Every multi-level facility — from power plants and refineries to data centers and warehouses — faces the same inspection bottleneck: stairs. Wheeled drones stop at the stairwell, elevators slow the process, and sending technicians floor-to-floor burns hours, creates fatigue-driven blind spots, and puts people in high-risk zones they should not need to enter. Quadruped robots solve this by doing what no other inspection platform can — walking up and down stairs autonomously, scanning each floor with thermal, acoustic, and visual sensors, then feeding every finding directly into your CMMS. Schedule a demo to see how Oxmaint turns stair-climbing robot patrols into closed-loop maintenance workflows across every level of your facility.

How Do Robot Dogs Climb Stairs in Industrial Facilities?

Stair climbing is the single capability that makes quadruped robots viable for multi-level inspection. Unlike tracked or wheeled machines, four-legged robots use dynamic locomotion — adjusting each foot placement in real time based on step geometry, surface condition, and body balance. The latest models navigate standard industrial stairs, spiral staircases, open grating, and ramps up to 35 degrees without human assistance.

Step 1

3D Stairwell Mapping

Onboard LiDAR and depth cameras generate a real-time 3D point cloud of the stairwell before the robot takes its first step. The system identifies step height, tread depth, railing position, and any debris or obstructions — building a precise movement plan in under two seconds.

Step 2

Adaptive Gait Selection

The locomotion controller switches from a trotting gait (used on flat floors) to a deliberate crawl gait optimized for stairs. Each leg lifts, reaches, and plants on the next step while three legs maintain ground contact — ensuring stability throughout the climb even on wet or uneven treads.

Step 3

Real-Time Balance Correction

IMU sensors and torque-feedback joints adjust the robot's posture over 500 times per second. If a foot slips, contacts an unexpected edge, or lands on debris, the system redistributes weight instantly — the same reflex that keeps a real dog steady on wet stairs.

Step 4

Floor-Level Localization

Upon reaching the new floor, the robot matches its surroundings against pre-loaded facility maps to confirm exactly which level it is on. It then seamlessly transitions into that floor's inspection route — no operator input, no delay, no guesswork.

See stair navigation and floor-by-floor reporting live. Our team will walk you through a real multi-level inspection mission inside Oxmaint.

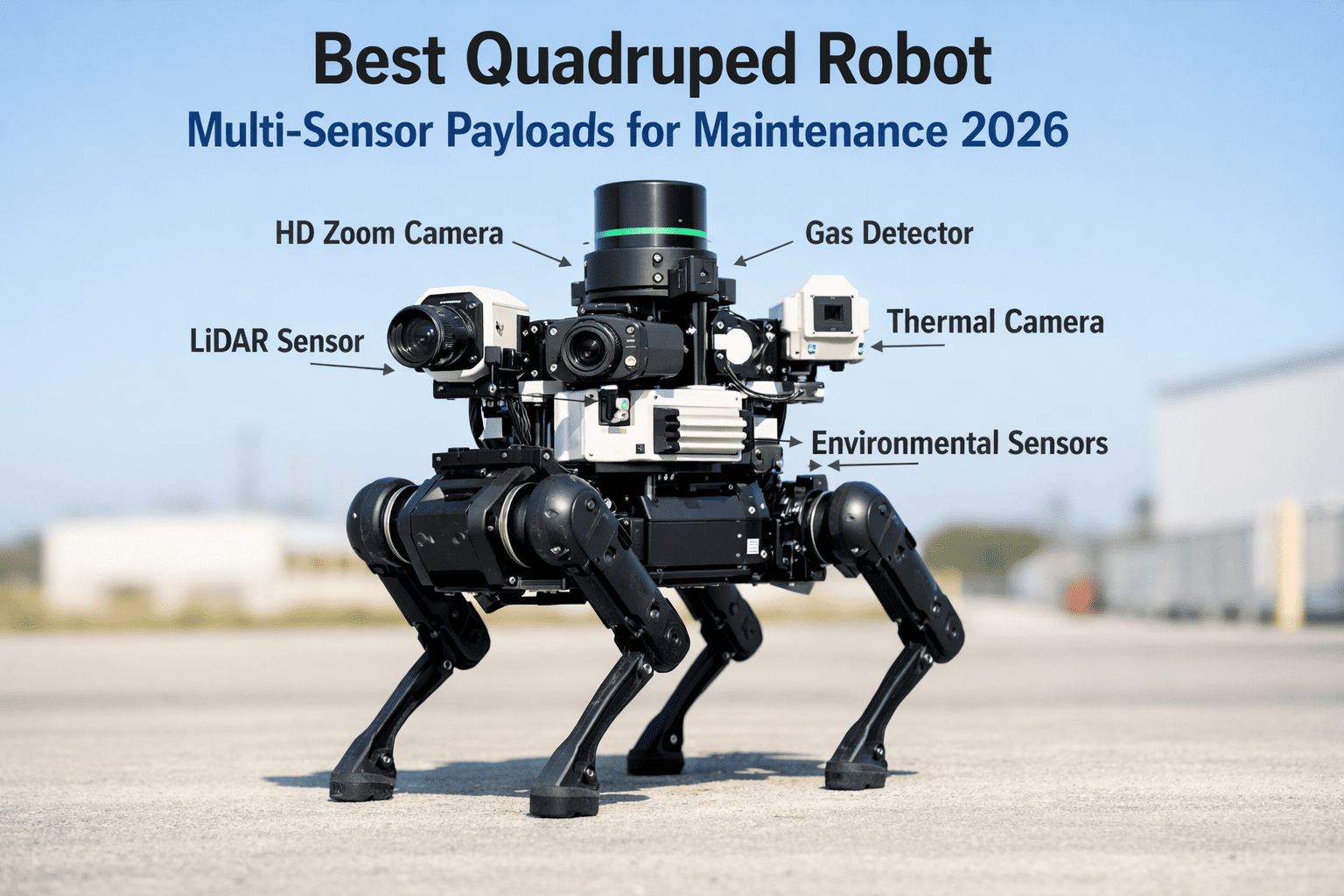

What Can a Quadruped Robot Inspect on Each Floor?

Climbing stairs is only the means — what the robot captures on every floor is where the maintenance value lives. A single quadruped carries sensor payloads that would require multiple human specialists and separate instruments to replicate, completing an entire floor's inspection checklist in one autonomous pass.

Sensor Capabilities Per Floor

Thermal Imaging

Radiometric IR cameras detect overheating electrical panels, insulation gaps, steam leaks, and HVAC faults at 0.05 degrees C sensitivity — flagging issues invisible to the naked eye on every floor.

Acoustic Leak Detection

Ultrasonic microphones pinpoint compressed air leaks, bearing degradation, and electrical arcing by frequency signature — catching failures weeks before they become visible damage.

Visual AI & Gauge Reading

HD cameras with computer vision read analog gauges, verify valve positions, check safety signage, and document corrosion — replacing clipboard rounds with consistent digital records.

Gas & Air Quality Mapping

Onboard sensors for methane, CO, H2S, and VOCs create spatial air quality maps as the robot moves — locating leak sources by floor zone instead of relying on fixed-point detectors.

Vibration Analysis

Contact and non-contact vibration sensors assess rotating equipment health, piping resonance, and structural integrity at every checkpoint — building trend data across repeated missions.

LiDAR Structural Scanning

3D point clouds track floor deflection, equipment displacement, and structural deformation over time by comparing scans across successive patrols — detecting drift humans cannot perceive.

How CMMS Software Turns Robot Patrol Data Into Work Orders

Raw sensor data from a robot means nothing without a system to interpret, route, and act on it. When quadruped inspection robots connect to a CMMS, every anomaly detected on every floor automatically becomes a tracked maintenance event. Sign up for Oxmaint to automate robot-to-work-order data flow across your entire building — with asset location, severity classification, and supporting evidence attached.

From Robot Sensor to Maintenance Action

Robot Detects Anomaly

Thermal spike, abnormal vibration, gas reading, or gauge deviation flagged during floor patrol

AI Classifies & Prioritizes

Onboard algorithms assign severity level, asset ID, and floor location based on detection type and threshold

Oxmaint Receives Data

API pushes finding with thermal image, vibration chart, or photo directly into the asset's history in Oxmaint

Work Order Created

Critical issues generate immediate work orders; routine findings queue for next scheduled maintenance window

Technician Resolves & Closes

Maintenance team acts on the order; resolution is logged and the next robot patrol verifies the fix automatically

Eliminate manual data entry from inspection reports. Sign up for Oxmaint and connect robot findings to your work order pipeline instantly.

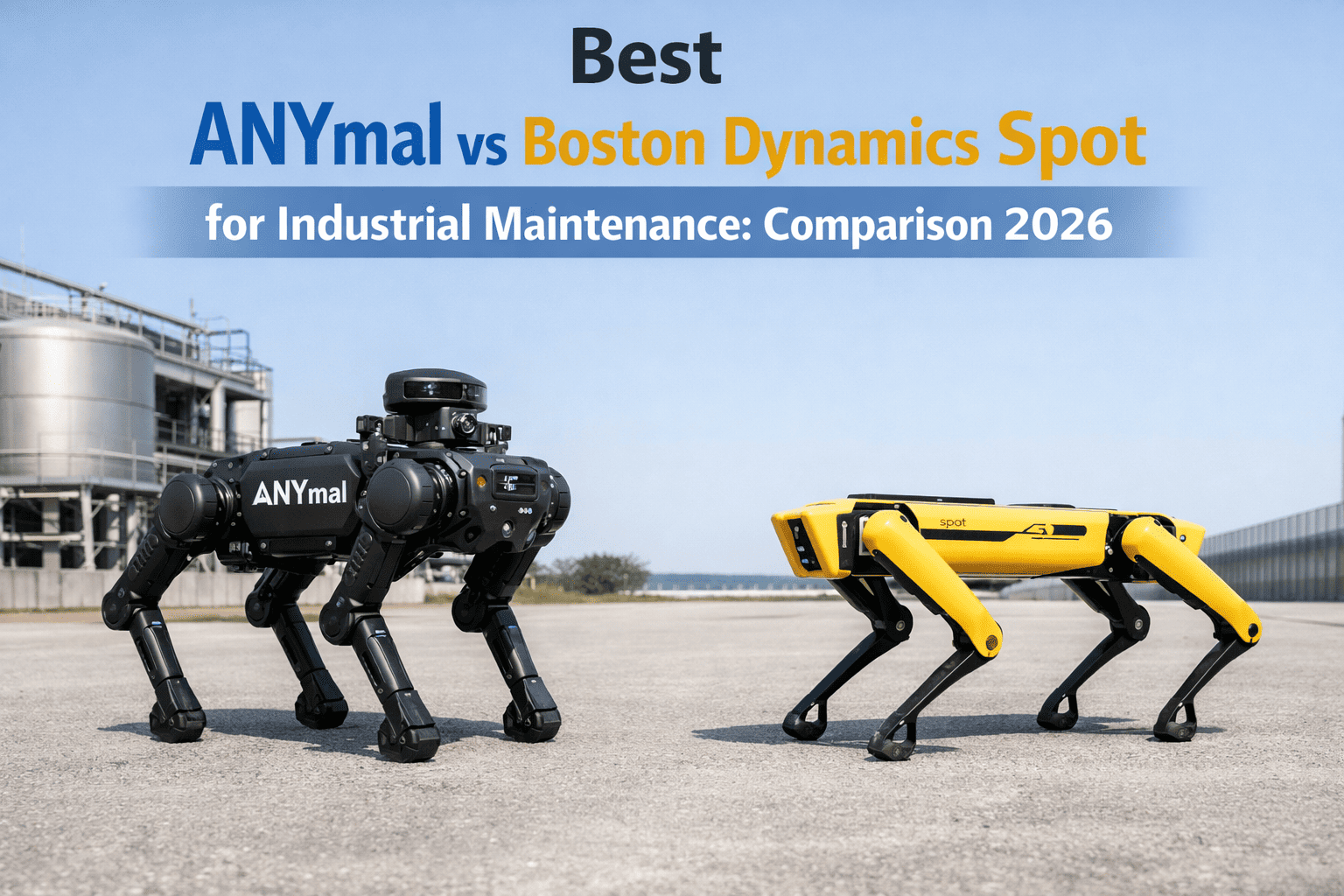

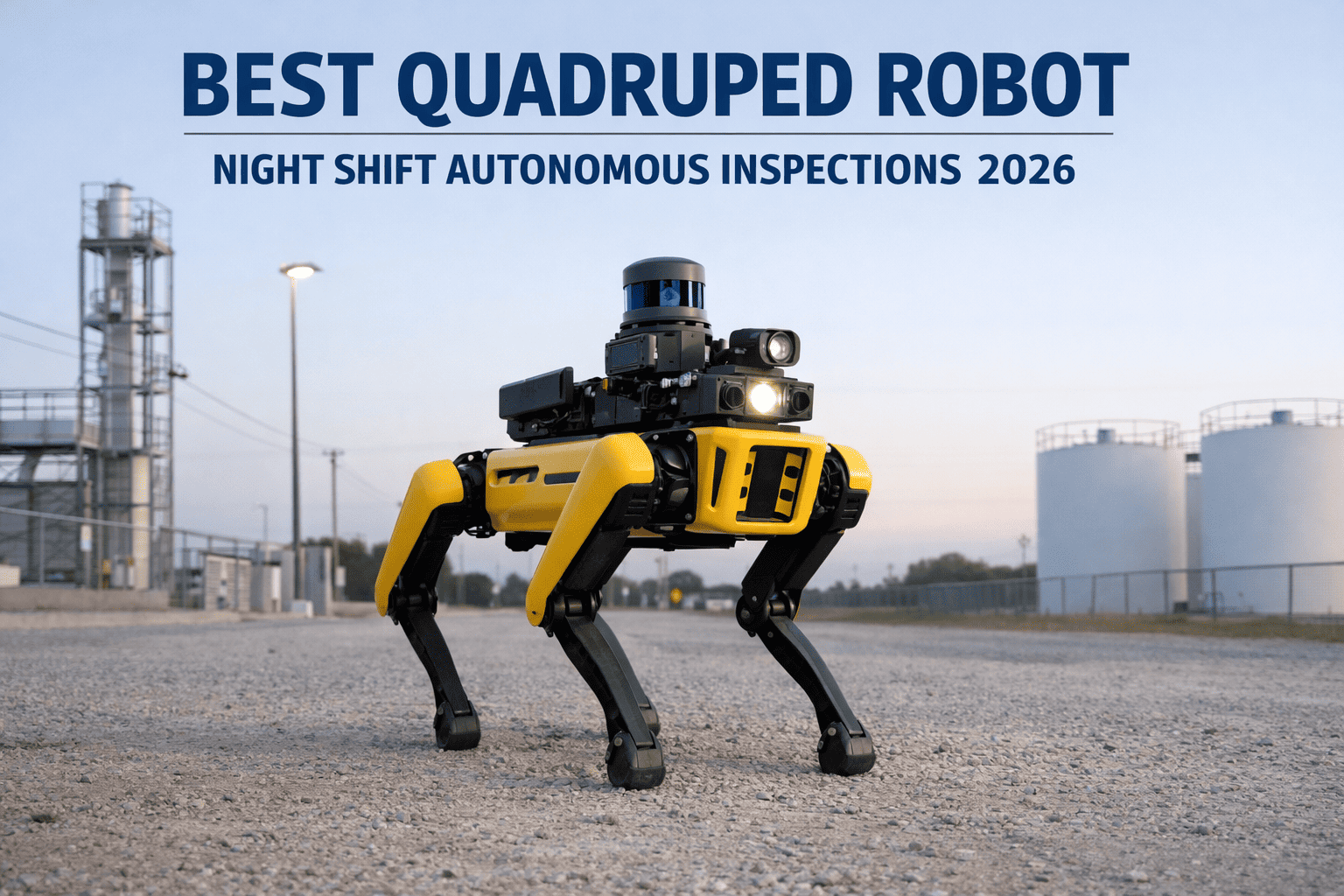

Top Stair-Climbing Robot Dogs for Building Inspection in 2026

Not all quadruped platforms perform equally on stairs. Stair incline capacity, payload weight, battery endurance, and CMMS integration readiness vary significantly. Here is how the leading platforms compare for multi-level facility inspection this year.

Boston Dynamics Spot

Most Deployed

Stair AngleUp to 30 degrees

Payload14 kg sensor capacity

Runtime~90 min per charge

Best ForPower plants, data centers, construction

CMMS ReadyREST API, Oxmaint-compatible

ANYbotics ANYmal

IP67 Rated

Stair AngleIndustrial stairs, gratings, ladders

Payload15 kg integrated sensors

Runtime~120 min per charge

Best ForOil and gas, petrochemical, offshore

CMMS ReadyNative API, Oxmaint-compatible

Unitree B2

Cost-Effective

Stair AngleUp to 35 degrees

Payload20 kg modular payload

Runtime~100 min per charge

Best ForWarehouses, manufacturing, fleet deployment

CMMS ReadyREST API, Oxmaint-compatible

PUDU D5 Hybrid

Fastest Climber

Stair AngleUp to 30 degrees, 1.5 m/s climb speed

Payload30 kg capacity

Runtime~90 min per charge

Best ForMixed terrain, logistics, large campuses

CMMS ReadyAPI available, custom integration

Robot Dog Inspection vs. Manual Walkthrough: Real Cost and Accuracy Differences

The performance gap between sending a technician through a multi-story building and deploying a quadruped robot is not marginal — it is structural. Understanding the measurable differences helps maintenance leaders build the business case for robotic inspection.

Multi-Level Inspection Comparison

Manual Floor-by-Floor Walkthrough

2-3 days to complete a 10-floor inspection cycle

Technician fatigue increases missed defects on upper floors

Limited to visual and basic handheld instrument checks

Findings vary between inspectors and shift conditions

Manual data entry into CMMS delays response by hours or days

60-70%

of detectable issues missed between cycles

Quadruped Robot + Oxmaint CMMS

Full 10-floor sweep completed in under 4 hours

Identical scan quality on floor 1 and floor 10

Thermal, acoustic, visual, gas, and vibration combined

Repeatable, data-consistent results every single mission

Findings auto-populate Oxmaint work orders in real time

98.5%

anomaly detection with auto-logged CMMS evidence

Replace Manual Walkthrough Gaps With Continuous Robotic Coverage

Oxmaint connects stair-climbing robot platforms to your maintenance operation — every floor scanned, every anomaly logged, every work order created automatically. No clipboard handoffs. No missed floors. No delayed reports.

Which Industries Use Stair-Climbing Robots for Multi-Floor Inspection?

Any facility with multiple levels and critical assets benefits from quadruped inspection. However, some industries see outsized returns because their buildings combine height, hazardous conditions, and high inspection frequency requirements — exactly the combination where stair-climbing robots deliver the strongest ROI.

Power Plants & Substations

Multi-story boiler buildings, turbine halls, and switchgear rooms with thermal, acoustic, and gas monitoring needs across 5-15 levels. Robots reduce human exposure to high-voltage and high-temperature zones.

Oil, Gas & Petrochemical

Process towers, pipe racks, and offshore platform decks connected by steep industrial stairs. Robots navigate ATEX/IECEx zones for gas leak detection and fired heater monitoring without exposing workers.

Data Centers

Raised-floor server rooms across multiple stories require constant thermal monitoring. Quadruped robots patrol between floors detecting hotspots, cooling failures, and environmental anomalies 24/7.

Manufacturing & Warehousing

Multi-level production floors, mezzanines, and storage areas with rotating equipment, conveyor systems, and electrical distribution requiring floor-by-floor vibration and thermal assessment.

Mining & Minerals Processing

Processing plants with multiple elevation levels, crusher buildings, and conveyor transfer towers. Robots handle dust, vibration-heavy environments, and steep industrial staircases that challenge human inspectors.

Commercial & Government Buildings

High-rise facilities with HVAC, fire suppression, and electrical systems distributed across dozens of floors.

Sign up for Oxmaint to get compliance-ready inspection records automatically generated per floor after every robotic patrol.

Measured ROI: What Multi-Level Robotic Inspection Actually Delivers

Facility managers considering quadruped robots need numbers, not promises. The following metrics reflect documented outcomes from industrial deployments where stair-climbing robots replaced or augmented manual multi-floor inspections during 2025 and early 2026.

73%

Reduction in inspection labor costs for facilities with 5+ floors

80%

Fewer safety incidents during routine inspection operations

55%

More defects caught per inspection cycle compared to manual rounds

70%

Reduction in O&M costs reported at power substations

Model the ROI for your specific facility. Create a free Oxmaint account and our team will calculate projected savings based on your floor count and inspection schedule.

How to Deploy a Quadruped Inspection Robot in Your Facility

Successful deployment follows a structured rollout — from stairwell mapping through fully autonomous multi-floor patrols. Schedule a consultation to receive a deployment timeline customized for your building configuration and CMMS requirements.

Phase 1

Facility & Stairwell Assessment

Week 1-2

Map stairwell dimensions, surface types, and obstructions

Identify inspection checkpoints per floor level

Document CMMS integration requirements with Oxmaint

Phase 2

Robot Setup & CMMS Connection

Week 3-4

Configure sensor payloads for your asset types

Program navigation routes including stair transitions

Connect robot API to Oxmaint work order pipeline

Phase 3

Supervised Trial Missions

Week 5-6

Operator-accompanied stair climbing on all routes

Validate detection accuracy against known conditions

Calibrate alert thresholds and work order severity in Oxmaint

Phase 4

Autonomous Multi-Floor Operations

Week 7+

Scheduled autonomous patrols across all building levels

Continuous AI model refinement from inspection data

Expand to additional buildings and facilities

The stair-climbing capability changed everything. We went from a three-day manual inspection cycle across seven floors to a four-hour autonomous mission that catches issues we never found before. The direct connection to our CMMS means nothing slips between floors anymore.

— Facilities Director, Multi-Level Manufacturing Plant

Connect Every Floor of Your Facility to One Maintenance Workflow

Your multi-level building deserves inspection that reaches every floor, every time. Oxmaint integrates with stair-climbing quadruped robots to convert autonomous patrol data into organized work orders — assets updated, compliance documented, and corrective actions tracked across every single level without manual effort.

Frequently Asked Questions

Can robot dogs climb spiral stairs and open-grating staircases?

Yes. Current quadruped robots including Spot, ANYmal, and Unitree B2 handle standard straight stairs, spiral staircases, and open-grating industrial stairs. They adapt to varying step heights up to 25 cm and manage wet, dusty, or debris-covered steps using real-time force feedback and dynamic balance control.

Book a demo to discuss your specific stairwell configurations with our team.

How many floors can a robot inspect on one battery charge?

Most industrial quadruped robots operate for 90 to 120 minutes per charge — enough to cover 8 to 12 floors including stair climbing and detailed inspection stops at each level. For larger buildings, autonomous docking stations placed at strategic floors allow the robot to recharge and resume its mission without human intervention.

Does robot inspection data go directly into Oxmaint CMMS?

Yes. Oxmaint provides API connectors that receive inspection data from leading quadruped platforms. Thermal images, vibration readings, gas alerts, and gauge readings are automatically tagged with asset IDs and floor locations, then converted into work orders or asset condition updates. No manual data entry required.

Sign up for a free account to explore the integration features.

What happens if a stairwell is blocked or obstructed?

The robot uses LiDAR and depth cameras for real-time obstacle detection. If a stairwell is blocked, it stops, logs the obstruction as a finding in the CMMS, and either waits for operator clearance or reroutes to an alternative stairwell if one exists in its navigation map. Safety is never compromised during autonomous operation.

Is Oxmaint compatible with multiple quadruped robot brands?

Yes. Oxmaint supports integration with Boston Dynamics Spot, ANYbotics ANYmal, Unitree B2, and other platforms through standard REST APIs. You can run different robots across different facilities and consolidate all inspection data into a single maintenance management workflow inside Oxmaint.

Schedule a consultation to plan your multi-platform integration strategy.