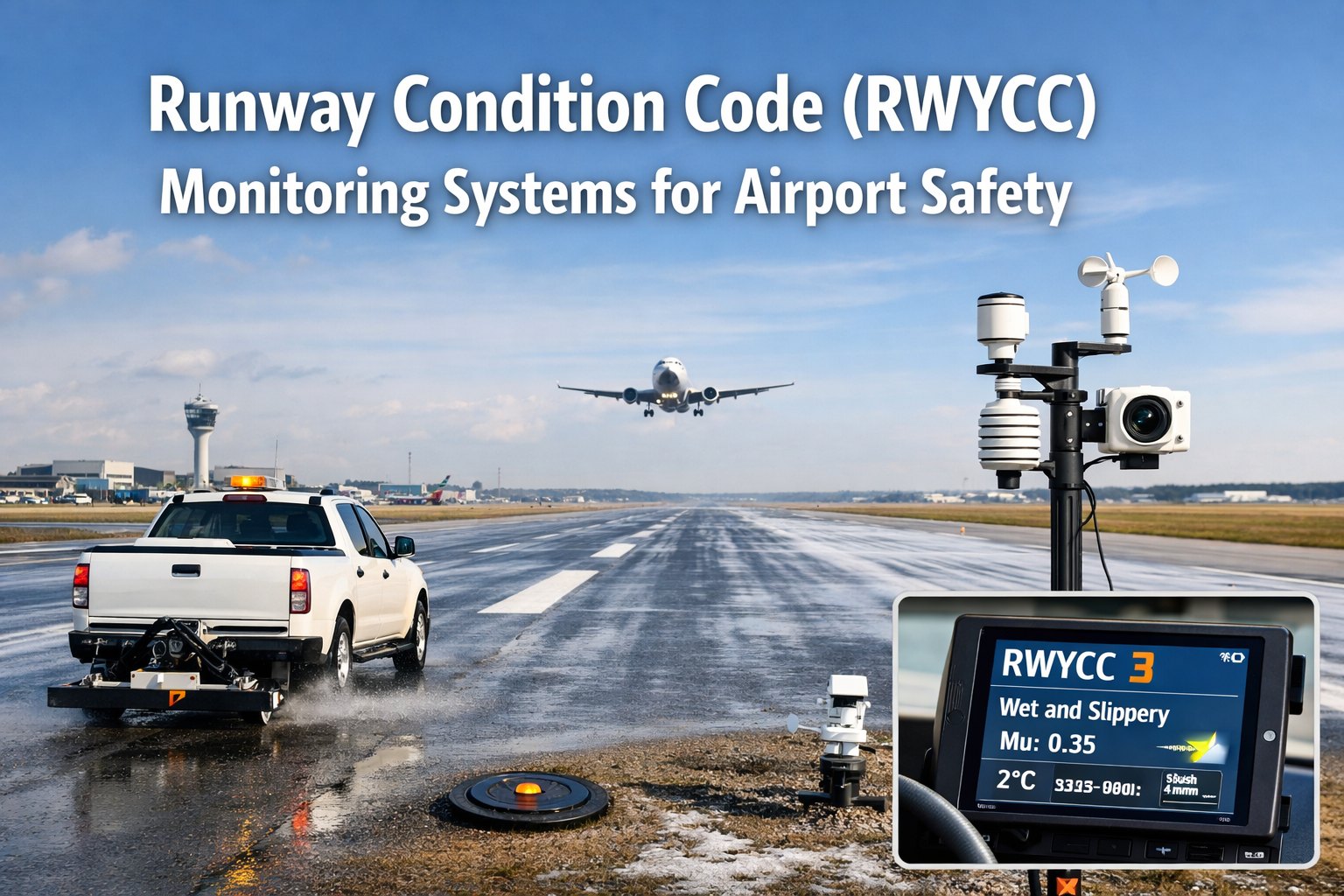

Every year, runway excursions account for 21% of all aviation accidents worldwide—with contaminated surface conditions among the leading causes. The ICAO Global Reporting Format now mandates standardized runway condition assessments, yet many airports still rely on manual inspections that create delays and inconsistencies. Real-time RWYCC monitoring transforms runway safety from reactive guesswork into proactive intelligence. Schedule a consultation to discover how automated runway condition monitoring can enhance safety and streamline GRF compliance at your airport.

Understanding Runway Condition Codes

The Runway Condition Code (RWYCC) is a standardized numerical rating from 0 to 6 that indicates how slippery a runway surface is. Developed through ICAO's Global Reporting Format, these codes provide pilots with critical information for calculating safe takeoff and landing performance on contaminated runways.

6

DRY

Optimal braking, no contamination

5

WET / FROST

Good braking action expected

4

COMPACTED SNOW

Medium-good braking action

3

DRY SNOW / WET SNOW

Medium braking action

2

STANDING WATER / SLUSH

Medium-poor braking action

1

ICE

Poor braking action

0

WET ICE / WATER ON ICE

NIL braking—runway closure required

104

Runway excursion accidents (2015-2024)

21%

Of all aviation accidents are runway excursions

5×

Increase in excursions: 2024 vs 2023

The GRF Compliance Challenge

Since November 4, 2021, ICAO's Global Reporting Format requires airports worldwide to assess and report runway surface conditions using standardized terminology and the Runway Condition Assessment Matrix (RCAM). This harmonized approach ensures pilots everywhere receive consistent, actionable information—but implementation presents real operational challenges.

Time-Critical Reporting

Conditions can change within minutes during weather events. Manual inspections create reporting delays that put aircraft at risk.

Assessment Consistency

Human observations vary between inspectors. Different assessors may assign different RWYCCs to identical conditions.

Third-by-Third Monitoring

GRF requires separate condition codes for each runway third. Manual inspection of long runways is labor-intensive.

Documentation Trail

Regulatory audits require complete assessment records. Paper-based systems create compliance gaps and liability exposure.

Struggling with GRF compliance? Create a free OXmaint account and our team will help you assess your current runway monitoring capabilities and identify improvement opportunities.

Sign Up Free

How Digital Monitoring Transforms Runway Safety

Modern IoT sensors and automated systems supplement human assessment with objective, continuous data—giving airfield operations teams real-time visibility into runway surface conditions across the entire airfield.

RWY 09L/27R

5

First Third

Wet

4

Middle Third

Compacted Snow

3

Last Third

Dry Snow 15mm

RWYCC: 5/4/3 • Last Updated: 2 min ago

Surface Temp

-3°C

↓ Falling

Water Film

0.8mm

Detected

Friction (μ)

0.42

Medium

Ice %

12%

Forming

Key Monitoring Technologies

Effective RWYCC monitoring combines multiple sensor technologies to capture the full picture of runway surface conditions. Each technology addresses specific contamination types and environmental factors.

Flush-mounted sensors in the runway pavement continuously measure surface temperature, water film height, freezing point, and ice percentage. Active sensors can detect freezing conditions independent of de-icing chemicals applied.

Surface temperature

Freezing point

Water film depth

Ice percentage

Vehicle-mounted sensors measure runway conditions in real-time during inspection runs. Modern systems capture 100 measurements per second, providing precise friction coefficients and contamination detection across all three runway thirds.

Friction coefficient

Road condition

Thermal mapping

Contaminant type

Airport weather observation systems provide ambient conditions that affect runway state—precipitation type and intensity, humidity, wind speed, and visibility. Integration enables predictive alerts before conditions deteriorate.

Precipitation type

Ambient temperature

Humidity levels

Dew point

See automated RWYCC reporting in action. Book a demo and we'll show you how leading airports are streamlining GRF compliance with real-time monitoring.

Schedule Demo

Manual vs. Automated Assessment

While trained human inspectors remain essential for GRF compliance, sensor-augmented monitoring dramatically improves accuracy, speed, and coverage of runway condition assessments.

Manual Inspection Only

- Periodic assessments with gaps between inspections

- Subjective observations vary by inspector

- Labor-intensive during adverse weather

- Limited coverage of long runways

- Paper-based records create compliance risks

15-30 min

typical assessment cycle time

Sensor-Augmented Monitoring

- Continuous real-time condition updates

- Objective measurements support human assessment

- Automated alerts when conditions change

- Complete third-by-third coverage

- Digital audit trail for regulatory compliance

Real-time

continuous monitoring with instant alerts

The RCAM Workflow Simplified

The Runway Condition Assessment Matrix is the cornerstone of GRF reporting. Understanding how sensor data maps to RWYCC codes helps operations teams make faster, more accurate assessments.

1

Data Collection

Embedded sensors and mobile units continuously capture surface temperature, water film, friction, and contamination data across all runway sections.

2

RCAM Analysis

System correlates sensor readings with RCAM criteria to suggest preliminary RWYCC for each runway third based on detected contaminants.

3

Human Validation

Trained inspector reviews sensor data and visual observations to confirm, upgrade, or downgrade the preliminary RWYCC assessment.

4

Report Generation

Validated Runway Condition Report (RCR) is automatically formatted for SNOWTAM, ATIS broadcast, and ATC coordination.

Benefits of Real-Time RWYCC Monitoring

Airports implementing automated runway condition monitoring see measurable improvements across safety, efficiency, and compliance metrics.

Enhanced Safety

Immediate detection of hazardous conditions enables proactive runway closures and maintenance actions before aircraft operations are affected.

Operational Efficiency

Faster assessment cycles reduce runway closure time during weather events. Data-driven decisions optimize snow removal and de-icing operations.

GRF Compliance

Automated documentation creates complete audit trails. Digital RCR generation ensures consistent formatting per ICAO standards.

Cost Reduction

Optimized chemical application based on actual surface conditions. Reduced manual inspection labor during 24/7 winter operations.

Frequently Asked Questions

What is the difference between RWYCC and friction coefficient (μ)?

RWYCC is a qualitative code (0-6) that describes contamination type and expected braking action. Friction coefficient (μ) is a quantitative measurement of actual surface grip. Sensor-measured friction helps validate RWYCC assessments—a RWYCC of 4 should correlate with medium-good friction readings. When they don't match, it signals the need for reassessment.

Does automated monitoring replace human inspectors?

No. GRF requires trained human assessors to make final RWYCC determinations. Sensors provide objective data to support and validate human observations, but the inspector's judgment—considering factors like temperature trends, chemical treatments, and operational context—remains essential for accurate reporting.

How quickly must runway conditions be reported under GRF?

ICAO requires airports to report significant changes in runway surface conditions without delay. During active weather, this typically means updates every 15-30 minutes or whenever conditions deteriorate. Real-time monitoring enables continuous awareness so changes can be reported immediately.

What happens when RWYCC reaches 0?

A RWYCC of 0 indicates NIL braking action—the runway must be closed until conditions improve. Under FAA and ICAO guidance, it is not acceptable to report NIL conditions on an open runway. Monitoring systems provide early warning as conditions approach RWYCC 1, allowing time for treatment or closure decisions.

Can monitoring systems integrate with existing airport infrastructure?

Yes. Modern runway monitoring platforms connect with airport operational databases, AWOS/ASOS weather systems, and ATC communication channels through standard protocols.

Sign up for a free account to explore integration capabilities for your airfield.

Upgrade Your Runway Condition Monitoring

OXmaint's airfield monitoring platform provides real-time runway surface intelligence, automated RWYCC assessment support, and complete GRF compliance documentation—enabling safer operations and faster decision-making during critical weather events.