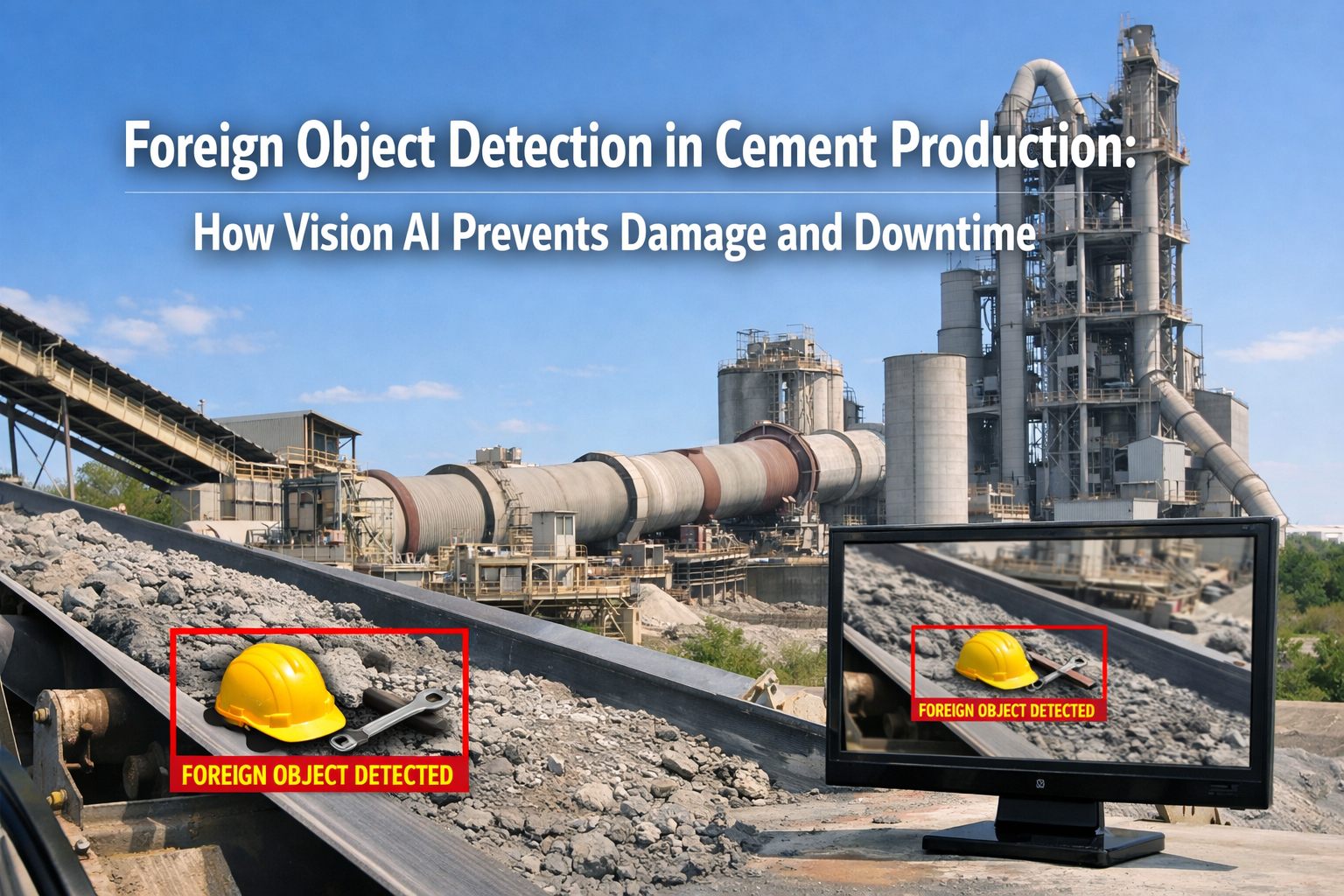

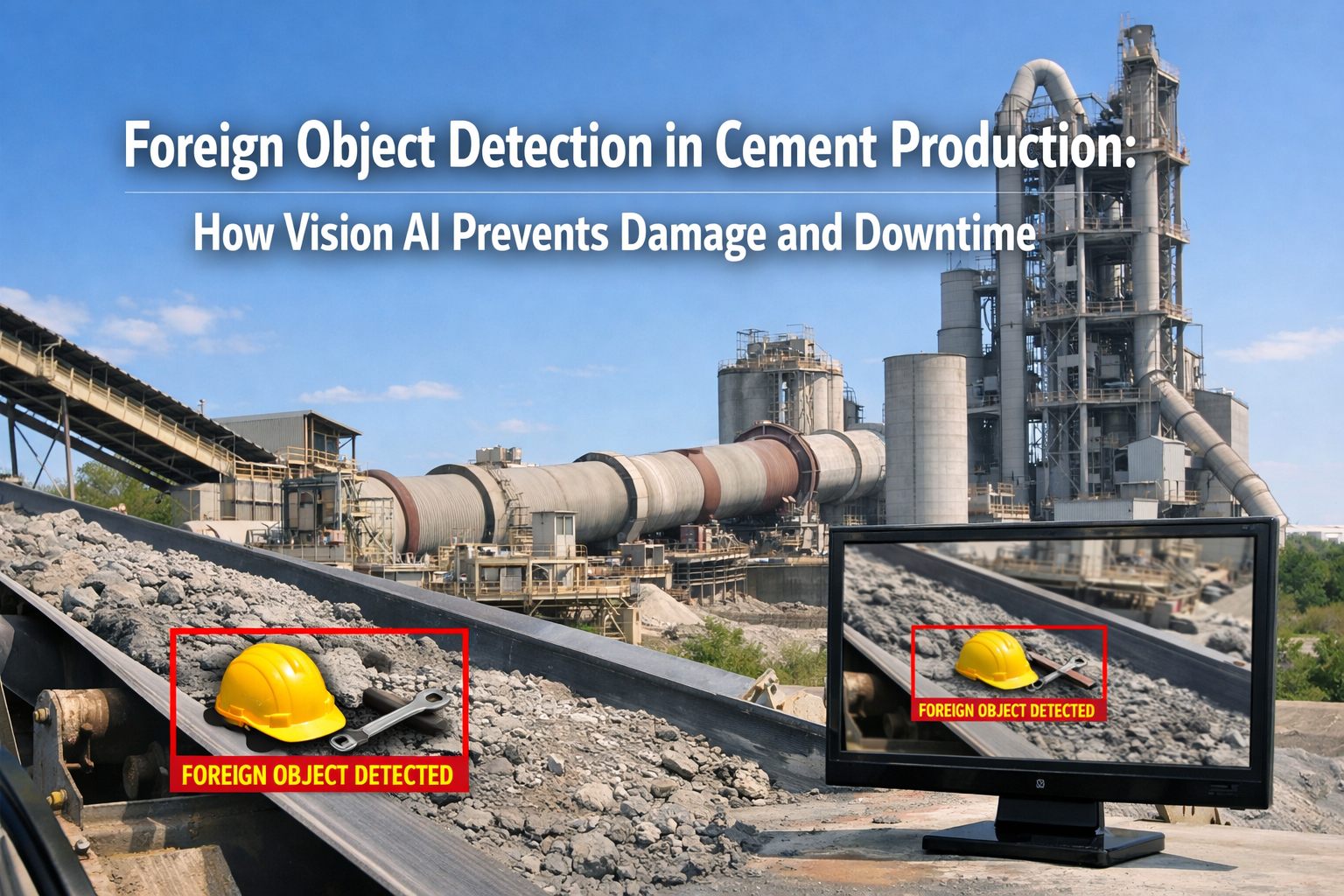

A chunk of unprocessed metal enters your raw material feed. It travels undetected through the conveyor system, past the pre-heater, and into the crusher. Within seconds, the impact destroys hammer heads worth $15,000. But that's just the beginning—the unplanned shutdown that follows costs your plant $100,000 per hour in lost production. This scenario plays out in cement plants worldwide, where foreign objects like tramp metal, oversized rocks and debris cause catastrophic equipment damage that could have been prevented with a single technology: Vision AI-based foreign object detection.

What Foreign Objects Threaten Cement Production?

Cement manufacturing involves processing millions of tons of raw materials annually—limestone, clay, shale, iron ore, and increasingly, alternative fuels. Within this massive material stream, foreign objects regularly infiltrate the production process. These contaminants range from tramp metal (bolts, tools, equipment fragments) to oversized rocks that bypass screening systems, and debris from alternative fuel sources. When these objects reach crushers, mills, or kilns, the consequences cascade through the entire operation. The global foreign object detection system market reached $12.93 billion in 2024, reflecting industrial recognition that prevention costs far less than repair. Cement operations ready to protect their equipment can start a free trial to explore Vision AI monitoring capabilities.

How Vision AI Detects Foreign Objects in Real-Time

Vision AI transforms standard industrial cameras into intelligent detection systems capable of identifying anomalies that human inspectors would miss—especially at the speeds cement conveyors operate. High-resolution cameras positioned at strategic points capture continuous imagery of the material stream. Deep learning algorithms, trained on thousands of images of normal material flow and foreign object intrusions, analyze each frame in milliseconds. When the system identifies an object that doesn't match the expected material profile, it triggers immediate alerts and can automatically activate rejection mechanisms or conveyor stops before the contaminant reaches critical equipment.

The technology integrates seamlessly with existing plant infrastructure. Modern Vision AI systems connect to programmable logic controllers (PLCs) via standard industrial protocols like MQTT and OPC-UA, enabling automated responses without requiring operators to manually intervene. When a foreign object is detected, the system can stop conveyors, activate diverter gates, or simply alert operators while logging the event for maintenance planning. Plants exploring how Vision AI connects with their existing control systems can schedule a technical demo to see the integration in action.

The Cost of Not Detecting: Equipment Damage Breakdown

In cement production, where even an hour of unplanned downtime can translate to $100,000 in lost revenue, the financial case for foreign object detection is compelling. A single metal fragment entering a vertical roller mill can destroy grinding rollers that cost $50,000-$150,000 to replace—not including the 2-4 days of downtime for repairs. Crusher hammer damage from tramp metal can require 8-12 hours of emergency maintenance. And bearing failures caused by contaminated material can halt cement mills for up to 56 hours while replacement parts are sourced and installed.

| Equipment | Common Damage | Repair Cost | Downtime | Total Impact |

|---|---|---|---|---|

| Primary Crusher | Hammer/jaw damage | $15K - $40K | 8-12 hours | $95K - $160K |

| Vertical Roller Mill | Roller/table damage | $50K - $150K | 2-4 days | $250K - $550K |

| Ball Mill | Liner puncture | $25K - $60K | 24-48 hours | $125K - $260K |

| Conveyor Belt | Tears, punctures | $10K - $30K | 4-8 hours | $50K - $110K |

| Rotary Kiln | Refractory damage | $100K - $300K | 5-10 days | $600K - $1.3M |

Strategic Camera Placement for Maximum Coverage

Effective foreign object detection requires strategic camera positioning at critical control points throughout the cement production process. The most valuable detection points are upstream of expensive equipment—catching contaminants before they can cause damage rather than documenting destruction after it occurs. Primary positions include raw material and feed conveyors (before crushers), clinker transport systems (before cement mills), and alternative fuel input lines (before kilns). Secondary positions monitor inter-stage transfers where debris can accumulate or new contaminants can enter the material stream.

Camera selection and housing matter significantly in cement environments. Industrial-grade cameras rated IP67 or higher protect against the pervasive dust that characterizes cement operations. Proper lighting—often LED arrays synchronized with camera exposure—ensures consistent image quality regardless of ambient conditions. Plants implementing Vision AI for the first time can sign up to access camera placement guidelines and integration documentation.

Expert Insight: Why Traditional Detection Falls Short

Traditional metal detectors have served the cement industry for decades, but they're fundamentally limited. They can only detect metallic objects, missing the rocks, wood, plastic, and other debris that increasingly enter material streams through alternative fuel sources. Vision AI doesn't discriminate by material composition—it identifies anything that doesn't belong, regardless of whether it's ferrous metal or a chunk of tire from your AFR supply.

The computer vision market for industrial applications reached $19.82 billion in 2024 and is projected to hit $58.29 billion by 2030—a 19.8% compound annual growth rate that reflects rapid enterprise adoption. In cement specifically, early adopters report an 82% reduction in crusher blockages and 70% reduction in conveyor-related downtime after implementing Vision AI monitoring. Operations teams evaluating detection technologies can request a side-by-side comparison demo to see the difference in detection capabilities.

Implementation: Getting Started in 30 Days

Deploying Vision AI for foreign object detection doesn't require replacing existing infrastructure. Modern systems integrate with standard CCTV cameras already installed in many plants, adding intelligent monitoring without significant hardware investment. The critical success factor is selecting AI models trained specifically on industrial material streams rather than generic computer vision systems. A phased implementation typically starts with 2-3 cameras at the highest-risk detection points, validating performance before expanding coverage throughout the plant.

Maintenance costs in cement plants range between 15% and 40% of total production costs. By implementing proactive detection systems, plants can reduce maintenance expenses by 5-10% while simultaneously avoiding the catastrophic costs of foreign object damage. The ROI calculation is straightforward: a single prevented crusher incident can justify an entire year of Vision AI monitoring. Teams ready to begin implementation can create a free account to access deployment resources and start their pilot program.