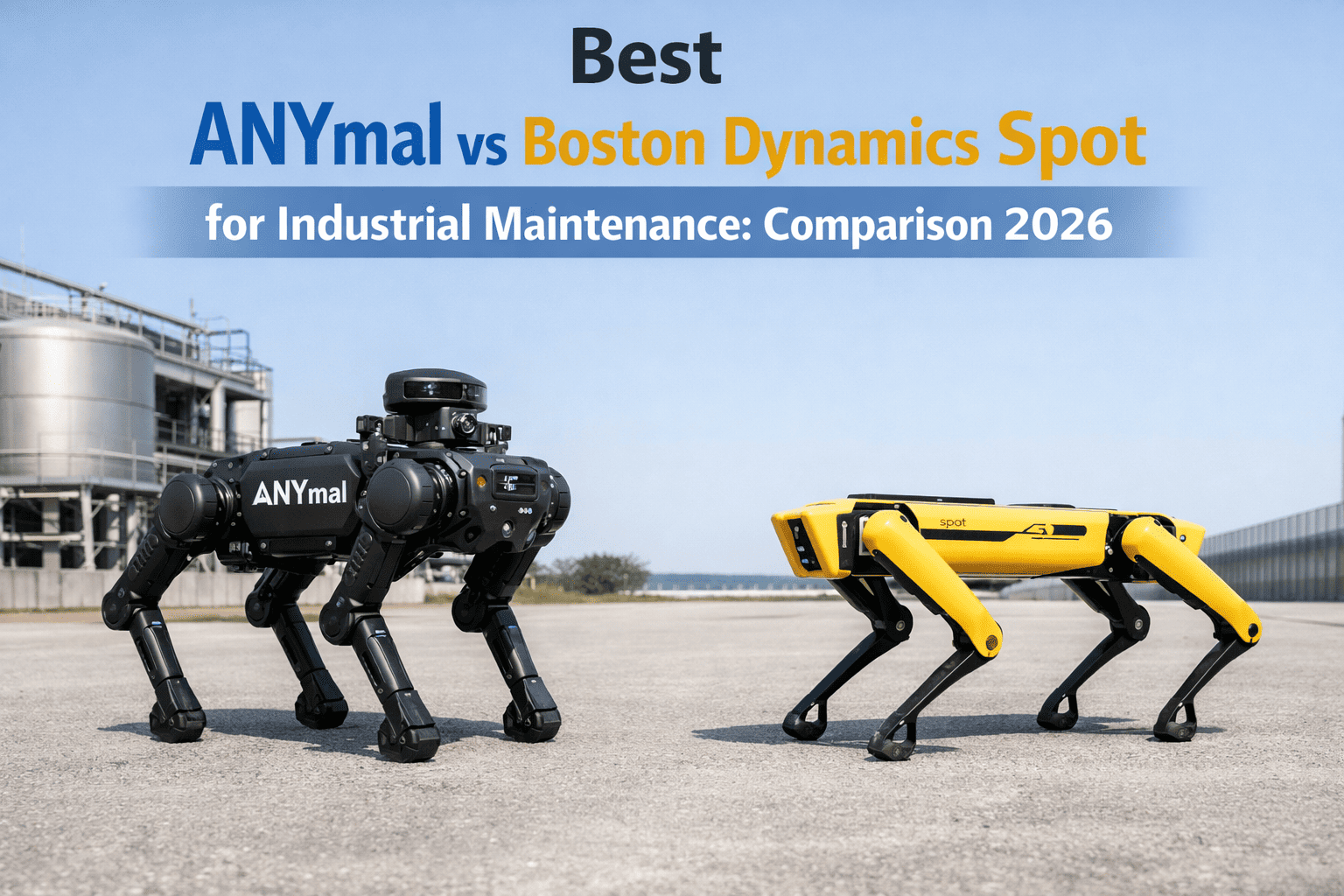

If your facility is evaluating quadruped robots for autonomous inspection, the decision likely comes down to two platforms—ANYbotics ANYmal and Boston Dynamics Spot. Both are proven in real-world industrial deployments, yet they are engineered for fundamentally different operating priorities. ANYmal is purpose-built for hazardous, harsh-environment inspection with integrated industrial sensors and ATEX Zone 1 certification. Spot offers unmatched versatility, a broad developer ecosystem, and a lower entry price with optional manipulation via Spot Arm. This 2026 comparison covers every factor maintenance teams need—specs, terrain handling, sensor capabilities, CMMS integration, and total cost of ownership—so you can select the right robot for your specific operation. Not sure which robot fits your facility? Book a free demo and our team will walk you through how each platform connects to Oxmaint CMMS for automated inspection workflows.

What Drives the Shift Toward Robotic Inspection in 2026

Manual inspection rounds are no longer sustainable for energy-intensive and high-hazard facilities. Aging workforces, stricter safety regulations, and the demand for continuous condition monitoring have pushed industries toward autonomous robotic platforms that patrol 24/7 without fatigue, inconsistency, or safety incidents. Quadruped robots—unlike wheeled or tracked alternatives—navigate the stairs, grated walkways, and multi-floor structures that define refineries, chemical plants, power stations, and offshore platforms.

$6.76B

Inspection robotics market size projected for 2026, growing toward $30B by 2034

72%

Reduction in manual inspection hours reported by early-adopter facilities

24/7

Autonomous patrol coverage with automated docking and recharging cycles

Head-to-Head Technical Specifications

Before evaluating use cases, your engineering team needs hard numbers. This specification table compares the two platforms across the metrics that matter most for industrial maintenance deployment—weight, payload, ruggedization, battery endurance, and hazardous area certification.

Technical Specification Comparison: ANYmal vs Spot (2026)

How specifications translate to maintenance results: Raw specs only matter when they connect to your CMMS. Oxmaint integrates with both ANYmal and Spot, turning thermal anomalies, gas detections, and visual defects into automated work orders assigned to the right technician—with full asset history attached.

Start your free Oxmaint account and see how robotic inspection findings automatically become prioritized work orders your team can act on.

Where Each Robot Wins: Terrain and Environment Analysis

A robot that cannot physically reach your critical assets delivers zero inspection value. Terrain capability is the single most important differentiator between ANYmal and Spot—and it directly determines which facilities each platform can serve.

ANYbotics ANYmal

Built for the harshest industrial environments

Climbs steep industrial stairs up to 45 degrees with full autonomy—no operator assistance required

IP67 sealing survives rain, snow, washdown zones, and temporary water immersion

ANYmal X operates in ATEX Zone 1 explosive atmospheres—the only certified legged robot available

Proven on offshore platforms including Petronas and Equinor floating and fixed installations

Sideways stepping and in-place rotation navigates narrow corridors and pipe racks

Ideal for: Oil and gas, offshore, chemical plants, mining, heavy industry

Boston Dynamics Spot

Maximum versatility across diverse environments

Exceptionally fluid gait across rubble, gravel, slopes, and uneven construction terrain

Lighter at 32.5 kg—deploys in weight-sensitive structures and temporary installations

Self-righting capability recovers from falls and tip-overs without human intervention

Optional Spot Arm enables physical manipulation—turning valves, flipping switches, opening doors

Orbit software manages fleet-wide autonomous missions from remote operations centers

Ideal for: Construction, general manufacturing, data centers, research, multi-purpose facilities

Inspection Sensors and AI Vision: What Each Platform Sees

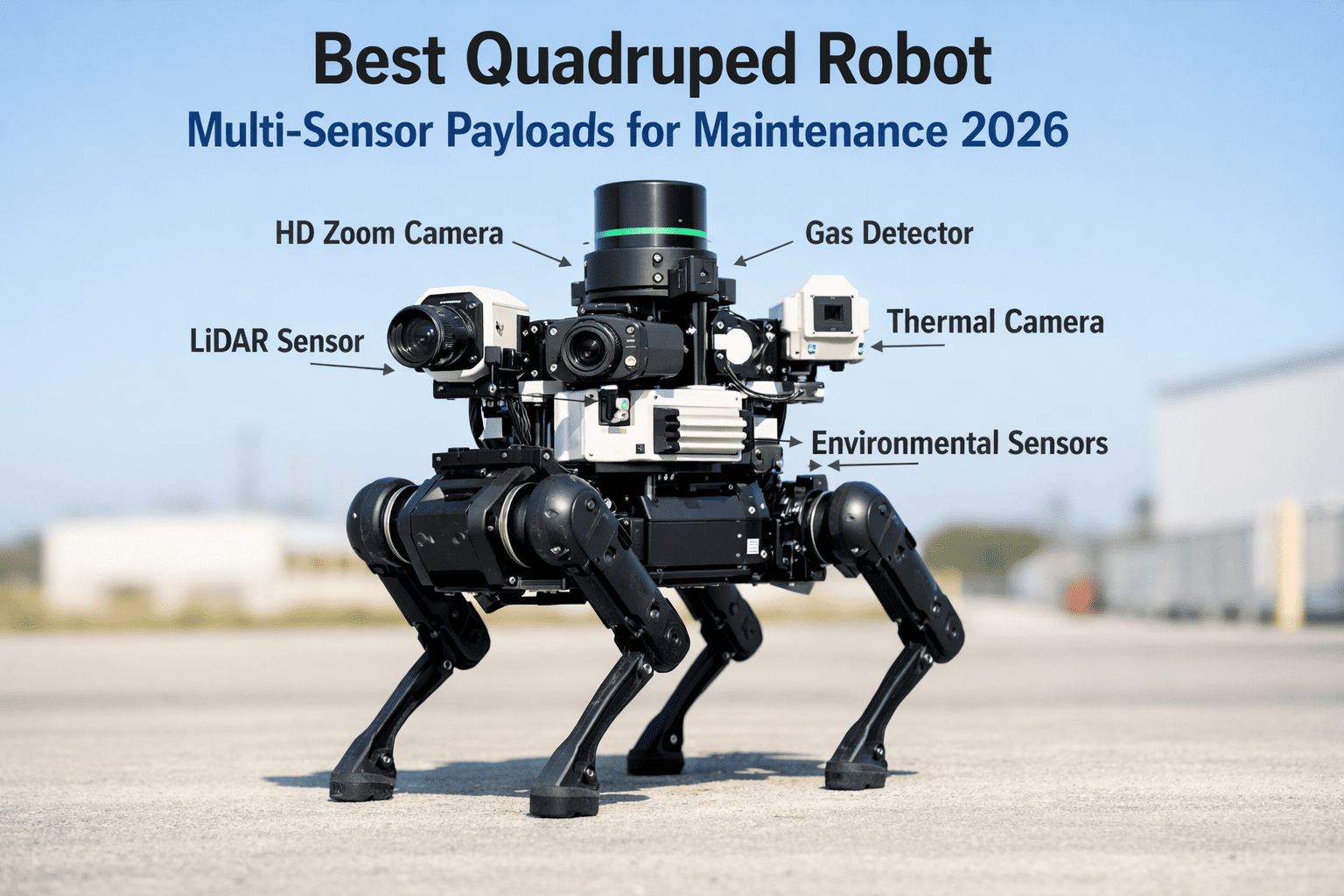

The quality of your predictive maintenance program is only as good as the data your robot collects. Sensor architecture—what is built-in versus what requires additional payload purchases—directly impacts both initial cost and long-term effectiveness. Sign up for Oxmaint to centralize inspection sensor data from either platform into one asset management dashboard.

Visual Inspection

ANYmal

20x optical zoom camera with 4K video. Pan-tilt unit covers +/-90 degrees vertical and +/-165 degrees horizontal. Reads gauges, valve positions, and digital displays from distance. Powerful LED spotlight (3790 lm) enables full operation in complete darkness.

Spot

Base 360-degree camera with integrated lighting (above 2 lux). Extended visual capability through Spot CAM and partner ecosystem payloads. Pan-tilt-zoom options available as add-ons. Wide selection of third-party camera integrations via payload mount.

Thermal and Acoustic Analysis

ANYmal

Integrated thermal camera reading -40 to 550 C for hotspot and insulation fault detection. Built-in ultrasonic microphone captures 0–384 kHz for compressed air leak detection and early bearing degradation identification.

Spot

Spot CAM+ IR provides radiometric thermal imaging as a payload add-on. Acoustic sensors available through third-party integrations. Requires separate payload purchase and mounting configuration for each sensor type.

Gas Detection and Environmental Sensing

ANYmal

Optional integrated gas detection system monitoring combustible and toxic gas concentrations continuously. Acoustic imager identifies gas leakage sources. ANYmal X designed for active gas monitoring in Zone 1 environments.

Spot

Gas detection configurable through open payload platform and API. Not certified for explosive atmospheres, limiting deployment in classified zones. Custom sensor packages available through developer ecosystem.

See how robotic sensor data becomes maintenance action. Book a demo to explore how Oxmaint auto-generates work orders from thermal anomalies, gas detections, and visual defects captured by either platform.

Book a Demo

From Robot Patrol to Work Order: CMMS Integration Workflow

Collecting inspection data without a system that converts findings into prioritized maintenance actions wastes the entire investment. The bridge between robotic inspection and reduced downtime is your CMMS—the platform that turns a thermal hotspot flagged at 2 AM into a work order waiting for your morning shift technician.

1

Robot Executes Autonomous Patrol

ANYmal or Spot follows pre-programmed routes across your facility, capturing thermal, visual, acoustic, and environmental readings at every configured inspection point. Patrols run on schedule without operator involvement.

2

AI Flags Anomalies Against Baselines

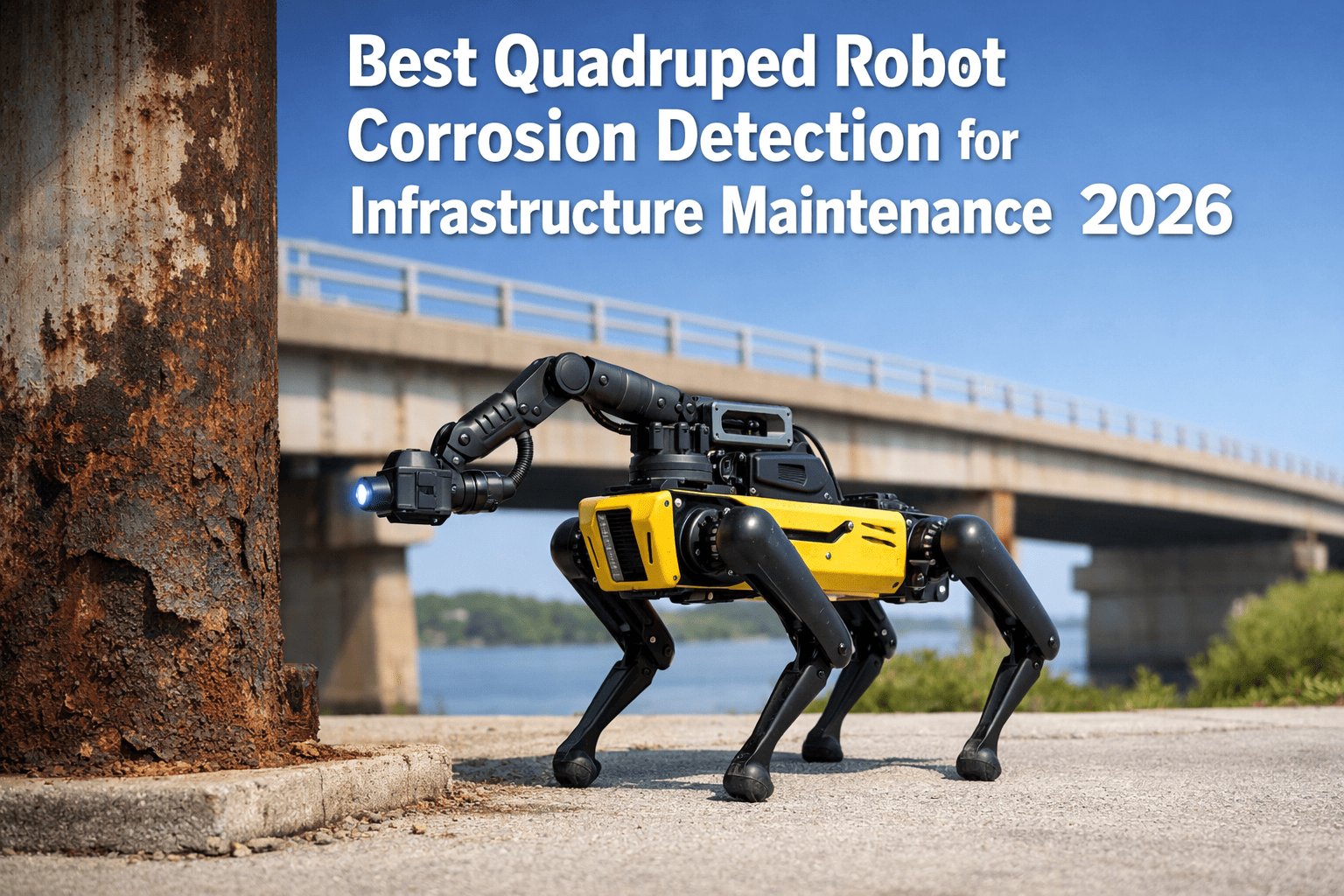

Machine learning compares each reading against historical equipment baselines. Overheating bearings, abnormal acoustic signatures, visible corrosion, and gas concentration spikes are automatically flagged with severity scores.

3

Oxmaint Receives and Maps Findings

Anomaly data flows into Oxmaint CMMS via API. Each finding is linked to the correct asset record, building a comprehensive condition history that strengthens predictive maintenance models over time.

4

Automated Work Orders Reach Your Team

Critical findings automatically generate prioritized work orders in Oxmaint—assigned to the right technician, with thermal images, location data, and repair context attached. Your team fixes problems before they cause downtime.

Create your free Oxmaint account to start building automated inspection-to-work-order workflows for your facility.

Which Industries Should Choose Which Robot

The right platform depends on your operating environment, regulatory requirements, and the specific maintenance outcomes you need to achieve. This selection guide maps common industrial scenarios to the platform that delivers the strongest return.

Oil and Gas — Classified Zones

ANYmal X

Only commercially available quadruped with IECEx / ATEX Zone 1 certification. Deployed by Shell, Equinor, and BASF in active petrochemical environments.

Offshore Platforms

ANYmal

IP67 protection, all-weather operation, and proven performance on fixed and floating offshore installations with steep stairs and exposed environments.

Construction and Site Monitoring

Spot

Lighter weight, laser scanning for digital twin creation, and Spot Arm enables physical interaction with site elements. Lower cost suits project-based budgets.

Data Centers and Facilities

Either Platform

Both deliver autonomous thermal monitoring. ANYmal deployed at Digital Realty. Spot's Orbit software offers mature fleet management for multi-site deployments.

General Manufacturing

Spot

Lower entry cost, extensive developer ecosystem for custom applications, and manipulation capability via Spot Arm for physical tasks beyond inspection.

Mining and Heavy Industry

ANYmal

IP67 dust and water protection critical for underground and open-pit environments. Ruggedized design handles impacts and debris better than IP54 alternatives.

Regardless of which robot you choose, Oxmaint CMMS unifies your inspection data. Centralize findings from ANYmal, Spot, or mixed fleets into one platform—with automated work orders, asset tracking, and predictive analytics built in.

Sign Up Free

Cost, ROI, and the Factors Beyond Price Tags

Spot's lower entry price is frequently cited as an advantage, but total cost of ownership tells a different story depending on your requirements. ANYmal's higher upfront cost includes integrated sensors that Spot requires as paid add-ons, and ex-proof certification that Spot simply cannot match. The right calculation depends on what you need the robot to do and where it needs to operate.

Initial Hardware Investment

Sensor Suite (Included Out-of-Box)

SpotBasic — add-ons needed

ANYmalFull industrial suite

Hazardous Zone Access Value

ANYmal XZone 1 ATEX/IECEx

Developer Ecosystem and Flexibility

ANYmalGrowing partnerships

The Verdict: How to Decide for Your Facility

There is no universal winner in the ANYmal vs Spot comparison. ANYmal is the clear choice when your facility operates in hazardous classified zones, offshore environments, or conditions that demand IP67 ruggedization and integrated industrial-grade sensors. Spot wins when you need maximum flexibility, lower initial investment, physical manipulation via its robotic arm, and access to the broadest payload and software ecosystem in the quadruped market. For many large organizations, the answer may be both—with ANYmal deployed in classified and harsh zones while Spot handles general industrial areas and construction sites. What matters most is that whichever platform you choose, the inspection data it collects feeds directly into a CMMS that converts findings into maintenance action. Without that connection, you are paying for data collection—not downtime prevention.

Connect Robotic Inspection to Maintenance Results

Whether you deploy ANYmal, Spot, or both—Oxmaint CMMS turns robotic inspection data into automated work orders, real-time asset tracking, and predictive maintenance intelligence. Stop collecting data that sits idle. Start preventing failures before they cause downtime.

Frequently Asked Questions

Can Oxmaint CMMS integrate with both ANYmal and Boston Dynamics Spot?

Yes. Oxmaint supports API-based integration with both platforms. Inspection findings—thermal anomalies, gas detections, visual defects, acoustic alerts—flow directly into Oxmaint asset records. Critical findings automatically generate prioritized work orders assigned to the correct maintenance team with photos, sensor data, and location context attached.

Sign up free and explore the integration setup to connect your robotic inspection data with Oxmaint work order automation.

Which robot is certified for explosive or hazardous zone inspections?

ANYmal X is the only commercially available quadruped robot with IECEx and ATEX Zone 1 certification as of 2026. It has been deployed by major operators including Shell, Equinor, and BASF in active petrochemical environments. Boston Dynamics Spot is not certified for explosive atmospheres. If your facility includes classified hazardous zones, ANYmal X is currently the only legged robot option for those areas.

How does battery life compare between ANYmal and Spot?

ANYmal operates approximately 2 to 4 hours per charge depending on terrain and activity level. Spot averages around 90 minutes of runtime with a 120-minute recharge cycle. Both platforms support automated docking stations for continuous 24/7 autonomous operations without human intervention. Multiple docking stations can extend patrol reach across larger facilities.

Book a demo with our team to see how Oxmaint helps you design patrol routes and docking station placement for maximum coverage with either robot platform.

Is Spot or ANYmal better for predictive maintenance programs?

Both platforms collect the high-frequency inspection data that predictive maintenance requires—thermal trends, vibration patterns, visual condition changes—at consistent intervals impossible for human inspectors. The key differentiator for predictive maintenance is not the robot itself but how its data integrates with your CMMS. Oxmaint centralizes robotic inspection data from either platform, applies trend analysis, and triggers condition-based work orders before equipment failures occur.

Can Spot physically manipulate equipment during inspections?

Yes. The optional Spot Arm provides up to 11 kg of lift capacity and 1800 mm of reach, enabling the robot to turn valves, flip switches, open doors, and physically interact with equipment. ANYmal is designed purely for inspection and data collection, without manipulation capability. If your maintenance workflow requires physical intervention alongside inspection, Spot with Arm is the stronger choice.