The manufacturing landscape in 2025 presents unprecedented challenges that demand innovative digital solutions. From supply chain disruptions to skilled labor shortages, manufacturers across the United States are grappling with complex issues that threaten operational efficiency and profitability. However, the same technological advances creating some of these challenges also offer powerful solutions.

Modern manufacturing facilities face a perfect storm of complications: aging infrastructure, increasing regulatory requirements, sustainability pressures, and rapidly evolving customer expectations. These challenges aren't just operational inconveniences—they represent fundamental shifts in how manufacturing must operate to remain competitive in the global marketplace.

The good news? Digital transformation offers concrete solutions to address each of these challenges. From AI-powered predictive maintenance to IoT-enabled supply chain visibility, manufacturers who embrace digital solutions are achieving 20-35% improvements in operational efficiency while reducing costs and improving product quality.

Ready to revolutionize your manufacturing operations with cutting-edge digital solutions?

Join thousands of manufacturers who have already transformed their operations and achieved remarkable results. Our proven digital solutions have helped facilities reduce downtime by up to 60% and cut operational costs by 30%. Don't let your competitors gain the advantage—take action today and secure your facility's future success.

Start Your Digital TransformationSee Live Demo

The Top 10 Manufacturing Challenges Facing US Facilities in 2025

Understanding the specific challenges impacting manufacturing operations is crucial for developing effective digital solutions. These ten issues represent the most significant obstacles manufacturers report facing in 2025, based on industry surveys and operational data from facilities nationwide.

Each challenge interconnects with others, creating cascading effects that can significantly impact overall facility performance. Addressing these issues requires systematic approaches that leverage digital technologies to create sustainable improvements rather than temporary fixes.

1. Supply Chain Visibility and Disruption

Limited visibility into supplier performance, inventory levels, and potential disruptions continues to plague manufacturers. 73% of facilities report supply chain issues as their primary operational concern in 2025.

2. Skilled Labor Shortage and Retention

Manufacturing faces a projected shortage of 2.1 million skilled workers by 2025. Finding and retaining qualified technicians, operators, and maintenance personnel remains critical for operational continuity.

3. Equipment Downtime and Maintenance Costs

Unplanned downtime costs manufacturers an average of $50,000 per hour. Rising maintenance costs and aging equipment infrastructure create ongoing operational challenges.

4. Quality Control and Compliance

Increasing regulatory requirements and customer quality expectations demand more sophisticated quality management systems and real-time monitoring capabilities.

5. Energy Costs and Sustainability Requirements

Rising energy costs combined with corporate sustainability mandates require manufacturers to optimize energy consumption while meeting environmental targets.

6. Data Integration and Decision Making

Manufacturing facilities generate massive amounts of data, but 68% report difficulty integrating and analyzing this information for actionable insights.

7. Cybersecurity and Operational Technology

Increased connectivity creates cybersecurity vulnerabilities. Manufacturing experiences 40% more cyberattacks than other industries, making security a critical operational concern.

8. Inventory Management and Working Capital

Balancing inventory levels to ensure production continuity while minimizing working capital requirements becomes increasingly complex with supply chain volatility.

9. Production Flexibility and Customization

Customer demands for customization and shorter lead times require manufacturing systems capable of rapid changeovers and flexible production scheduling.

10. Regulatory Compliance and Documentation

Evolving safety, environmental, and quality regulations require comprehensive documentation and reporting capabilities that many facilities struggle to maintain efficiently.

Digital Solutions Transforming Manufacturing Operations

Digital transformation in manufacturing isn't about adopting individual technologies—it's about creating integrated systems that address multiple challenges simultaneously. The most successful implementations combine several digital solutions to create synergistic effects that deliver greater value than individual technology deployments.

Modern digital solutions for manufacturing focus on three core areas: operational visibility, predictive capabilities, and automated decision-making. These capabilities work together to create more resilient, efficient and responsive manufacturing operations.

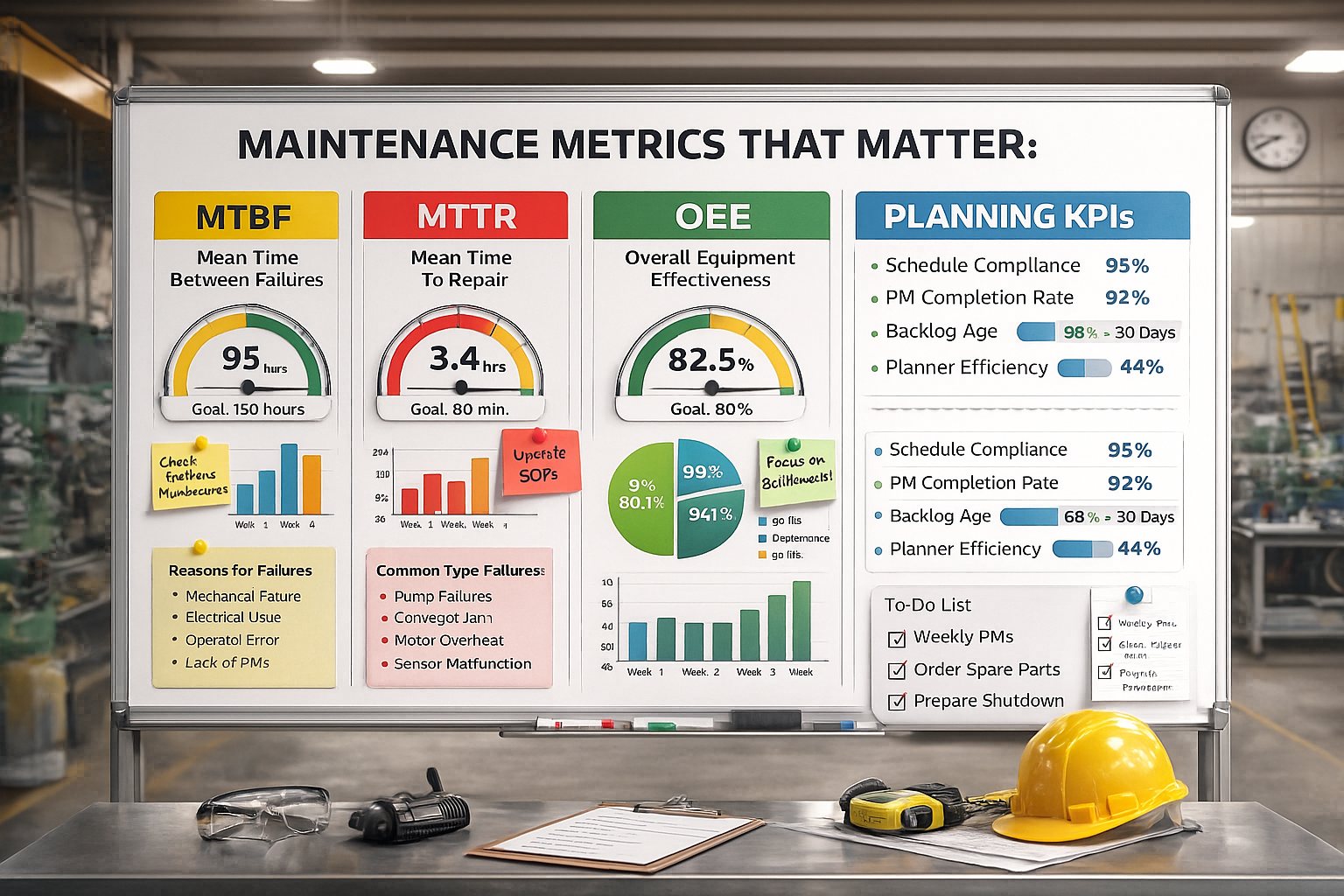

Predictive Maintenance and Asset Management

IoT sensors and AI algorithms predict equipment failures before they occur, reducing unplanned downtime by 40-60% while optimizing maintenance schedules and resource allocation. Real-time condition monitoring enables data-driven maintenance decisions that extend asset life and improve reliability.

Supply Chain Visibility and Management

Digital supply chain platforms provide real-time visibility into supplier performance, inventory levels, and potential disruptions. Advanced analytics identify risks and recommend mitigation strategies, while automated systems manage purchase orders and inventory replenishment.

Quality Management and Control Systems

Computer vision and machine learning enable automated quality inspection and defect detection. Statistical process control systems identify trends and variations before they impact product quality, while digital documentation ensures compliance and traceability.

Energy Management and Optimization

Smart energy monitoring systems track consumption patterns and identify optimization opportunities. Automated controls adjust equipment operation to minimize energy usage while maintaining production requirements, delivering 15-25% energy savings.

Workforce Management and Training

Digital training platforms and augmented reality systems accelerate worker onboarding and skill development. Mobile work order systems and digital procedures reduce errors while improving productivity and safety compliance.

Data Analytics and Business Intelligence

Integrated analytics platforms combine operational data from multiple sources to provide comprehensive insights into facility performance. Real-time dashboards and automated reporting enable faster decision-making and continuous improvement initiatives.

Implementation Strategies for Successful Digital Transformation

Successful digital transformation in manufacturing requires strategic planning, phased implementation, and organizational change management. The most effective approaches start with clear objectives, assess current capabilities, and develop roadmaps that align technology investments with business priorities.

Implementation success depends on selecting the right technologies for specific operational challenges while ensuring systems integrate effectively with existing infrastructure. Change management and workforce development play equally important roles in realizing the full potential of digital investments.

Digital Transformation Implementation Framework

Technology selection should prioritize solutions that address multiple challenges simultaneously while integrating with existing systems. Cloud-based platforms offer scalability and reduced infrastructure requirements, while edge computing enables real-time processing for critical operations.

Partnerships with technology providers and system integrators can accelerate implementation while reducing internal resource requirements. However, maintaining internal capabilities for system management and optimization remains essential for long-term success.

Implementation Best Practices

- Start with high-impact, low-complexity projects to build momentum and demonstrate value

- Establish clear success metrics and regularly measure progress against objectives

- Invest heavily in workforce training and change management initiatives

- Ensure robust cybersecurity measures are integrated from the beginning

- Develop vendor partnerships that provide ongoing support and system optimization

- Create internal champions who can drive adoption and provide user support

- Plan for scalability and future technology integration from initial design

- Maintain focus on solving business problems rather than implementing technology

Measuring Success and ROI in Digital Manufacturing

Measuring the success of digital transformation initiatives requires comprehensive metrics that capture both operational improvements and financial returns. The most effective measurement systems track leading indicators that predict future performance alongside traditional lagging indicators that show historical results.

ROI calculations for digital manufacturing solutions must consider both direct cost savings and indirect benefits such as improved quality, reduced risk, and enhanced competitiveness. Many benefits may take 6-18 months to fully materialize, making patient and comprehensive measurement approaches essential.

| Metric Category | Key Performance Indicators | Typical Improvement Range | Measurement Timeline |

|---|---|---|---|

| Equipment Effectiveness | OEE, MTBF, MTTR, Planned Downtime | 15-35% improvement | 3-6 months |

| Quality Performance | First Pass Yield, Defect Rates, Customer Complaints | 20-40% improvement | 2-4 months |

| Operational Efficiency | Labor Productivity, Energy Consumption, Cycle Times | 10-25% improvement | 4-8 months |

| Supply Chain Performance | Inventory Turns, Fill Rates, Lead Times | 15-30% improvement | 6-12 months |

| Cost Management | Cost per Unit, Maintenance Costs, Overhead Allocation | 12-28% reduction | 6-18 months |

| Safety and Compliance | Incident Rates, Audit Scores, Regulatory Compliance | 25-50% improvement | 3-9 months |

Continuous improvement processes ensure that digital solutions deliver sustained value rather than one-time improvements. Regular review of performance metrics, user feedback, and system optimization opportunities enables ongoing refinement of digital systems and processes.

Conclusion

Manufacturing challenges in 2025 require sophisticated digital solutions that address multiple operational issues simultaneously. The ten key challenges—from supply chain disruptions to workforce shortages—create interconnected problems that demand integrated technology approaches rather than isolated point solutions.

Digital transformation success depends on strategic implementation that combines the right technologies with organizational change management and workforce development. Manufacturers who approach digital transformation systematically achieve significantly better results than those implementing individual technologies without comprehensive planning.

The measurement of success requires comprehensive metrics that capture both immediate operational improvements and long-term strategic benefits. ROI typically materializes within 18-24 months, with ongoing operational benefits that justify continued investment in digital capabilities.

The path forward requires commitment to continuous improvement, investment in workforce capabilities, and partnerships with technology providers who understand manufacturing operations. The manufacturers who embrace this transformation today will lead their industries tomorrow.

Ready to become a manufacturing leader with industry-proven digital solutions?

The time for transformation is now. Every day you wait, competitors are gaining ground with advanced digital capabilities. Our comprehensive solutions have helped over 10,000 manufacturing facilities achieve breakthrough performance improvements. Join the ranks of industry leaders who chose to act decisively and secure their competitive future.

Begin Your Transformation JourneySchedule Expert Consultation