Manufacturing operations today demand unprecedented levels of efficiency, precision, and uptime. As equipment becomes increasingly complex and interconnected, traditional diagnostic methods are proving insufficient for modern manufacturing challenges. Smart glass technology emerges as a transformative solution, offering manufacturing professionals an innovative approach to equipment diagnostics that combines augmented reality with real-time data analytics.

This cutting-edge technology overlays critical diagnostic information directly onto your field of view, enabling technicians to diagnose equipment issues faster, more accurately, and with greater confidence than ever before. From predictive maintenance alerts to step-by-step repair guidance, smart glass is reshaping how manufacturing professionals interact with their equipment and data.

Understanding Smart Glass Technology in Manufacturing Context

Smart glass technology, also known as augmented reality (AR) glasses or mixed reality headsets, represents a paradigm shift in how manufacturing professionals access and interact with equipment data. These wearable devices project digital information directly into the user's field of view, creating an immersive experience where real-world equipment and digital diagnostics coexist seamlessly.

In manufacturing environments, smart glass devices connect to existing industrial IoT networks, SCADA systems, and maintenance management platforms. This integration allows technicians to view real-time sensor data, historical performance metrics, maintenance schedules, and diagnostic alerts without looking away from the equipment they're servicing.

Real-Time Equipment Monitoring and Data Visualization

One of the most significant advantages of smart glass technology lies in its ability to present complex equipment data in an intuitive, visual format. Traditional monitoring systems require technicians to switch between multiple screens, dashboards, and physical gauges, creating opportunities for oversight and inefficiency.

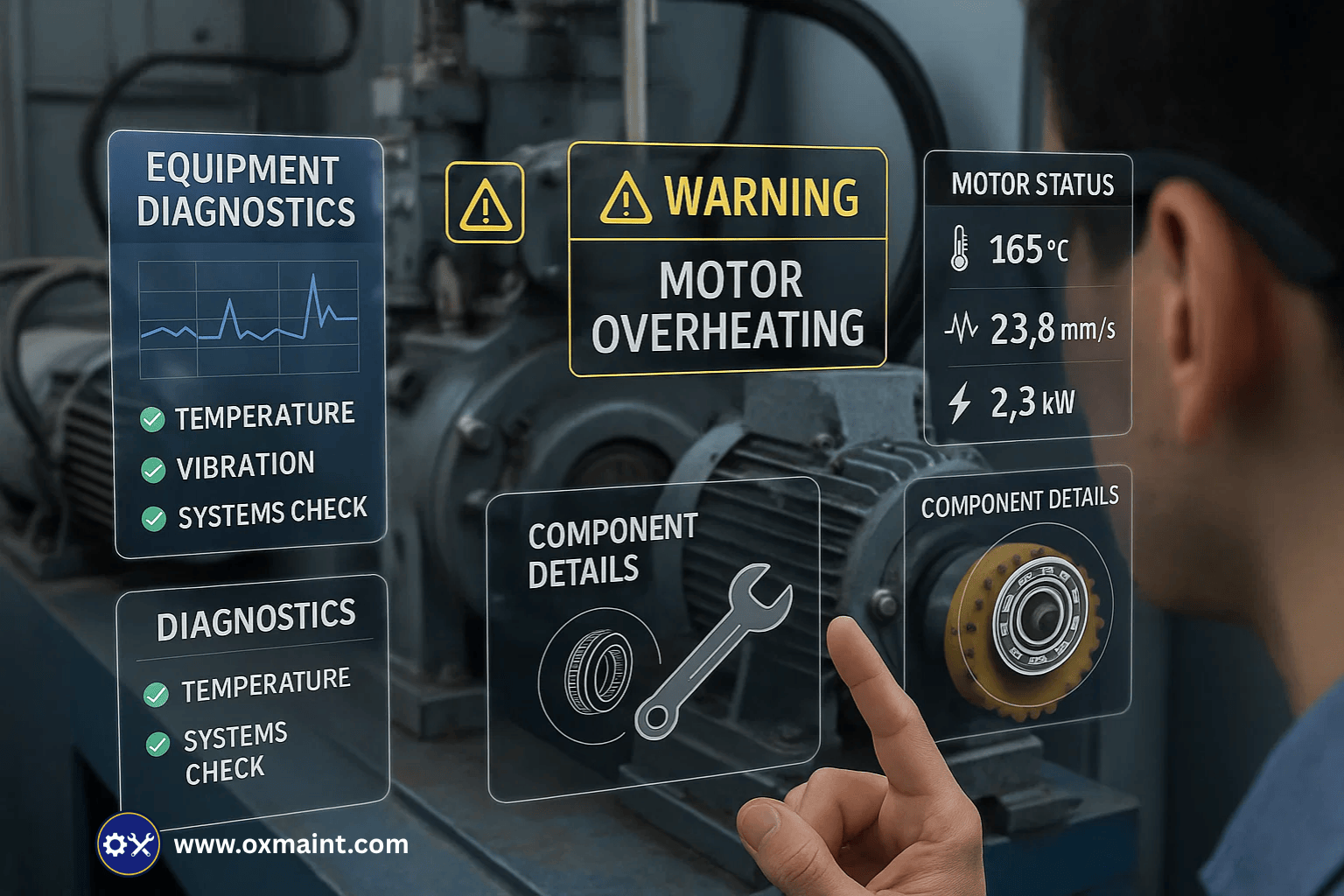

Smart glass eliminates these challenges by overlaying critical metrics directly onto equipment components. Temperature readings appear next to heating elements, vibration data displays alongside rotating machinery, and pressure measurements show up precisely where sensors are located. This contextual data presentation reduces interpretation errors and enables faster decision-making.

Manufacturing facilities utilizing smart glass technology report 25-40% faster diagnostic procedures and significantly improved accuracy in equipment assessments. The technology excels particularly in complex manufacturing environments where multiple systems operate simultaneously, providing technicians with unprecedented visibility into interconnected equipment performance.

Enhanced Predictive Maintenance Capabilities

Predictive maintenance represents the holy grail of manufacturing operations, and smart glass technology brings this concept to life through advanced analytics and machine learning integration. By analyzing patterns in equipment behavior, smart glass systems can identify potential failures before they occur, displaying predictive alerts directly in the technician's field of view.

These systems leverage historical data, current operating conditions, and sophisticated algorithms to calculate equipment health scores and failure probabilities. When maintenance is required, smart glass provides detailed guidance on necessary procedures, required parts, and optimal scheduling to minimize production disruption.

Manufacturing benefits include: Reduced unplanned downtime by up to 50%, extended equipment lifespan through optimized maintenance timing, improved spare parts inventory management, and enhanced technician training through immersive, hands-on experiences.

Streamlined Maintenance Workflows and Documentation

Traditional maintenance documentation processes often involve paper-based checklists, separate digital systems, and time-consuming data entry tasks that pull technicians away from their primary responsibilities. Smart glass technology revolutionizes these workflows by integrating documentation directly into the maintenance process.

Technicians can access step-by-step maintenance procedures through voice commands or gesture controls, capture photos and videos of equipment conditions hands-free, and update maintenance records in real-time without interrupting their work. This seamless integration ensures accurate documentation while maintaining focus on equipment servicing.

Quality control processes benefit significantly from smart glass implementation. The technology guides technicians through standardized inspection procedures, automatically documents compliance checkpoints, and flags any deviations from established protocols. This systematic approach reduces human error and ensures consistent maintenance quality across all equipment and personnel.

Safety Improvements and Risk Mitigation

Manufacturing safety takes on new dimensions with smart glass technology, as these devices provide continuous access to safety information without requiring technicians to divert their attention from potentially hazardous equipment. Safety protocols, emergency procedures, and hazard warnings can be displayed contextually based on the technician's location and the equipment being serviced.

Smart glass systems integrate with facility safety systems to provide real-time alerts about environmental conditions, equipment status, and potential dangers. When approaching equipment with elevated temperatures, toxic gases, or high-voltage components, technicians receive immediate visual and auditory warnings along with appropriate safety guidelines.

Cost-Benefit Analysis and ROI Considerations

Implementing smart glass technology requires significant initial investment, but manufacturing organizations consistently report strong returns through operational improvements and cost reductions. The technology's impact spans multiple operational areas, creating cumulative benefits that justify implementation costs within 12-18 months for most facilities.

Direct cost savings emerge from reduced equipment downtime, improved maintenance efficiency, and decreased need for specialized technical support. Manufacturing facilities typically see 15-30% reduction in maintenance costs and 20-45% improvement in first-time fix rates when implementing smart glass solutions.

Indirect benefits include improved technician productivity, enhanced knowledge transfer between experienced and new personnel, and better regulatory compliance through standardized documentation processes. These factors contribute to long-term operational excellence and competitive advantage in manufacturing markets.

Conclusion

Smart glass technology represents a fundamental shift in how manufacturing professionals approach equipment diagnostics and maintenance. By seamlessly integrating digital information with physical equipment, this technology empowers technicians to work more efficiently, safely, and effectively than ever before.

The convergence of augmented reality, IoT connectivity, and advanced analytics creates unprecedented opportunities for manufacturing optimization. Organizations that embrace smart glass technology position themselves at the forefront of Industry 4.0, gaining competitive advantages through improved operational efficiency, reduced costs, and enhanced safety performance.

As manufacturing complexity continues to increase and skilled technician shortages persist, smart glass technology offers a scalable solution that enhances human capabilities rather than replacing them. The future of manufacturing diagnostics is here, and it's visible through smart glass.

Frequently Asked Questions

What types of manufacturing equipment can benefit from smart glass diagnostics?

Smart glass technology works with virtually any equipment that generates data through sensors or monitoring systems. This includes CNC machines, conveyor systems, HVAC equipment, pumps, compressors, robots, and process control systems. The technology is particularly effective with complex machinery that requires frequent monitoring or has multiple operational parameters.

How does smart glass technology integrate with existing maintenance management systems?

Smart glass platforms typically offer API integrations with popular CMMS, ERP, and SCADA systems. The integration allows real-time data synchronization, automatic work order updates, and seamless access to historical maintenance records. Most implementations require minimal changes to existing workflows while significantly enhancing data accessibility and documentation accuracy.

What is the typical implementation timeline for smart glass technology in manufacturing facilities?

Implementation timelines vary based on facility size and complexity, but most manufacturers see initial deployment within 4-8 weeks. This includes system integration, technician training, and pilot program execution. Full facility rollout typically occurs over 3-6 months, allowing for gradual adoption and continuous optimization of workflows and procedures.

How does smart glass technology perform in harsh manufacturing environments?

Modern smart glass devices are designed specifically for industrial environments, featuring rugged construction, chemical resistance, and protection against dust, moisture, and temperature extremes. Most devices meet IP65 or higher ratings and can operate in temperatures ranging from -20°C to 60°C, making them suitable for most manufacturing applications.

What training is required for technicians to effectively use smart glass technology?

Initial training typically requires 4-8 hours per technician, covering device operation, safety protocols, and basic troubleshooting. The intuitive nature of smart glass interfaces means most technicians become proficient within their first week of use. Ongoing training focuses on advanced features and system updates, usually requiring minimal time investment.