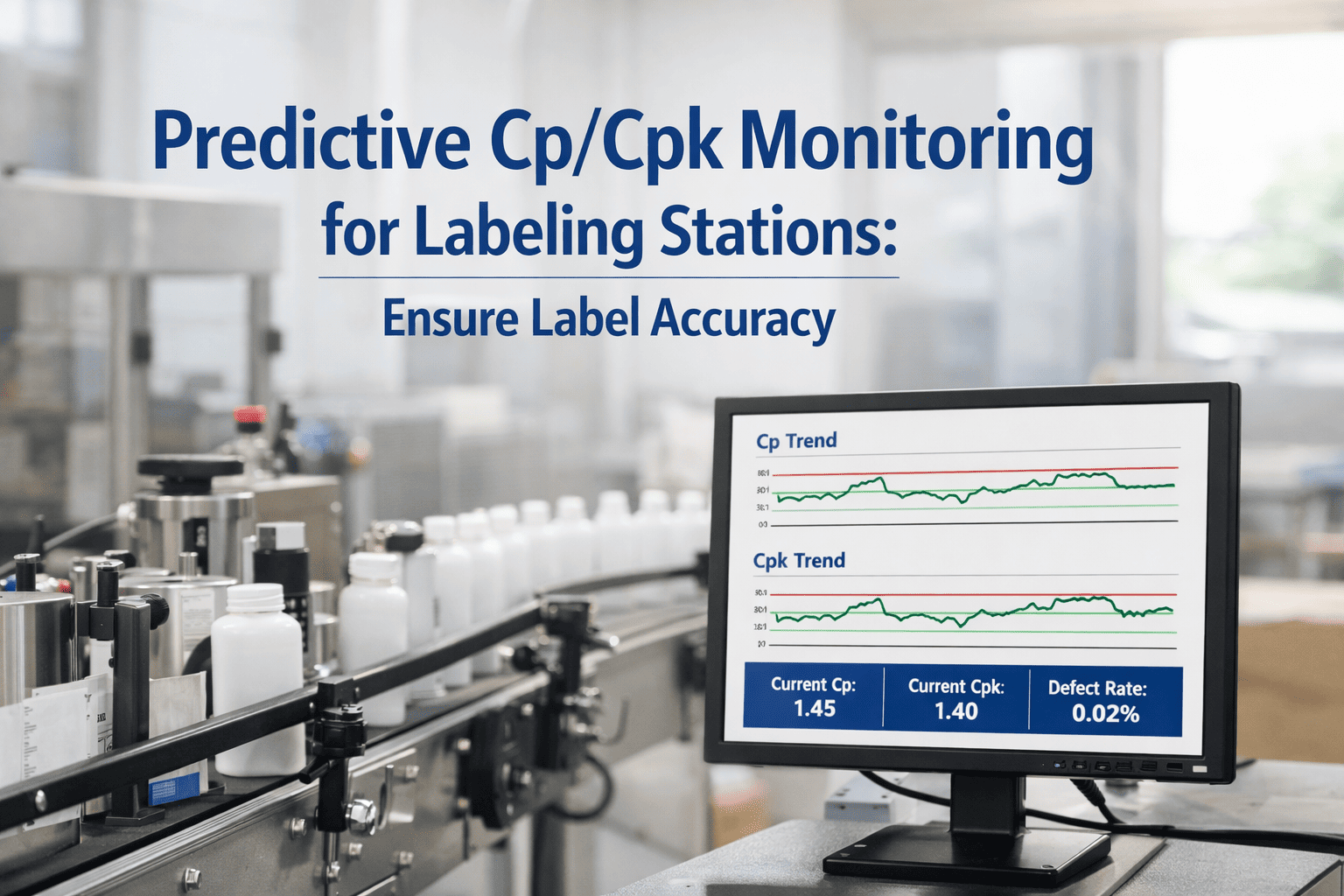

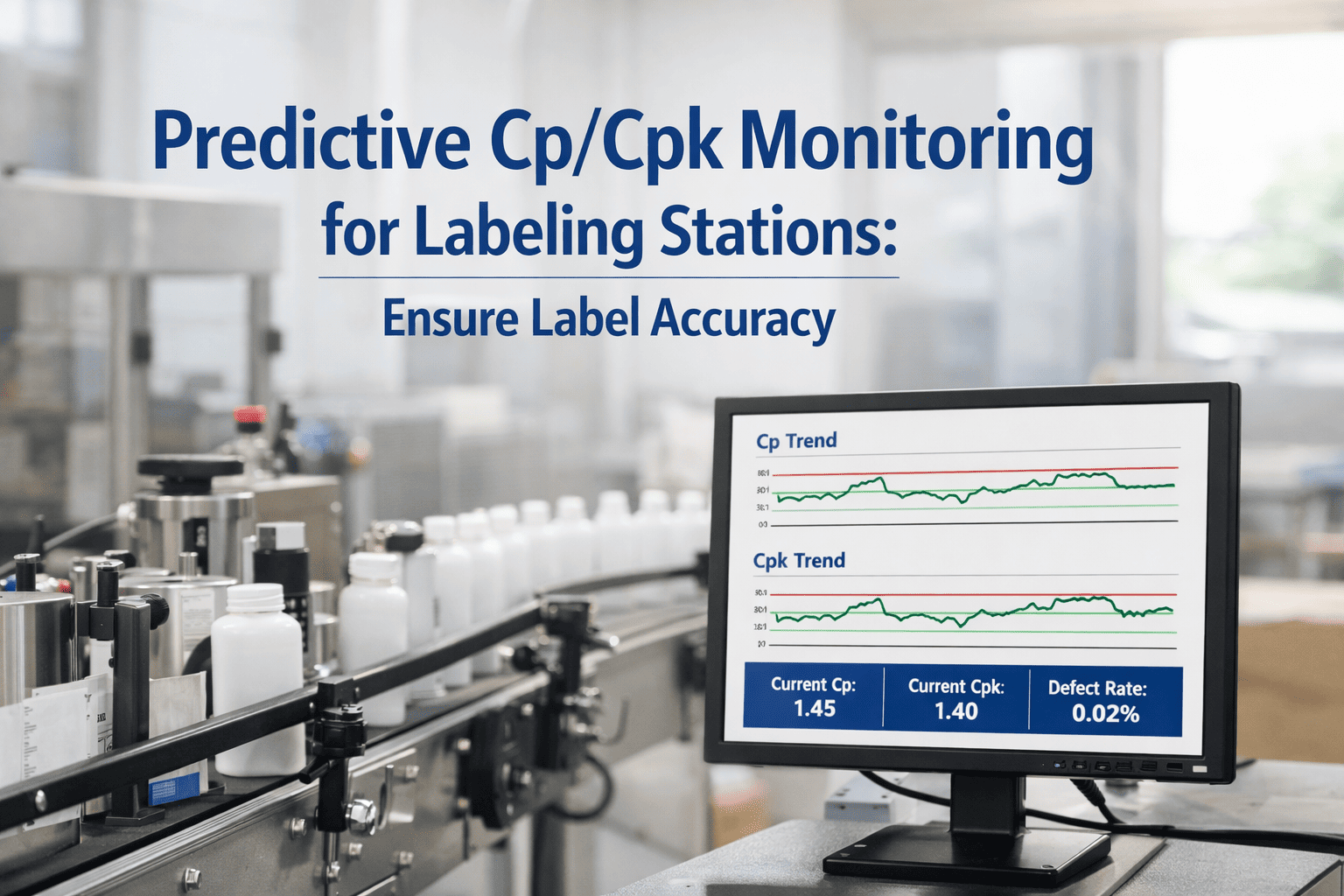

Every food and beverage manufacturer knows the nightmare scenario: thousands of mislabeled products shipped to retailers, a mandatory recall triggered, and millions lost overnight. The root cause is almost always the same—label placement drifted out of tolerance hours ago, and nobody caught it until the damage was done. Predictive Cp/Cpk monitoring changes this equation entirely by watching your labeling stations in real time, measuring process capability every few seconds, and alerting your team before a single defective label leaves the line. Schedule a consultation to see how predictive SPC can protect your labeling operations.

The Hidden Cost of Label Placement Drift

Labeling errors are the leading cause of food recalls in the United States, responsible for nearly 40% of all FDA enforcement actions. Yet most food plants still rely on periodic manual checks—sampling one container out of every hundred—to catch problems that develop gradually over hours or entire shifts. By the time an operator spots a crooked label or misaligned barcode, hundreds or thousands of defective units have already been packed and palletized.

What Cp and Cpk Actually Tell You About Your Labels

Process capability indices are the statistical backbone of labeling quality. Cp measures whether your labeling station has the potential to place labels within specification limits—think of it as measuring the width of your car versus the width of the garage. Cpk goes further by also checking whether the process is centered—whether the car is actually driving down the middle of the garage or veering dangerously close to one wall.

From Reactive Checks to Predictive Intelligence

The fundamental shift in predictive Cpk monitoring is timing. Traditional SPC tells you what already went wrong. Predictive monitoring analyzes the direction and speed of capability change to tell you what is about to go wrong—giving your team a 30 to 60 minute window to intervene before defects occur. Here is how the entire system works from sensor to corrective action.

What Gets Measured: Critical Label Parameters

A label is not just "on" or "off"—it has multiple measurable dimensions that each require their own Cpk tracking. Monitoring all parameters simultaneously ensures that a perfectly positioned label is not also rotated, skewed, or poorly adhered.

| Parameter | Typical Tolerance | Sensor Type | Target Cpk |

|---|---|---|---|

| X-Axis Position | +/- 1.5 mm | Machine vision camera | 1.67 or higher |

| Y-Axis Position | +/- 1.5 mm | Machine vision camera | 1.67 or higher |

| Rotation Angle | +/- 1.0 degree | Angular vision measurement | 1.50 or higher |

| Label Skew | +/- 0.5 degree | Edge detection algorithm | 1.33 or higher |

| Adhesion Strength | Minimum 2N peel force | In-line pressure sensor | 1.50 or higher |

| Barcode Readability | Grade C or better (ISO 15416) | OCV scanner | 1.33 or higher |

Where Manual Inspection Falls Short

The contrast between traditional periodic sampling and continuous predictive monitoring is not incremental—it is a fundamentally different approach to quality assurance that eliminates the blind spots inherent in manual methods.

Cpk Targets by Label Type and Risk Level

Not all labels carry the same risk. An allergen warning misplaced by 2mm could endanger a consumer with a life-threatening allergy. A slightly off-center brand label is a cosmetic issue. Your Cpk targets should reflect the actual risk each label type carries for your products and consumers.

| Label Type | Min Cpk | Recommended Cpk | Primary Risk |

|---|---|---|---|

| Allergen Warnings | 1.67 | 2.00 | Consumer safety—undeclared allergens can be fatal |

| Nutritional Facts Panels | 1.33 | 1.67 | FDA enforcement—illegible or misplaced panels trigger violations |

| Barcode and QR Labels | 1.50 | 1.67 | Supply chain halt—unscannable codes stop distribution |

| Date Code and Lot Marking | 1.33 | 1.50 | Traceability failure—incorrect codes undermine recall readiness |

| Tamper-Evident Seals | 1.50 | 2.00 | Food safety—improperly applied seals create contamination risk |

| Brand and Front-of-Pack | 1.00 | 1.33 | Brand perception—misaligned labels signal poor quality to consumers |

Measurable Impact on Labeling Operations

Predictive Cp/Cpk monitoring delivers returns that compound across multiple areas—reduced scrap, prevented recalls, faster changeover validation, and lower compliance costs. The investment typically pays for itself within the first prevented recall event.

Getting Started: Deployment in Three Phases

Implementing predictive Cpk monitoring does not require replacing your existing labeling equipment. The system layers onto your current infrastructure through vision sensors, data integration, and CMMS connectivity—delivering value within weeks, not months. Sign up for free to get started with Oxmaint.

Solving the Five Most Persistent Labeling Problems

Every food and beverage quality manager knows these challenges. Predictive Cpk monitoring provides specific, data-driven solutions to each one—not by adding more manual inspectors, but by giving your existing team earlier, more actionable intelligence.

| Problem | What Happens | How Predictive Cpk Solves It |

|---|---|---|

| Gradual applicator wear | Labels drift slowly over days or weeks, undetected until QC audit | Cpk trend analysis spots degradation weeks before tolerance breach—triggers proactive pad replacement via CMMS |

| Temperature-sensitive adhesive | Adhesion varies with seasonal or shift-based temperature changes | Correlation analytics link Cpk shifts to ambient conditions, enabling automatic adhesive temperature compensation |

| Container batch variation | Different substrate batches cause inconsistent label behavior | Per-batch Cpk recalculation distinguishes substrate issues from equipment issues for targeted correction |

| Post-changeover misalignment | Labels misaligned after product or label changeovers | Automatic post-changeover Cpk verification confirms capability before full-speed production resumes |

| Multi-line inconsistency | Parallel lines produce different quality levels | Cross-line Cpk benchmarking identifies underperformers and standardizes best practices across all stations |