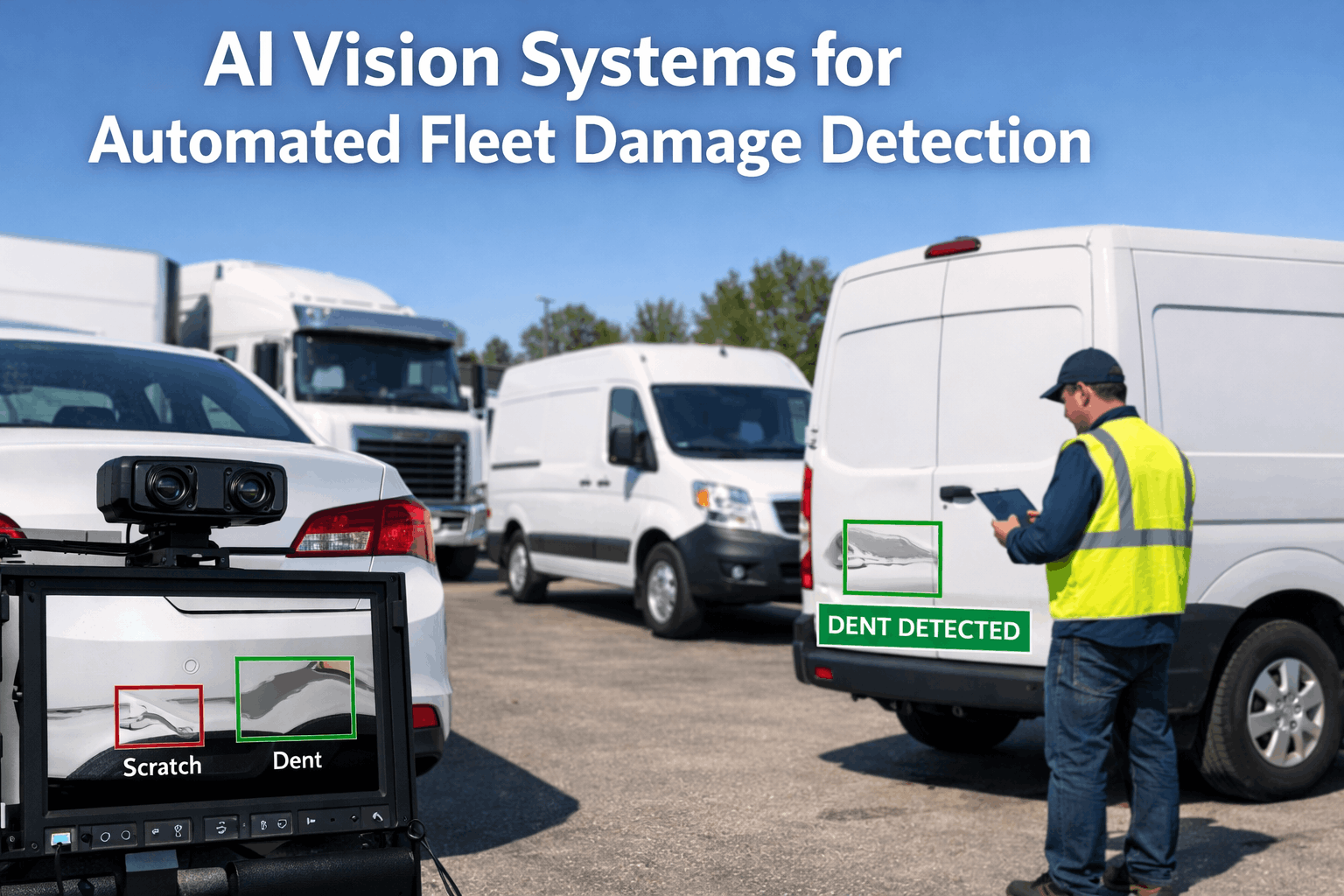

Every fleet manager knows the frustration: a vehicle returns from a route with a new dent nobody reported, a crack that somehow went unnoticed during the morning walk-around, or tire wear that escalated from minor to dangerous between scheduled inspections. Manual damage detection has been the industry standard for decades, but it comes with a steep cost. Missed defects, inconsistent reporting, and hours of labor spent on visual checks that still miss up to 40% of existing damage. Now, AI-powered vision systems are fundamentally changing how fleets identify, document, and respond to vehicle damage. These systems use computer vision and deep learning algorithms to scan fleet vehicles in seconds, detecting dents, scratches, cracks, corrosion, and component wear with up to 90% accuracy. For fleet operators looking to cut inspection time, reduce repair costs, and keep vehicles safely on the road, this technology is no longer futuristic; it is here and delivering measurable results. Platforms like OxMaint are making it easier than ever to integrate AI-driven damage insights directly into your maintenance workflows.

How AI Vision Systems Detect Fleet Vehicle Damage

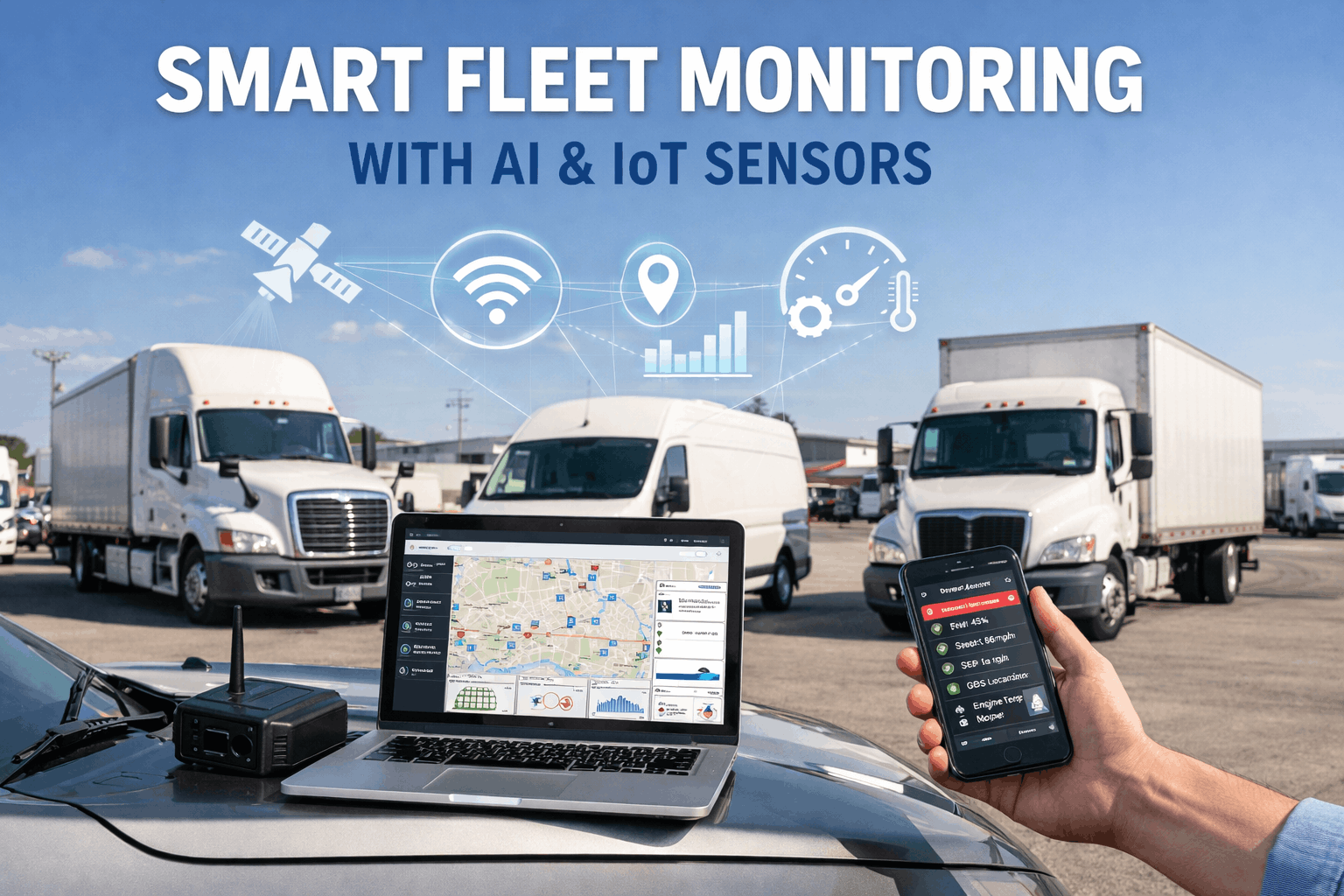

AI vision systems for fleet damage detection work by combining high-resolution cameras with advanced machine learning models trained on millions of vehicle images. When a fleet vehicle passes through a scanning station or is photographed using a smartphone, the AI engine analyzes every frame to identify anomalies on the vehicle body, undercarriage, tires, and glass surfaces.

The AI Damage Detection Process

High-resolution cameras or smartphones capture vehicle images from multiple angles during drive-through or walk-around inspection

Computer vision algorithms scan every pixel to detect dents, scratches, cracks, and wear patterns across the entire vehicle surface

Machine learning models classify each damage by type and rate severity from cosmetic to safety-critical, with location mapping

Detailed condition reports with repair estimates, damage photos, and severity scores are generated within seconds

Data flows directly into maintenance software like OxMaint for automated work order creation and repair scheduling

The core technology relies on two types of deep learning models. Object detection models like YOLO and Faster R-CNN draw bounding boxes around damaged areas to locate and identify defects. Segmentation models like U-Net and Mask R-CNN go deeper, classifying each pixel to understand the exact shape, size, and boundary of the damage. Together, they provide fleet managers with a comprehensive, pixel-level understanding of every vehicle's condition. Modern systems can identify over 6,000 damage combinations, analyzing not just the presence of damage but its severity, affected body parts, and related component systems.

Why Manual Inspections Fall Short

Traditional fleet inspections depend heavily on human judgment, and that introduces significant variability. A technician inspecting their 30th vehicle of the day will not catch the same details as they did on their first. Lighting conditions, time pressure, and individual expertise all affect inspection quality.

Manual Inspection vs. AI Vision Inspection

Manual Inspection

Speed15-30 min per vehicle

ConsistencyVaries by inspector

Hidden DamageOften missed

RecordsPaper-based, losable

Cost EstimatesNot automated

DocumentationFrequently incomplete

AI Vision Inspection

Speed30 sec - 2 min

ConsistencyIdentical every scan

Hidden DamageMicro-damage detected

RecordsDigital, instant

Cost EstimatesAuto-generated

Documentation100% complete

The financial impact of inspection gaps is significant. Undocumented damage accumulates, leading to more expensive repairs when finally discovered. Liability disputes arise when no clear record exists of when damage occurred. Fleet managers who want to eliminate these blind spots are turning to AI vision systems integrated with CMMS platforms like OxMaint to create an automated, reliable inspection pipeline.

Ready to Automate Your Fleet Inspections?

OxMaint integrates AI-powered damage data directly into your maintenance workflows. Automate work orders, track repair costs, and keep every vehicle documented across your entire fleet.

Key Benefits for Fleet Operations

AI vision-based damage detection delivers tangible operational and financial advantages that directly impact a fleet's bottom line. Here is what fleet operators are experiencing after implementation.

90%

Accuracy in identifying both surface-level and structural vehicle damage

60%Reduction in vehicle inspection times with AI automation

22%More damage documented than traditional manual methods

30 secComplete condition report generated after image capture

3xMore damages found per inspection that would go unreported

Beyond speed and accuracy, these systems deliver cost savings through early damage detection. Catching a small crack before it becomes a windshield replacement, or identifying tire wear before a blowout, means lower repair bills and fewer roadside emergencies. When paired with a maintenance management platform, these insights translate directly into preventive action. Book a demo with OxMaint to see how automated damage data feeds directly into work order generation and repair scheduling.

Types of Damage AI Vision Can Detect

Modern AI vision systems are trained on massive datasets covering virtually every type of vehicle damage. The scope of detection goes far beyond what a quick visual walk-around can catch.

Body Damage

From parking lot impacts to hail damage, AI identifies deformations in body panels with precise location mapping and depth estimation. Scratches and scuffs are classified by depth — surface, primer, or metal.

Detects: Dents, dings, scratches, scuffs, paint chips, creases, and panel deformations

Structural Issues

Windshield chips, bumper cracks, and structural fractures are identified early before they spread into major safety hazards. AI spots early-stage rust formation and spreading corrosion on undercarriage and frame.

Detects: Cracks, fractures, corrosion, rust, frame damage, weld failures

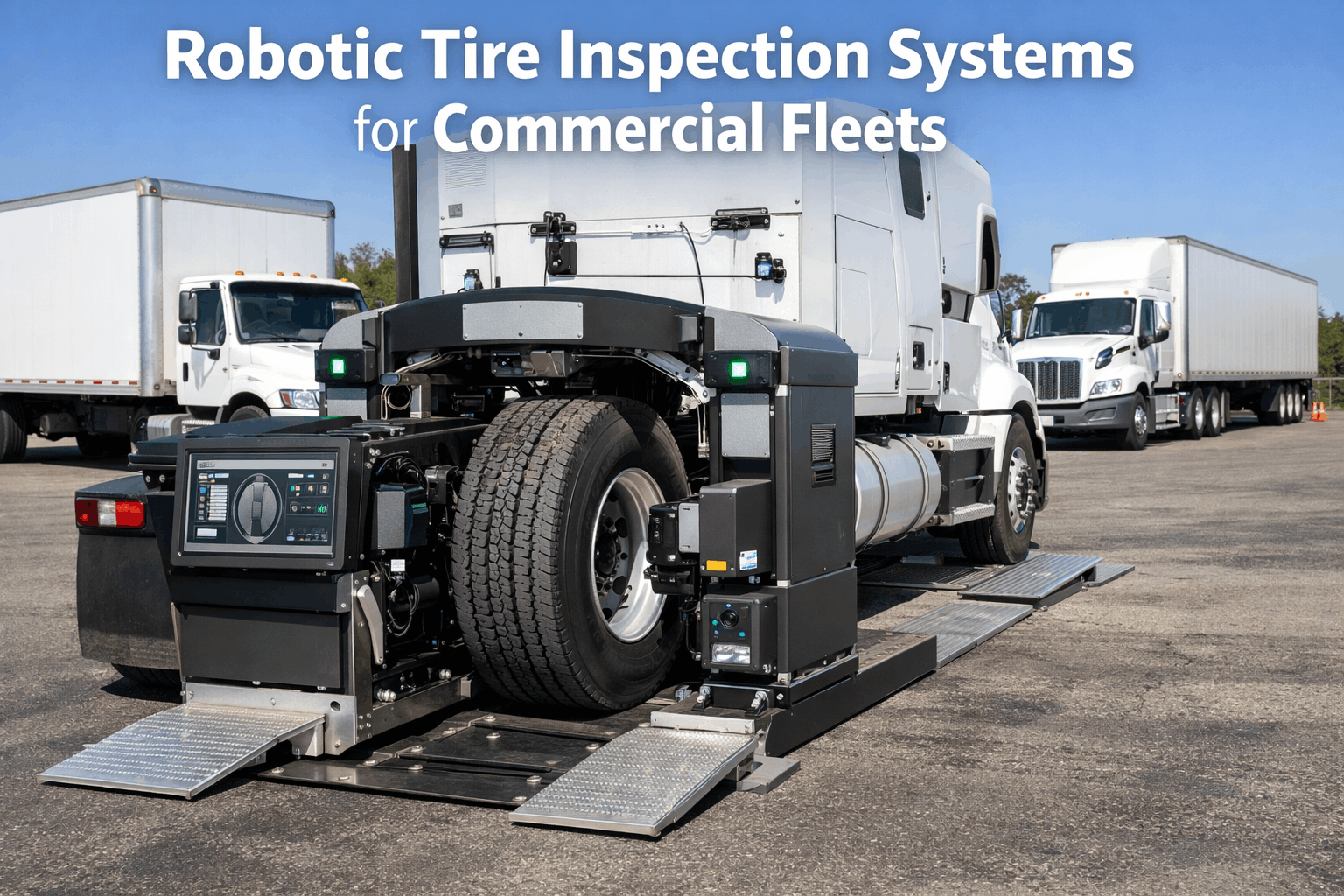

Wear Components

Tread depth analysis, sidewall bulges, uneven wear patterns, and puncture detection keep tires within safe parameters. Broken lenses, foggy headlights, and mirror damage flagged for compliance.

Detects: Tire wear, light damage, glass chips, mirror cracks, seal deterioration

Each detected issue is automatically tagged with its severity level, location on the vehicle, and an estimated repair cost. This structured data is what makes CMMS integration so powerful. Instead of a technician writing "dent on driver door" on a clipboard, the system generates a precise digital record that can trigger automated work orders. Sign up for OxMaint to start building complete digital damage histories for every vehicle in your fleet.

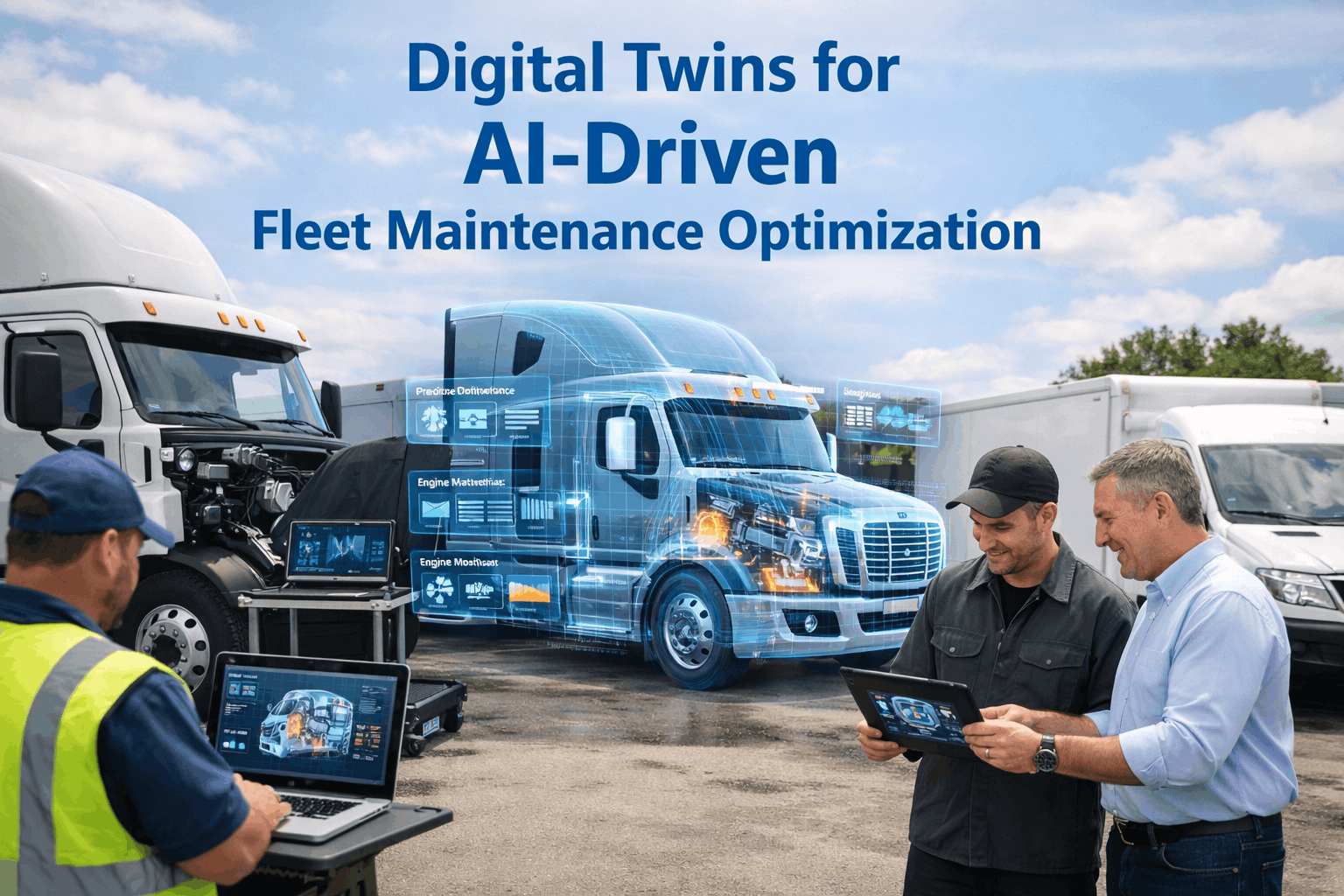

Integration with CMMS: From Detection to Repair

The real power of AI vision systems is unlocked when damage detection data flows seamlessly into a Computerized Maintenance Management System. Without this integration, AI scans produce reports that still require manual review. With CMMS integration, the entire pipeline from damage detection to repair completion becomes automated.

AI Detection to CMMS Repair: Automated Workflow

SCAN

AI camera detects a 4-inch crack on Vehicle #247's windshield during routine drive-through inspection

CLASSIFY

System classifies as "Safety-Critical" with estimated repair cost of $380 and maps exact location on vehicle

ASSIGN

CMMS auto-generates work order and assigns to available technician with glass repair certification

TRACK

Repair progress tracked in real-time with cost logged to vehicle history and fleet-wide analytics dashboard

Closed-Loop System

This eliminates the lag between discovering damage and taking action. Fleet managers no longer need to manually review inspection reports, create work orders, or chase technicians for updates. OxMaint's CMMS platform connects inspection data with maintenance scheduling, parts inventory, and cost tracking in one unified system.

Book a Demo

Predictive Analytics: Seeing Damage Before It Happens

AI vision systems do more than detect existing damage. Over time, as they build a comprehensive history of each vehicle's condition, they become predictive tools. By analyzing patterns in damage occurrence, environmental exposure, mileage, and component aging, these systems can forecast when and where damage is likely to appear next.

Pattern Recognition

AI identifies that vehicles on Route 12 consistently develop undercarriage corrosion 40% faster due to road salt exposure, triggering proactive undercoating treatments before damage starts.

Wear Trend Analysis

Brake pad wear rates are tracked across scans. When AI detects accelerating wear, it schedules replacement before pads reach unsafe levels, preventing costly rotor damage.

Fleet-Wide Intelligence

Recurring damage patterns across a specific vehicle model trigger manufacturer warranty claims and inform future purchasing decisions with hard data rather than anecdotal reports.

This shift from reactive to predictive maintenance is where the biggest cost savings emerge. Fixing a small issue caught early costs a fraction of emergency repairs on the roadside. Fleet operators using predictive analytics report significantly lower unplanned downtime and extended vehicle lifespans. With OxMaint's maintenance platform, these predictive insights connect directly to your scheduling engine, ensuring the right repairs happen at the right time.

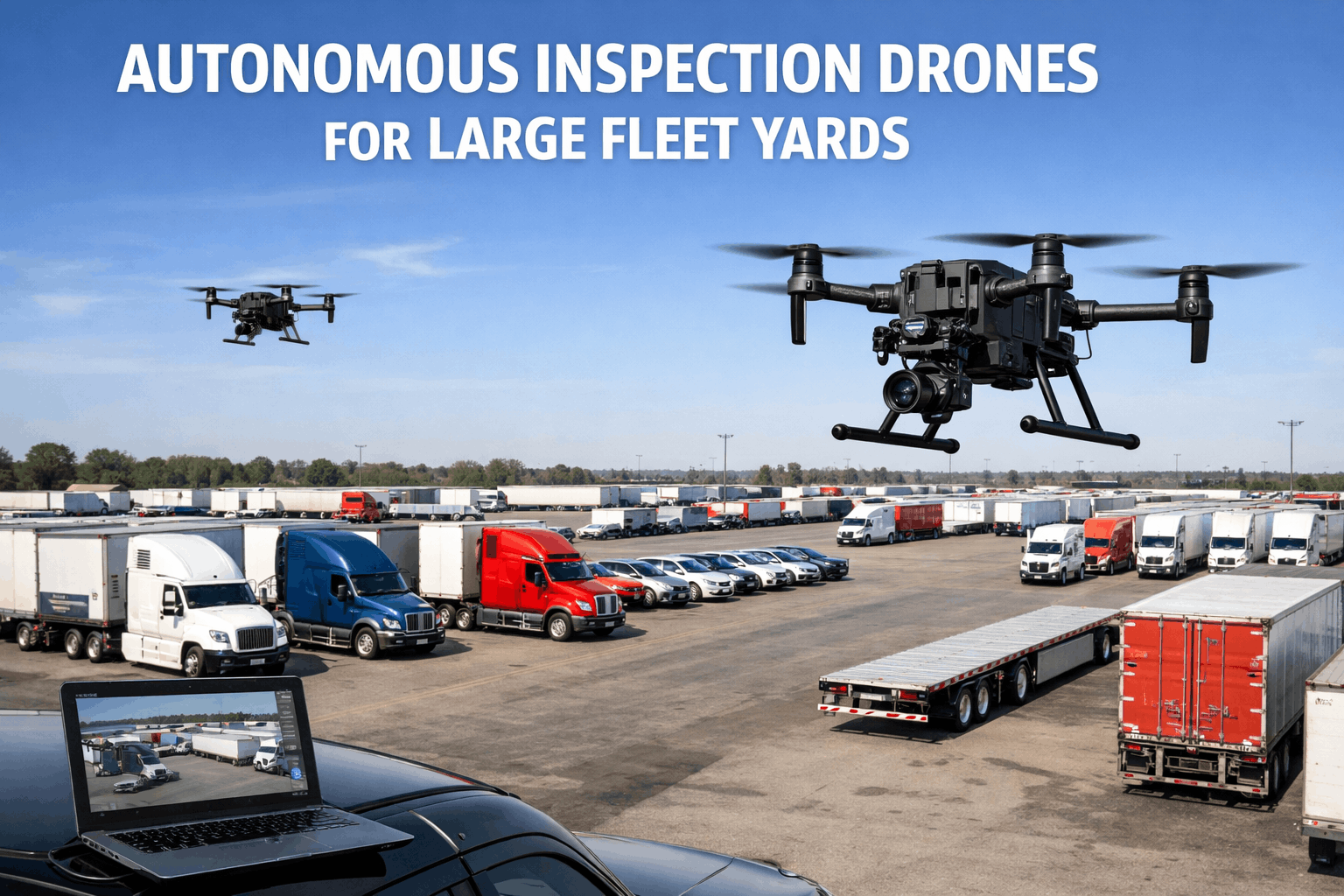

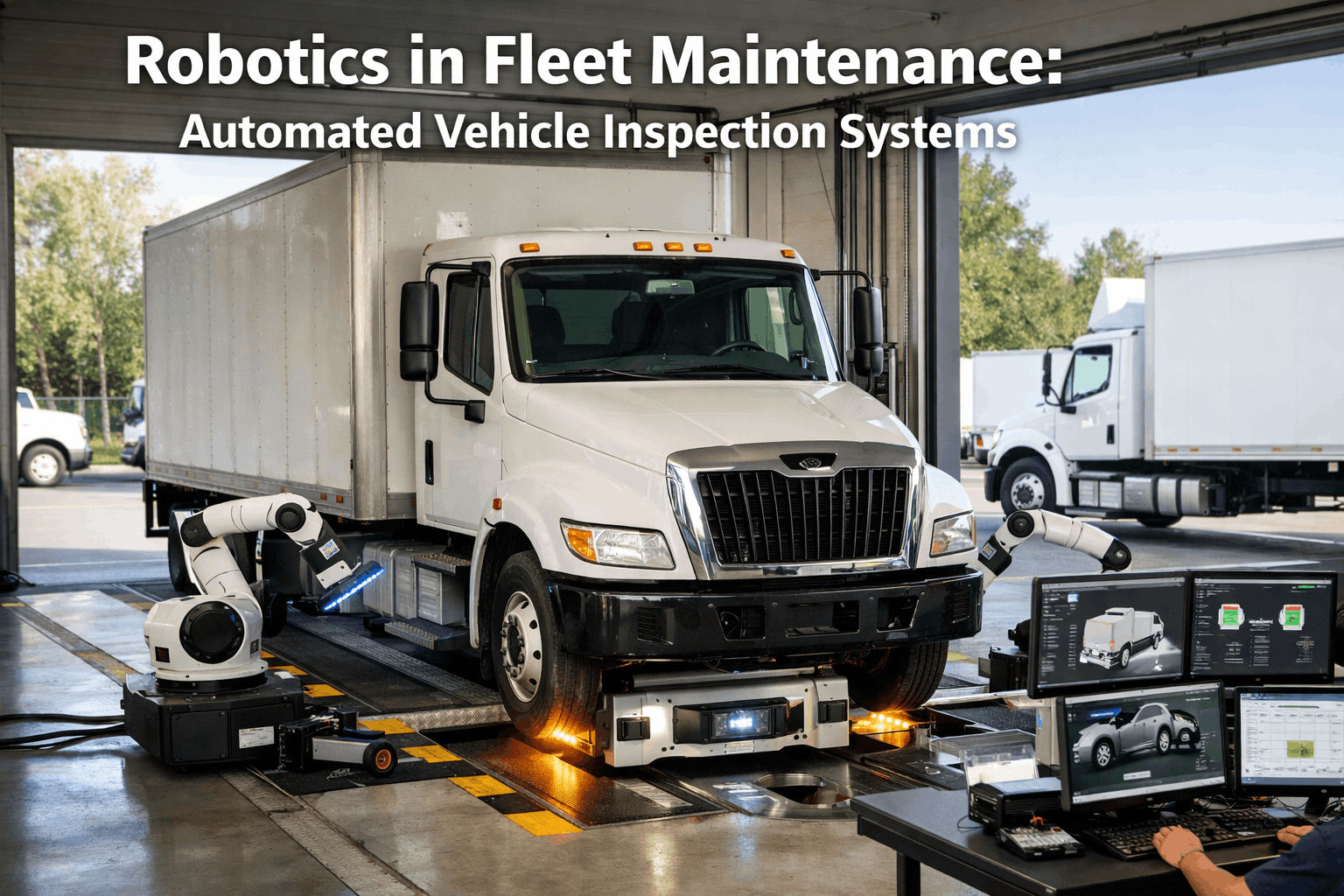

Real-World Implementation Options

Deploying AI vision systems does not require replacing your entire fleet infrastructure overnight. Modern solutions are designed for flexibility, offering multiple implementation paths depending on fleet size, budget, and existing technology.

Implementation Approaches by Fleet Size

Regardless of capture method, the AI analysis and CMMS integration workflow remains the same. OxMaint supports API-based integrations with leading AI inspection providers.

Transform Your Fleet Maintenance Strategy

Join thousands of fleet managers using OxMaint to move from reactive repairs to proactive, data-driven maintenance. The AI vehicle inspection market is growing at over 18% annually — early adopters are gaining the competitive edge through lower costs and better vehicle documentation.

Frequently Asked Questions

What types of vehicle damage can AI vision systems detect

AI vision systems detect a wide range of damage including dents, scratches, cracks, chips, corrosion, rust, tire wear, glass damage, paint peeling, and structural deformations. Advanced systems identify over 6,000 damage combinations and classify each by severity, location, and estimated repair cost.

How accurate is AI-based damage detection compared to manual inspection

Studies show AI damage detection systems achieve up to 90% accuracy in identifying both surface-level and structural damage. In controlled tests, AI cameras documented over 22% more damage than traditional manual inspections. The consistency of AI eliminates variability caused by inspector fatigue and experience levels.

How does AI damage detection integrate with CMMS software

AI vision systems generate structured damage data including type, severity, location, and repair estimates. This integrates with CMMS platforms like

OxMaint through APIs, automatically generating work orders, scheduling repairs, tracking costs, and building complete vehicle maintenance histories.

What equipment is needed to implement AI damage detection

Implementation can be as simple as smartphone-based scanning using guided mobile apps, or as comprehensive as fixed camera stations at facility entry points. Some fleets also use drone-mounted cameras for large vehicles. AI processing runs in the cloud, so no specialized on-site computing hardware is required.

How long does an AI-powered vehicle inspection take

AI-powered inspections dramatically reduce inspection time. Smartphone-based scans take 2-5 minutes including photo capture. Drive-through camera stations scan vehicles in under 30 seconds. Complete condition reports with damage analysis and cost estimates are generated almost instantly.

Book a demo to see the speed firsthand.

Can AI damage detection help reduce fleet maintenance costs

Yes. By catching damage early before it worsens, AI detection reduces average repair costs by 25-35%. Inspection labor costs drop by up to 60%. Complete damage documentation also reduces liability disputes, improves insurance claims, and maintains higher vehicle resale values through verified condition histories.

Is AI damage detection suitable for all fleet sizes

AI damage detection scales for fleets of any size. Small fleets start with smartphone-based scanning at minimal cost. Large operations benefit from fixed camera stations processing hundreds of vehicles daily. Cloud-based AI processing means no significant infrastructure investment regardless of fleet size.