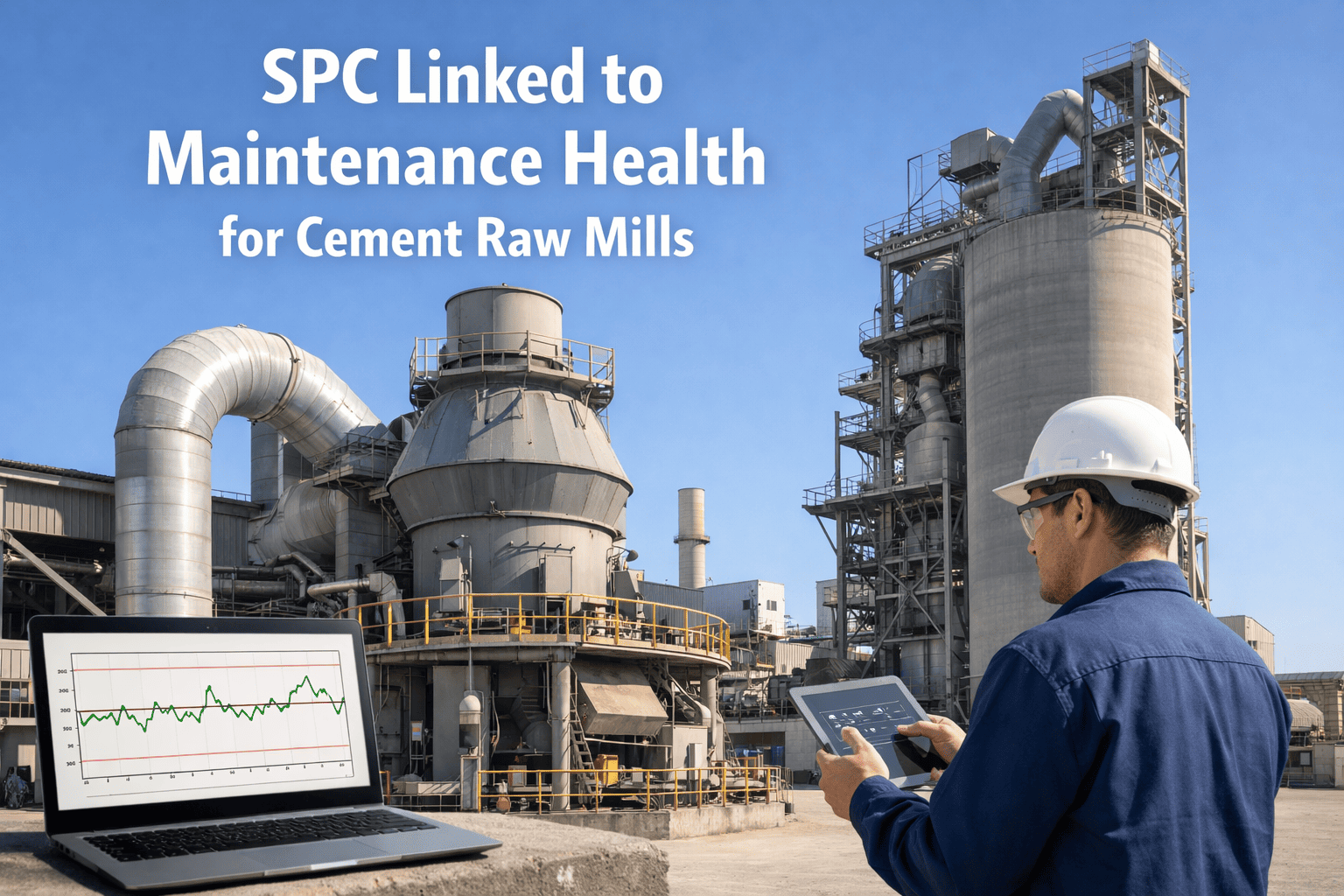

Every cement plant quality lab generates SPC data from raw mill operations—residue percentages, fineness values, chemical composition readings, and specific power consumption figures charted hour after hour. Yet in most plants, this data serves only one purpose: quality compliance. What if those same control charts held the key to predicting when your grinding media needs recharging, when your separator blades are wearing thin, or when your mill liners are weeks away from failure? Connecting SPC trends to raw mill maintenance health transforms reactive shutdowns into precisely timed interventions, saving cement operations hundreds of thousands in avoided downtime and emergency repairs. Schedule a consultation to discover how Oxmaint bridges the gap between your quality data and maintenance planning.

The Hidden Maintenance Intelligence Inside Your Control Charts

Raw mill SPC data contains far more information than quality teams typically extract. When grinding media wears down, residue values drift upward. When separator blades erode, variance in cut-point data expands. When liners degrade, power draw patterns shift. These signals appear on control charts weeks before a breakdown occurs, but without a system that connects SPC deviations to asset health models, they remain invisible to the maintenance team sitting one building away.

From Control Chart Violations to Maintenance Work Orders

The core innovation of SPC-linked maintenance is translating statistical signals into actionable repair and inspection tasks. Instead of waiting for a breakdown or relying on time-based schedules that often result in premature or late interventions, the system watches your control charts continuously and triggers work orders only when the data confirms real component degradation. Sign up for Oxmaint to start automating this quality-to-maintenance pipeline at your plant.

Which SPC Signals Reveal Which Failures

Not every process deviation points to the same maintenance issue. The power of SPC-linked asset health lies in mapping specific chart patterns to specific component wear modes. Here is how cement raw mill SPC parameters correlate with the most common failure mechanisms that maintenance teams need to address proactively.

| SPC Parameter | Chart Type | Pattern to Watch | Indicates | Maintenance Response |

|---|---|---|---|---|

| 90-micron Residue | X-bar + CUSUM | Gradual upward drift over 5-10 days | Grinding media mass loss and impact energy reduction | Schedule ball top-up or recharge |

| Specific Power (kWh/t) | EWMA | Sustained shift above historical mean | Liner wear reducing mill diameter; media depletion; higher circulation | Inspect liners; verify media charge level |

| Separator Cut-Point | R-chart | Expanding range / increased variance | Classifier blade erosion or rotor vane damage | Schedule separator internal inspection |

| Mill Differential Pressure | CUSUM | Step change or sudden shift | Diaphragm slot blockage; internal flow disruption; liner plate dislodgement | Emergency inspection if severe; planned stop if gradual |

| Vibration Amplitude | X-bar + Range | Cyclical pattern synced with mill RPM | Loose liner bolts; uneven media distribution; bearing wear | Tighten liners; rebalance charge; bearing assessment |

| Mill Sound Level (dB) | Individuals | Steady upward trend | Declining media charge level (less material cushioning) | Confirm with power data; plan media addition |

Grinding Media Wear: Reading the SPC Story

Grinding media is the single largest consumable cost in ball mill raw grinding, with wear rates ranging from 20 to 80 grams per tonne of material processed. Traditionally, charge condition is assessed only during mill shutdowns—meaning operators fly blind between inspections. SPC control charts, when properly calibrated, tell the complete wear story in real time without ever stopping the mill.

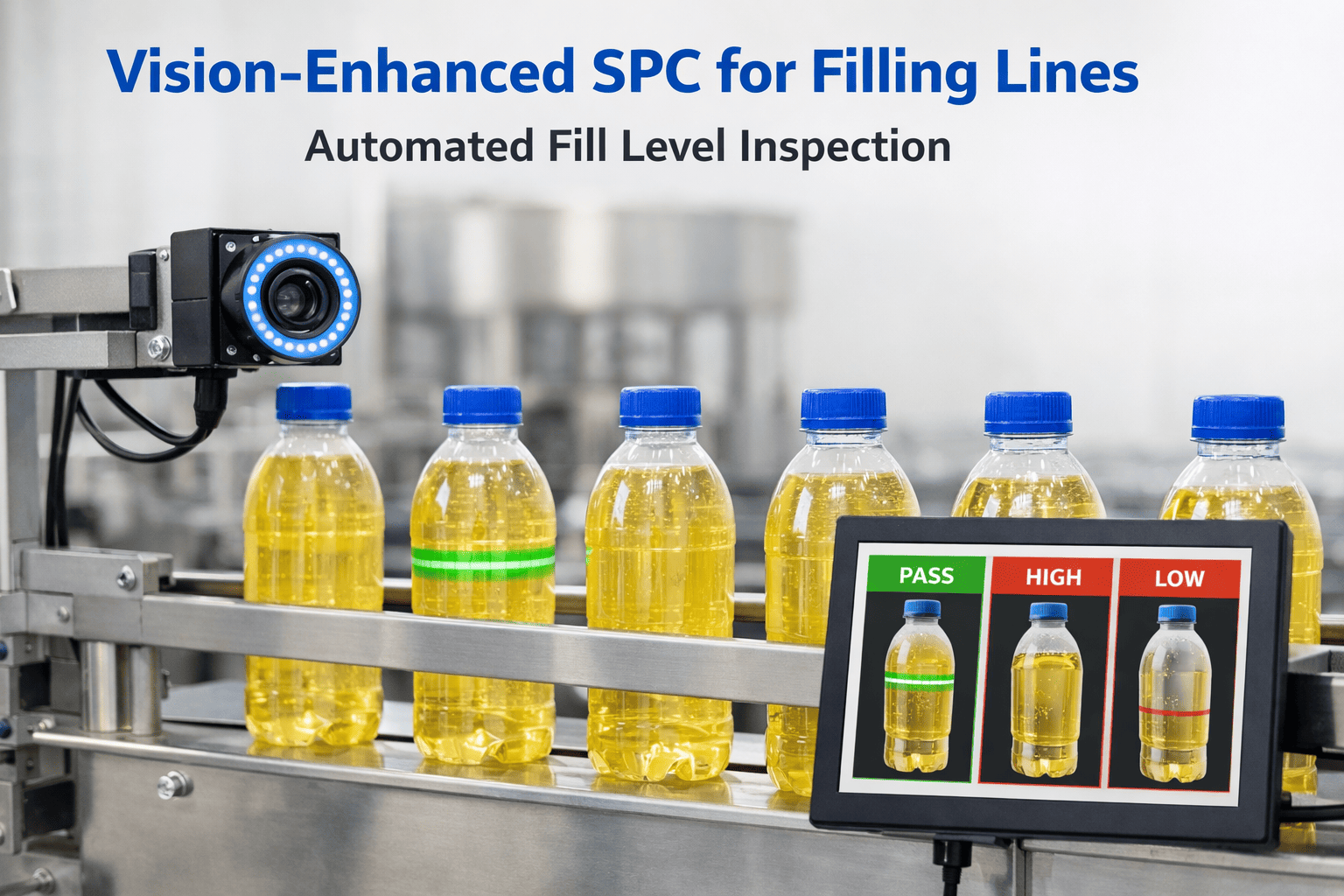

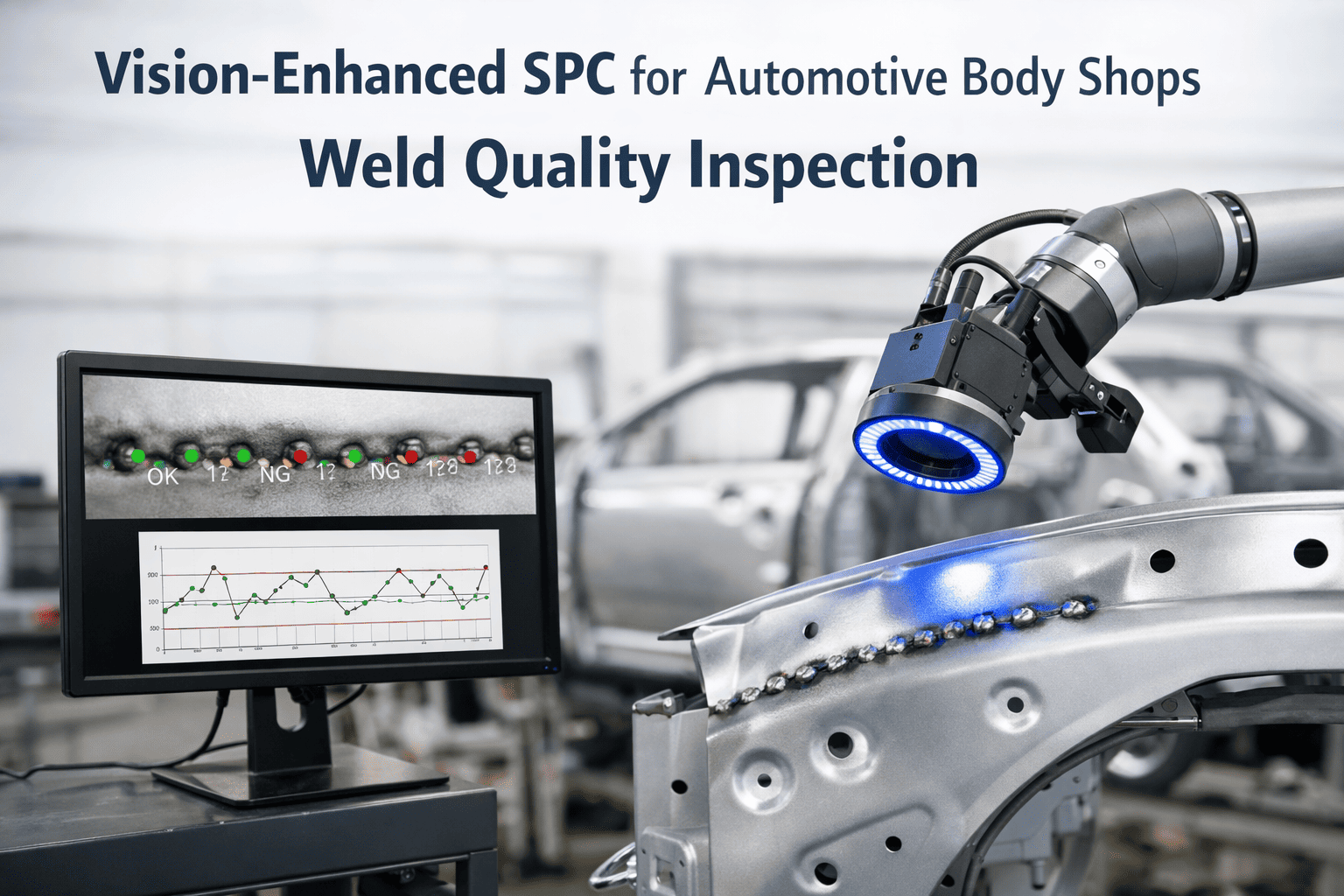

Separator Health Decoded Through Process Variance

The separator is the brain of the grinding circuit—classifying particles, controlling circulation load, and determining final product fineness. Unlike grinding media which degrades gradually, separator issues can manifest as either slow erosion (blade wear) or sudden events (vane cracking). SPC variance charts are uniquely suited to catching both failure modes early, because separator degradation always increases output variability before it shifts the mean.

Liner Wear Tracking Without Stopping the Mill

Mill liner replacement in a cement raw mill is a major maintenance event—typically requiring 3-7 days of downtime and $50,000 to $150,000 in direct costs for a ball mill. Getting the replacement timing right is critical: too early wastes remaining liner life, too late risks shell damage or catastrophic failure. SPC-linked health scoring enables continuous liner wear estimation between shutdowns using process signals that correlate with liner condition.

| Liner Zone | SPC Signal | What It Reveals | Validation Method |

|---|---|---|---|

| Lifting Liners (Chamber 1) | 212-micron residue drift upward on X-bar chart | Worn lifters reduce cascade height, weakening impact grinding in the coarse chamber | Visual inspection during next planned stop confirms reduced lifter profile |

| Classifying Liners (Chamber 2) | 90-micron residue increase with abnormal media sizing | Classification function lost—large and small balls no longer segregate properly along mill length | Media sorting during shutdown shows poor size distribution |

| Diaphragm Plates | Differential pressure step-change on CUSUM chart | Slot blockage or slot widening altering material flow between chambers | Airflow measurement at constant fan speed confirms flow change |

| Shell Plate Integrity | Vibration amplitude increase at 1x mill RPM frequency | Loose bolt connections or cracked plate allowing localized movement during rotation | External ultrasonic thickness measurement at flagged locations |

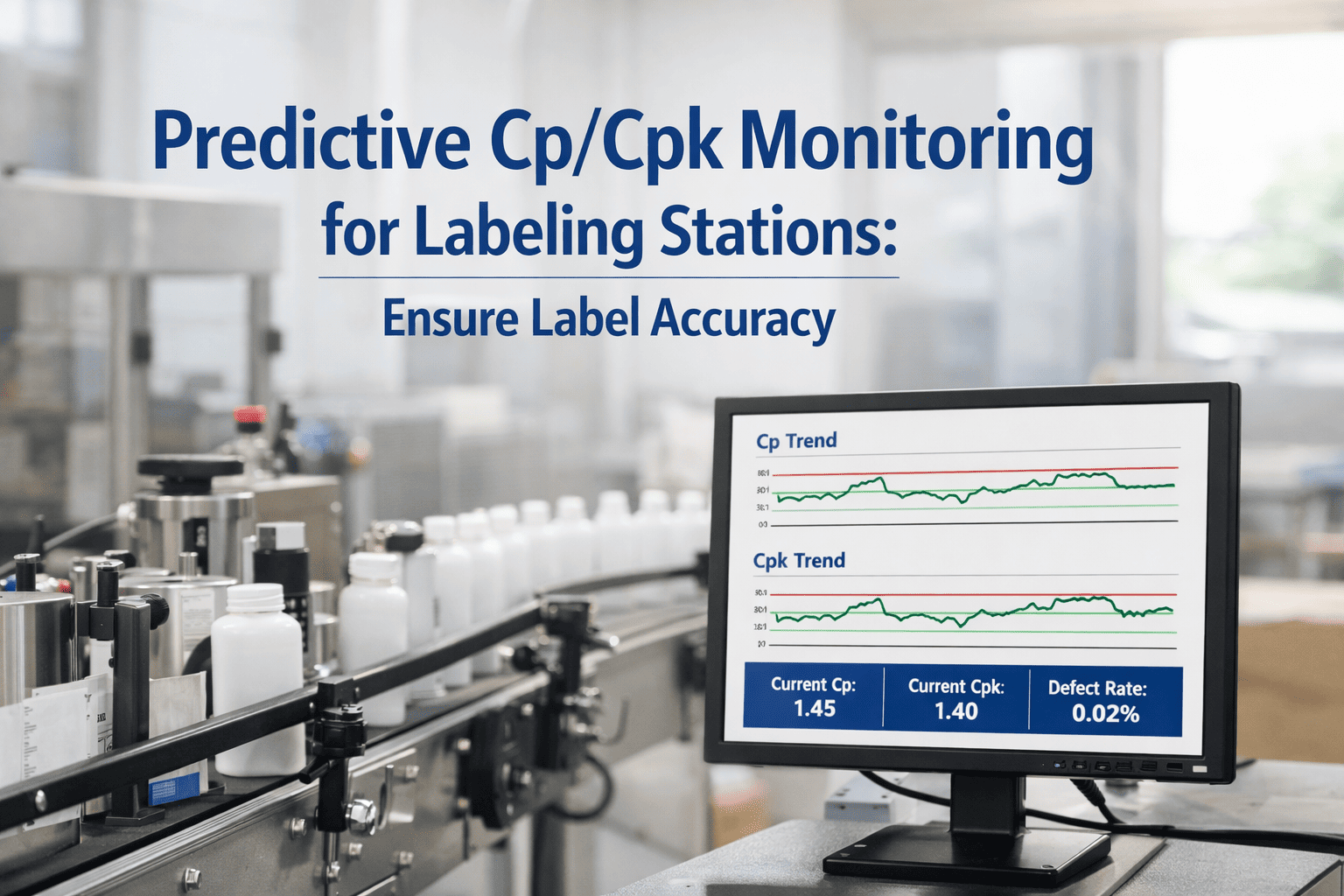

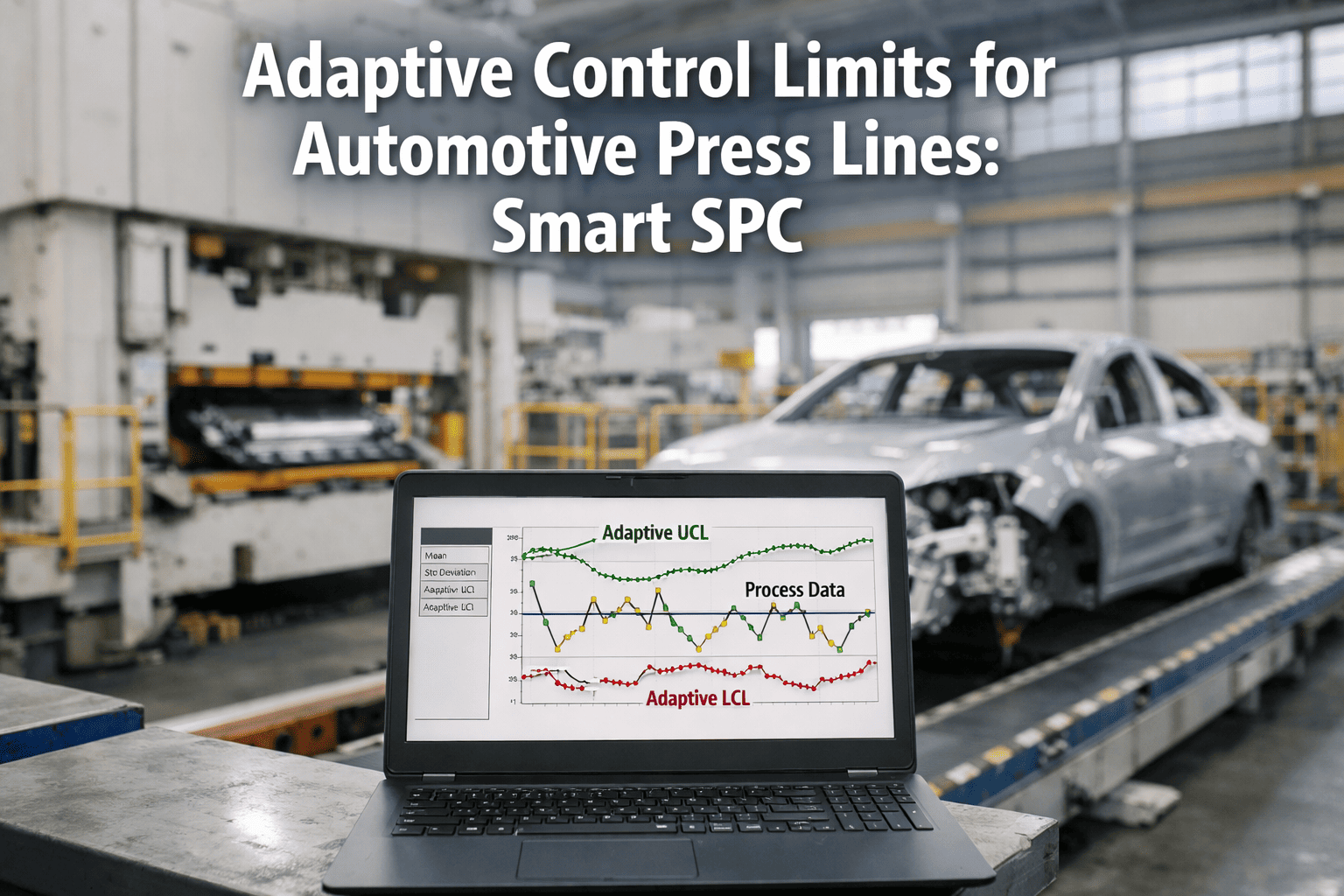

What Your Dashboard Should Look Like

An effective SPC + Asset Health dashboard for cement raw mills is not just another screen in the control room—it is the connective tissue between quality data and maintenance decisions. The best implementations give both teams a shared, real-time view that eliminates the communication gap responsible for most missed early-warning signals. Here is the modular layout Oxmaint recommends for sign up to get started with - cement plants with SPC-driven maintenance.

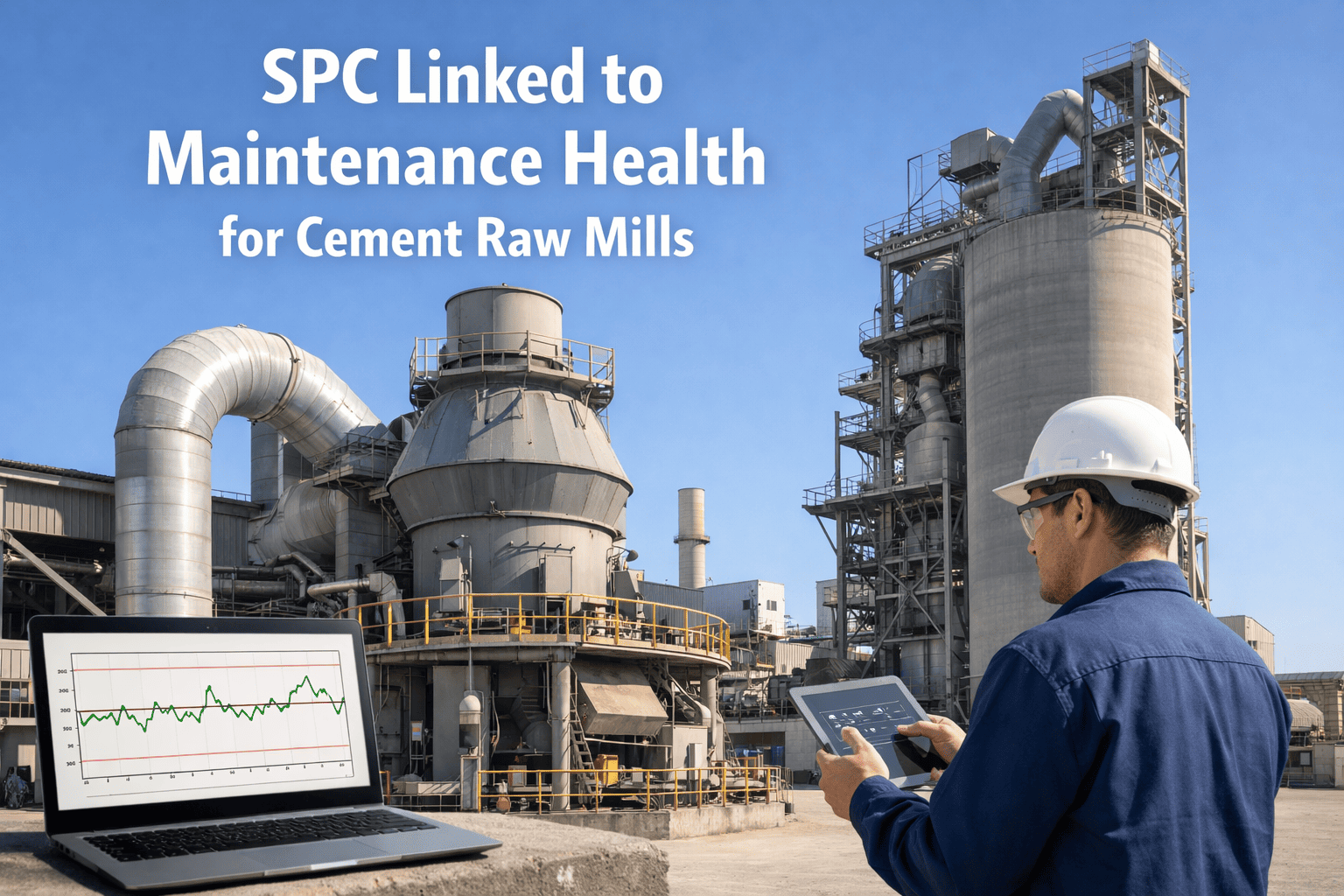

Getting Started: Your Plant in 6 Weeks

Deploying SPC-linked maintenance health monitoring does not require replacing your existing quality systems or installing new sensors. Most cement plants already have 80% of the data needed—it just needs to be connected to asset health models and your CMMS. Schedule a consultation to map out your specific implementation path.