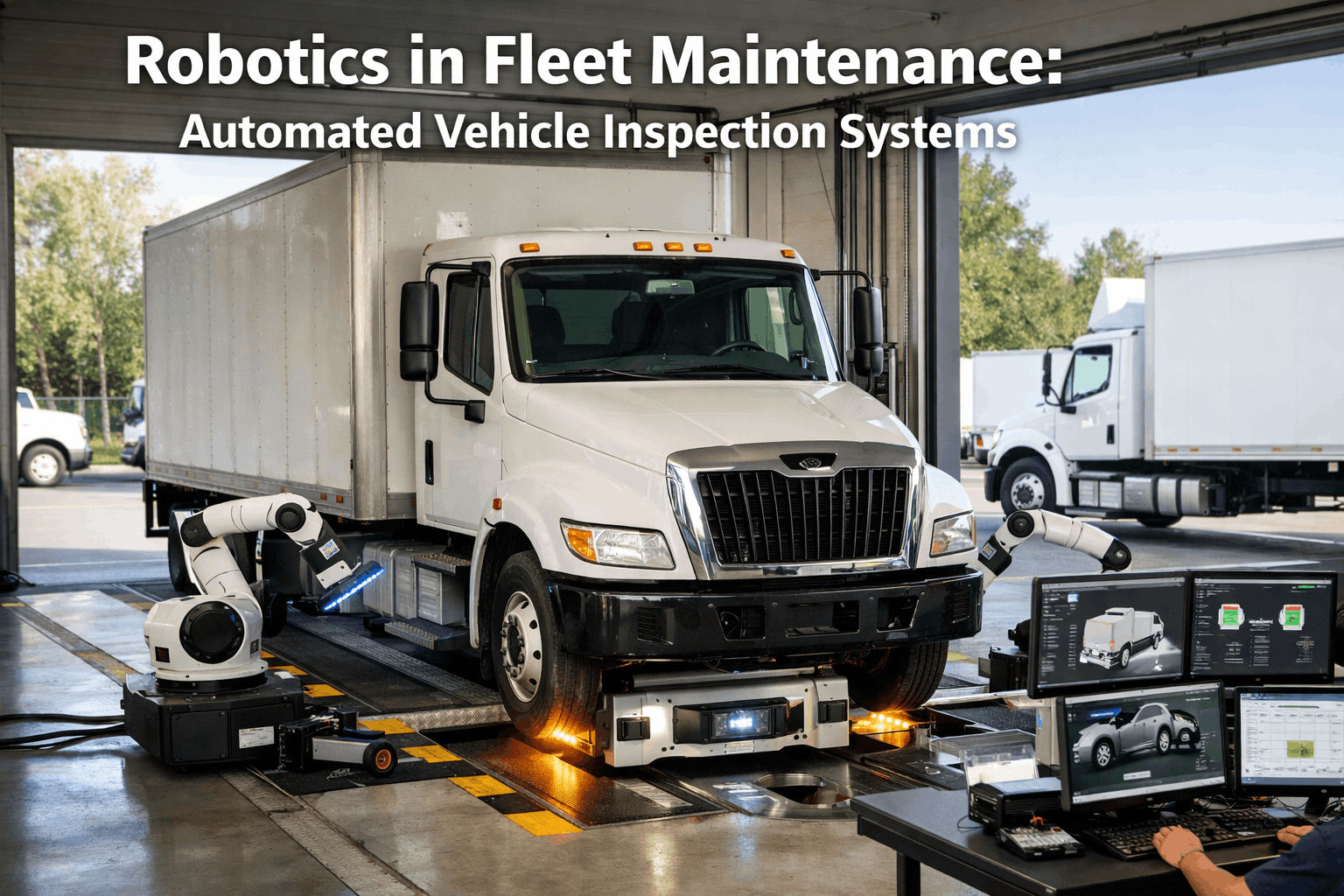

Fleet maintenance is entering a new era. Where technicians once walked around vehicles with clipboards and flashlights, robotic inspection systems now glide underneath chassis, scan body panels with high-resolution cameras, and detect hairline cracks invisible to the human eye — all in a matter of seconds. These automated vehicle inspection systems, powered by AI vision and advanced sensor arrays, are fundamentally changing how fleets identify defects, schedule repairs, and stay compliant. For fleet managers dealing with rising maintenance costs, technician shortages, and tighter regulatory demands, robotics offers something that manual processes simply cannot: speed, consistency, and data that feeds directly into your CMMS. The result is safer vehicles on the road, fewer surprise breakdowns, and maintenance budgets that finally make sense.

What Are Robotic Vehicle Inspection Systems

Robotic vehicle inspection systems combine mobile robotics, computer vision, and sensor technology to perform comprehensive vehicle assessments without human intervention. Think of them as an MRI for your fleet — vehicles drive through or over scanning stations, and within seconds, the system captures detailed data about tire condition, underbody integrity, exterior damage, fluid leaks, and structural anomalies. Companies like UVeye have already deployed drive-through scanning systems that perform complete 360-degree inspections of heavy-duty trucks and buses, detecting everything from mismatched tire sets to hidden structural corrosion. The technology uses high-resolution cameras, thermal imaging, ultrasonic sensors, and laser profiling to build a complete digital picture of each vehicle's condition. Unlike a human inspector who might miss a developing crack during a rushed pre-trip check, these systems deliver the same thorough assessment every single time.

What makes this especially valuable for fleet operations is the automatic generation of digital inspection reports. Every scan produces annotated images and structured data that can be shared with drivers, compliance officers, and maintenance teams — and more importantly, fed directly into maintenance management platforms. If you are ready to bring this level of precision to your fleet, sign up for OxMaint and start digitizing your inspection workflow today.

How AI Vision Powers Automated Fleet Inspections

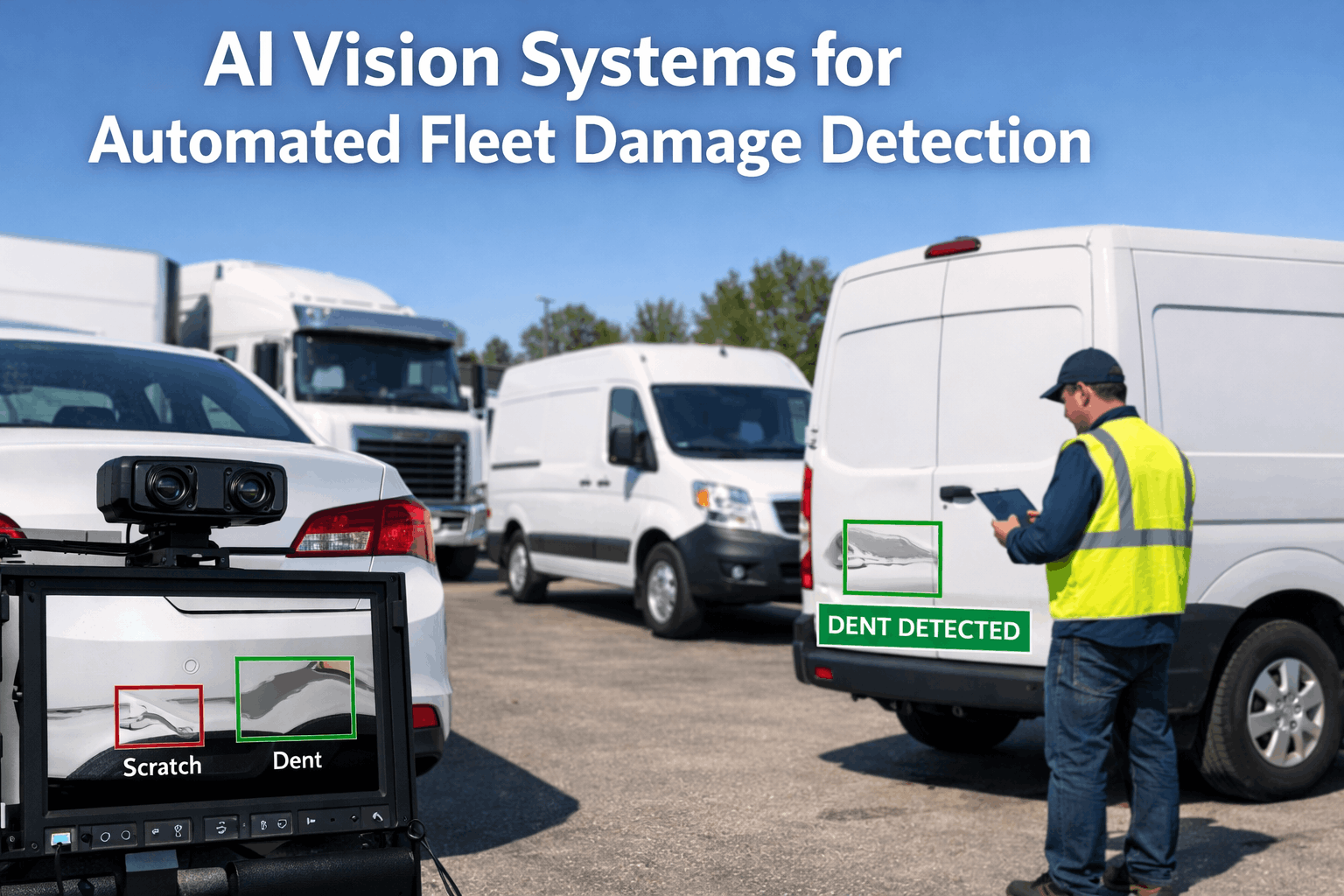

The intelligence behind robotic inspection systems lies in computer vision — the branch of artificial intelligence that enables machines to interpret visual information the way humans do, but faster and with greater consistency. In fleet maintenance, AI vision systems use convolutional neural networks (CNNs) trained on thousands of annotated images of vehicle defects. These models learn to recognize patterns associated with tire wear, paint blemishes, rust formation, weld fatigue, fluid leaks, and component misalignment.

The real breakthrough is accuracy. Vision AI systems now exceed 98% defect detection accuracy, outperforming even experienced human inspectors in identifying micro-cracks, subtle corrosion, and early-stage component wear. These systems also operate under varying lighting conditions and weather, using polarized lighting and multi-angle cameras to inspect reflective or shadowed surfaces. And because they generate structured data, every inspection becomes a data point that improves the model over time — creating a continuous improvement loop that makes the system smarter with every vehicle it scans.

Why Fleets Are Moving Beyond Manual Inspections

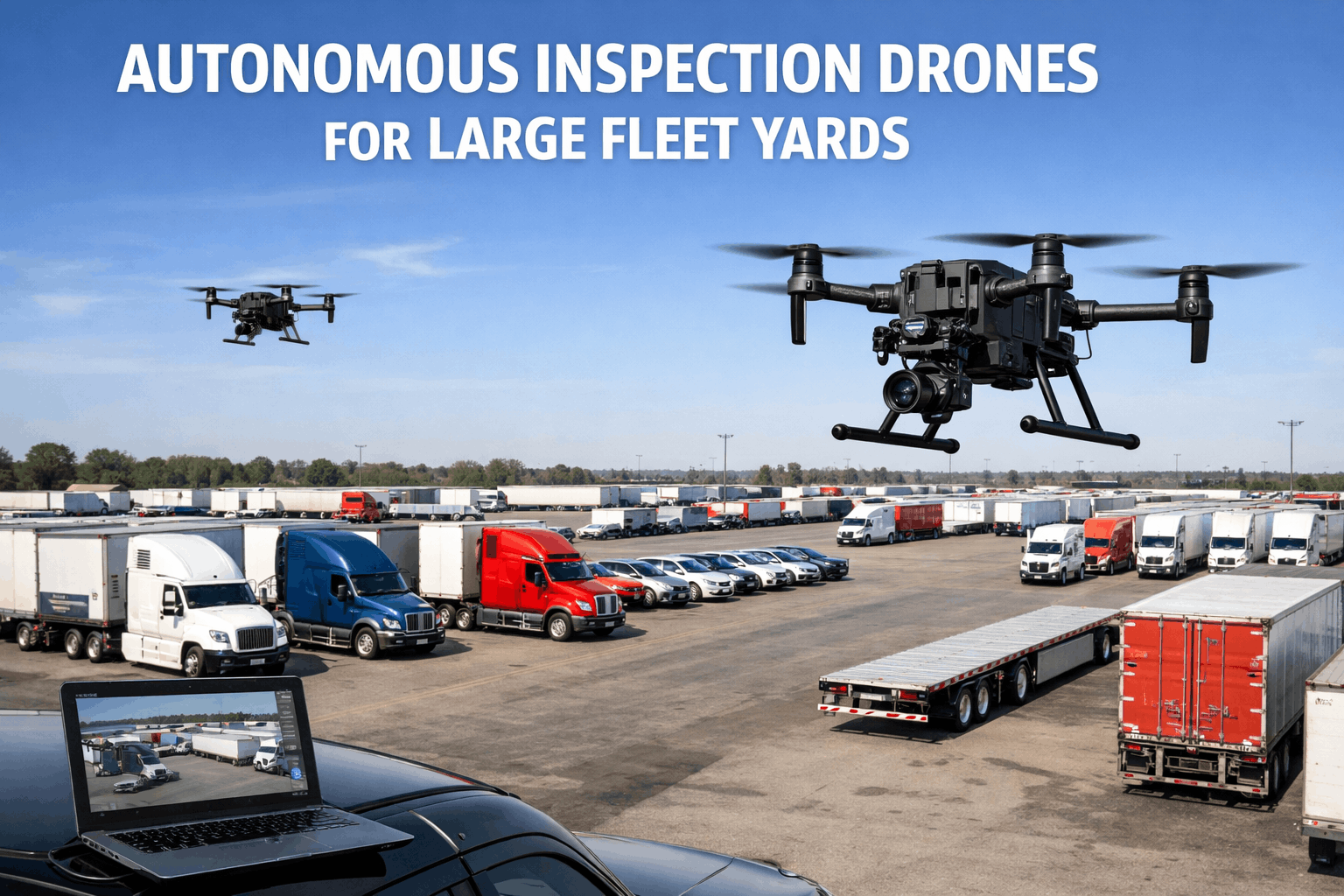

Manual vehicle inspections have served the industry for decades, but they come with well-documented limitations. Human inspectors are subject to fatigue, inconsistency, and the simple physical constraint of not being able to see everything. Pre-trip and post-trip inspections often happen under time pressure, in poor lighting, and with minimal documentation beyond a checkbox on a form. The consequences are real: missed defects lead to roadside breakdowns, compliance violations, and in worst cases, accidents that put drivers and the public at risk.

The workforce challenge makes this shift even more urgent. Experienced inspectors are retiring, and younger technicians often prefer roles in digital manufacturing or robotics over repetitive visual inspection work. For fleet operations managing hundreds or thousands of vehicles, robotic inspection is not just a technology upgrade — it is a strategic response to a shrinking labor pool. Want to future-proof your maintenance operations? Book a demo with OxMaint to see how digital inspections and automated work orders work together.

The CMMS Connection: Turning Inspection Data into Action

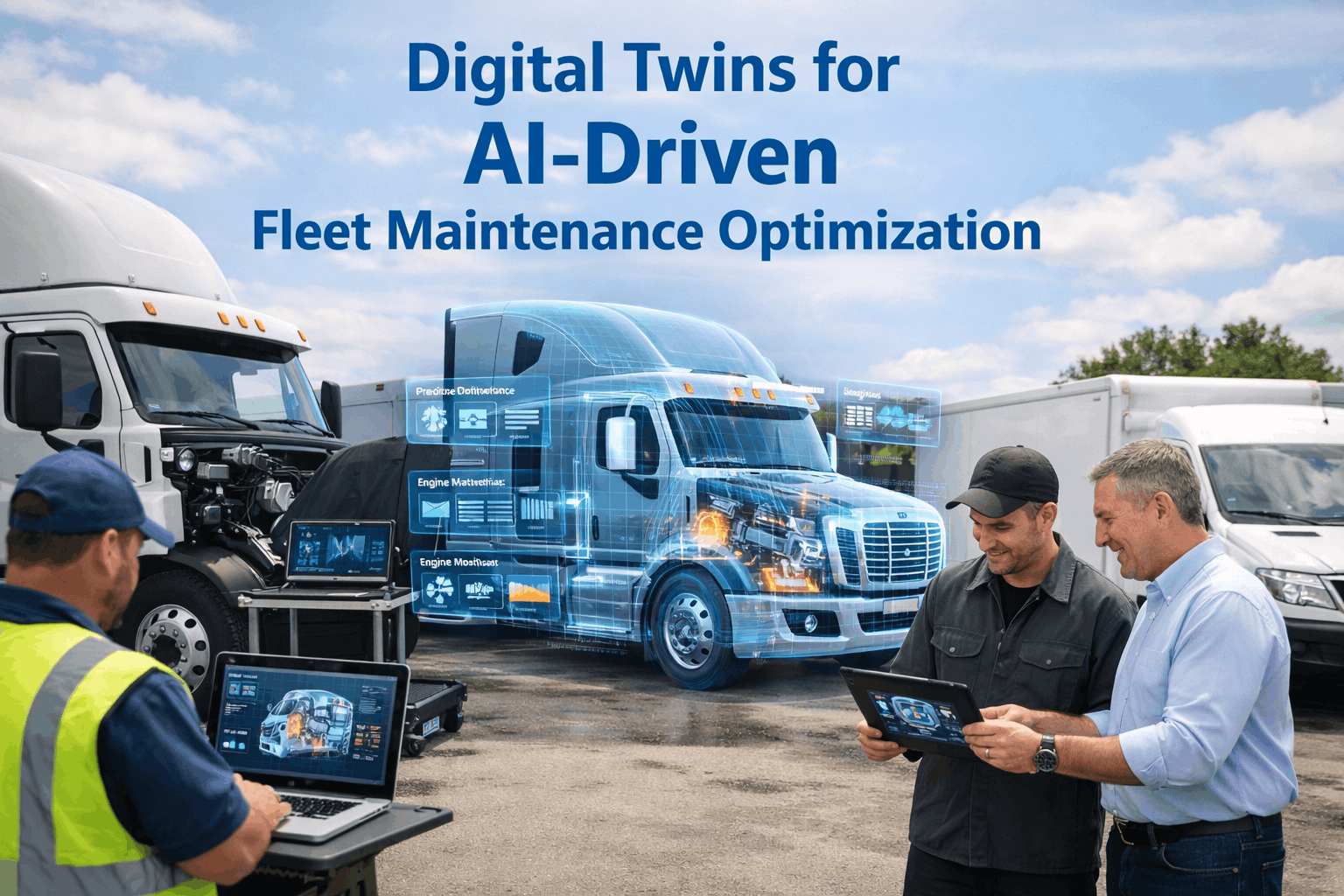

Robotic inspection systems generate enormous amounts of structured data — but that data only becomes valuable when it flows into a system that can act on it. This is where CMMS integration becomes the critical link in the chain. When a robotic scanner identifies a tire with uneven wear or an underbody leak, that finding should automatically trigger a prioritized work order in your maintenance management platform. The technician receives the alert on their mobile device, sees the annotated image of the defect, and knows exactly what needs attention before the vehicle leaves the yard.

Modern CMMS platforms with API connectivity make this seamless. Inspection results populate asset maintenance histories, update compliance records, and feed into predictive analytics engines that identify patterns across your entire fleet. Maybe a particular vehicle model consistently shows brake wear at 40,000 miles, or a specific route causes accelerated suspension damage. These insights are impossible to extract from paper inspection forms, but they emerge naturally when robotic inspection data meets intelligent maintenance software. Platforms like OxMaint are built for exactly this kind of integration — connecting inspection findings to work orders, parts inventory, and compliance tracking in a single workflow. Sign up now and experience what connected maintenance looks like.

OxMaint connects robotic inspection data to intelligent work order management, helping you catch defects faster, stay compliant, and reduce maintenance costs across your entire fleet.

Key Technologies Driving Robotic Fleet Inspection

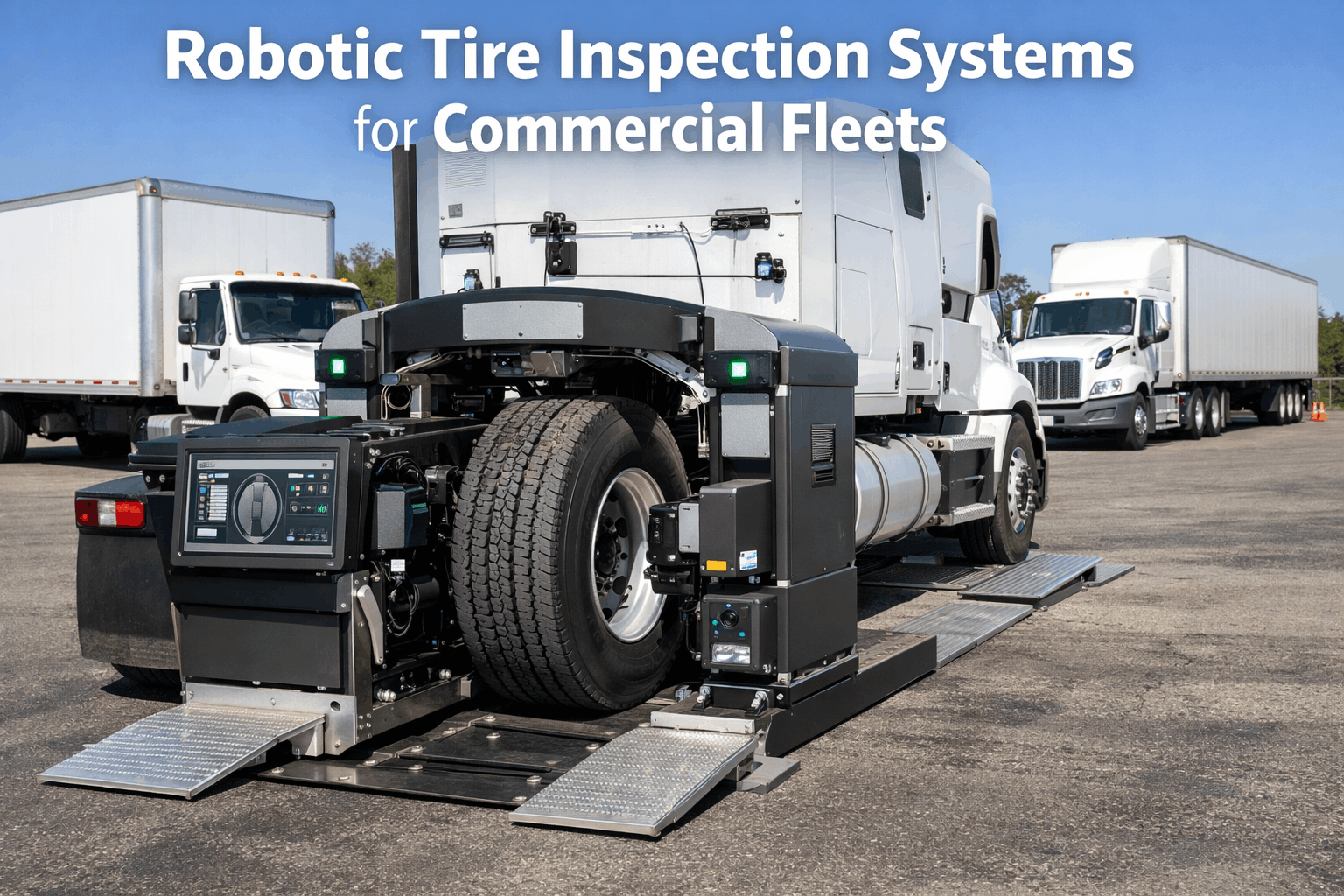

Convolutional neural networks trained on defect image datasets identify surface damage, corrosion, cracks, and component misalignment with accuracy exceeding 98%. Models continuously improve through feedback loops with non-destructive testing results.

Infrared cameras detect heat anomalies that indicate bearing failure, electrical faults, brake overheating, and fluid system leaks — problems invisible to standard cameras but critical for preventing roadside breakdowns.

Structured light and laser scanners capture precise dimensional data, measuring tire tread depth, brake pad thickness, suspension geometry, and chassis deformation down to sub-millimeter accuracy.

High-frequency sound waves penetrate materials to detect internal cracks, weld defects, and wall thickness changes in structural components — finding problems before they become visible surface failures.

On-site processing delivers inspection results in under 50 milliseconds, enabling real-time decision-making without relying on cloud connectivity. Critical for high-throughput fleet yards processing dozens of vehicles per hour.

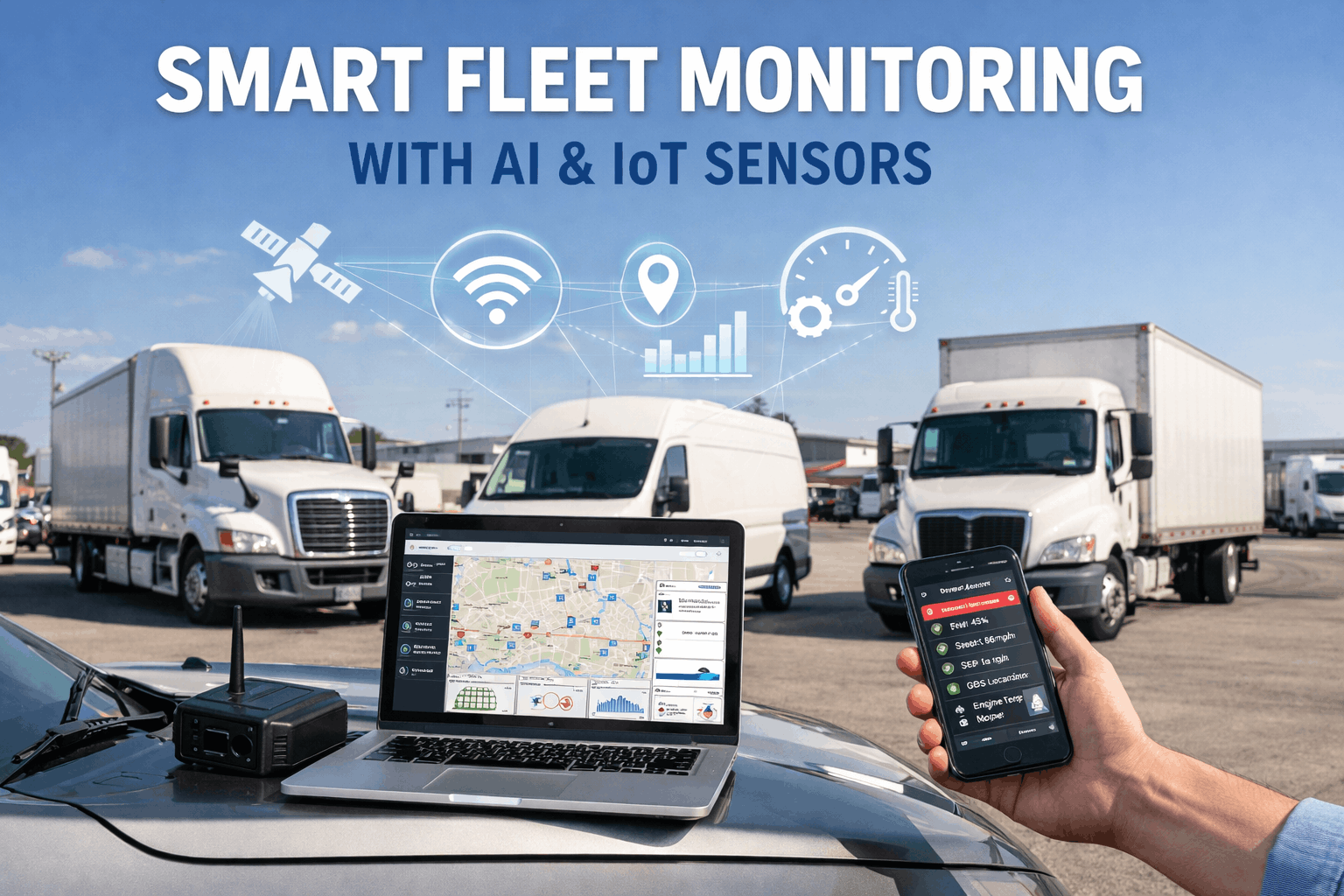

Connected sensors across the fleet continuously stream condition data — oil quality, coolant temperature, vibration patterns — feeding predictive models that complement periodic robotic inspections with real-time monitoring.

Real-World Impact: What the Numbers Show

The business case for robotic fleet inspection is supported by compelling data from early adopters across industries. Organizations combining AI-powered inspection with automated work order generation have reported up to 75% decreases in unplanned downtime. Vision AI alone cuts manual inspection time by 60% while reducing rework by 23%. When inspection data flows into CMMS platforms that drive predictive maintenance, the compounding effect is significant: parts spending drops by an average of 19% over three years, and equipment failure rates fall by as much as 70%.

For fleet managers, the ROI calculation is straightforward. A single prevented roadside breakdown avoids towing costs, driver downtime, missed deliveries, and potential regulatory penalties. Multiply that across a fleet of hundreds of vehicles running daily inspections, and the savings from even a modest improvement in defect detection become substantial. The typical payback period for robotic inspection systems ranges from 12 to 24 months through labor savings, reduced scrap, and improved compliance. If those numbers resonate with your operation, book a demo with OxMaint and let us show you how CMMS-driven maintenance delivers measurable results.

Getting Started: Practical Steps for Fleet Managers

Adopting robotic inspection technology does not require replacing your entire maintenance operation overnight. The most successful implementations follow a phased approach. Start by digitizing your current inspection process — moving from paper DVIRs to mobile digital forms that capture structured data. This creates the foundation for eventually connecting automated inspection systems to your maintenance workflow. Next, identify your highest-impact inspection points: pre-trip checks at fleet yards, post-maintenance quality verification, and compliance-critical assessments where consistency matters most.

When evaluating robotic inspection solutions, prioritize systems that offer open API integration with your CMMS platform. The technology only delivers full value when inspection findings automatically generate work orders, update asset records, and feed predictive maintenance models. Invest in training your team to interpret and act on the data these systems produce — robotic inspection enhances your technicians, it does not replace them. The goal is to free skilled maintenance professionals from repetitive visual checks so they can focus on complex diagnostics and repairs. Start building your digital inspection foundation today — sign up for OxMaint and take the first step toward automated fleet maintenance.

Join thousands of fleet managers who have moved beyond paper inspections. OxMaint gives you digital DVIRs, automated work orders, predictive maintenance insights, and the CMMS backbone your fleet needs for the robotic future.