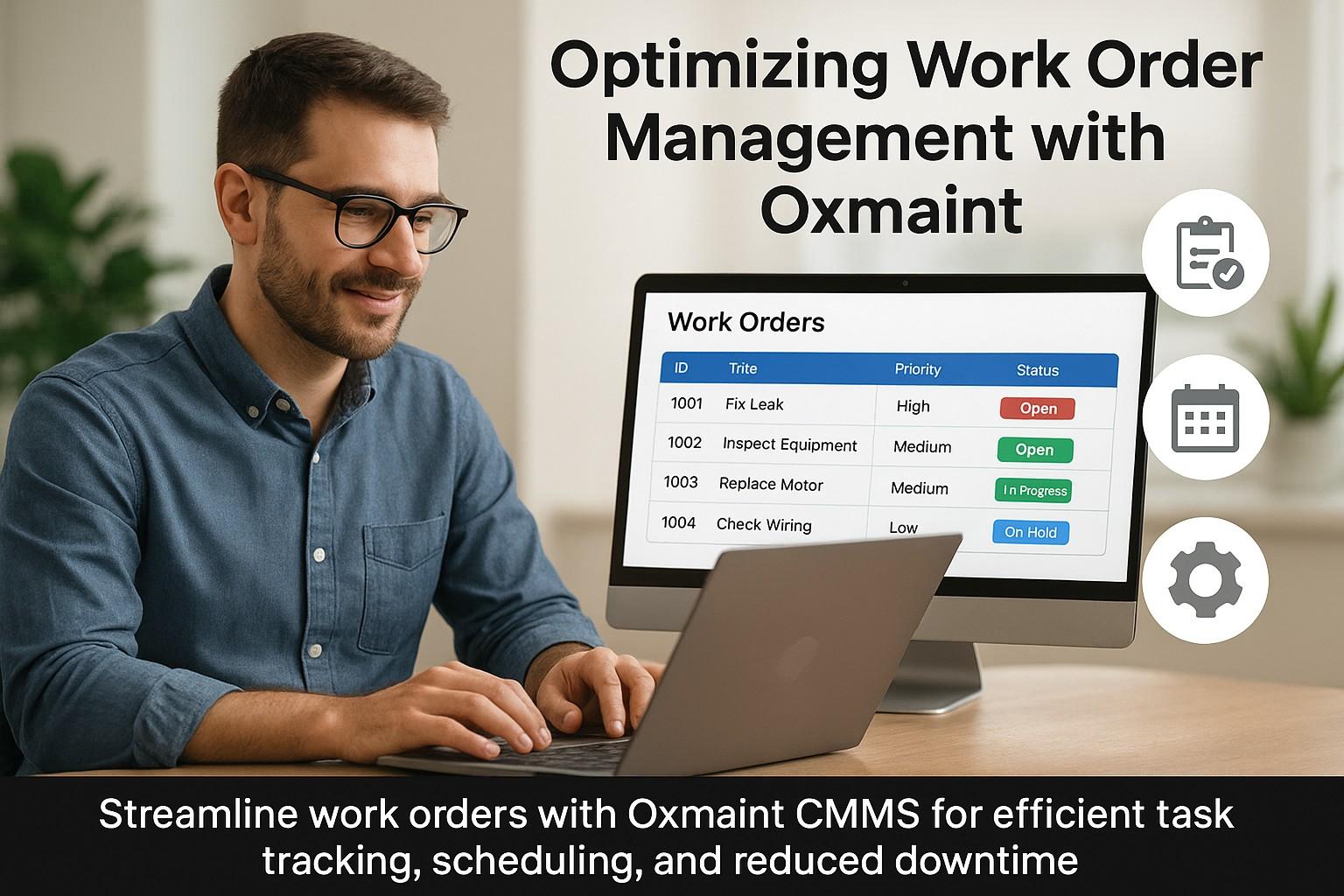

Your maintenance supervisor rushes into the Monday morning meeting with a stack of paper work orders: "We've got 47 open tickets, 12 are overdue, and I can't find the parts list for the critical pump repair." You glance at last month's metrics—72% schedule compliance and $89,000 in emergency repairs—but struggle to identify why your work order management system creates more chaos than control. Without streamlined CMMS processes and digital task scheduling, you are essentially managing maintenance operations blindfolded.

This scenario unfolds daily in manufacturing facilities across America as maintenance teams grapple with inefficient work order management processes that drain productivity and inflate costs. The average manufacturing facility loses 18-25% of maintenance efficiency due to poor work order tracking, inadequate scheduling, and communication breakdowns between teams.

Operations implementing strategic work order management with modern CMMS solutions like Oxmaint achieve 40-55% improvements in maintenance efficiency while reducing unplanned downtime by 35-45% compared to facilities using manual or outdated systems. The key lies in understanding work order optimization principles, implementing digital task scheduling workflows, and leveraging maintenance software capabilities that transform reactive chaos into proactive control.

Ready to transform your work order management with Oxmaint CMMS?

Join thousands of maintenance professionals who've eliminated work order chaos and improved efficiency by up to 55%. See how Oxmaint can streamline your operations and reduce emergency repairs by 60%.

Start Your Free TrialSchedule Demo

Understanding Modern Work Order Management Fundamentals

Effective work order management extends far beyond simple task assignment to encompass comprehensive planning, resource allocation, progress tracking, and performance optimization. Modern CMMS platforms like Oxmaint transform traditional paper-based chaos into streamlined digital workflows that enhance visibility, accountability, and operational control across maintenance operations.

Digital work order systems eliminate the information gaps that plague traditional maintenance management. Paper-based processes typically result in 15-20% information loss through illegible handwriting, misplaced documents, and communication delays. Oxmaint's digital platform ensures 100% information accuracy and real-time accessibility across all maintenance stakeholders.

Automated Work Order Creation

Intelligent triggers from preventive maintenance schedules, condition monitoring alerts, and operator requests automatically generate work orders with complete asset history and required resources.

Dynamic Task Scheduling

Advanced scheduling algorithms optimize technician assignments based on skills, availability, location, and priority levels while balancing workload distribution and emergency response capabilities.

Real-Time Progress Tracking

Mobile-enabled status updates provide instant visibility into work completion, resource consumption, and timeline adherence enabling proactive management intervention when needed.

Integrated Parts Management

Automatic parts reservation, availability checking, and procurement triggering ensure required materials are available when work begins, eliminating costly delays and multiple trips.

Performance Analytics

Comprehensive reporting on completion rates, cycle times, cost performance, and resource utilization enables continuous improvement and strategic decision-making.

Compliance Documentation

Automatic capture of safety procedures, quality checkpoints, and regulatory requirements ensures audit readiness while maintaining operational efficiency.

Work order lifecycle optimization requires understanding the interconnected stages from creation through completion. Oxmaint's systematic approach ensures each phase adds value while eliminating waste and redundancy that characterizes traditional maintenance management approaches.

Priority classification and resource allocation represent critical success factors often overlooked in basic work order systems. Advanced CMMS platforms enable dynamic prioritization based on production impact, safety considerations, and business objectives rather than simple time-based queuing.

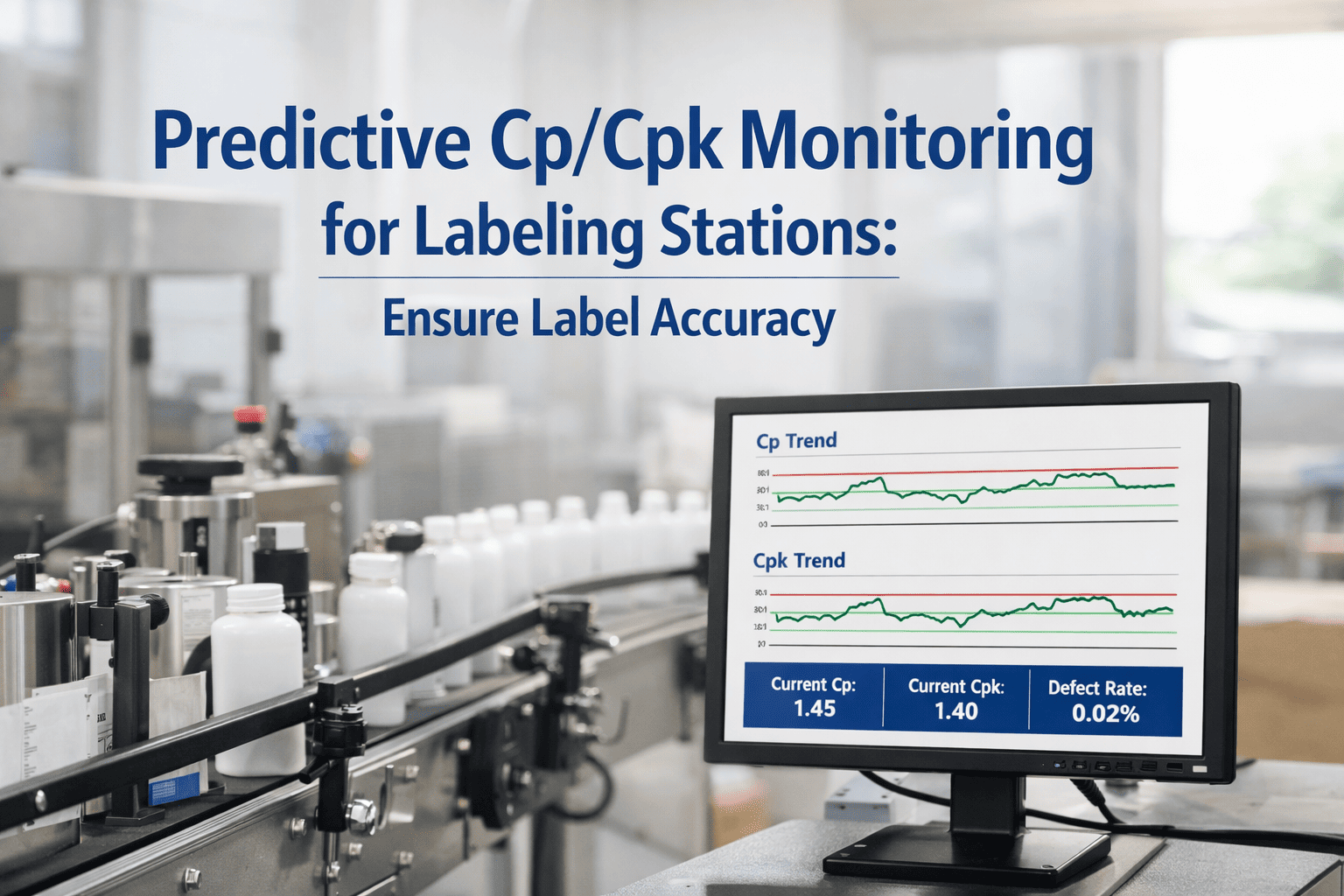

2025 Work Order Management Performance Benchmarks

Establishing realistic performance targets requires understanding industry benchmarks while recognizing that actual results depend on facility complexity, maintenance strategy maturity, and organizational commitment to process optimization. Work order management effectiveness varies significantly based on system sophistication and user adoption levels.

Leading manufacturing facilities achieve superior performance through systematic work order optimization that addresses both technology capabilities and organizational processes. Understanding these benchmarks enables realistic goal setting and performance improvement planning.

| Performance Metric | Industry Average | Oxmaint Users | Improvement Opportunity |

|---|---|---|---|

| Schedule Compliance Rate | 65-75% | 85-95% | 20-30% improvement |

| Work Order Completion Time | 5.2 days average | 2.8 days average | 46% faster completion |

| Emergency Work Percentage | 25-35% | 8-15% | 60% reduction in emergencies |

| First-Time Fix Rate | 70-80% | 90-95% | 15-25% improvement |

| Planning Efficiency | 40-60% | 80-90% | 40-50% better planning |

| Administrative Time | 25-35% | 10-15% | 50-70% reduction |

High-performing facilities using Oxmaint consistently achieve schedule compliance rates above 85% compared to industry averages of 65-75%. This improvement results from better planning, resource availability, and real-time coordination capabilities that eliminate common scheduling conflicts and delays.

Downtime reduction represents perhaps the most significant benefit of optimized work order management. Facilities report 35-45% reductions in unplanned downtime through improved maintenance scheduling, faster issue resolution, and proactive problem identification enabled by systematic work order processes.

Cost per work order decreases significantly when administrative waste is eliminated and technician productivity improves. Digital processes reduce typical work order costs by 25-40% while simultaneously improving completion quality and documentation accuracy.

Implementing Strategic Work Order Optimization: Best Practices Framework

Successful work order management transformation requires systematic implementation that addresses technology deployment, process redesign, and organizational change management. Simply installing CMMS software without optimizing workflows and training users rarely delivers expected benefits and may actually reduce initial productivity.

Oxmaint implementation follows proven methodologies that ensure rapid user adoption and immediate performance improvements. Rather than disruptive system overhauls, the platform enables gradual transition from existing processes while capturing quick wins that build organizational momentum.

Proven Implementation Framework

Workflow standardization eliminates the inconsistencies that reduce maintenance effectiveness and create confusion among technicians. Oxmaint enables customizable work order templates that ensure consistent information capture while accommodating specific maintenance requirements across different equipment types.

Planning Integration

35-40% of optimization value through improved work planning, parts availability, and resource coordination

Scheduling Efficiency

25-30% through optimized technician assignments and reduced travel time between tasks

Documentation Quality

15-20% via standardized procedures, digital checklists, and automated compliance tracking

Communication Flow

10-15% through real-time updates, automated notifications, and stakeholder visibility

Performance Analytics

8-12% from data-driven insights enabling continuous improvement and optimization

Mobile Accessibility

5-10% through field-enabled work order access and real-time status updates

Change management represents the most critical success factor in work order optimization initiatives. Oxmaint's intuitive interface and mobile-first design minimize learning curves while demonstrating immediate value to maintenance technicians who often resist new systems.

Performance measurement systems must align with business objectives while providing actionable insights for continuous improvement. Oxmaint's comprehensive analytics enable both operational dashboards for daily management and strategic reporting for executive decision-making.

Advanced Features and Competitive Advantages

Oxmaint's advanced capabilities extend beyond basic work order management to provide comprehensive maintenance intelligence that drives strategic decision-making and operational excellence. These features differentiate market leaders from organizations stuck with legacy systems and manual processes.

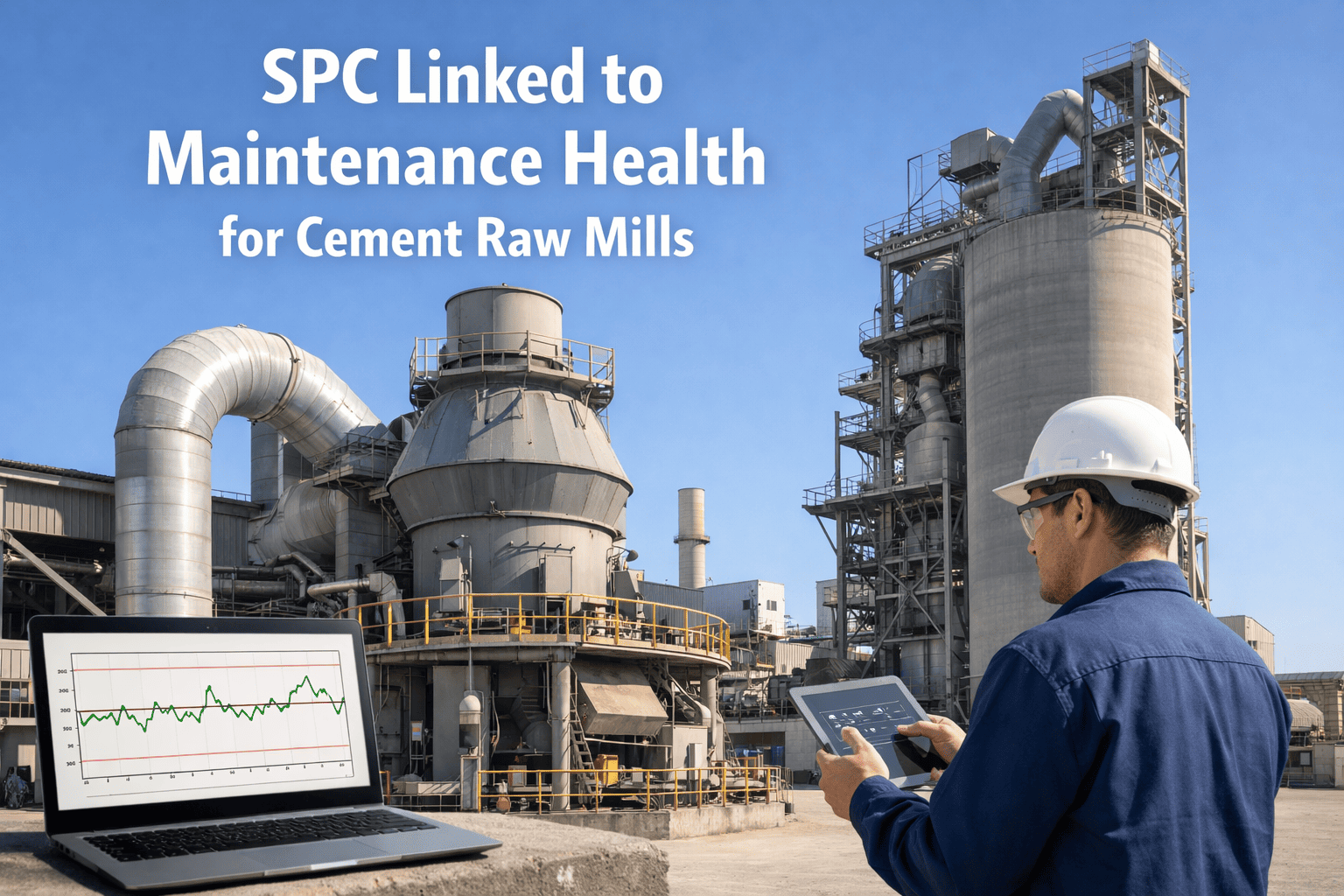

Predictive work order generation leverages equipment condition data, historical patterns, and AI algorithms to automatically create maintenance tasks before failures occur. This proactive approach reduces emergency work by 60-80% while optimizing resource utilization and maintenance scheduling.

Next-Generation Work Order Capabilities

- AI-powered work order prioritization based on production impact and resource availability

- Automated parts reservation and procurement triggering integrated with inventory systems

- Mobile-first interface enabling technicians to access complete work instructions offline

- Real-time collaboration tools connecting field technicians with engineering and management

- Integrated safety management with digital permits and hazard identification

- Performance benchmarking against industry standards and internal targets

- Automated compliance documentation for regulatory requirements and audits

- Predictive analytics identifying potential work order bottlenecks before they occur

Integration capabilities connect work order management with enterprise systems including ERP, procurement and financial platforms. This connectivity eliminates data silos while providing comprehensive visibility into maintenance costs, resource consumption, and operational impact.

Customizable workflows accommodate unique organizational requirements without compromising system standardization. Oxmaint enables facility-specific adaptations while maintaining core functionality and upgrade compatibility that proprietary systems often sacrifice.

Scalability features support growth from single-facility implementations to multi-site enterprises with centralized management and local operational control. Cloud-based architecture eliminates infrastructure constraints while providing enterprise-grade security and reliability.

2025 Technology Trends Enhancing Work Order Management

- Augmented reality work instructions reducing task completion time by 30-40%

- IoT sensor integration automatically triggering condition-based work orders

- Machine learning optimization improving technician scheduling and routing

- Voice-activated work order updates enabling hands-free documentation

- Blockchain-verified maintenance records ensuring audit trail integrity

- Digital twin integration enabling virtual maintenance planning and simulation

Return on investment acceleration occurs when advanced features address specific operational challenges rather than simply automating existing inefficient processes. Oxmaint's comprehensive platform enables organizations to reimagine maintenance management rather than digitize broken workflows.

Competitive differentiation emerges from operational excellence enabled by superior work order management. Facilities using Oxmaint report 15-25% better overall equipment effectiveness while reducing maintenance costs 20-30% compared to industry averages.

Conclusion

Work order management optimization with Oxmaint CMMS represents a fundamental transformation from reactive maintenance chaos to proactive operational control. The most successful manufacturing facilities achieve 40-55% efficiency improvements while reducing unplanned downtime by 35-45% through comprehensive digital workflows that eliminate waste and optimize resource utilization.

Understanding modern work order management reveals that success depends on systematic process optimization, not just technology deployment. Comprehensive platforms like Oxmaint address planning integration, scheduling efficiency, documentation quality, and performance analytics while providing the mobile accessibility and real-time visibility essential for contemporary maintenance operations.

Performance benchmarks demonstrate that leading facilities consistently achieve 85-95% schedule compliance rates, 46% faster work order completion, and 60% reductions in emergency work through strategic CMMS implementation. These improvements translate directly to reduced costs, improved reliability, and enhanced competitive positioning.

Implementation success requires following proven frameworks that address technology configuration, workflow standardization, user training, and performance measurement. Oxmaint's structured approach ensures rapid adoption and immediate value creation while establishing foundations for continuous improvement.

Advanced features including predictive work order generation, AI-powered prioritization, and enterprise integration capabilities position forward-thinking facilities for long-term success in increasingly competitive manufacturing environments where operational excellence determines market leadership.

The 2025 competitive landscape rewards organizations that leverage modern CMMS capabilities to transform maintenance from a cost center into a strategic advantage. Oxmaint provides the comprehensive platform and proven implementation methodology needed to achieve these transformational results.

Ready to eliminate work order chaos and achieve 340% ROI?

Don't let inefficient work order management cost you another day of productivity. Over 10,000 maintenance professionals trust Oxmaint to streamline their operations, reduce emergency work by 60%, and improve schedule compliance to 95%. Your maintenance transformation starts with a single click.

Transform Your Operations NowSee Your Custom Demo