Lighting panel maintenance teams face unique challenges that demand seamless coordination between electrical inspections, preventive schedules, and real-time issue resolution. When workflows remain siloed across spreadsheets, emails, and disconnected systems, teams lose an average of 7.47 hours per week to ineffective communication alone. Modern CMMS integrations transform fragmented processes into unified workflows where lighting panel data flows automatically between inspection checklists, work orders, and compliance documentation. Schedule a consultation to explore how integrated workflows can streamline your lighting panel maintenance operations.

Why Integration Matters for Lighting Panel Teams

Lighting panel maintenance involves multiple touchpoints including circuit breaker testing, ballast inspections, emergency lighting verification, and energy consumption monitoring. Without integrated systems, teams juggle separate platforms for each function, creating data silos that delay response times and increase error rates.

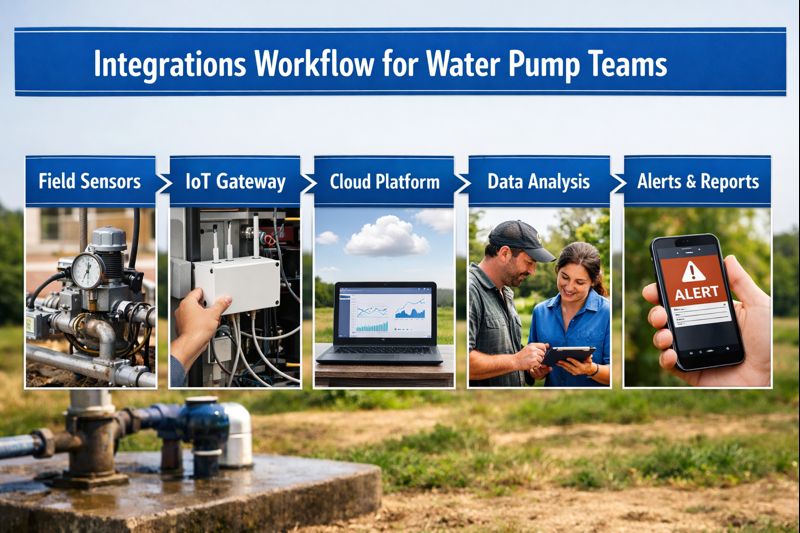

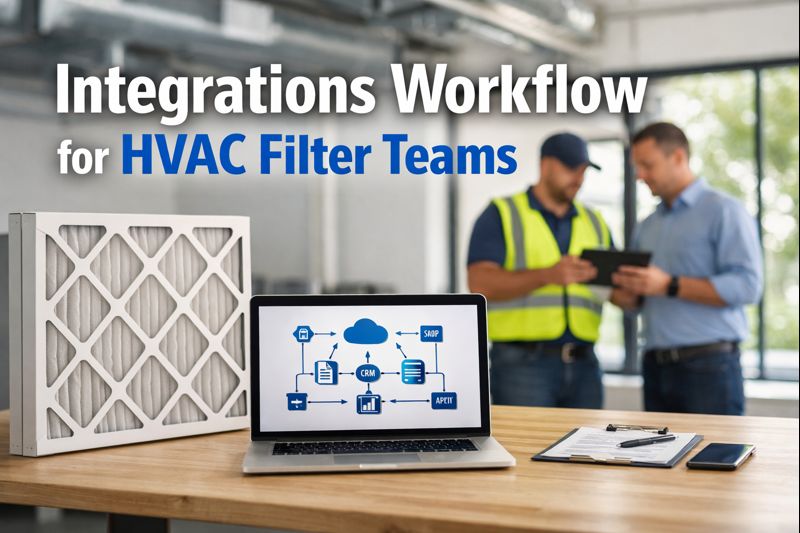

Core Integration Components for Lighting Maintenance

A comprehensive lighting panel workflow integrates multiple system layers, from sensor data collection to automated work order generation and compliance reporting. Each component serves a specific function while contributing to the unified maintenance intelligence.

Key Integration Features for Lighting Panel Teams

Effective workflow integration addresses the specific challenges lighting panel teams face daily, from coordinating multi-site inspections to tracking component lifecycles and ensuring regulatory compliance across diverse fixture types.

Lighting Panel Inspection Workflow Components

Comprehensive lighting panel maintenance requires systematic inspection across multiple components. Integrated workflows ensure nothing gets missed while automatically documenting compliance with electrical codes and safety standards.

| Inspection Point | Frequency | Key Checks | Integration Value |

|---|---|---|---|

| Panel Enclosures | Monthly | Physical damage, corrosion, secure covers, proper labeling | Photo documentation, condition trending, automatic work orders for repairs |

| Circuit Breakers | Annually | Operation testing, overcurrent response, contact condition | Test result logging, replacement scheduling, compliance verification |

| Electrical Connections | Quarterly | Loose wiring, heat discoloration, torque verification | Thermal imaging integration, predictive maintenance alerts |

| Grounding Systems | Annually | Resistance testing, bonding verification, electrode connections | Test value trending, automatic alerts for degradation |

| Emergency Lighting | Monthly/Annually | Battery backup function, illumination levels, exit sign visibility | Test scheduling automation, battery replacement tracking, compliance logs |

| Lighting Fixtures | Quarterly | Bulb condition, ballast function, driver health, lens cleaning | Group relamping scheduling, energy efficiency monitoring |

Disconnected vs. Integrated Workflow Comparison

Understanding the operational differences between traditional siloed approaches and integrated CMMS workflows reveals why maintenance teams increasingly adopt unified platforms for lighting panel management.

- Paper checklists and manual data entry

- Spreadsheet-based scheduling and tracking

- Email chains for issue escalation

- Separate systems for inventory and work orders

- Manual compliance report compilation

- Digital mobile checklists with offline access

- Automated preventive maintenance scheduling

- Real-time alerts and automatic work orders

- Unified asset, inventory, and task management

- One-click compliance documentation

Integration Benefits by Team Role

Different team members benefit from integrated workflows in distinct ways. From technicians executing daily inspections to managers overseeing compliance, unified systems improve efficiency across all roles.

| Team Role | Key Workflow Needs | Integration Benefits |

|---|---|---|

| Field Technicians | Inspection checklists, work instructions, parts access | Mobile access to procedures, automatic parts staging, digital documentation |

| Maintenance Supervisors | Team scheduling, workload visibility, priority management | Real-time dashboards, drag-and-drop scheduling, automatic escalation alerts |

| Facility Managers | Compliance tracking, cost control, performance metrics | Automated compliance reports, budget tracking, KPI dashboards |

| Safety Officers | Audit documentation, incident tracking, regulatory adherence | Audit-ready records, safety inspection logs, regulatory compliance verification |

| Inventory Managers | Stock levels, reorder points, vendor management | Automatic reorder alerts, usage trending, vendor integration |

Implementation Roadmap

Successful workflow integration follows a structured approach that delivers quick wins while building toward comprehensive maintenance optimization. A phased rollout ensures team adoption and system refinement at each stage.

ROI of Integrated Lighting Panel Workflows

Workflow integration delivers measurable returns through reduced downtime, improved team productivity, optimized inventory management, and streamlined compliance processes.