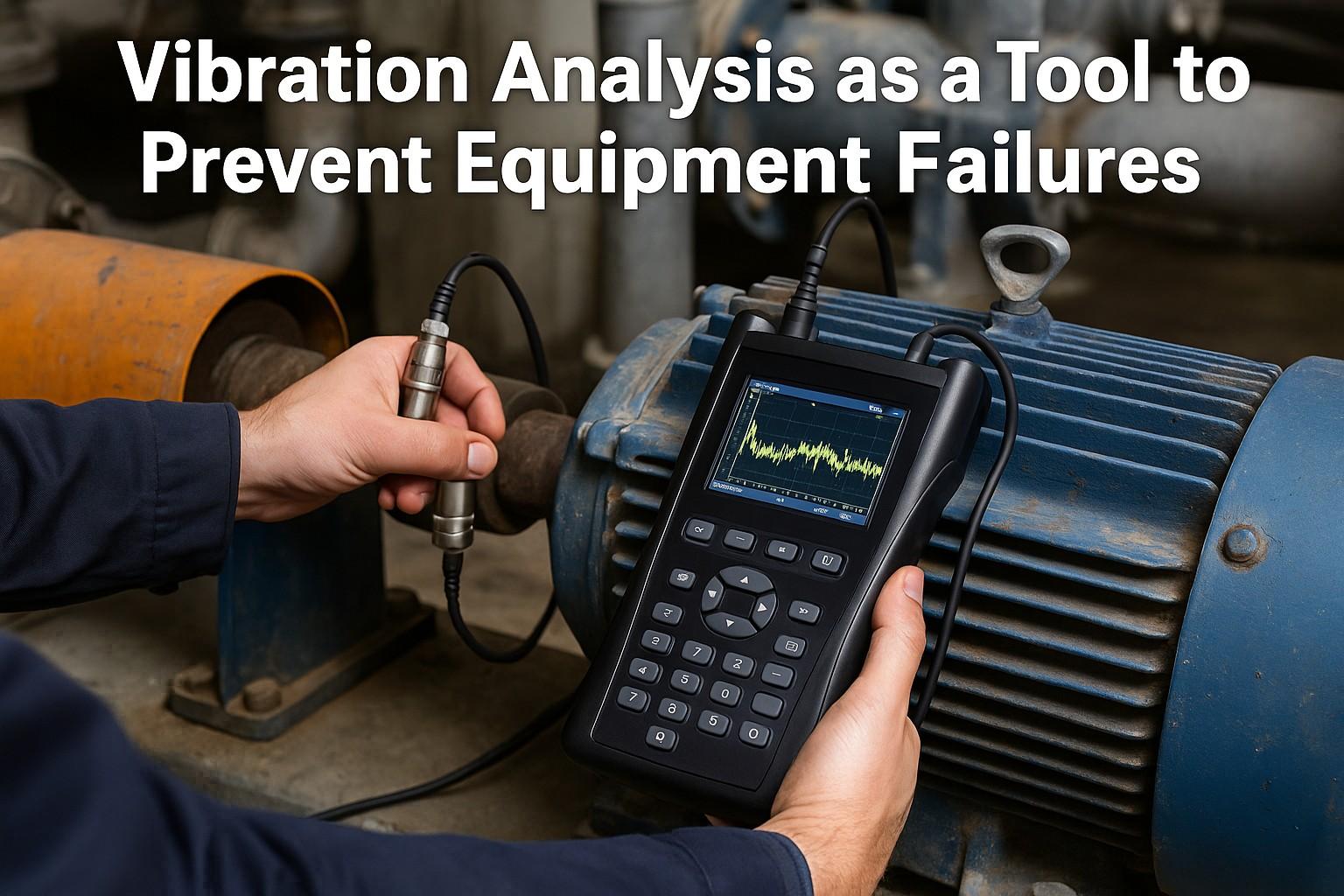

Your production supervisor bursts into Monday's morning briefing with alarming news: "The main conveyor motor failed catastrophically Friday night, causing $420,000 in emergency repairs and 84 hours of unplanned downtime." You examine last quarter's maintenance reports—$3.8 million spent on reactive repairs—but realize your current preventive maintenance schedule provided no early warning of this critical bearing failure. Without vibration analysis maintenance systems and predictive vibration monitoring, you are operating in darkness, waiting for catastrophic equipment failures rather than detecting problems weeks in advance through machine diagnostics.

This devastating scenario repeats across American manufacturing facilities as operations struggle with unpredictable mechanical failures that crush productivity and profits. The average industrial facility experiences 18-25% of maintenance work as emergency repairs, costing 4-6 times more than planned maintenance, but vibration analysis for early detection can reduce catastrophic failures by 80-90%.

Facilities implementing strategic vibration analysis maintenance programs achieve 50-70% reductions in unplanned downtime while improving overall equipment effectiveness by 35-50% compared to traditional time-based maintenance approaches. The transformation lies in leveraging condition monitoring through vibration sensors that reveal actual bearing wear, misalignment, and mechanical degradation patterns 4-12 weeks before catastrophic failure occurs.

Ready to eliminate $420,000 motor failures with vibration analysis that predicts problems 60-90 days in advance?

Every hour of delay costs you potential savings. Manufacturing leaders are already preventing 80-90% of equipment failures with predictive vibration monitoring. Don't let your competitors get ahead while you're stuck with reactive maintenance disasters.

Why Vibration Analysis Beats Traditional Maintenance

Traditional maintenance approaches operate reactively, addressing problems only after failures occur, often resulting in catastrophic damage and extended downtime. Predictive vibration monitoring continuously analyzes mechanical condition through vibration sensors, triggering maintenance activities when data indicates developing problems, typically reducing maintenance costs by 30-45% while dramatically improving reliability through early problem detection.

Bearing Fault Detection

Advanced vibration analysis identifying bearing defects through frequency domain analysis. Detects 90-95% of bearing problems 6-12 weeks before failure, preventing catastrophic seizures.

Shaft Misalignment Analysis

Precise measurement of coupling and belt misalignment through phase analysis. Identifies alignment issues causing premature bearing wear and energy waste.

Rotor Unbalance Detection

Dynamic balancing analysis preventing excessive vibration and bearing stress. Reduces vibration levels by 70-85% through targeted correction.

Machine Diagnostics Integration

Comprehensive condition monitoring combining vibration with temperature and current analysis. Provides complete equipment health assessment for optimal maintenance timing.

Proven Detection Methods by Equipment Type

| Equipment Type | Detection Method | Success Rate | Warning Time |

|---|---|---|---|

| Electric Motors | FFT Spectrum + Envelope Analysis | 92-97% | 6-12 weeks |

| Pumps | Vibration + Cavitation Analysis | 88-94% | 4-8 weeks |

| Compressors | Overall + Harmonic Analysis | 90-96% | 8-16 weeks |

| Gearboxes | Gear Mesh Analysis | 93-98% | 10-20 weeks |

Simple 4-Step Implementation

Get Started in Just 30 Days

Advanced Features That Set Leaders Apart

- Wireless vibration sensors for continuous monitoring of remote rotating equipment

- AI-powered algorithms for automatic fault classification and priority ranking

- Real-time dashboards providing instant equipment condition visibility

- Automated diagnostic systems reducing analysis time by 75%

- Mobile apps for technicians with augmented reality integration

- Cloud-based platforms enabling remote expert consultation

The Bottom Line: Stop Losing Money on Preventable Failures

Vibration analysis as a tool to prevent equipment failures delivers the highest ROI of any predictive maintenance technology. While your competitors waste millions on emergency repairs and unplanned downtime, smart manufacturers are using vibration monitoring to predict problems 4-12 weeks in advance, achieving 50-70% downtime reductions, and 35-50% equipment effectiveness improvements.

The numbers don't lie: facilities with vibration analysis maintenance programs consistently achieve 85-98% fault detection accuracy while preventing 80-90% of mechanical failures. A single avoided motor failure ($100,000-500,000) often pays for the entire monitoring system.

Transform Your Maintenance Strategy Before Your Next Costly Breakdown

Don't wait for the next $420,000 failure. Join manufacturing leaders who've already eliminated 80-90% of equipment breakdowns with vibration analysis. The technology exists now to predict these problems months in advance—implement it before your competitors do.