Your press line just stamped 2,000 panels. Everything looked fine—until the OEM quality audit flagged dimensional drift on 12% of the batch. The Cpk dropped from 1.45 to 1.08 during a single shift, invisible to manual inspection but devastating to your supplier scorecard. With automotive downtime costing $2.3 million per hour, discovering process drift after the fact is a competitive death sentence. Predictive Cp/Cpk monitoring transforms stamping quality from reactive firefighting into proactive prevention, catching capability degradation hours before defects reach downstream assembly.

Average automotive manufacturing downtime cost according to Siemens 2024 True Cost of Downtime report

72%

of structural vehicle parts are produced through metal stamping processes

40%

scrap reduction achieved with real-time quality monitoring systems

95%

of predictive analytics adopters report positive ROI within first year

Understanding Cp vs Cpk: The Quality Language Every Press Shop Speaks

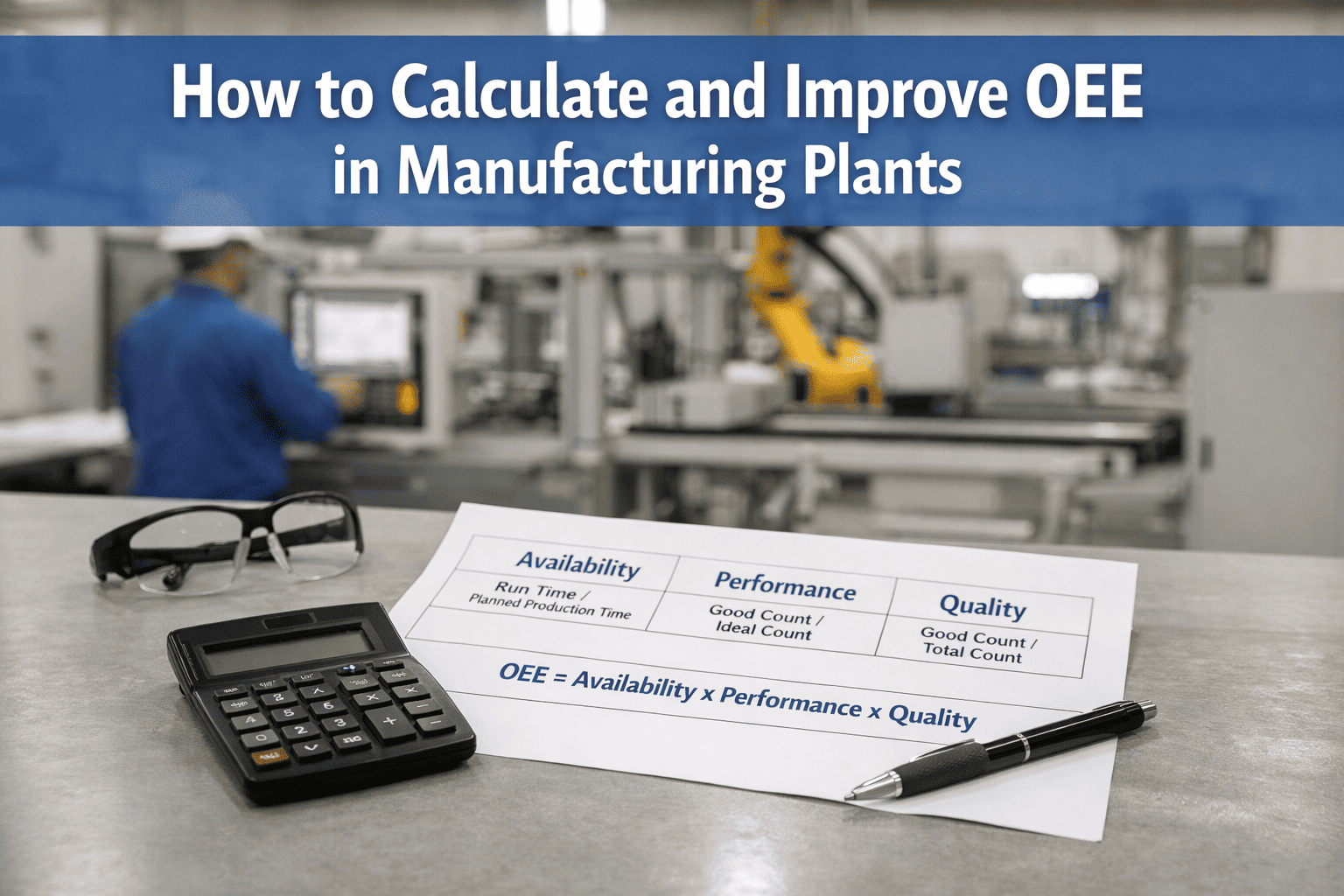

Process capability indices quantify whether your press line can consistently produce parts within specification limits. Cp measures process potential—the spread of your variation compared to tolerance width. Cpk adds the critical dimension: centering. A press with Cp of 1.5 but Cpk of 0.9 has tight variation but runs off-center, trending toward specification limits. Press shops implementing real-time capability monitoring catch centering problems before they become scrap—saving thousands in rework costs daily.

< 1.0

NOT CAPABLE

Process cannot meet specs. 6,210+ PPM defects. Stop production and investigate.

1.0 – 1.33

MARGINAL

Barely capable. 66–6,210 PPM defects. Requires improvement for OEM approval.

1.33 – 1.67

AIAG COMPLIANT

Meets automotive standard. <66 PPM defects. PPAP approved for production.

≥ 2.0

WORLD CLASS

Six Sigma quality. <3.4 PPM defects. Process uses only 50% of tolerance.

Why Traditional SPC Falls Short at Press Line Speed

Traditional statistical process control relies on periodic sampling—measuring five panels every hour and plotting the data manually. By the time a control chart reveals a trend, hundreds of off-spec parts have already been stamped. Die wear, material batch changes, cushion pressure drift and temperature variations don't wait for scheduled inspections. Modern press lines running at 18 strokes per minute stamp 10,000+ panels daily. Quality teams ready to move beyond reactive control can schedule a demo of continuous Cpk monitoring—watching process capability update stroke-by-stroke rather than shift-by-shift.

Traditional SPC

Hourly manual sampling

Cpk calculated end-of-shift

Detects drift after defects produced

Paper-based control charts

Reactive corrections only

Typical Detection Delay:

2-4 Hours

Predictive SPC

Continuous real-time monitoring

Live Cpk with trend forecasting

Predicts drift before spec violation

AI-powered pattern recognition

Proactive alerts to operators

Typical Detection Lead:

30+ Minutes Ahead

See Real-Time Cpk Monitoring in Action

Watch how predictive SPC transforms raw press data into actionable quality intelligence—detecting capability drift before your first defect is stamped.

Root Causes: What Drives Cpk Drift in Press Operations

Understanding what degrades process capability helps you configure monitoring systems to catch problems early. Die wear gradually increases dimensional variation, and burr formation. Material batch changes shift your process mean even when nothing mechanical changes. Press parameters—cushion pressure, ram velocity, lubrication flow—introduce variation that compounds across production runs. Facilities implementing integrated SPC and maintenance systems correlate capability trends with equipment conditions, scheduling preventive action before quality escapes occur.

01

Die Wear

Gradual dimensional drift, increased burrs, surface defects

Monitor: Tonnage trends, thickness variation

02

Material Variation

Mean shift between coils, springback changes

Monitor: First-piece data, tensile properties

03

Press Parameters

Cushion pressure drift, ram velocity shifts

Monitor: Servo feedback, pressure sensors

04

Temperature Effects

Die expansion, lubricant viscosity changes

Monitor: Thermal sensors, ambient conditions

Expert Perspective: The Shift to Predictive Quality

Traditional SPC is fundamentally reactive—by the time a control chart flags an out-of-control condition, non-conforming parts have already been produced. The fusion of real-time digital SPC with deep learning enables a paradigm shift from detection to prediction, moving toward the zero-defect aspirations of modern smart factories.

37%

Defect rate reduction within 6 months of SPC implementation

22%

Throughput increase from reduced rework and scrap

134%

Average ROI on advanced analytics investments

The most successful press shops connect Cpk monitoring directly to their CMMS. When a die shows wear patterns correlating with capability decline, the system automatically schedules maintenance during planned downtime rather than waiting for quality failures. Plants seeking this integration can consult with our press shop specialists to design a monitoring strategy tailored to their specific equipment and OEM requirements.

Getting Started: Your Path to Predictive Quality

Implementing predictive Cpk monitoring doesn't require replacing existing equipment. Modern solutions integrate with PLCs, press controllers, and inline gauging systems already in place. Start with your most critical stamping operations—typically high-volume body panels or safety-critical components—and establish baseline capability data. From there, predictive algorithms learn your process patterns and begin forecasting capability trends. Press shops ready to transform their quality approach can create a free OXmaint account and begin their predictive SPC journey with expert implementation support.

Stop Reacting. Start Predicting.

Join automotive manufacturers using OXmaint to monitor Cp/Cpk in real-time, predict process drift before quality escapes, and integrate SPC data with maintenance workflows.

Frequently Asked Questions

What's the difference between Cp and Cpk in press line monitoring?

Cp measures process potential—the ratio of specification width to process variation, assuming perfect centering. Cpk measures actual capability by accounting for how far your process mean has shifted from target. A press might have Cp of 1.5 (tight variation) but Cpk of only 1.0 if running off-center. Predictive monitoring tracks both because Cp shows what's possible while Cpk shows what's actually happening.

What Cpk value should automotive stamping operations target?

The Automotive Industry Action Group (AIAG) requires minimum Cpk of 1.33 for critical characteristics in PPAP submissions—approximately 66 PPM defects. Many OEMs require 1.67 for safety-critical components (under 1 PPM). World-class operations target 2.0+, achieving Six Sigma levels where the process uses only 50% of available tolerance.

How does predictive Cpk monitoring integrate with existing press controls?

Modern predictive SPC platforms connect through standard industrial protocols—OPC-UA, Ethernet/IP, or direct PLC communication. The system collects data from tonnage monitors, servo feedback, and inline gauges without interrupting production. Most implementations achieve full connectivity within days using existing network infrastructure.

Can predictive monitoring detect problems before traditional SPC methods?

Yes—predictive systems typically identify process drift 30 minutes to 2 hours before traditional sampling would detect the same issue. Machine learning algorithms recognize subtle pattern combinations that precede capability degradation, enabling intervention before the first defective part is stamped.

What ROI can we expect from implementing predictive Cpk monitoring?

Automotive plants typically see ROI within 6-12 months through reduced scrap (30-40% improvement), fewer customer quality escapes, extended die life via condition-based maintenance, and improved OEE. With downtime exceeding $2 million per hour, preventing even one quality-related line stoppage can justify the entire investment.