Your maintenance supervisor walks into Monday's meeting with concerning news: "Our packaging line went down for six hours Friday, and we discovered the bearing failure could have been prevented with proper maintenance scheduling." You review last month's unplanned downtime—18 hours total costing $47,000 in lost production—but struggle to identify which maintenance management approach could prevent these expensive disruptions without overwhelming your limited resources. Without systematic maintenance planning and cost-effective solutions, you are essentially reactive to equipment failures that threaten your business profitability.

This scenario repeats across small manufacturing businesses nationwide as operations struggle to balance maintenance effectiveness with resource constraints and budget limitations. The average small manufacturing facility loses 15-20% of potential production capacity to unplanned downtime, but comprehensive maintenance management often seems beyond reach due to complexity and cost concerns.

Small businesses implementing strategic CMMS solutions achieve 40-60% reductions in unplanned downtime while decreasing maintenance costs by 25-35% compared to those relying on reactive maintenance approaches. The key lies in selecting appropriate CMMS technology, establishing efficient maintenance processes, and leveraging automation that matches small business operational realities and resource availability.

Discover how small manufacturers are achieving 60% downtime reduction with the right CMMS strategy—see what's possible for your operation!

Start Your Maintenance TransformationSee Live CMMS Demo

Understanding CMMS for Small Business Operations

Effective CMMS implementation for small businesses requires understanding how computerized maintenance management systems address specific operational challenges without creating administrative burden. These systems extend far beyond simple work order tracking to include asset management, predictive analytics and resource optimization tailored for smaller operational scales.

Traditional maintenance approaches often fail small businesses due to resource limitations and competing priorities. However, modern CMMS solutions deliver sophisticated capabilities through user-friendly interfaces that require minimal IT infrastructure and training investment while providing enterprise-level functionality.

Preventive Maintenance Scheduling

Automated scheduling based on time, usage, or condition triggers. Prevents 70-80% of equipment failures while optimizing technician productivity and parts inventory management.

Asset Lifecycle Management

Complete equipment history tracking from installation to retirement. Enables data-driven replacement decisions and warranty management saving 15-25% on equipment costs.

Work Order Management

Streamlined request processing, priority management, and completion tracking. Improves response times by 50% while ensuring critical repairs receive appropriate attention.

Inventory Optimization

Parts tracking, automatic reordering, and cost management. Reduces inventory carrying costs by 20-30% while preventing stockouts that delay repairs.

Performance Analytics

Real-time dashboards and maintenance KPIs. Identifies improvement opportunities and validates maintenance strategy effectiveness through data-driven insights.

Mobile Accessibility

Smartphone and tablet access for field technicians. Eliminates paperwork, improves data accuracy, and enables real-time communication between maintenance and operations teams.

Cloud-based CMMS solutions eliminate IT infrastructure requirements while providing automatic updates and data backup. Small businesses achieve enterprise-level capabilities without dedicated IT staff or significant hardware investment, making sophisticated maintenance management accessible and affordable.

Integration capabilities with existing business systems enable comprehensive operational visibility. Modern CMMS platforms connect with accounting, inventory, and production systems to provide unified business intelligence that supports better decision-making across all operational areas.

Cost-Effectiveness and ROI Analysis for Small Businesses

Establishing CMMS value for small businesses requires understanding both direct cost savings and operational improvements that impact profitability. Investment requirements, implementation complexity, and return timelines vary significantly based on business size, equipment complexity, and current maintenance maturity levels.

Small business CMMS solutions offer scalable pricing models that align costs with operational size and complexity. Understanding cost structures and value creation potential enables better investment decision-making and realistic ROI expectations for different implementation approaches.

| Business Size | Monthly CMMS Cost | Implementation Time | Expected ROI Timeline | Primary Benefits |

|---|---|---|---|---|

| 5-15 Assets | $150 - $300/month | 2-4 weeks | 6-9 months | Prevent breakdowns, organize maintenance |

| 15-50 Assets | $300 - $600/month | 4-8 weeks | 8-12 months | Reduce downtime 40%, optimize scheduling |

| 50-150 Assets | $600 - $1,200/month | 6-12 weeks | 9-15 months | Predictive analytics, inventory optimization |

| 150+ Assets | $1,200 - $2,500/month | 8-16 weeks | 12-18 months | Advanced analytics, full automation |

Hidden costs of reactive maintenance significantly exceed CMMS investment for most small businesses. Emergency repairs typically cost 3-5x more than planned maintenance, while unplanned downtime can cost $500-2,000 per hour depending on production value and customer commitments.

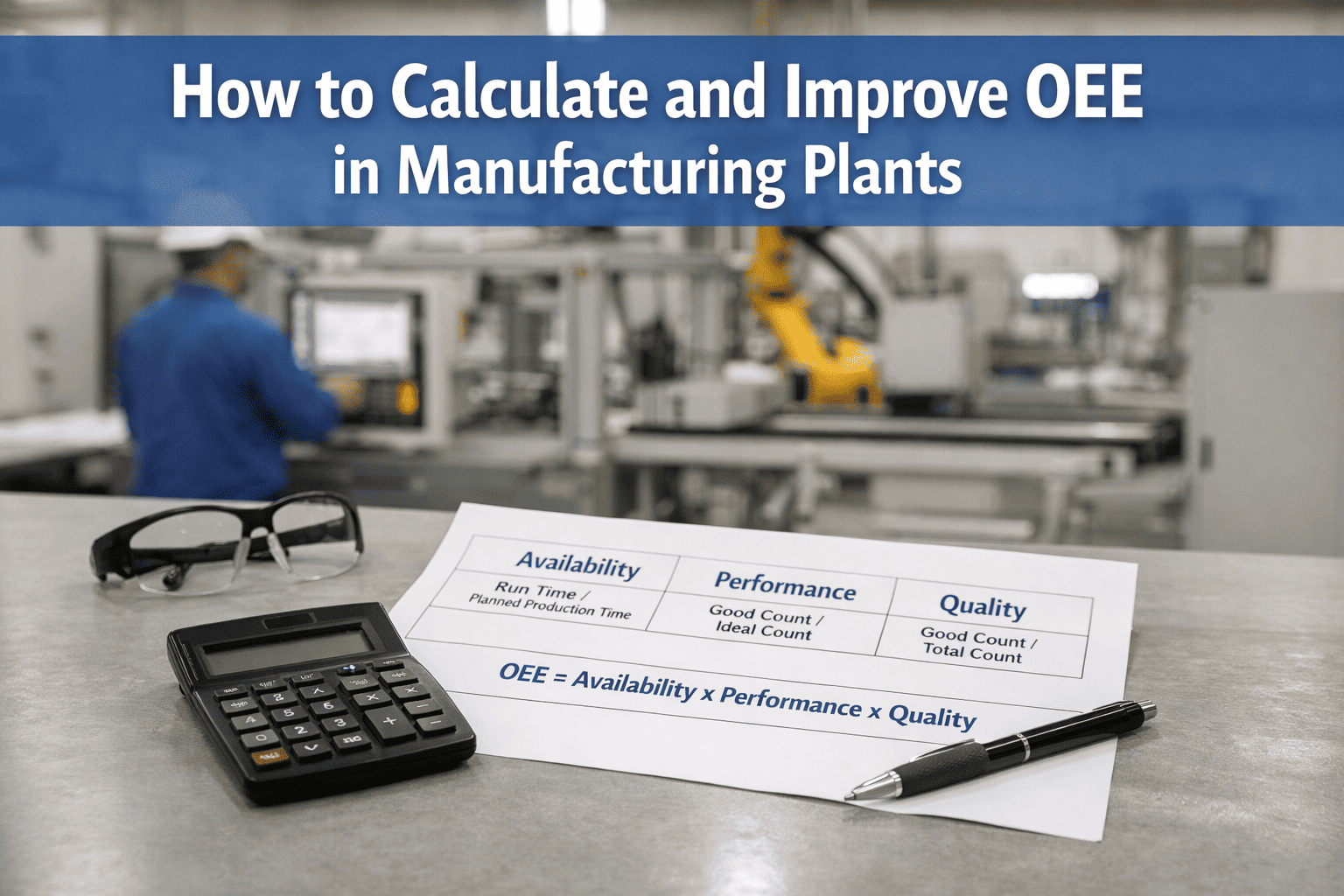

Productivity improvements through better maintenance planning often exceed direct cost savings. Small businesses report 15-25% improvements in overall equipment effectiveness (OEE) through systematic maintenance approaches enabled by CMMS functionality.

Scalability advantages enable small businesses to grow maintenance capabilities alongside business expansion. Cloud-based solutions accommodate increasing asset counts, user additions, and functionality requirements without major system changes or infrastructure investment.

Implementation Framework for Small Business Success

Creating successful CMMS deployment requires systematic approach balancing functionality needs with implementation simplicity. Small businesses achieve better results through phased implementations that deliver immediate value while building organizational capabilities for advanced features.

Resource allocation and timeline planning enable smooth transitions from reactive to proactive maintenance. Proper implementation framework reduces disruption while ensuring user adoption and system effectiveness that delivers promised benefits.

CMMS Implementation Process

Data migration and system setup require careful planning to ensure accuracy and completeness. Small businesses benefit from starting with critical assets and expanding systematically rather than attempting comprehensive data entry before system launch.

Software Licensing

60-70% of total project cost for cloud-based CMMS subscription and user licenses

Implementation Services

15-20% for setup assistance, configuration, and initial data entry support

Training Programs

10-15% for user training, documentation, and change management activities

Integration Costs

5-10% for connecting with existing accounting, inventory, or production systems

Hardware/Mobile

3-8% for tablets, smartphones, or barcode scanners enabling mobile functionality

Contingency

5-10% reserve for unexpected requirements and system customization needs

User adoption strategies significantly impact implementation success rates. Small businesses achieve 90%+ adoption rates through hands-on training, gradual rollout, and demonstrating immediate value rather than overwhelming users with advanced features initially.

Vendor support and partnership quality often determine long-term success. Small businesses should prioritize CMMS providers offering comprehensive support, regular training resources, and proven track records with similar-sized operations rather than focusing solely on feature comparisons.

Optimization Strategies and Competitive Advantages

Strategic CMMS optimization extends beyond basic implementation to continuous improvement and capability expansion that creates sustainable competitive advantages. Small businesses leverage CMMS data and automation to achieve maintenance excellence typically associated with larger operations while maintaining operational agility and cost effectiveness.

Predictive maintenance capabilities enabled by modern CMMS platforms allow small businesses to transition from reactive to proactive strategies. Data-driven maintenance decisions reduce emergency repairs while optimizing maintenance intervals based on actual equipment condition rather than generic manufacturer recommendations.

Proven Small Business CMMS Optimization Strategies

- Implement condition-based maintenance reducing unnecessary service by 30-40%

- Establish automated reorder points preventing stockouts while minimizing inventory

- Create performance dashboards enabling real-time maintenance decision-making

- Develop preventive maintenance schedules optimized for actual usage patterns

- Integrate CMMS with production scheduling for coordinated planned downtime

- Establish vendor management reducing procurement time and improving pricing

- Build maintenance knowledge base capturing institutional expertise

- Enable mobile work order completion improving technician productivity 25%

Competitive differentiation through superior equipment reliability enables small businesses to offer better service levels and delivery commitments than competitors relying on reactive maintenance. Consistent production capability becomes a significant competitive advantage in customer relationships and market positioning.

Cost structure optimization through systematic maintenance management enables more competitive pricing while maintaining profitability margins. Small businesses reduce total cost of ownership for production equipment while improving capacity utilization through reduced downtime.

Scalability preparation through CMMS implementation enables small businesses to handle growth without proportional increases in maintenance overhead. Systematic processes and data management support facility expansion and equipment additions without compromising maintenance effectiveness.

2025 Trends Benefiting Small Business CMMS Users

- AI-powered failure prediction becoming accessible through cloud-based solutions

- Mobile-first design improving field technician productivity and data accuracy

- Integration marketplaces simplifying connections with business systems

- Subscription pricing models reducing upfront investment requirements

- Industry-specific templates accelerating implementation timelines

- Regulatory compliance automation reducing administrative burden

Knowledge management and documentation capabilities preserve maintenance expertise and enable consistent service quality. Small businesses build institutional knowledge that survives personnel changes while improving training effectiveness for new maintenance team members.

Performance measurement and continuous improvement processes ensure CMMS investments deliver sustained value rather than one-time improvements. Regular review of maintenance KPIs enables ongoing optimization and validates system effectiveness for continued business value creation.

Conclusion

CMMS implementation for small businesses in 2025 provides accessible path to maintenance excellence previously available only to larger operations. Strategic CMMS adoption achieves 40-60% reductions in unplanned downtime while decreasing maintenance costs by 25-35% through systematic approaches that optimize resource utilization and equipment reliability.

Understanding small business requirements reveals that cloud-based CMMS solutions eliminate traditional barriers of cost, complexity, and IT infrastructure while providing enterprise-level functionality. Comprehensive maintenance management becomes achievable for businesses with 5-150 assets through scalable solutions matching operational size and budget constraints.

Cost-effectiveness analysis demonstrates clear ROI potential with typical returns of 300-500% within 18 months through reduced emergency repairs, improved equipment reliability, and optimized maintenance resource allocation. Investment requirements scale appropriately with business size, making sophisticated maintenance management accessible across all small business categories.

Implementation success requires structured approach balancing immediate value delivery with long-term capability building. Phased deployment, comprehensive training, and vendor partnership quality significantly impact adoption rates and benefit realization timelines for small business implementations.

Optimization strategies focus on leveraging CMMS data and automation for competitive advantage through superior equipment reliability, cost optimization, and scalability preparation. Small businesses position themselves for growth while achieving operational excellence through systematic maintenance management.

The 2025 technology environment provides unprecedented opportunities for small businesses to implement sophisticated maintenance management solutions. Cloud-based platforms, mobile accessibility, and AI-powered analytics enable small operations to achieve maintenance excellence while maintaining resource efficiency and operational flexibility essential for small business success.

Transform your maintenance operations today—join hundreds of small manufacturers already saving thousands monthly with proven CMMS solutions!

Begin Your Maintenance RevolutionWatch Success Stories Demo