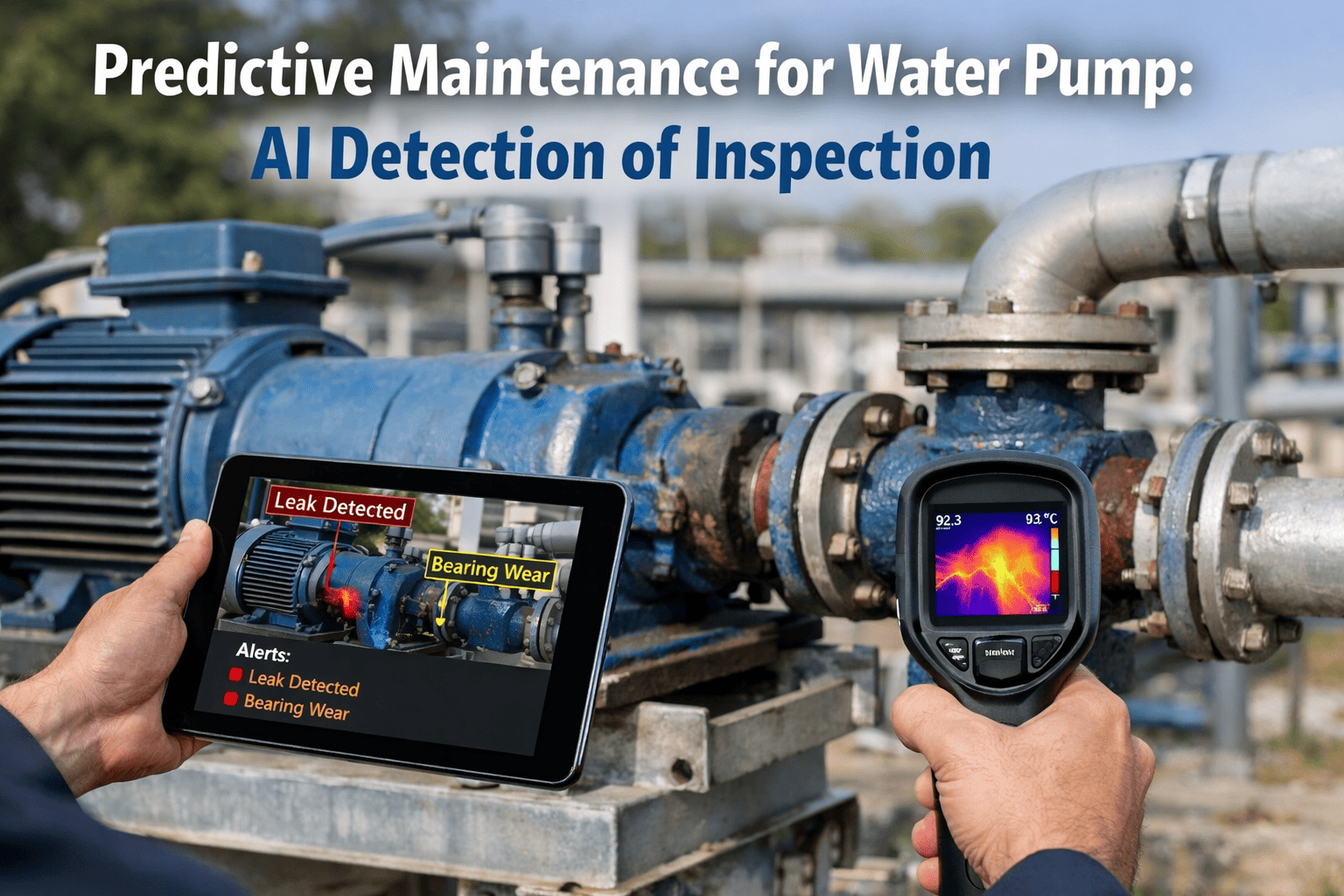

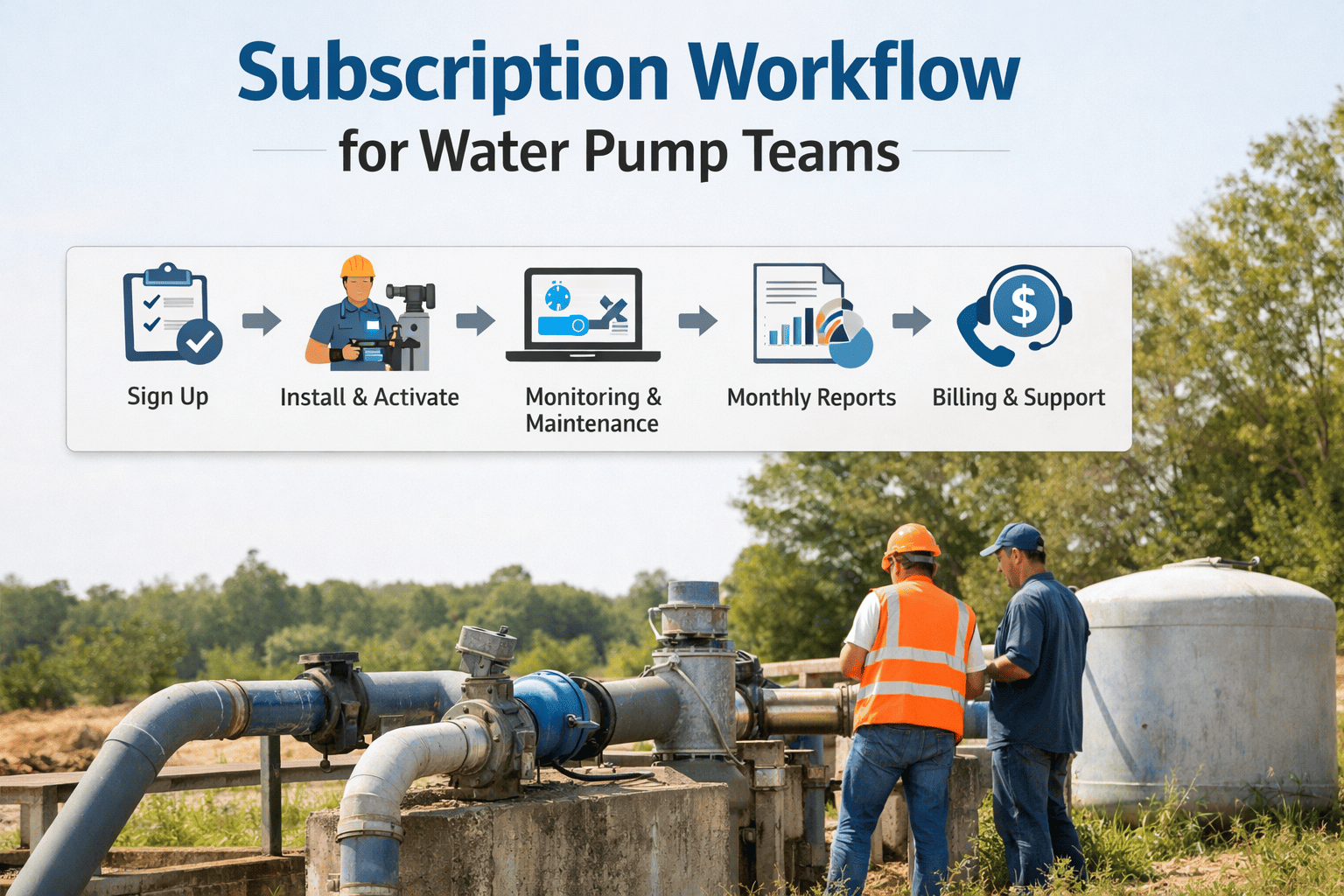

Traditional water pump maintenance relies on fixed schedules and reactive repairs—waiting for failures before taking action. This approach leads to unexpected downtime, costly emergency repairs, and shortened equipment lifespan. Predictive maintenance powered by AI transforms pump management by detecting early warning signs before failures occur, enabling proactive intervention when repairs are simplest and cheapest.

Oxmaint delivers AI-powered predictive maintenance for water pumps with intelligent inspection detection that identifies developing problems weeks before failure. Machine learning algorithms analyze vibration patterns, temperature trends, and operational data to predict bearing wear, seal degradation, and impeller damage with remarkable accuracy. Teams using Oxmaint AI detection reduce unplanned pump failures by 85% and cut maintenance costs by 40%. Start free to bring predictive intelligence to your pump maintenance today.

AI Detection Categories

Predictive AI monitors multiple failure modes simultaneously. Each detection category uses specialized algorithms trained on thousands of pump failure patterns. Understanding these categories helps teams prioritize sensor deployment and response protocols.

AI detection enables maintenance teams to schedule repairs during planned downtime windows. Schedule a demo to see how Oxmaint AI identifies developing problems before they cause failures.

Predictive Sensor Integration

Effective AI prediction requires continuous data from strategically placed sensors. Oxmaint integrates with all major industrial sensor platforms. Start free to connect your existing sensors to AI analysis.

Vibration Sensors

Triaxial accelerometers detect bearing defects, imbalance, misalignment, and cavitation through advanced spectral analysis algorithms.

Temperature Sensors

RTD and thermocouple sensors track thermal patterns indicating friction increases, lubrication breakdown, and electrical issues.

Power Monitors

Current signature analysis detects motor winding issues, rotor bar defects, and mechanical load changes affecting pump performance.

Pressure Transmitters

Suction and discharge pressure monitoring reveals developing blockages, impeller wear, and system resistance changes.

Flow Meters

Non-invasive flow measurement tracks pump efficiency degradation and identifies developing impeller or wear ring problems.

Edge Gateway

Industrial edge computing aggregates sensor data, performs initial AI analysis, and transmits insights to cloud platform.

Connect Your Sensors to AI

Oxmaint integrates with 200+ sensor types and protocols for comprehensive predictive coverage.

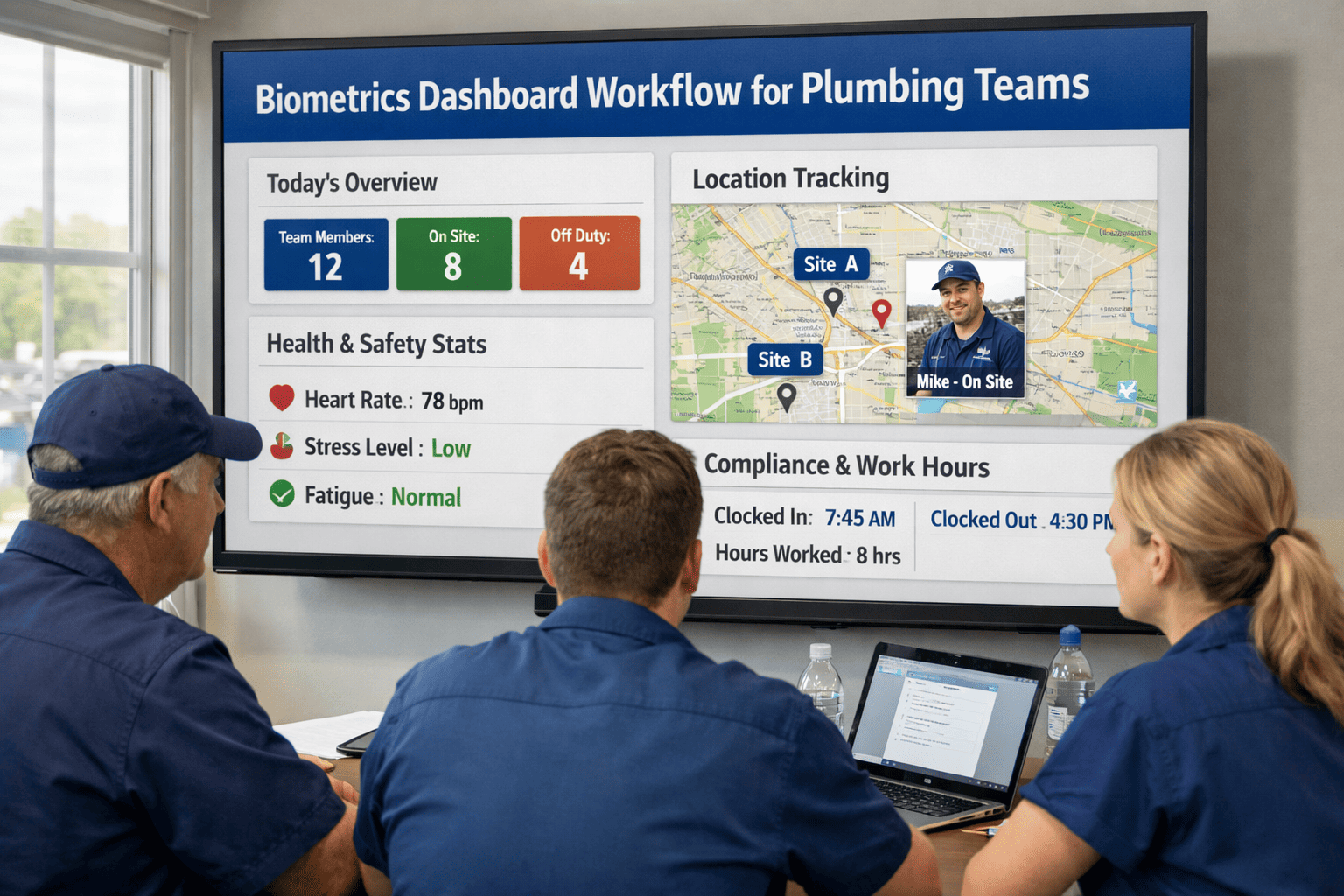

AI Prediction Dashboard

Monitor AI health scores, failure predictions, and recommended actions across your entire pump fleet in real-time.

How AI Detection Works

Machine learning transforms raw sensor data into actionable maintenance predictions. Book a demo to see the AI analysis workflow in action.

Data Collection

Sensors continuously stream vibration, temperature, pressure, and power data to edge gateways at high frequency.

Pattern Analysis

AI algorithms analyze data patterns, comparing against baseline signatures and known failure progression models.

Failure Prediction

Machine learning models calculate remaining useful life and predict specific failure modes with confidence intervals.

Automated Response

System generates work orders, alerts technicians, orders parts, and schedules repairs before failure occurs.

AI Detection Capabilities

Oxmaint AI identifies specific failure signatures that traditional monitoring misses. These detection capabilities protect your most critical pump assets.

AI Health Score Grading

AI continuously calculates health scores for each pump based on all monitored parameters. Start free to enable AI health scoring across your pump fleet.