenance resources are allocated based on systematic analysis rather than tradition, intuition, or vendor recommendations.

The RCM Framework: Building Your Integration Foundation

Reliability-Centered Maintenance provides the systematic framework needed to integrate preventive and condition-based maintenance approaches effectively. The RCM process creates a logical structure for determining which maintenance strategy is most appropriate for each piece of equipment based on its criticality, failure modes, and operational context.

The classical RCM process begins with functional analysis—understanding what each piece of equipment is supposed to do and how it can fail to perform those functions. This analysis reveals the specific failure modes that could prevent the equipment from meeting performance expectations, along with the consequences of each potential failure.

The RCM decision logic systematically evaluates each failure mode against specific criteria to determine whether preventive maintenance, condition-based maintenance, failure-finding tasks, or run-to-failure is most appropriate. This decision process considers factors such as failure predictability, monitoring feasibility, safety implications, and economic impact.

For integration purposes, the RCM framework helps resolve the common dilemma of choosing between preventive and condition-based approaches. Instead of making this choice organizationally or by equipment type, RCM enables failure-mode-specific decisions that optimize maintenance effectiveness for each specific risk.

Step-by-Step Integration Process: From Analysis to Implementation

Implementing an integrated maintenance strategy requires a systematic approach that combines RCM analysis with practical considerations about organizational capabilities, technology availability, and operational constraints. The following process provides a proven framework for successful integration.

Phase 1: Asset Criticality Assessment

Begin by categorizing all equipment based on criticality to operations, safety, environment, and economics. This assessment determines which equipment receives the most detailed RCM analysis and guides resource allocation for monitoring and maintenance activities. High-criticality equipment typically justifies more sophisticated condition monitoring, while lower-criticality assets may be candidates for simplified preventive maintenance or run-to-failure strategies.

Phase 2: Failure Mode and Effects Analysis (FMEA)

Conduct detailed FMEA for critical equipment to understand specific failure modes, their likelihood, detectability, and consequences. This analysis provides the foundation for determining whether each failure mode is best addressed through preventive maintenance, condition monitoring, or other strategies.

Phase 3: Maintenance Strategy Selection

Apply RCM decision logic to select the optimal maintenance approach for each failure mode. Key decision criteria include: Is the failure mode age-related and predictable (favoring PM)? Can the failure mode be detected through condition monitoring before functional failure occurs (favoring CBM)? Are the consequences of failure acceptable with appropriate contingency planning (allowing run-to-failure)?

Phase 4: Technology and Resource Planning

Determine the technology, skills, and resources required to implement the selected maintenance strategies. This includes condition monitoring equipment, preventive maintenance scheduling systems, training requirements, and organizational changes needed to support the integrated approach.

Phase 5: Implementation and Optimization

Roll out the integrated maintenance strategy in phases, starting with pilot areas or equipment types. Monitor performance metrics, gather feedback from maintenance teams, and refine the approach based on actual results. The integration process should be iterative, with continuous improvement based on operational experience.

Technology and Tools for Seamless Integration

Modern technology platforms play a crucial role in making integrated maintenance strategies practical and sustainable. The key is selecting and implementing tools that support all three maintenance approaches while providing the visibility and coordination needed for effective integration.

Computerized Maintenance Management Systems (CMMS) serve as the central platform for integrating preventive and condition-based maintenance activities within an RCM framework. Advanced CMMS platforms can manage time-based preventive maintenance schedules, integrate with condition monitoring systems to trigger CBM activities, and maintain the RCM analysis documentation that guides maintenance strategy decisions.

Condition Monitoring Integration requires platforms that can connect various monitoring technologies—vibration analysis, oil analysis, thermal imaging, ultrasonic testing, and IoT sensors—into a unified system that triggers maintenance activities based on predetermined condition thresholds. The most effective systems use machine learning algorithms to refine these thresholds based on actual equipment performance and failure history.

Mobile Platforms enable field technicians to access RCM analysis results, execute preventive maintenance procedures, and report condition monitoring findings from a single interface. This mobility is essential for maintaining the integrated approach during actual maintenance execution, ensuring that strategic decisions translate into effective field activities.

Analytics and Reporting Capabilities provide the visibility needed to optimize the integrated approach over time. Effective platforms track performance metrics for each maintenance strategy, identify opportunities to shift equipment from preventive to condition-based approaches (or vice versa), and measure the overall effectiveness of the RCM-based integration.

The most successful implementations focus on platforms that grow with organizational capabilities rather than trying to implement every advanced feature immediately. Start with solid CMMS functionality that supports both PM and CBM, then add advanced analytics and AI capabilities as the organization develops the skills and processes needed to leverage these tools effectively.

Measuring Success and Continuous Improvement

The success of integrated maintenance strategies depends on systematic measurement and continuous improvement processes that evaluate both individual maintenance approaches and their overall integration effectiveness. This measurement framework should capture leading indicators that predict future performance as well as lagging indicators that demonstrate achieved results.

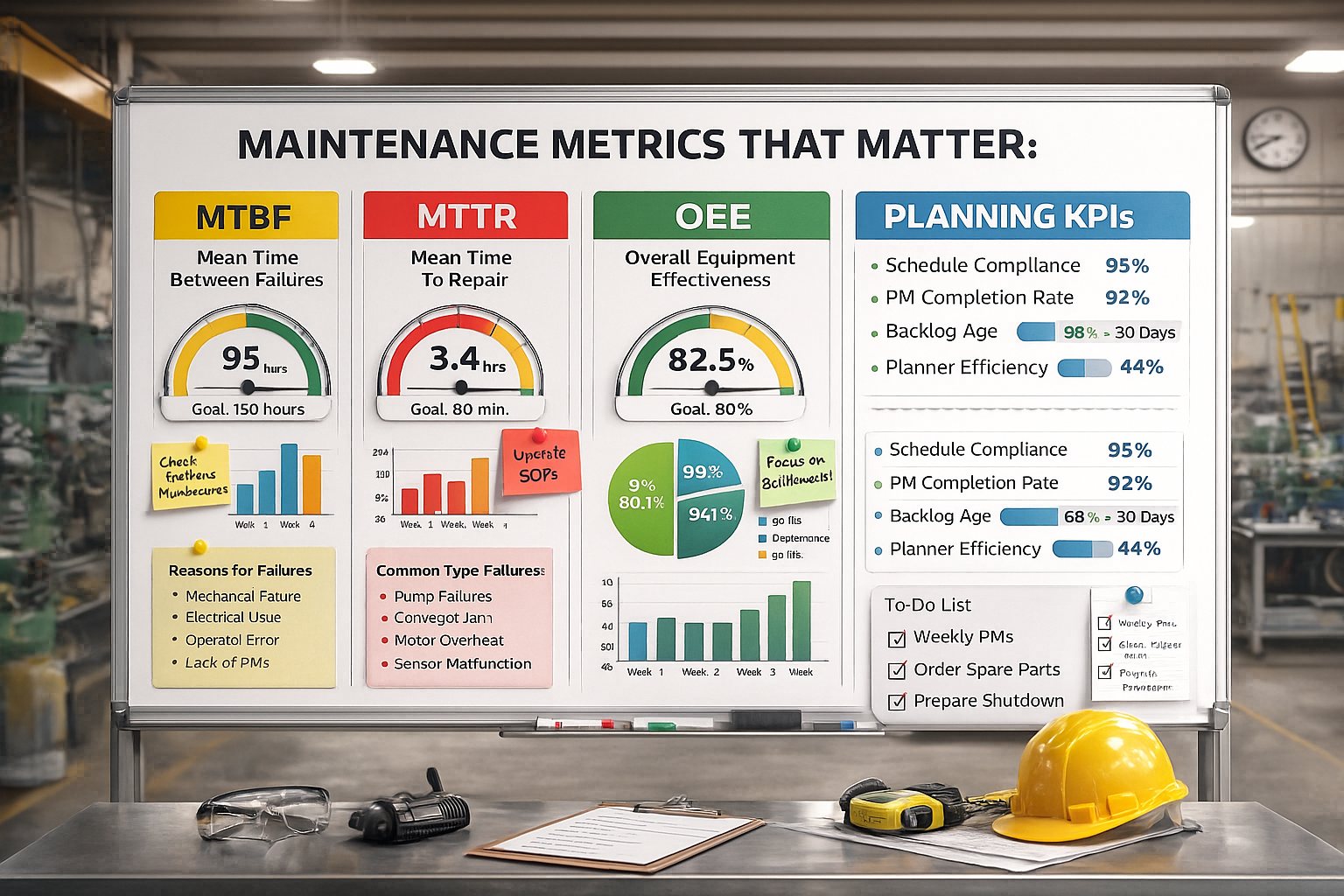

Equipment Performance Metrics provide the foundation for evaluating integration success. Key metrics include Overall Equipment Effectiveness (OEE), Mean Time Between Failures (MTBF), Mean Time to Repair (MTTR), and availability percentages. These metrics should be tracked by equipment type and maintenance strategy to identify which approaches deliver the best results for different situations.

Maintenance Efficiency Metrics evaluate how well the integrated approach optimizes maintenance resource utilization. Track maintenance cost per unit produced, maintenance labor productivity, parts inventory turns, and emergency maintenance percentages. These metrics help identify opportunities to shift maintenance strategies for better resource optimization.

Integration Effectiveness Indicators measure how well the different maintenance approaches work together. Monitor metrics like condition monitoring accuracy (percentage of CBM alerts that lead to actual maintenance needs), preventive maintenance optimization (percentage of PM tasks that reveal actual maintenance requirements), and RCM coverage (percentage of critical failure modes covered by appropriate maintenance strategies).

Continuous Improvement Process should systematically review integration performance and identify optimization opportunities. This includes regular updates to RCM analysis based on actual failure experience, refinement of condition monitoring thresholds based on false alarm rates and missed detections, and adjustment of preventive maintenance intervals based on actual component life data.

Conclusion: Building Your Integrated Maintenance Excellence

The integration of preventive maintenance, condition-based maintenance, and reliability-centered maintenance represents more than a technical implementation—it's a strategic transformation that positions manufacturing operations for sustained competitive advantage through superior equipment reliability and optimized maintenance costs.

Success requires understanding that these approaches are complementary rather than competitive. Reliability-Centered Maintenance provides the analytical framework for making informed decisions about when to use preventive maintenance for safety-critical and regulatory requirements, when to deploy condition-based maintenance for monitored equipment with predictable failure patterns, and when to accept run-to-failure strategies for non-critical assets with appropriate contingency plans.

The implementation process demands systematic execution: start with asset criticality assessment, conduct thorough failure mode analysis, apply RCM decision logic to select optimal maintenance strategies, invest in technology platforms that support integration, and establish measurement systems that drive continuous improvement.

Remember that integration is a journey rather than a destination. Begin with pilot programs focused on critical equipment, build organizational capabilities through training and experience, and gradually expand the integrated approach based on demonstrated results and lessons learned.

The manufacturers who will lead their industries in the coming decade will be those that move beyond traditional maintenance approaches to embrace integrated strategies that optimize reliability, efficiency, and cost-effectiveness simultaneously. The framework and processes outlined in this guide provide the roadmap for that transformation.

Most importantly, maintain focus on the ultimate goal: creating a maintenance organization that consistently delivers superior equipment reliability while optimizing resource utilization. Technology, processes, and frameworks are simply enablers—the real value comes from empowering maintenance professionals to make better decisions and execute more effective strategies.