Running a single robot dog through a test corridor is a proof of concept. Running 10 or more quadruped robots across a refinery, power plant, or manufacturing campus 24 hours a day — that is an operations problem. And the organizations solving it in 2026 are not doing it with spreadsheets or standalone fleet dashboards. They are anchoring every robot, every dock, every inspection route, and every sensor finding inside a CMMS that already manages the rest of their assets. The result is a closed-loop system where robots inspect equipment, findings become work orders, and maintenance teams act before failures happen — all without anyone manually copying data between platforms. Book a demo to see how Oxmaint turns robot inspection data into automated work orders across your entire fleet from a single dashboard.

Why Robot Dog Fleets Are Replacing Manual Inspection Rounds in Heavy Industry

The shift from pilot programs to fleet-scale deployment is accelerating faster than most maintenance leaders expected. The industrial quadruped robot market hit $2.2 billion in 2025 and is growing at over 20% annually, driven by energy companies, chemical plants, and large manufacturers who need continuous inspection coverage in environments too hazardous, too large, or too repetitive for human rounds.

1,500+

Boston Dynamics Spot robots now in commercial operation worldwide — the largest deployed quadruped fleet on the planet

44%

Of energy companies piloted quadruped robots for predictive maintenance programs in 2025

$9.9B

Projected industrial quadruped robot market by 2033, a nearly 5x increase from current levels

The reasons are practical, not futuristic. AB InBev deployed Spot at their Leuven brewery and cut average repair times from months to 13 days by catching anomalies earlier. Michelin's Lexington plant generated 72 CMMS work orders from robot inspection data in the first six months alone. A North American refinery reduced manual patrol hours by 40% overnight using autonomous quadruped fleets. These are not experiments — they are production deployments integrated into daily maintenance operations. The common thread is that every successful deployment runs through a CMMS platform that centralizes robot data and facility maintenance. Sign up for Oxmaint free to start building your robot fleet asset profiles and automated work order workflows.

What Changes When You Go from 2 Robots to 10+: The Scaling Challenges Nobody Talks About

Most fleet deployment guides skip the hard part. Adding robots is easy — managing them is where organizations stall. Here are the operational challenges that surface specifically at 10+ unit scale, and why CMMS integration is not optional at this level.

01

Scheduling Collisions

With 10+ robots sharing corridors, stairwells, and inspection zones, route conflicts multiply exponentially. Two robots converging on the same narrow aisle wastes battery, delays inspections, and creates safety risks. CMMS-driven scheduling assigns time-slotted routes that eliminate overlap and maximize coverage density per shift.

02

Dock Congestion and Battery Management

A single charging dock per robot works at pilot scale. At fleet scale, you need a multi-dock grid with 1.5-2x docks per robot — and each dock becomes a managed CMMS asset with its own uptime tracking, power consumption records, and maintenance schedule. When a dock fails, the CMMS reroutes affected robots automatically.

03

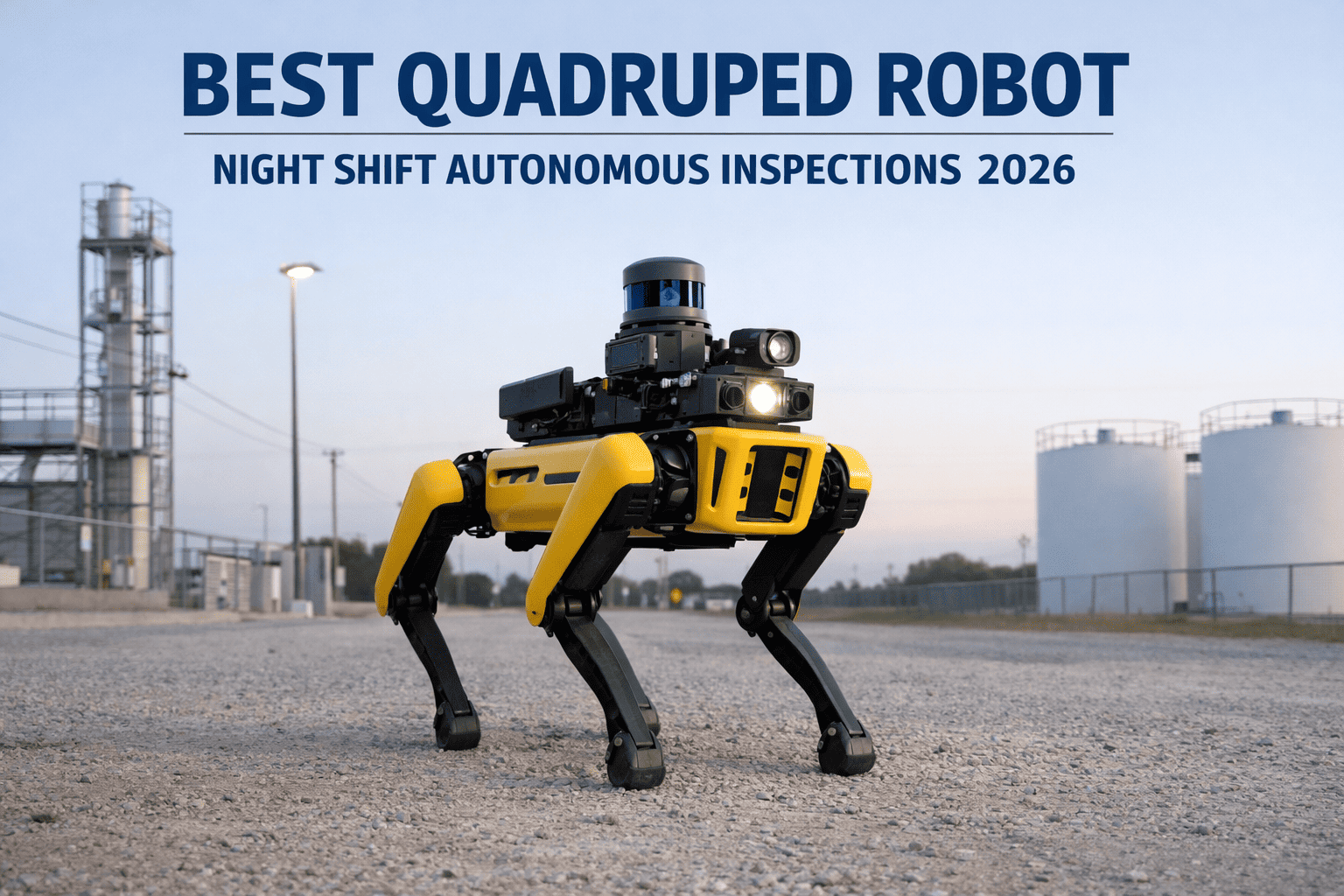

Data Overload Without Action

Ten robots running 3 inspection missions per day generate thousands of thermal images, vibration readings, and visual captures weekly. Without automated CMMS ingestion, this data accumulates in robot fleet software and never reaches the technicians who need it. The inspection-to-work-order pipeline must be automatic, not manual.

04

Robot Maintenance at Fleet Scale

Every robot is itself an asset requiring preventive maintenance — foot gripper replacement every 500-1,000 km, battery health monitoring, sensor calibration, joint inspection, and firmware updates. Without CMMS tracking, robot downtime becomes unpredictable and inspection coverage gaps go unnoticed.

05

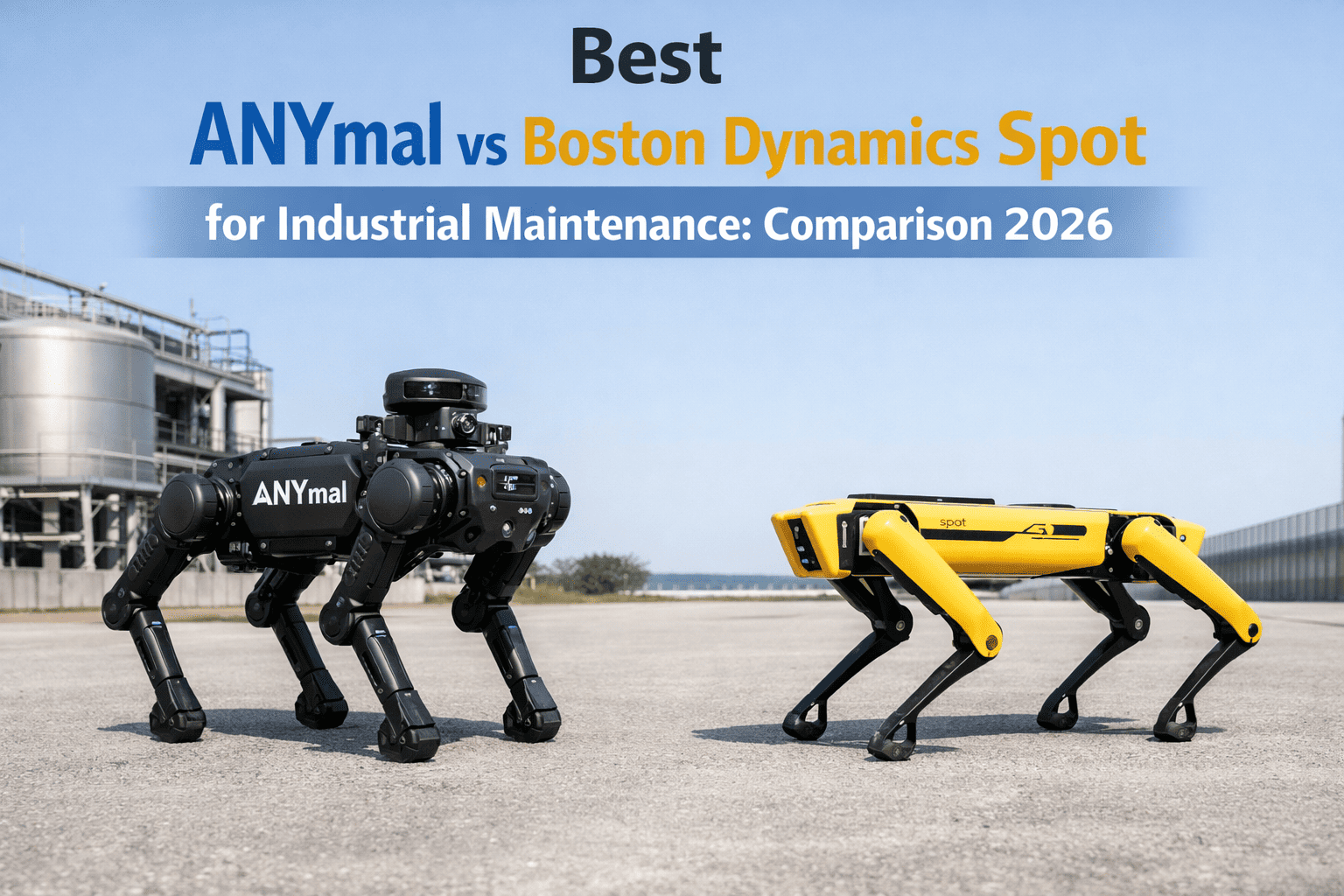

Multi-Vendor Fleet Complexity

Many enterprise deployments mix platforms — Spot for indoor inspections, ANYmal for ATEX-rated hazardous zones, Unitree for cost-effective perimeter patrols. Each vendor has different spare parts, maintenance intervals, and API protocols. A platform-agnostic CMMS unifies everything.

Start Managing Your Robot Fleet as Trackable CMMS Assets Today

Create your free Oxmaint account to register each quadruped as a managed asset — set up preventive maintenance schedules, track battery cycles, configure spare parts inventories, and build work order templates ready for your first robot-generated finding.

Sign Up Free

How to Structure a Multi-Dock Charging Grid for Maximum Autonomous Coverage

Battery endurance defines how far a quadruped can patrol before returning to charge. Boston Dynamics' multi-docking feature now lets Spot recharge at the nearest available dock along its route — but the physical dock layout determines whether your fleet achieves continuous coverage or spends half its time commuting back to a single home base. The following configurations have been validated at operational sites running 10+ unit fleets.

Every dock is registered as a managed asset in Oxmaint with uptime tracking, power draw logging, and automated maintenance alerts. Dock failures trigger instant rerouting of assigned robots.

Building the Automated Inspection-to-Work-Order Pipeline Inside Your CMMS

The single most valuable outcome of CMMS-integrated robot fleets is eliminating manual data transfer. When a quadruped detects a thermal anomaly on a motor bearing at 2 AM, the finding should become a prioritized work order in your CMMS before the morning shift arrives — with photos, GPS coordinates, severity classification, and the affected asset's full maintenance history attached. Here is how the pipeline works inside Oxmaint.

1

Robot Completes Inspection Route

Quadruped runs scheduled autonomous mission capturing thermal, acoustic, visual, and vibration data at each configured checkpoint. Onboard AI performs initial anomaly classification in real time.

2

Findings Upload to Fleet Software

Data syncs to the robot manufacturer's fleet platform (Orbit, ANYmal Fleet, etc.) where AI models refine severity scores and flag anomalies against historical baselines for that specific inspection point.

3

API Pushes Findings to Oxmaint

Critical and high-severity findings push automatically into Oxmaint via API. Each finding is matched to the correct asset record using location coordinates and asset tags configured during fleet setup.

4

CMMS Generates and Assigns Work Orders

Oxmaint creates work orders with attached images, sensor readings, recommended actions, and priority levels. Orders route to the correct technician based on skill, zone assignment, and current workload.

5

Completed Repairs Feed Back Into Asset History

When technicians close work orders, the repair data joins the asset's continuous condition record — building the predictive maintenance intelligence that makes each subsequent robot patrol more valuable.

Watch a Robot Finding Become a Resolved Work Order in Under 60 Seconds

In your personalized demo, we will walk through the full pipeline — a real quadruped thermal anomaly flowing into Oxmaint, auto-generating a prioritized work order with photos and location, routing it to the right technician, and closing the loop with documented repair data.

Book a Demo

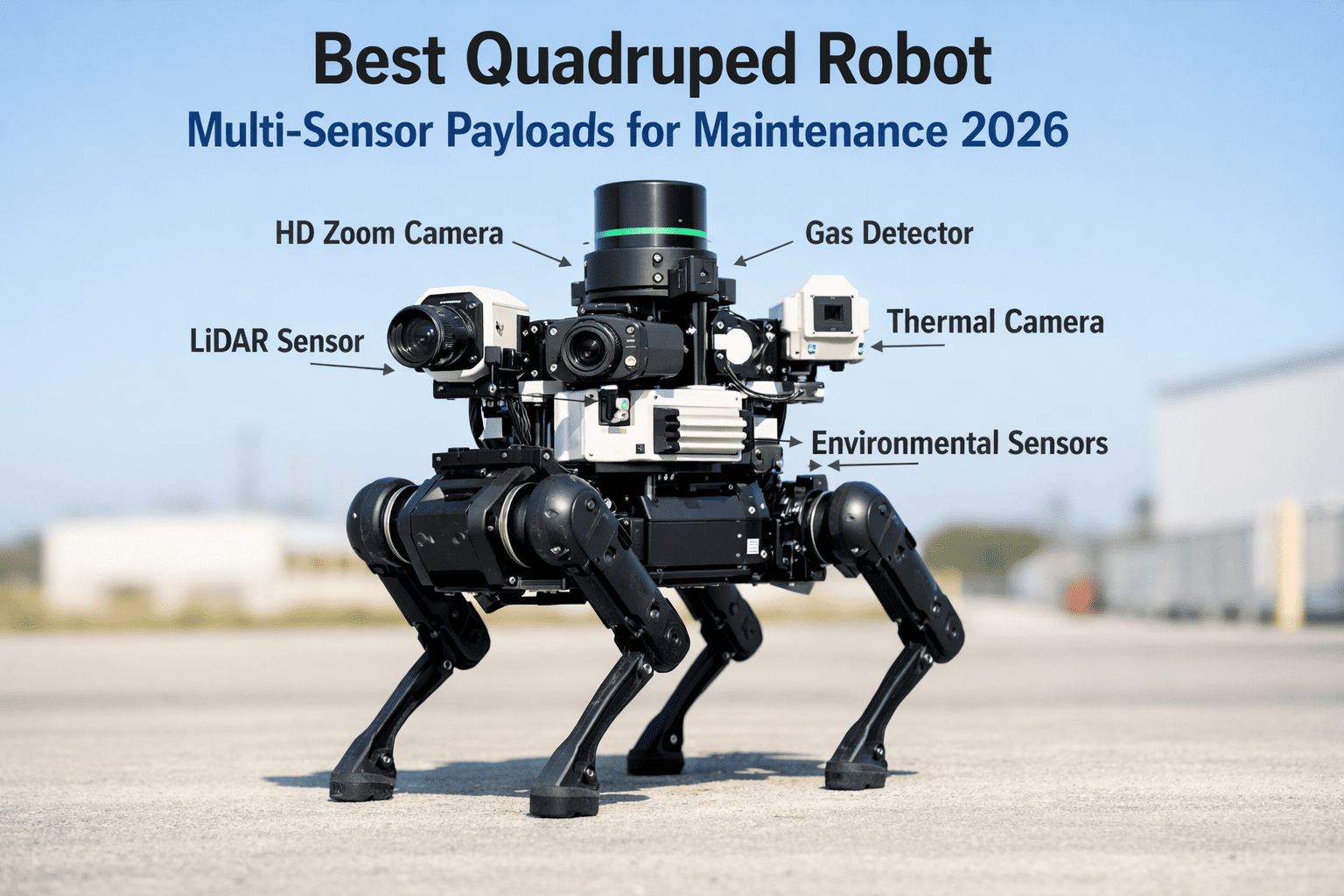

Connecting Robot Fleet Software to SCADA, ERP, and Enterprise Systems

At enterprise scale, robot data cannot live in a silo. The CMMS serves as the integration hub connecting quadruped fleet software to the broader operational technology stack. This is the architecture that facilities operating 10+ robots at POSCO, Cargill, J-POWER, and similar enterprises have implemented.

Robot Fleet Platform

Real-time API

Mission status, inspection alerts, robot health telemetry, sensor payloads, and anomaly classifications flow into Oxmaint continuously.

SCADA / DCS

Event-triggered

Robot findings correlate with live process variables — a thermal spike on a pump cross-references with SCADA flow data to confirm or dismiss the anomaly.

ERP / Financial

Scheduled batch

Fleet operating costs, spare parts procurement, robot depreciation, and ROI tracking feed into financial planning systems automatically.

Digital Twin Platform

Continuous sync

Robot-captured 3D scans and inspection data keep facility digital twins current — Spot's Leica BLK ARC integration enables automated reality capture.

Safety & Compliance

Continuous feed

Gas detection, hazard zone verification, and environmental monitoring data from robot patrols feed directly into compliance reporting systems.

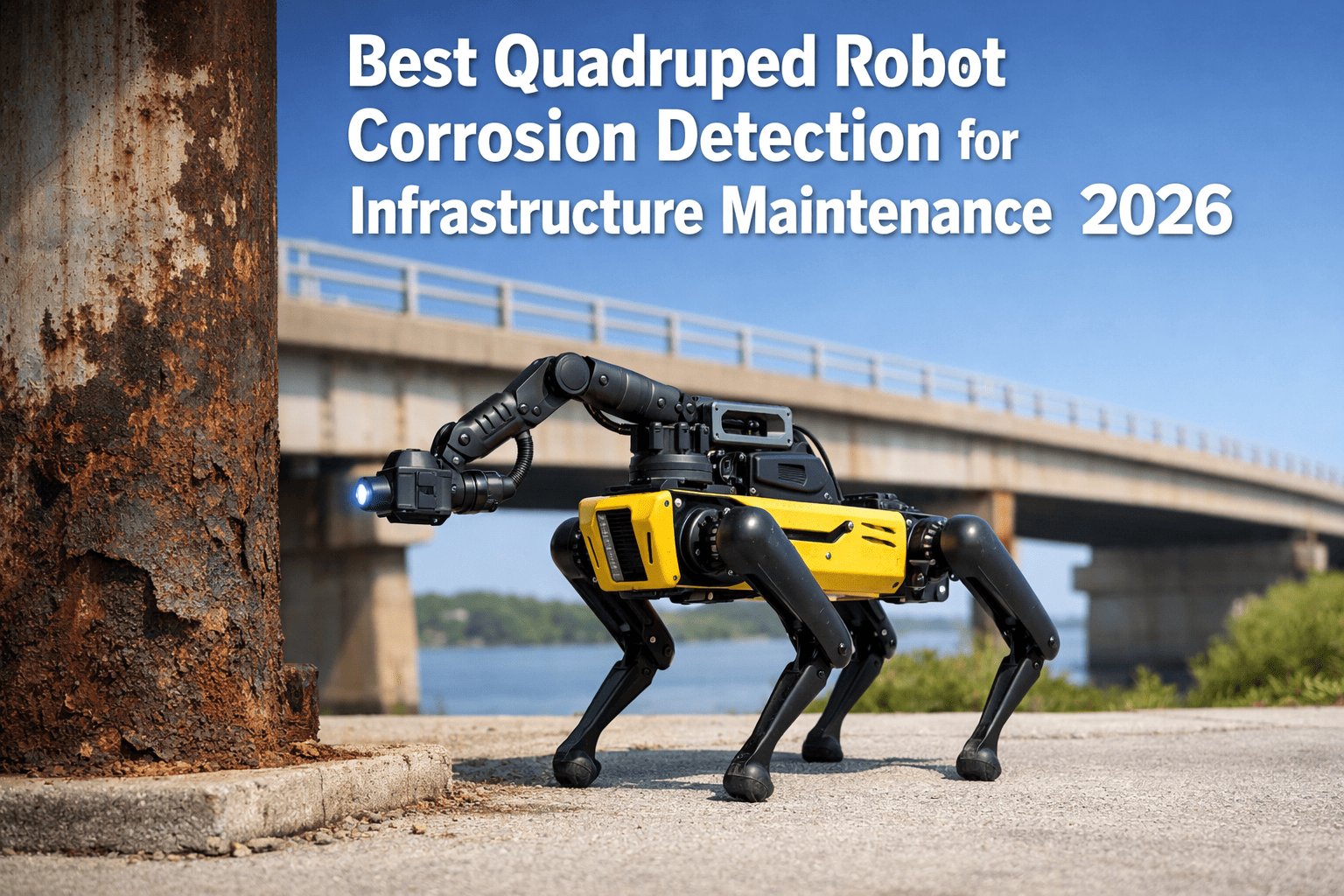

Which Quadruped Platforms Support Enterprise Fleet Deployment in 2026

Not every quadruped robot is built for multi-unit fleet operations. Enterprise deployment requires autonomous multi-docking, fleet management software, open APIs for CMMS integration, and proven long-term reliability. These are the platforms that facilities running 10+ unit fleets are selecting in 2026.

All platforms listed offer API-based connectivity with CMMS systems like Oxmaint. Platform selection depends on your operating environment, hazardous area classification, and budget.

Measurable Outcomes from Facilities Running 10+ Robot Fleets

Fleet-scale quadruped deployment delivers compounding returns — each additional robot increases inspection density while the CMMS infrastructure cost stays flat. These outcomes are drawn from documented deployments at breweries, steel mills, power plants, and refineries operating fleet-scale quadruped programs between 2024 and 2026.

13 days

Average repair time at AB InBev after Spot deployment — down from several months with traditional inspection methods

72

Maintenance work orders created from robot inspection data at Michelin Lexington in the first 6 months of operation

40%

Reduction in manual patrol hours at a North American refinery using autonomous overnight quadruped fleet patrols

Vendors now differentiate via SDKs, ROS2 support, APIs, and partner ecosystems — offering turnkey workflows integrated with VMS, CMMS, and digital-twin systems. The shift from robot-as-product to robot-as-platform is the defining trend for 2026 fleet deployments.

— Research and Markets, Quadruped Robot Market Outlook 2026-2034

Step-by-Step: Scaling from Pilot to Full Fleet in Under 12 Months

The organizations that reach 10+ robots fastest share one trait: they build CMMS workflows during the pilot, not after. Here is the proven phased approach used by facilities that have scaled successfully.

Month 1-2

Focused Pilot with CMMS Foundation

Deploy 1-2 robots in highest-value inspection zone. Register robots as assets in Oxmaint. Configure work order templates, establish inspection baselines, and validate API connectivity between fleet software and CMMS.

Month 3-5

Multi-Zone Expansion

Add 3-5 robots covering additional buildings or zones. Install multi-dock grid. Integrate robot inspection data with existing preventive maintenance schedules. Train maintenance staff on robot-generated work order workflows.

Month 6-9

Fleet Operations Mode

Scale to 6-10 robots running shift-based schedules. Enable automated anomaly-to-work-order pipeline. Begin tracking fleet KPIs — mission completion rates, anomaly detection rates, mean time between robot PM events.

Month 10-12

Enterprise Scale and Multi-Site Rollout

Deploy 10+ robots with centralized CMMS dashboards. Benchmark fleet performance across sites. Activate cross-facility inspection standardization. Connect to ERP, SCADA, and digital twin systems for full operational integration.

Your Robots Inspect. Your CMMS Acts. Your Facility Improves.

Whether you are deploying your first Spot or orchestrating 20+ quadrupeds across multiple sites, Oxmaint gives your fleet the maintenance backbone it needs — automated work orders, asset-level robot tracking, multi-dock management, and enterprise dashboards your team already knows how to use.

Frequently Asked Questions

What is the difference between robot fleet software and a CMMS for managing quadruped robots?

Robot fleet software like Boston Dynamics Orbit manages robot missions, routes, and telemetry — it is the robot's operating system. A CMMS like Oxmaint manages maintenance operations: work orders, asset histories, spare parts, technician scheduling, and compliance reporting for every asset in your facility, including the robots. The two systems integrate via API so that robot-detected anomalies automatically become prioritized maintenance actions in Oxmaint.

Sign up for a free Oxmaint account to connect your robot fleet API and see automated work orders in action.

How many charging docks do I need for a fleet of 10 or more quadruped robots?

The established best practice is a 1.5x to 2x dock-to-robot ratio. For a 12-robot fleet, plan 18-24 docking stations positioned so no robot travels more than half its battery capacity to reach a charger. Each dock becomes a tracked asset in your CMMS with uptime monitoring, power draw records, and automated maintenance alerts. Strategic dock placement eliminates charging queue conflicts and ensures uninterrupted coverage.

Can Oxmaint manage a mixed fleet of robots from different manufacturers?

How quickly can a facility scale from a pilot to 10+ quadruped robots?

Typical timelines are 6-12 months from a 1-2 robot pilot to full fleet operations at 10+ units. The critical accelerator is integrating CMMS from day one of the pilot — organizations that do this scale 3-5x faster because workflows, work order templates, and data pipelines are already production-ready when new robots are added to the fleet.

What preventive maintenance do quadruped robots require, and how does Oxmaint track it?

Quadruped robots need periodic foot gripper replacement (every 500-1,000 km walked), battery cycle management, sensor calibration, joint lubrication, body panel inspection, and firmware updates. In Oxmaint, each robot has its own PM schedule triggered by operating hours, distance traveled, or calendar intervals — identical to how you manage pumps, motors, or any other critical asset.

Sign up free to set up preventive maintenance schedules for your quadruped fleet — track walk distance, battery cycles, and calibration intervals per robot.