The fire alarm panel in your main academic building triggers a ground fault trouble signal at 11:23 PM on Wednesday—a condition that's been degrading for three weeks. By Friday morning, the system fails during a routine test, forcing evacuation of 1,800 students mid-exam period while technicians scramble for replacement circuit boards. The fire marshal issues a citation. Students miss critical assessments. Your facilities director explains to the board why preventable equipment failure disrupted campus operations. Post-incident analysis reveals detector sensitivity had been drifting for six weeks, backup battery voltage declining for two months, and communication latency increasing for 90 days—degradation patterns that predictive maintenance would have caught, that IoT sensors would have flagged, and that AI analytics would have escalated before a $47,000 disruption materialized on your incident report.

Educational institutions manage fire alarm systems protecting thousands of lives daily while operating under budget constraints that discourage proactive investment. Campus facilities teams react to failures rather than preventing them—dispatching technicians after smoke detectors malfunction, replacing components after they've caused false alarms, and documenting problems only when fire marshals identify them during annual inspections. This reactive posture creates a dangerous cycle: deferred maintenance accelerates system degradation, increasing failure rates that trigger more emergency repairs, consuming budgets that could have funded predictive programs.

This guide establishes predictive maintenance frameworks that transform campus fire alarm management from compliance liability into operational excellence. Institutions implementing these protocols achieve 60-75% reduction in false alarms, 85% fewer emergency repairs, and audit-ready documentation demonstrating continuous system oversight. Facilities teams ready to modernize fire safety management can sign up free to implement condition-based maintenance with automated failure prediction and compliance tracking.

Your fire alarm system protects thousands of students and staff. Are you discovering problems through false alarms and system failures, or predicting them before they impact campus safety?

The Campus Fire Alarm Reliability Challenge

Educational facilities face unique fire alarm system pressures that commercial buildings rarely experience. Systems must protect high-density occupancies including mobility-impaired individuals, operate continuously through all seasons and weather conditions, withstand student tampering and accidental activations, and maintain compliance with increasingly stringent life safety codes—all while demonstrating responsible stewardship of limited public or tuition-funded budgets.

Chronic False Alarm Crisis

Average campus buildings experience 4-12 false alarms annually, disrupting 500-2,000 occupants per event, consuming 15-30 minutes of instructional time, and desensitizing students to real emergencies through repeated unnecessary evacuations.

Aging Infrastructure Reality

Approximately 35-45% of educational facilities operate fire alarm systems exceeding 15 years of age—well beyond typical 10-12 year replacement cycles—with components experiencing accelerated failure rates and limited spare parts availability.

Budget Constraint Pressure

Facilities departments face competing demands for limited capital funding. Fire alarm upgrades compete with HVAC replacements, roof repairs, and technology infrastructure—creating maintenance deferral that increases long-term costs and safety risks.

Regulatory Compliance Burden

NFPA 72 mandates specific inspection and testing frequencies. Fire marshals issue citations for incomplete documentation, overdue maintenance, or system deficiencies—creating liability exposure and reputational risk for institutional leadership.

From Reactive to Predictive: The Paradigm Shift

Traditional fire alarm maintenance operates on fixed calendars—quarterly inspections, annual testing, component replacement at predetermined intervals regardless of actual condition. This approach wastes resources replacing functional equipment while missing degrading components between scheduled checks. Predictive maintenance inverts this model: continuous monitoring detects degradation in real-time, AI analytics forecast failure timelines, and condition-based interventions occur at optimal moments before problems impact operations. Facilities implementing predictive approaches can try free IoT-enabled maintenance tracking with automated alerts and work order generation.

| Maintenance Approach | Detection Method | Intervention Timing | Typical Outcome |

|---|---|---|---|

| Reactive (Run-to-Failure) | Component fails, alarm triggers, occupants complain | Emergency response after operational impact | Maximum disruption, highest cost, safety exposure |

| Preventive (Time-Based) | Calendar schedules trigger inspections | Fixed intervals regardless of condition | Some early replacements, failures between checks |

| Predictive (Condition-Based) | Continuous sensor monitoring with AI analysis | Just-in-time service based on degradation patterns | Optimal resource use, minimal disruption, maximum reliability |

IoT Sensor Applications for Fire Alarm Systems

Modern IoT sensors transform fire alarm components from silent failure points into continuously monitored assets generating predictive intelligence. Sensors attach to existing equipment without system modifications, capturing performance data that reveals degradation weeks before failures occur. This continuous visibility eliminates the blind spots between scheduled inspections while creating audit evidence of ongoing system oversight.

Predictive Monitoring Applications by Component

Deployment Timeline: Campus fire alarm IoT sensor deployment typically completes in 4-8 weeks depending on building count. Systems begin generating predictive alerts within 2-3 weeks as baseline patterns establish. Start free trial to plan your sensor deployment strategy.

AI Analytics: Turning Sensor Data Into Predictive Intelligence

IoT sensors generate massive data streams—thousands of readings daily across hundreds of devices campus-wide. AI analytics transform this raw data into actionable intelligence, identifying subtle degradation patterns that human analysis would miss, predicting failure timelines with statistical confidence, and prioritizing interventions based on risk severity and operational impact. Machine learning algorithms continuously refine predictions as they accumulate historical data, improving accuracy over time while adapting to campus-specific usage patterns and environmental conditions.

Baseline Establishment

What is "normal" operation for each component in your specific environment?

- AI learns typical performance ranges during initial monitoring period (14-21 days)

- Accounts for environmental variables (temperature, humidity, occupancy patterns)

- Recognizes legitimate variations vs. anomalous degradation

- Establishes device-specific baselines rather than generic thresholds

- Continuously updates baselines as conditions change (seasonal, renovation)

Anomaly Detection

Which deviations indicate developing problems vs. normal operational variance?

- Statistical algorithms flag readings outside expected ranges

- Pattern recognition identifies gradual trends vs. sudden shifts

- Correlation analysis links related anomalies across multiple sensors

- False positive suppression prevents alert fatigue

- Severity scoring prioritizes critical vs. informational alerts

Failure Prediction

How much time remains before degradation causes operational failure?

- Machine learning models predict failure probability over time windows

- Historical failure data refines prediction accuracy

- Multi-variable analysis considers compound failure modes

- Confidence intervals quantify prediction certainty

- Recommended action timelines balance risk vs. disruption

Root Cause Analysis

Why is this component degrading and what systemic factors contribute?

- AI identifies common factors across similar failures campus-wide

- Environmental correlation reveals installation or design issues

- Maintenance history analysis highlights ineffective procedures

- Vendor component tracking identifies widespread defects

- Corrective action recommendations prevent recurrence

Continuous Improvement

How does the system become more accurate and valuable over time?

- Feedback loops refine models based on actual vs. predicted outcomes

- Campus-specific failure libraries build institutional knowledge

- Seasonal pattern recognition improves environmental adjustments

- Benchmark comparisons identify performance optimization opportunities

- Predictive maintenance ROI tracking quantifies program value

Transform thousands of daily sensor readings into clear action priorities. AI analytics tell you exactly which systems need attention and when.

Risk Scoring Framework for Predictive Maintenance

AI-generated risk scores aggregate multiple data streams into single actionable metrics that guide maintenance prioritization. Rather than overwhelming facilities teams with individual sensor alerts, risk scoring synthesizes degradation patterns, failure probability, operational impact, and compliance consequences into clear priority rankings. This enables optimal resource allocation—addressing highest-risk issues first while managing lower-priority items through standard PM cycles.

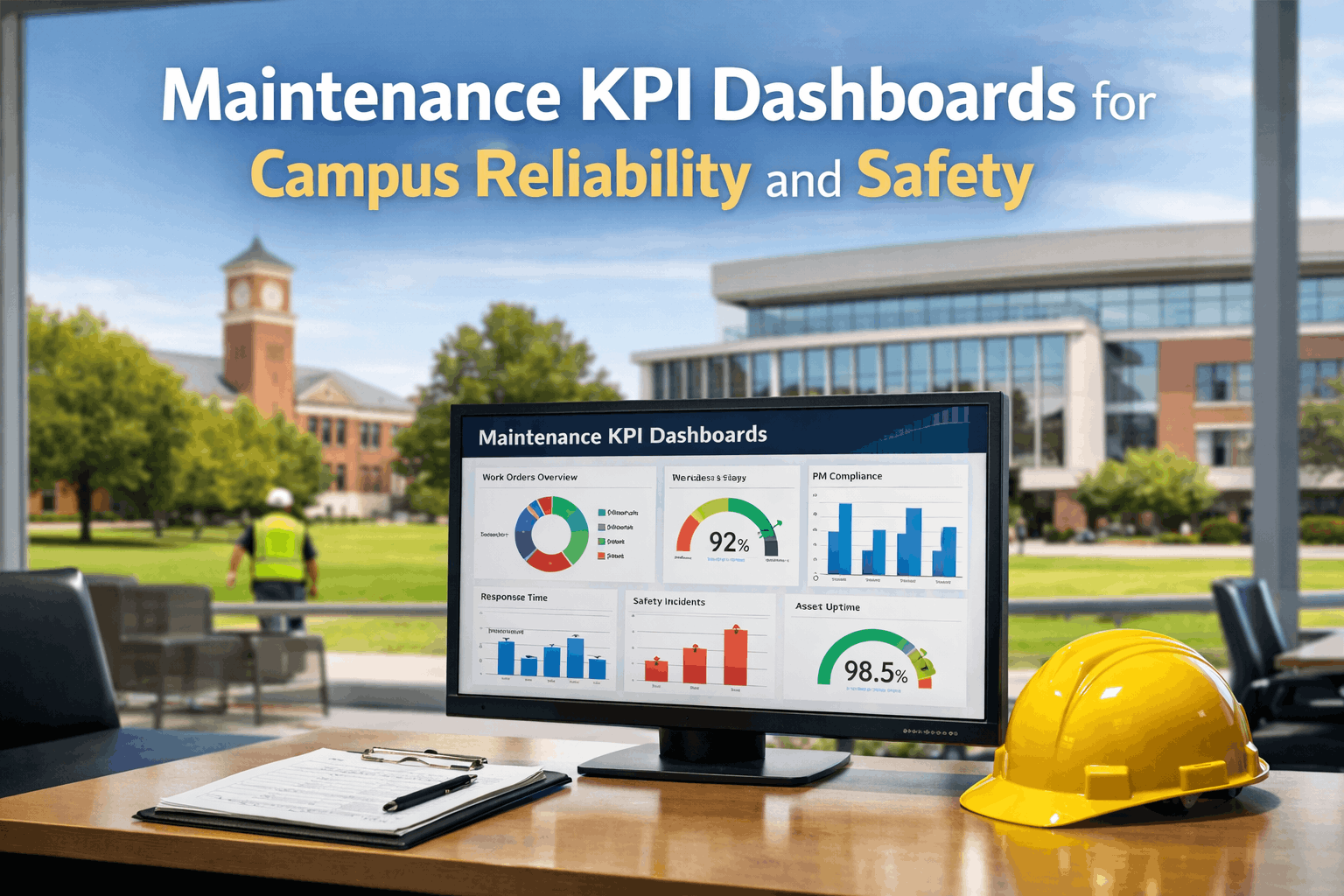

Predictive Maintenance KPIs: Measuring Program Success

Effective predictive maintenance programs require continuous measurement against defined targets. These KPIs demonstrate value to administration, guide resource allocation decisions, and satisfy auditors requesting performance evidence. Institutions tracking these metrics can sign up free to access automated dashboards with real-time visibility into fire safety system performance and predictive maintenance ROI.

False Alarm Reduction

Target: 65-75% decreaseYear-over-year reduction in non-emergency alarm activations through predictive cleaning, calibration, and component replacement before degradation causes false trips

Emergency Repair Elimination

Target: 85%+ reductionDecrease in after-hours emergency service calls and crisis repairs through proactive intervention before critical failures occur

System Availability

Target: 99.95%+ uptimePercentage of time all campus fire alarm systems remain fully operational and code-compliant without impairment or out-of-service conditions

Prediction Accuracy

Target: 90%+ confirmedPercentage of AI-predicted failures that manifest within forecasted timeframes when left unaddressed, validating model reliability

Mean Time to Detect

Target: <24 hoursAverage time from degradation onset to AI alert generation, demonstrating early warning system effectiveness

Cost per Building

Target: 40-60% savingsTotal fire alarm maintenance costs (emergency + planned service + parts) normalized per protected square footage, comparing predictive vs. reactive periods

Implementation Roadmap: From Concept to Campus-Wide Deployment

Successful predictive maintenance programs follow phased approaches that prove value before scaling investment. Starting with pilot buildings validates technology, refines processes, and generates data demonstrating ROI to stakeholders before campus-wide expansion. This de-risks implementation while building organizational confidence and expertise.

Pilot Selection

Weeks 1-2Identify 1-2 pilot buildings with chronic false alarm issues or aging systems, establish baseline metrics, secure stakeholder buy-in, configure initial sensor deployment

Sensor Deployment

Weeks 3-5Install IoT sensors on critical components, integrate with CMMS platform, establish alert thresholds, train facilities staff on dashboard interpretation and response protocols

Validation Phase

Weeks 6-18Monitor predictive alerts, respond to flagged issues, document outcomes, refine AI models based on campus patterns, measure KPI improvements, calculate ROI

Campus Expansion

OngoingRoll out sensors to additional buildings prioritized by risk/value, leverage pilot learnings, establish enterprise dashboards, integrate predictive maintenance into capital planning

Real-World Impact: Mid-Size University (12 Buildings, 8,500 Students)

Your campus fire alarm systems can operate with the reliability you need and the documentation you're required to maintain. Predictive maintenance delivers both.

Frequently Asked Questions

Q: Do we need to replace our existing fire alarm system to implement predictive maintenance?

No—IoT sensors retrofit onto existing equipment regardless of manufacturer or system age. Sensors attach externally to control panels, detectors, and other components without modifying core fire alarm infrastructure. The predictive maintenance platform integrates with your current CMMS and work order systems rather than replacing them. Even 20-year-old conventional systems can benefit from sensor-based condition monitoring. Try free to assess your current system compatibility.

Q: How does predictive maintenance affect NFPA 72 compliance requirements?

Predictive maintenance enhances rather than replaces NFPA 72 requirements. You still perform all mandated inspections, testing, and maintenance activities—but predictive monitoring identifies issues between scheduled checks, improving overall system reliability. The continuous monitoring data strengthens compliance documentation by demonstrating ongoing oversight beyond minimum code requirements. Fire marshals increasingly view predictive programs favorably as evidence of serious life safety commitment.

Q: What level of false alarm reduction should we realistically expect?

Educational institutions implementing predictive maintenance typically achieve 60-75% false alarm reduction within 12-18 months. Exact results depend on baseline conditions—facilities with chronic contamination issues see faster improvement than those with random component failures. The key driver is catching detector drift, control panel issues, and environmental factors before they trigger nuisance alarms. Most campuses reach target performance within 6-9 months as AI models learn building-specific patterns. Schedule a demo to see prediction modeling based on your campus data.

Q: How do we justify predictive maintenance costs during tight budget periods?

Build the business case around avoided costs rather than new investment. Calculate current emergency repair expenses, false alarm response fees, fire marshal violation remediation, and occupant disruption costs. For most campuses, eliminating 3-5 emergency service calls annually pays for basic sensor deployment. Add false alarm reduction savings (average $1,500-3,000 per event when including response, disruption, and PR impact) and payback typically occurs within 10-15 months. Start with a single high-problem building to prove ROI before requesting campus-wide funding.

Q: What happens if our facilities staff doesn't have technical expertise in IoT or AI?

Modern predictive maintenance platforms are designed for facilities professionals, not IT specialists. Dashboards present clear action recommendations ("Detector in Building 4, Zone 3 needs cleaning within 2 weeks") rather than raw sensor data. Training typically requires 2-4 hours for basic competency. AI runs in the background generating alerts—staff simply respond to prioritized work orders as they would any maintenance task. The system becomes smarter over time without requiring technical configuration from your team.

Q: Can predictive maintenance help with our capital planning for system replacements?

Yes—this is one of the most valuable but overlooked benefits. Sensor data reveals which buildings have systems degrading fastest, which components fail most frequently, and which environmental factors accelerate wear. This intelligence informs strategic replacement priorities rather than age-based assumptions. You can also monitor partially-upgraded systems to verify performance improvements, extending legacy equipment life where appropriate while targeting problem areas for capital investment. Multi-year trending helps forecast replacement timing and budget requirements with confidence.

.png)