Fleet managers in 2026 are facing a quiet revolution in how vehicle damage is detected, documented, and resolved. AI-powered vision systems, built on deep learning architectures like YOLO, Mask R-CNN, and EfficientNet, now scan fleet vehicles in seconds and identify dents, scratches, cracks, corrosion, tire wear, and structural defects that human inspectors routinely miss. The global AI vehicle inspection market was valued at $1.9 billion in 2024 and is projected to reach $6.9 billion by 2033, growing at a 15.8% CAGR. For fleet operators managing hundreds or thousands of trucks, vans, and service vehicles, this technology eliminates the inconsistency and time cost of manual walkaround inspections. But detecting damage is only half the equation. The real operational advantage comes when AI inspection data flows directly into a CMMS like Oxmaint, automatically generating work orders, scheduling repairs, tracking costs, and building a complete digital history for every vehicle in the fleet.

How AI Vision Systems Detect Fleet Vehicle Damage

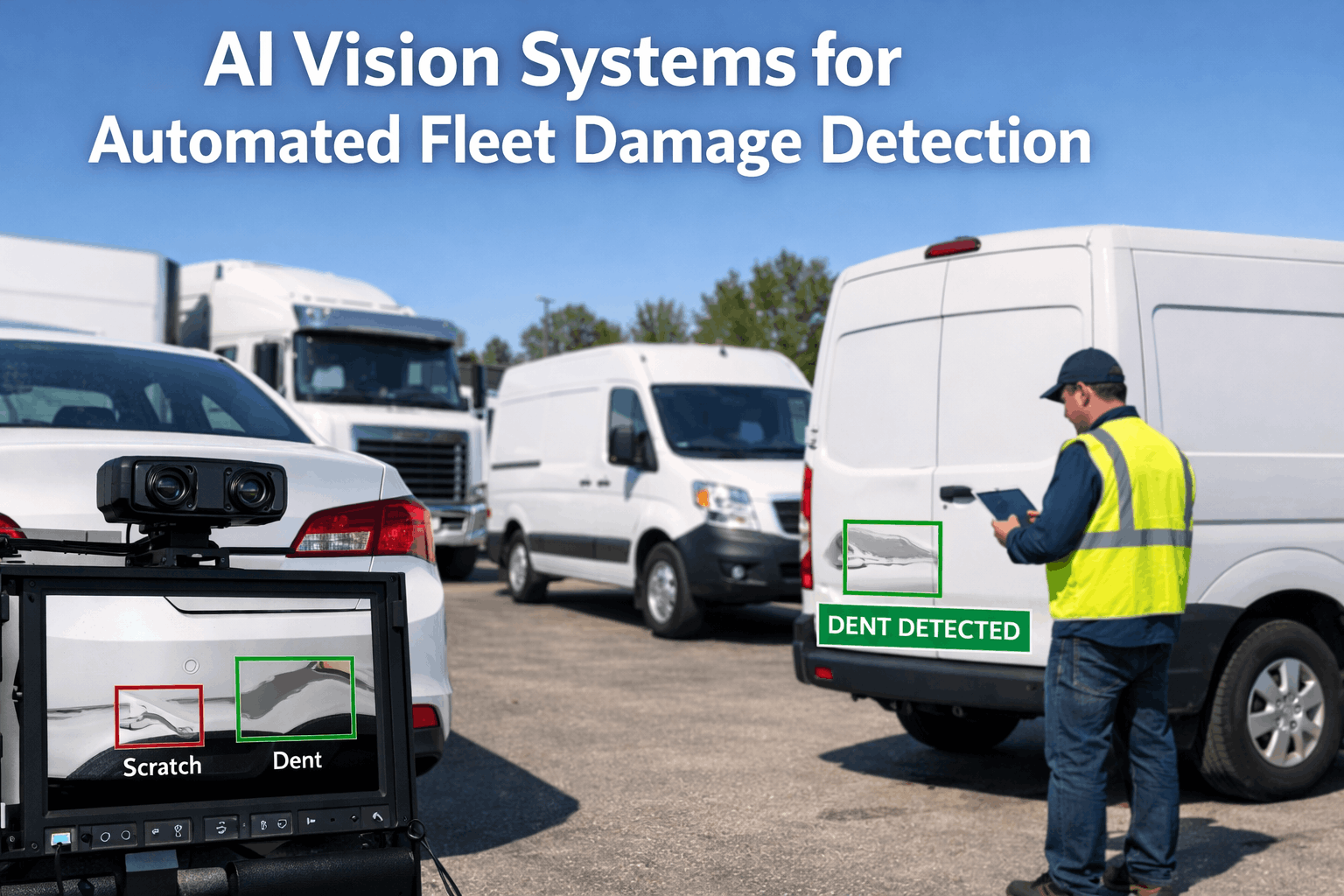

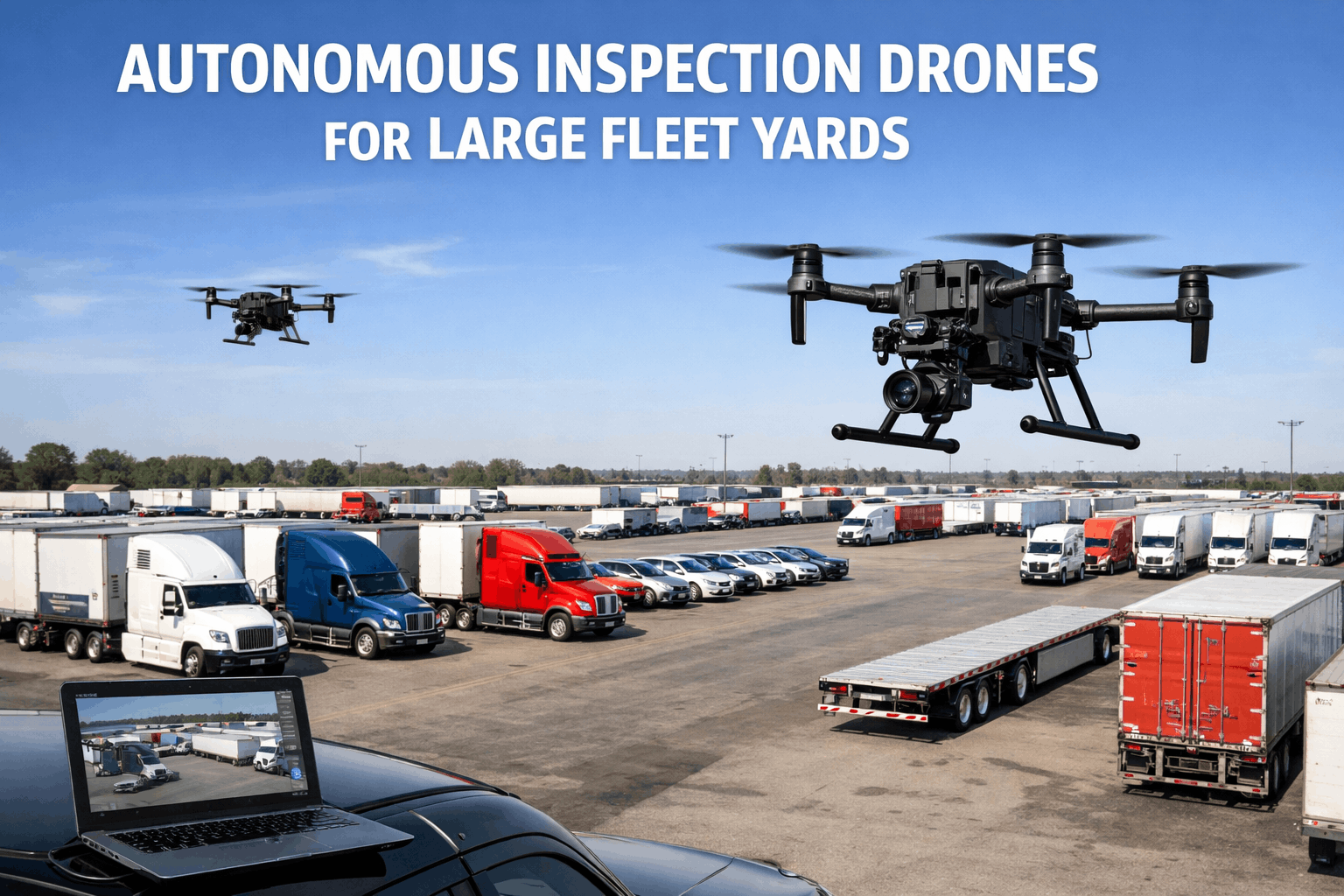

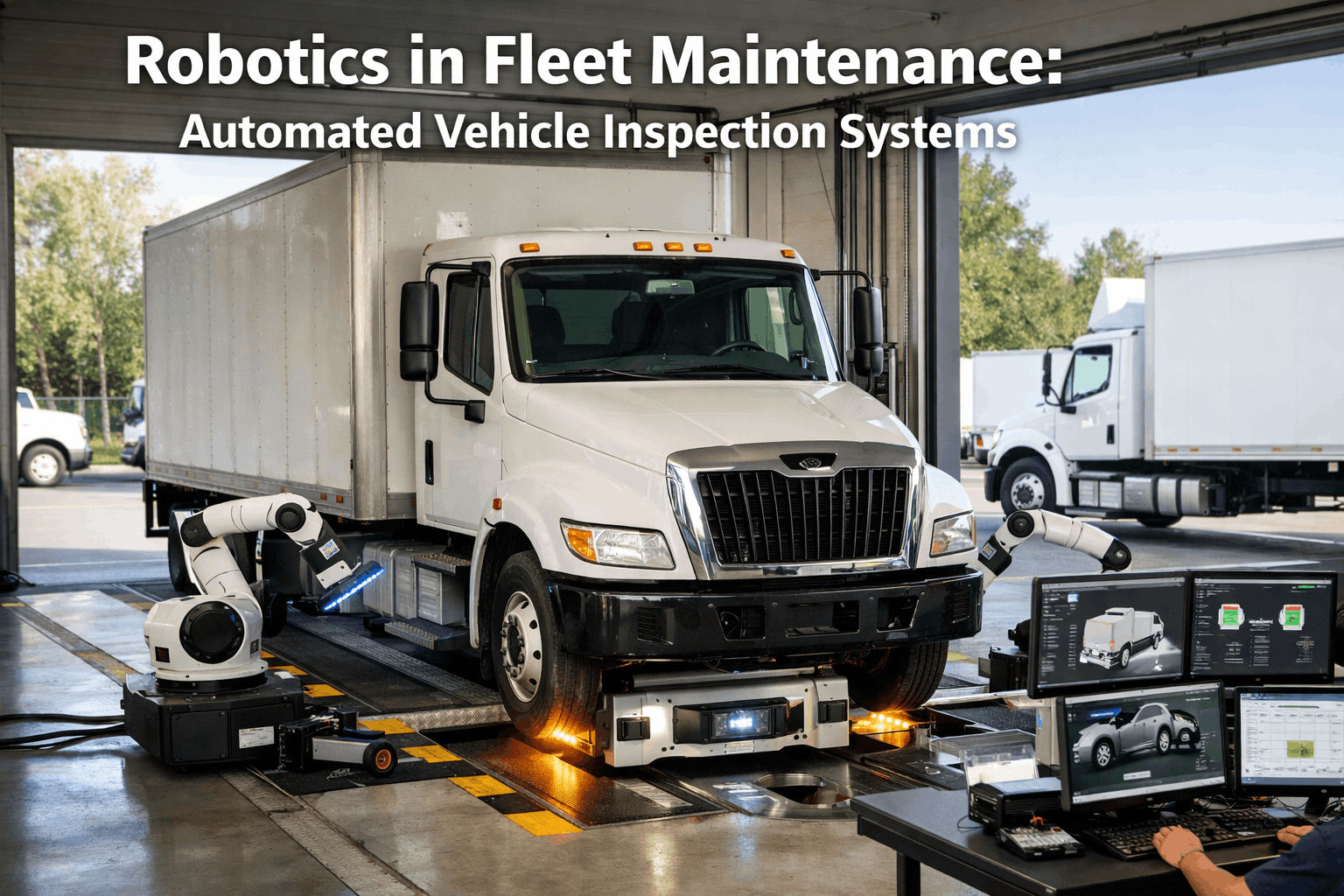

AI vision systems for fleet damage detection use high-resolution cameras and computer vision algorithms trained on millions of vehicle images to identify surface and structural anomalies. When a vehicle passes through a scanning station or a technician captures images using a smartphone or mounted camera, the AI processes every pixel in the frame to detect damage types including dents, scratches, paint chips, cracked windshields, tire sidewall damage, rust formation, and panel misalignment.

The underlying technology relies on convolutional neural networks (CNNs) that have been trained to distinguish real damage from environmental noise like shadows, dust, water droplets, and reflections. Modern systems like those from UVeye, Tchek, and Ravin AI achieve detection accuracy rates above 95 percent by analyzing video sequences across multiple frames rather than relying on single static images. This multi-frame approach confirms damage persistence and eliminates false positives that plagued earlier systems. For fleet operations, this means every vehicle returning to the yard or depot gets a consistent, objective inspection regardless of lighting conditions, weather, or inspector fatigue. Book a demo with Oxmaint to see how AI inspection data integrates directly with automated repair scheduling.

The Real Cost of Missed Vehicle Damage in 2026

Fleet managers who still rely on manual walkaround inspections are bleeding money in ways that rarely show up on a single line item. The numbers paint a clear picture of why AI-powered damage detection paired with CMMS automation is no longer a nice-to-have but a financial necessity for any fleet operation serious about controlling costs and protecting assets.

These numbers explain why 68 percent of fleets moved to digital inspection systems in 2024 alone. When a single missed brake defect can lead to a fatal crash, or a single day of unplanned downtime costs up to $760, the return on AI-powered inspection technology becomes obvious. Fleets using predictive and preventive maintenance report 40 to 60 percent reductions in emergency repairs and 20 to 30 percent improvements in vehicle availability. Connecting AI detection output to a CMMS like Oxmaint ensures that every detected defect becomes a tracked, resolved work order rather than a forgotten inspection note.

Types of Damage AI Vision Systems Can Identify

The range of defects that modern AI vision systems can detect has expanded dramatically beyond simple dent and scratch identification. Understanding these capabilities helps fleet managers appreciate why automated inspection is replacing subjective human assessment across the industry:

Dents, scratches, paint chips, scuffs, and clear coat deterioration across all body panels. AI systems detect damage as small as 5mm using pixel-level analysis, catching issues invisible to the naked eye during walkaround inspections.

Panel misalignment, frame deformation, bumper displacement, and weld joint stress indicators. These defects signal potential collision history or structural fatigue that impacts vehicle safety and resale value.

Hairline cracks, chips, star breaks, and delamination in windshields and side windows. AI tracks crack propagation over time by comparing sequential inspection images, predicting when replacement becomes necessary.

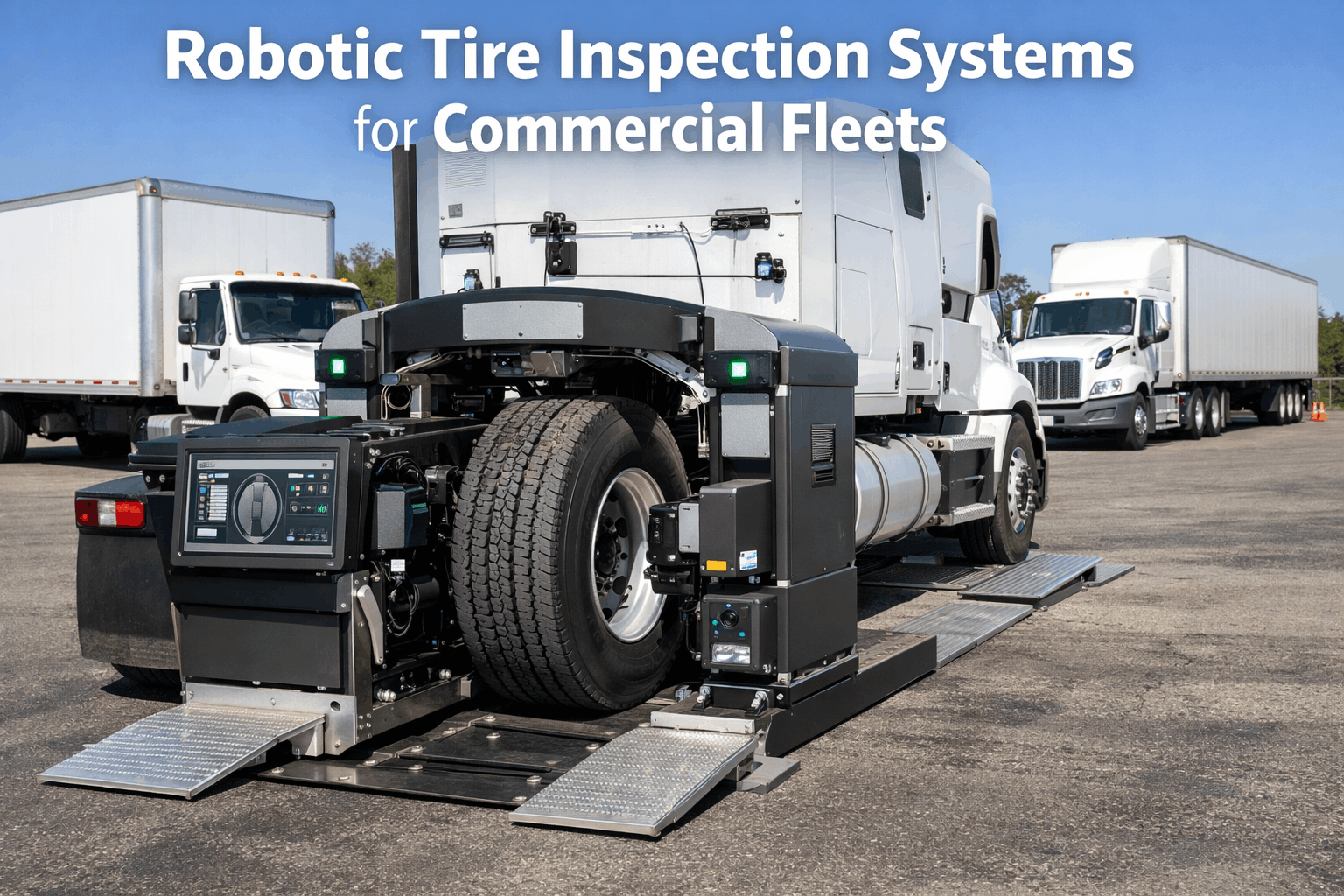

Tread depth estimation, sidewall bulges, uneven wear patterns, curb rash on rims, and valve stem damage. Computer vision combined with 3D imaging provides accurate wear assessment without manual gauging.

Surface oxidation, bubbling paint indicating subsurface corrosion, and undercarriage rust progression. Early detection at the pixel level prevents small spots from becoming structural integrity problems.

Fluid leaks, exhaust system damage, brake component wear, and suspension abnormalities captured by underbody scanning cameras. These systems identify mechanical issues that are invisible during standard visual walkarounds.

From Detection to Repair: How CMMS Closes the Loop

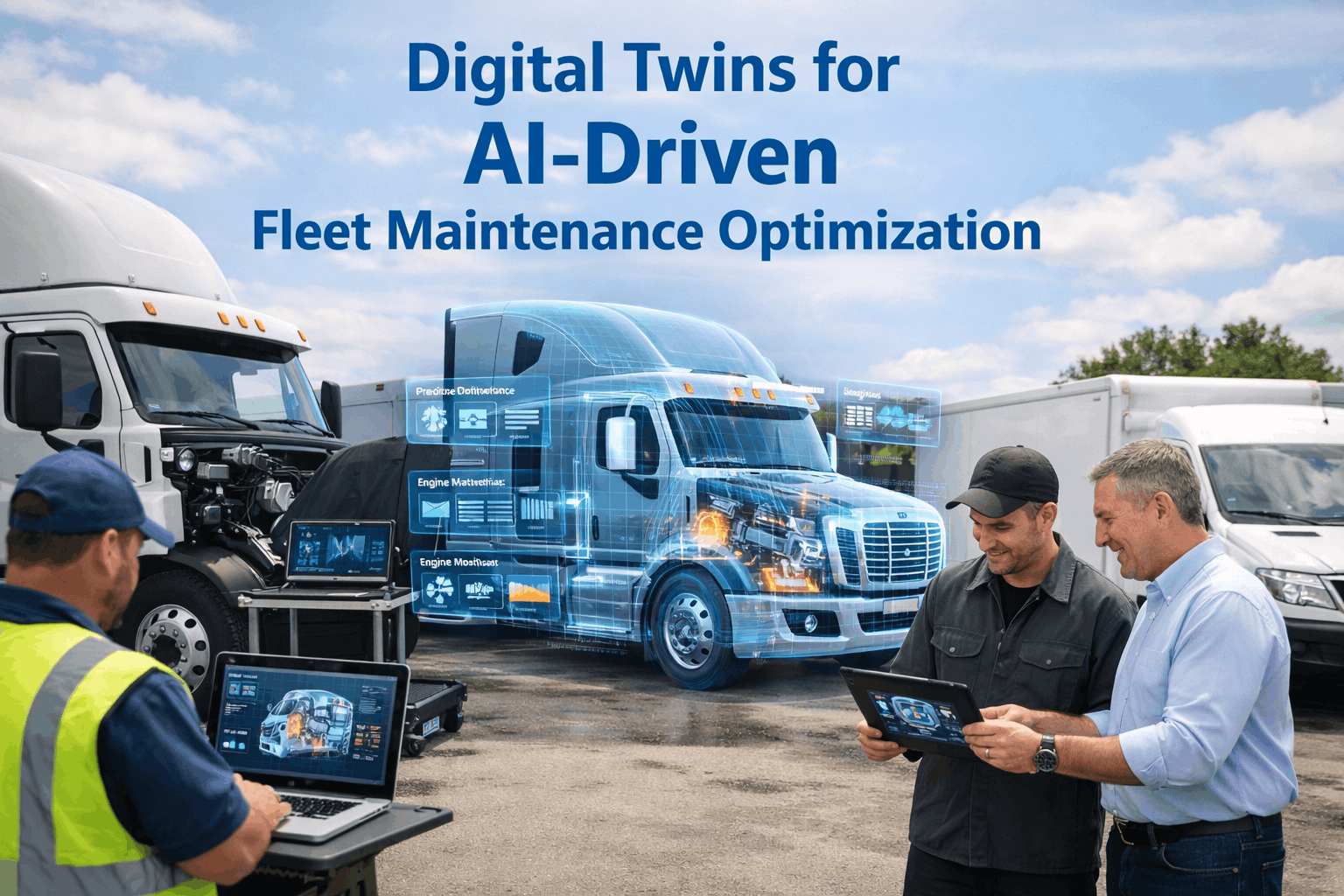

Identifying damage is valuable, but it only creates operational impact when that information triggers an organized repair response. This is where CMMS software transforms AI vision data from a detection report into a maintenance workflow. When an AI system flags a cracked windshield on Vehicle 247, the inspection data, including damage location, severity classification, and timestamped images, should automatically flow into the CMMS to create a work order, assign a technician, check parts availability for the replacement windshield, and schedule the repair around the vehicle's delivery commitments.

Without this integration, fleet managers end up with a folder full of AI inspection reports that still require manual data entry, phone calls to the shop, and spreadsheet tracking to resolve. The efficiency gains from automated detection get lost in manual follow-through. Oxmaint bridges this gap by accepting inspection data feeds and converting them into structured work orders with priority levels based on damage severity. A safety-critical item like brake component wear gets flagged as urgent. A cosmetic scratch gets queued for the next scheduled service window. Sign up for Oxmaint to connect your AI inspection workflow with automated repair scheduling today.

Turn AI Damage Detection into Automated Repairs

Oxmaint CMMS converts AI inspection findings into prioritized work orders, tracks repair costs per vehicle, and builds a complete digital maintenance history for your entire fleet.

Key AI Vision Technologies Powering Fleet Inspections

Several distinct AI and computer vision technologies work together to deliver the accuracy and speed that fleet damage detection demands. Understanding these technologies helps fleet managers evaluate which inspection solutions best fit their operations:

YOLO processes entire images in a single pass, making it the fastest detection model available. For fleet inspections, this means a vehicle can be scanned in seconds rather than minutes. YOLOv7 and later versions have demonstrated high accuracy in detecting and classifying multiple damage types simultaneously across diverse vehicle body styles, from sedans to semi-trucks.

While YOLO detects damage presence, Mask R-CNN goes further by creating pixel-level masks that outline the exact shape and boundary of each defect. This precision is critical for estimating repair costs, as it provides accurate damage area measurements that feed directly into cost estimation algorithms and CMMS work order details.

Two-dimensional cameras struggle to assess dent depth or panel deformation severity. 3D vision systems using structured light or LiDAR scanning create depth maps of the vehicle surface, measuring dent depth down to fractions of a millimeter. This data determines whether paintless dent repair is sufficient or whether panel replacement is needed.

Edge computing allows AI models to run directly on cameras or local hardware at the inspection point, eliminating the latency and bandwidth requirements of cloud processing. For fleet yards processing dozens of vehicles per hour, edge AI delivers instant results and continues operating even without internet connectivity.

Each of these technologies generates structured data, damage type, location, severity, confidence score, and images, that needs to land in a centralized system for action. Oxmaint serves as that system, ingesting inspection outputs and converting them into the work orders, cost tracking entries, and compliance records your fleet operation depends on. Book a demo to see how AI inspection data flows into Oxmaint work orders.

CMMS Features That Matter for AI-Driven Fleet Maintenance

Not every CMMS is equipped to handle the volume and structure of data that AI vision systems produce. Fleet managers evaluating CMMS platforms for AI integration should look for specific capabilities that turn raw detection data into operational outcomes:

Oxmaint delivers all of these capabilities in a cloud-based platform that is mobile-ready and deployable within weeks. Your technicians access work orders, log repairs, and close tasks from their phones or tablets right at the vehicle. Sign up for Oxmaint and give your fleet the CMMS backbone that AI inspection data deserves.

The ROI of AI Vision Plus CMMS for Fleet Operations

Fleet operators who combine AI damage detection with CMMS-driven repair workflows are seeing measurable returns across multiple dimensions. Manual walkaround inspections typically take 15 to 30 minutes per vehicle and vary wildly in thoroughness depending on the inspector. AI scanning reduces this to under 3 minutes with consistent, objective results every time. For a fleet of 200 vehicles inspected weekly, that is a savings of over 80 labor hours per week on inspections alone.

The cost impact extends beyond inspection time. Early damage detection prevents small issues from escalating into expensive repairs. A paint chip caught today costs a few dollars to touch up. The same chip left undetected for six months becomes a corrosion problem that requires panel repainting or replacement at ten times the cost. When AI detection feeds directly into the CMMS for immediate work order creation, the gap between finding damage and fixing it shrinks from weeks to days or even hours. Fleet operators report 25 to 40 percent reductions in overall repair costs after implementing integrated AI inspection and CMMS workflows.

AI scanning completes a full vehicle exterior inspection in under 3 minutes compared to 15 to 30 minutes for manual walkarounds, freeing technicians for higher-value maintenance tasks.

Early detection and immediate CMMS work order creation prevent damage escalation, delivering 25 to 40 percent reductions in total fleet repair expenses over 12 months.

Every inspection generates timestamped, image-backed records stored in the CMMS, creating an auditable history for insurance claims, lease returns, DOT compliance, and dispute resolution.

Aggregated damage data across the fleet reveals vehicle model reliability trends, route-specific damage patterns, and optimal replacement timing, supporting smarter capital planning decisions.

Smarter Inspections Start with Oxmaint

Connect your AI vision systems with Oxmaint CMMS to automate work orders, track repair costs, and build a complete digital record for every vehicle. Get started in minutes.

Frequently Asked Questions

What types of fleet vehicle damage can AI vision systems detect

AI vision systems can detect a wide range of damage types including dents, scratches, paint chips, cracked windshields, tire tread wear, sidewall bulges, panel misalignment, corrosion, rust formation, undercarriage fluid leaks, exhaust damage, and brake component wear. Advanced systems using 3D imaging can also measure dent depth and panel deformation to determine appropriate repair methods.

How accurate are AI-powered vehicle damage detection systems

Leading AI vehicle inspection platforms achieve detection accuracy rates above 95 percent when using deep learning models trained on millions of real-world vehicle images. Multi-frame video analysis further reduces false positives by confirming damage persistence across multiple angles. Systems covering over 1,200 vehicle models from 127 manufacturers can accurately detect damage regardless of make, model, or vehicle type.

How does AI damage detection integrate with CMMS software like Oxmaint

AI inspection systems generate structured data including damage type, location, severity classification, confidence scores, and timestamped images. This data feeds into Oxmaint through API connections, automatically creating work orders with priority levels based on damage severity. The CMMS then assigns technicians, checks parts inventory, schedules repairs, and tracks costs against each vehicle's maintenance history without manual data entry.

What is the cost benefit of using AI vision for fleet inspections

AI scanning reduces per-vehicle inspection time from 15 to 30 minutes down to under 3 minutes, saving over 80 labor hours per week for a 200-vehicle fleet. Early damage detection prevents costly escalation, and fleet operators report 25 to 40 percent reductions in overall repair costs. Combined with CMMS automation, the integration eliminates manual data entry, reduces administrative overhead, and creates insurance-ready documentation that speeds up claims processing.

Can AI vision systems work in all weather and lighting conditions

Modern AI inspection systems are designed to handle real-world conditions including varying lighting, rain, dust, and shadows. Environmental adaptation technology uses advanced noise reduction, weather data, and contextual analysis to filter out environmental distractions. Multi-frame video analysis cross-references damage detection across multiple frames to confirm real issues and dismiss false alarms caused by environmental artifacts.

How quickly can a fleet implement AI inspection with Oxmaint CMMS

Oxmaint is cloud-based and mobile-ready with no complex infrastructure requirements. Most fleet operations are fully operational within two to three weeks, including vehicle asset profile setup, work order template configuration, inspection workflow integration, and staff training. Technicians can begin logging repairs and managing AI-generated work orders from their mobile devices within days of starting the setup process.