Modern chiller maintenance has evolved beyond reactive repairs and paper-based logs. IoT-enabled workflows now connect every sensor, technician, and work order into a seamless digital ecosystem—transforming how chiller teams detect issues, coordinate responses, and optimize system performance. With approximately 300 data points captured by typical building HVAC systems, manual monitoring simply cannot match the precision and speed that connected workflows deliver. Schedule a consultation to explore how IoT workflows can transform your chiller maintenance operations.

Why IoT Workflows Matter for Chiller Teams

Chiller systems represent one of the most energy-intensive components in commercial and industrial facilities, often accounting for over one-third of total building energy consumption. Traditional maintenance approaches—monthly inspections, reactive repairs, and spreadsheet tracking—leave significant efficiency gaps and create costly downtime situations that connected workflows eliminate entirely.

How IoT Workflows Transform Chiller Operations

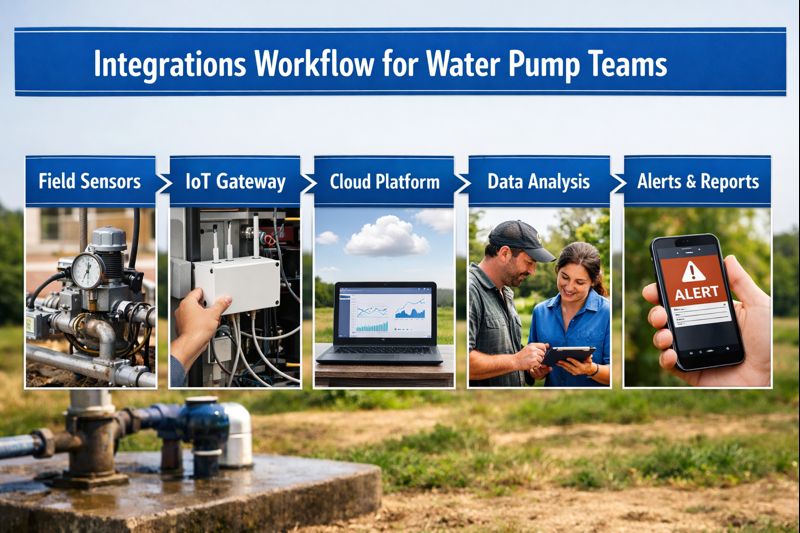

An IoT-enabled workflow creates a continuous loop of monitoring, analysis, action, and optimization. Sensors capture real-time data from compressors, condensers, evaporators, and cooling towers—then feed that intelligence directly into your maintenance management platform for immediate response.

Core IoT Workflow Components

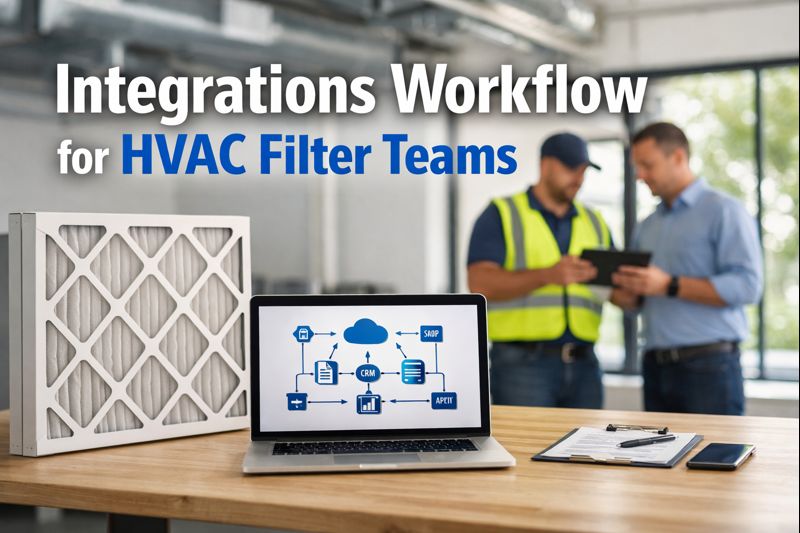

Building an effective IoT workflow for chiller teams requires integrating multiple technology layers—from physical sensors to cloud analytics platforms. Each component serves a specific function in the connected maintenance ecosystem.

Key Monitoring Points for Chiller Systems

Comprehensive IoT monitoring covers every critical component in the chiller system—from the compressor heart to the cooling tower periphery. Strategic sensor placement ensures complete visibility into system health and performance.

| Component | Sensor Type | Key Metrics | Alert Triggers |

|---|---|---|---|

| Compressor | Vibration, temperature, current | Discharge pressure, motor amps, bearing health | Vibration anomalies, overcurrent, high discharge temp |

| Evaporator | Temperature, pressure, flow | Approach temperature, refrigerant superheat | Low refrigerant, fouling indicators, freeze protection |

| Condenser | Temperature, pressure | Subcooling, condenser pressure, efficiency | High head pressure, tube fouling, airflow restriction |

| Cooling Tower | Temperature, flow, conductivity | Water quality, approach, fan motor status | Scale buildup, biological growth, motor failure |

| Pumps | Vibration, flow, pressure | Flow rate, differential pressure, bearing condition | Cavitation, seal wear, impeller damage |

Traditional vs. IoT-Connected Chiller Maintenance

Understanding the operational differences between legacy approaches and IoT-enabled workflows reveals why forward-thinking facilities are transitioning to connected maintenance strategies.

- Scheduled inspections regardless of equipment condition

- Reactive response after equipment failures occur

- Paper-based logs with manual data entry

- Technician dispatched without diagnostic information

- Limited visibility into system efficiency trends

- Condition-based maintenance triggered by actual need

- Predictive alerts before failures impact operations

- Automatic digital documentation and compliance trails

- Technician arrives with diagnostics and parts ready

- Real-time efficiency dashboards and optimization insights

Building Your IoT Workflow

Implementing connected workflows requires a structured approach that builds capability progressively—starting with critical monitoring points and expanding as your team gains experience with data-driven maintenance.

Industry Applications

IoT-connected chiller workflows deliver value across diverse facility types—each with unique operational requirements and compliance considerations that connected maintenance addresses comprehensively.

| Industry | Critical Requirements | IoT Workflow Benefits |

|---|---|---|

| Data Centers | 99.999% uptime, precise temperature control, redundancy management | Predictive failure alerts, automatic failover coordination, efficiency optimization |

| Healthcare Facilities | Patient comfort, OR temperature control, regulatory compliance | Critical zone monitoring, compliance documentation, maintenance scheduling around procedures |

| Manufacturing Plants | Process cooling precision, production schedule integration | Production-aware maintenance timing, efficiency tracking per unit output |

| Commercial Buildings | Tenant comfort, energy cost management, sustainability goals | Occupancy-based optimization, energy benchmarking, carbon tracking |

| Pharmaceutical | GMP compliance, validated temperature ranges, audit trails | Continuous validation monitoring, automated compliance reports, deviation alerts |

ROI of Connected Chiller Workflows

IoT workflow investments deliver measurable returns through reduced downtime, energy optimization, extended equipment life, and labor efficiency improvements that compound over time.