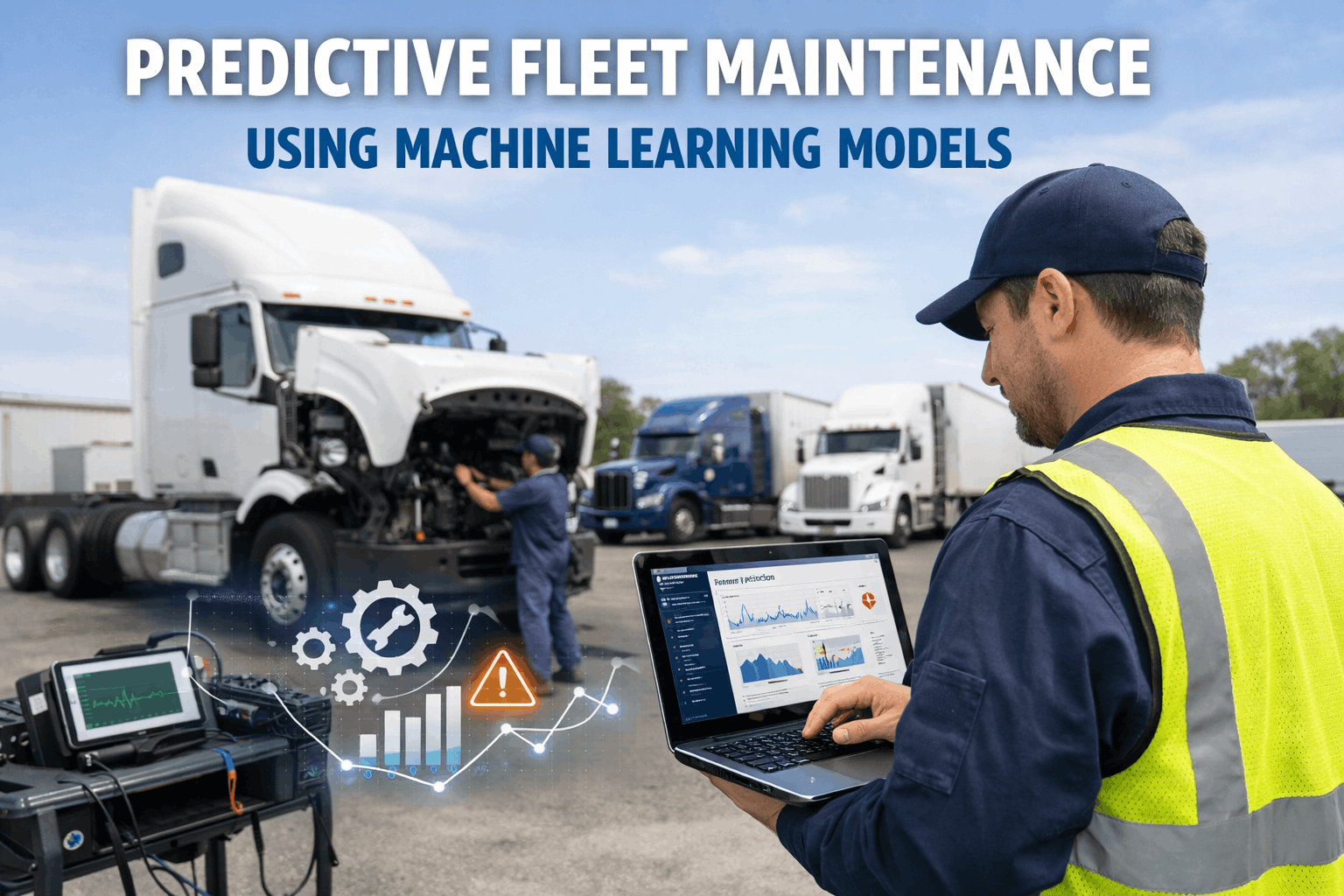

Running a fleet without real-time sensor data is like driving with your eyes closed. You only find out something is wrong when the engine overheats, the tire blows, or the breakdown truck arrives. For decades, fleet managers relied on scheduled inspections and driver reports to gauge vehicle health — methods that are slow, inconsistent, and reactive by nature. The convergence of IoT sensors and artificial intelligence is rewriting this playbook entirely. Today, connected sensors embedded in fleet vehicles continuously monitor engine temperature, vibration patterns, oil pressure, fuel consumption, brake wear, and dozens of other critical parameters. AI algorithms analyze this data in real time, detecting anomalies invisible to human observation and forecasting failures days or weeks before they happen. The IoT fleet management market reflects this transformation, projected to grow from $11.2 billion in 2025 to $36.3 billion by 2034 at a 14% compound annual growth rate. For fleet operators ready to move from reactive firefighting to intelligent, data-driven operations, platforms like OxMaint make it possible — sign up for OxMaint to turn this flood of sensor intelligence into automated maintenance actions that keep vehicles running and costs down.

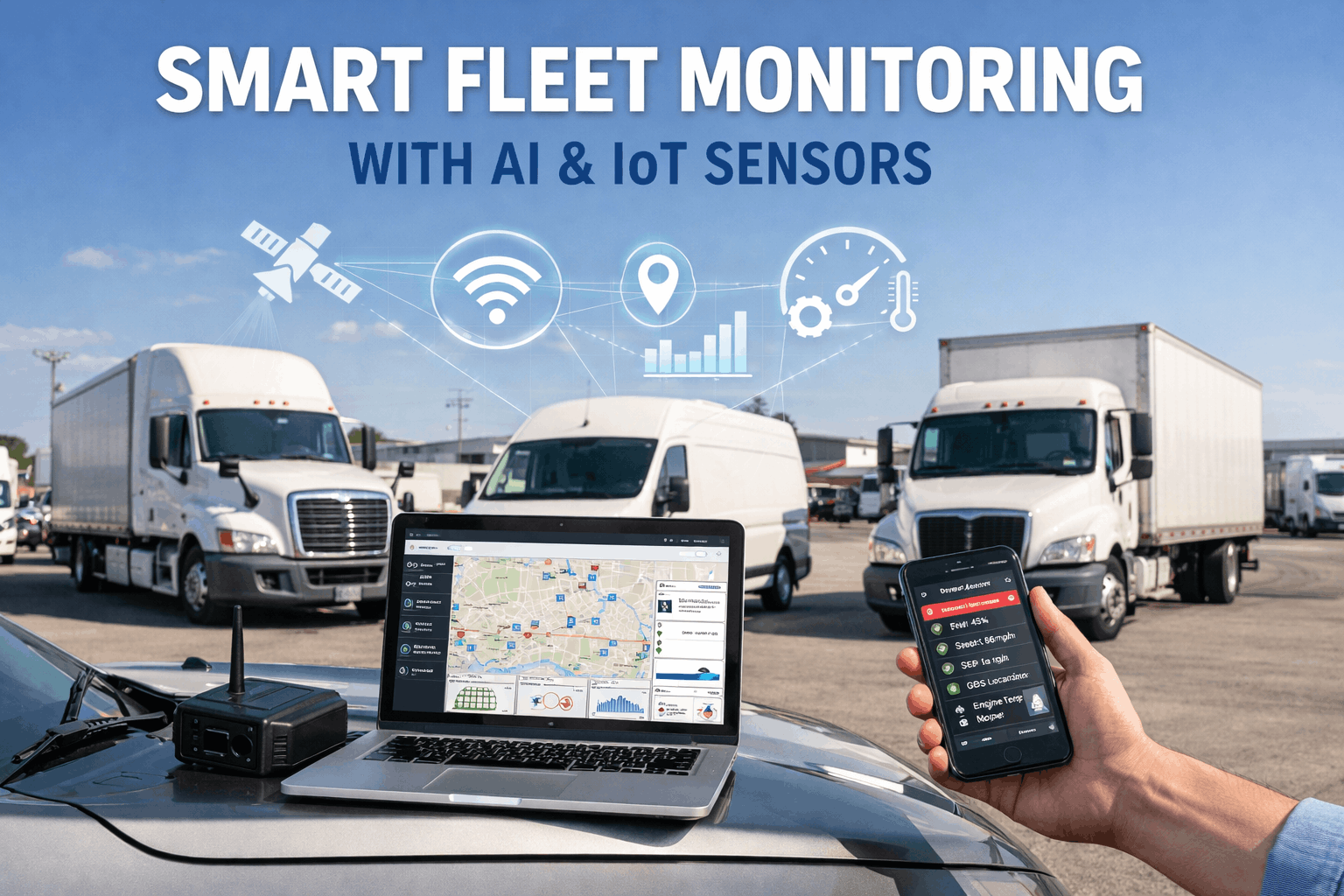

How IoT Sensors and AI Work Together in Fleet Monitoring

IoT fleet monitoring is not just about attaching sensors to vehicles. It is a complete intelligence system where hardware collects data, connectivity transmits it, and AI transforms raw numbers into actionable decisions. Understanding this architecture helps fleet managers evaluate solutions and plan their connected fleet strategy.

The Smart Fleet Monitoring Architecture

TemperatureVibrationPressureFuel LevelGPSAccelerometerHumidityRPM

IoT sensors embedded across the vehicle capture hundreds of data points per second from engine, drivetrain, brakes, tires, and cabin systems

4G/5GBluetooth LELPWANSatellite

Wireless protocols transmit sensor data to cloud platforms in real time, with edge computing handling time-critical processing on the vehicle itself

Anomaly DetectionPattern RecognitionPredictive ModelsTrend Analysis

Machine learning algorithms process incoming data against historical baselines to identify deviations, predict failures, and score vehicle health

Smart AlertsWork OrdersDashboard Updates

CMMS platforms like OxMaint receive AI-processed insights and automatically generate maintenance tasks, priority alerts, and compliance reports

The critical distinction between basic telematics and AI-powered IoT monitoring is intelligence. Traditional telematics tells you a sensor value crossed a threshold. AI tells you that the current pattern of temperature, vibration, and oil pressure readings on this specific vehicle, operating on this route, in these conditions, matches a signature that preceded compressor failure in 47 other similar vehicles. That contextual prediction is worth exponentially more than a simple alert. By 2027, nearly half of all Industrial IoT applications are forecasted to incorporate AI elements, making intelligent fleet monitoring the standard rather than the exception.

What IoT Sensors Monitor Across Your Fleet

Modern fleet vehicles can be instrumented with a comprehensive array of sensors, each monitoring a different dimension of vehicle health and performance. The data these sensors generate forms the foundation for every AI-driven insight and predictive maintenance decision.

Fleet IoT Sensor Reference Guide

A single fleet vehicle can generate thousands of data points per minute. AI transforms this volume into prioritized, actionable maintenance intelligence.

Did You Know

Fuel savings from telematics and IoT efficiency technology commonly reach 10-15% across monitored fleets. For a 100-vehicle fleet spending $500,000 annually on fuel, that translates to $50,000-$75,000 saved per year from sensor-driven insights alone.

Sign Up Free

From Raw Data to Maintenance Action: The AI Decision Engine

The volume of data IoT sensors produce is staggering — far beyond what any human team could manually review. This is precisely where AI becomes indispensable. Machine learning models running in the cloud continuously analyze incoming sensor streams, comparing real-time readings against historical baselines, manufacturer specifications, and fleet-wide patterns to make three types of decisions.

Immediate Alerts

When sensor values cross critical safety thresholds — a sudden spike in engine temperature, catastrophic drop in oil pressure, or abnormal brake response — AI triggers instant alerts to drivers and fleet managers for immediate action.

Response time: Milliseconds. Prevents roadside emergencies and safety-critical failures.

Predictive Warnings

AI detects gradual degradation patterns that indicate a component is trending toward failure. Vibration levels increasing week over week, oil pressure declining slightly each trip, or battery voltage dropping under load — these subtle shifts signal problems days or weeks ahead.

Response time: Days to weeks. Allows scheduled repair before failure occurs.

Optimization Insights

Beyond failure prevention, AI identifies efficiency opportunities: routes causing excessive brake wear, driving patterns increasing fuel consumption, or idle time patterns wasting resources. These insights improve operations even when nothing is broken.

Impact: Continuous improvement. Reduces operating costs fleet-wide over time.

The intelligence gap between a simple sensor alert and an AI-driven prediction is enormous. A basic system might tell you "oil pressure is low." An AI system tells you the oil pressure trajectory on Vehicle #208, combined with its mileage, route history, and operating conditions, indicates oil pump bearing wear that will likely cause failure within 18 days — and it has already generated a work order in your CMMS. Book a demo with OxMaint to see how AI-processed sensor data converts directly into automated maintenance scheduling.

Stop Reacting. Start Monitoring Intelligently.

OxMaint connects your IoT sensor data to automated maintenance workflows. Real-time dashboards, AI-driven alerts, and automatic work order generation — all in one platform built for fleet operations.

Real-World Impact: What Connected Fleets Are Achieving

The business case for IoT-powered fleet monitoring is built on measurable outcomes from fleets that have already deployed connected sensor systems with AI analytics. These are not projections — they are documented results from real operations.

$495B

Global IoT in transportation market projected by 2030

10-15%Fuel savings achieved through sensor-driven efficiency monitoring

35-50%Reduction in unplanned downtime with predictive IoT maintenance

25%Reduction in vehicle breakdowns through real-time monitoring

20.4%Annual growth rate of IoT predictive maintenance segment

The financial impact compounds across fleet size. A 200-vehicle fleet saving 12% on fuel, reducing downtime by 40%, and cutting emergency repair costs by 30% through IoT monitoring can realize six-figure annual savings. When sensor data feeds directly into a CMMS like OxMaint, every alert becomes a tracked work order, every repair becomes a data point that improves future predictions, and every dollar saved is documented against your maintenance budget.

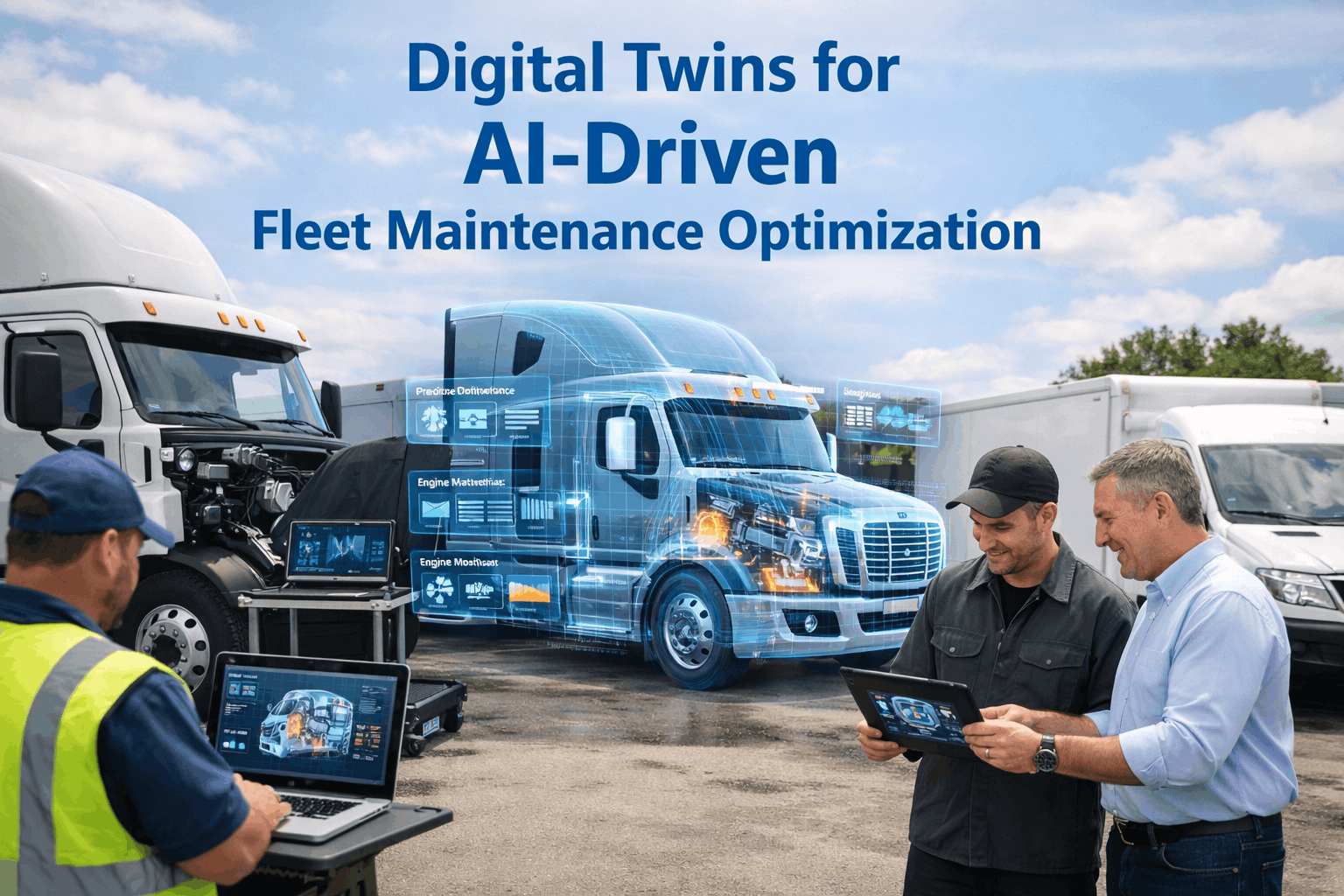

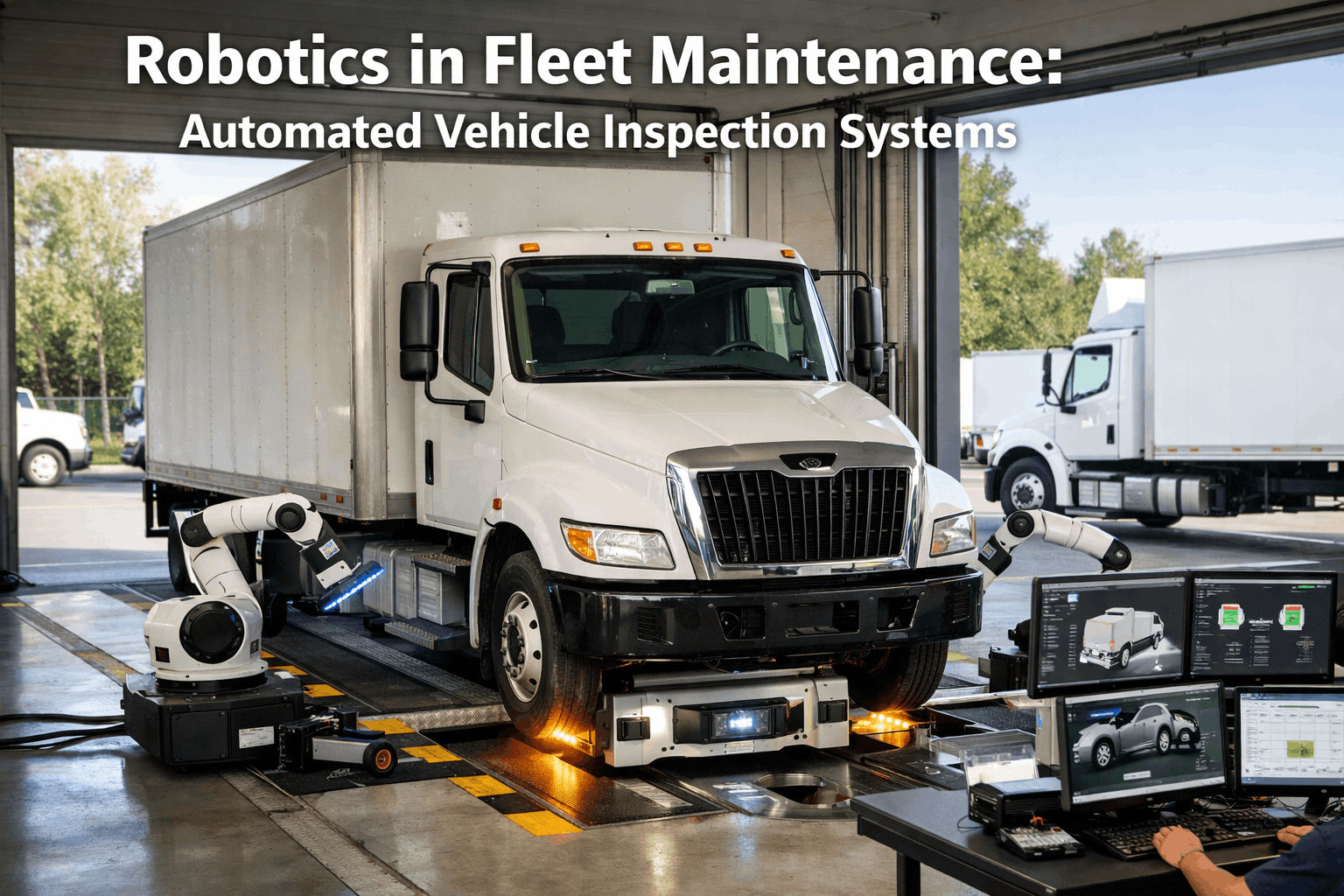

CMMS Integration: The Critical Link

IoT sensors generate data. AI generates insights. But without a CMMS to convert those insights into actual maintenance work, the value chain breaks down. Fleet managers end up drowning in dashboards and alerts with no systematic way to ensure the right repair happens at the right time on the right vehicle.

IoT Sensor to CMMS Repair: The Automated Workflow

SENSE

Vibration sensor on Vehicle #415's alternator bearing detects 0.3mm/s increase over 72 hours, exceeding normal degradation rate by 4x

ANALYZE

AI compares pattern against fleet-wide bearing failure database, calculates 82% probability of failure within 14 days at current degradation rate

SCHEDULE

CMMS auto-generates work order, checks parts inventory for replacement bearing, and schedules repair during vehicle's next planned depot stop

EXECUTE

Technician receives work order with full sensor history, AI diagnosis, and recommended procedure. Repair completed, outcome logged back to model

This closed-loop architecture is what transforms IoT monitoring from expensive data collection into a self-improving maintenance system. Each repair outcome — whether the prediction was correct, early, or late — feeds back into the AI model, making future predictions more accurate. Over 70% of telematics revenue is now recurring and subscription-based, reflecting the ongoing value of continuous monitoring versus one-time hardware purchases. Book a demo to see how OxMaint closes the loop from sensor alert to completed repair.

Edge Computing vs. Cloud Processing

Not all IoT data needs to travel to the cloud before action is taken. Smart fleet monitoring systems use a hybrid approach that balances real-time responsiveness with deep analytical power.

Edge Computing vs. Cloud Processing in Fleet IoT

Edge Computing (On-Vehicle)

LatencyMilliseconds

Best ForSafety-critical alerts

ConnectivityWorks offline

ProcessingBasic anomaly detection

Data VolumeFiltered, compressed

Cloud Processing (Off-Vehicle)

LatencySeconds to minutes

Best ForPredictive analytics

ConnectivityRequires network

ProcessingDeep ML models

Data VolumeFleet-wide analysis

The best fleet monitoring systems combine both approaches. Edge processors on the vehicle handle immediate safety alerts — a sudden pressure drop, critical temperature spike, or collision event gets flagged instantly without waiting for cloud connectivity. Meanwhile, cloud-based AI processes the full data stream for pattern recognition, fleet-wide trend analysis, and long-term predictive modeling. This hybrid architecture ensures nothing gets missed whether a vehicle is in a city with full connectivity or on a remote highway with spotty coverage. Sign up for OxMaint to integrate both edge and cloud monitoring data into a single maintenance management platform.

Implementation Strategy for Fleet Managers

Deploying IoT monitoring across a fleet does not require wiring every vehicle with every possible sensor on day one. The most effective implementations follow a phased strategy that starts with the highest-value data sources and expands as ROI is proven.

Smart Fleet Monitoring: Phased Rollout

Phase 1 — Weeks 1-4

Foundation: Telematics & GPS

Deploy OBD-II telematics devices across all vehicles for DTC codes and basic diagnosticsImplement GPS tracking for location, route, speed, and idle time monitoringConnect telematics data feed to CMMS for centralized fleet visibility

Phase 2 — Months 2-3

Expansion: Critical Sensors

Add temperature, pressure, and vibration sensors to highest-criticality vehicles firstEnable real-time fuel monitoring with consumption rate analyticsActivate AI anomaly detection on incoming sensor data streams

Phase 3 — Months 4-6

Intelligence: Predictive Analytics

Activate predictive maintenance models trained on your fleet's accumulated dataImplement automated work order generation from AI predictions in CMMSBegin driver behavior scoring and route optimization from sensor data

Ongoing

Optimization: Fleet-Wide Intelligence

Expand sensor coverage to all vehicles and auxiliary equipmentLeverage fleet-wide pattern analysis for purchasing and lifecycle decisionsIntegrate environmental and cargo monitoring for compliance and quality assurance

Start Smart

The most important first step is the CMMS foundation. Without a system to receive, organize, and act on IoT data, sensors just produce noise. OxMaint provides the digital backbone that turns sensor intelligence into scheduled, tracked, and measured maintenance actions from day one.

Sign Up Free

Give Your Fleet a Nervous System

IoT sensors are the nerves. AI is the brain. OxMaint is the muscle that turns intelligence into action. Connect your fleet's sensor data to automated maintenance workflows and start reducing downtime, cutting costs, and extending vehicle life today.

Frequently Asked Questions

What is AI-powered IoT fleet monitoring

AI-powered IoT fleet monitoring combines physical sensors installed on vehicles with artificial intelligence analytics in the cloud. Sensors continuously capture data on engine health, tire pressure, fuel consumption, temperature, vibration, and more. AI algorithms analyze this data in real time to detect anomalies, predict failures, and generate automated maintenance alerts through CMMS platforms like

OxMaint.

What types of sensors are used in smart fleet monitoring

Common fleet IoT sensors include temperature sensors (engine, coolant, brake), vibration sensors (bearings, drivetrain), pressure sensors (oil, tire, hydraulic), fuel level and consumption sensors, accelerometers (driver behavior, impact), GPS modules (location, speed, route), and emissions sensors (exhaust composition). The specific sensor mix depends on vehicle type and operational priorities.

How does IoT monitoring reduce fleet maintenance costs

IoT monitoring reduces costs through multiple channels: predictive maintenance catches failures early (reducing repair costs by 25-35%), fuel efficiency monitoring saves 10-15% on fuel, reduced downtime keeps vehicles earning revenue, and data-driven scheduling eliminates unnecessary servicing. Fleets using IoT predictive maintenance report 35-50% less unplanned downtime overall.

How does sensor data integrate with CMMS software

IoT platforms transmit sensor data to CMMS systems like OxMaint through APIs and cloud integrations. When AI detects an anomaly or predicts a failure, the CMMS automatically generates a work order with diagnosis details, assigns a technician, checks parts availability, and schedules the repair. This closed-loop workflow eliminates manual alert review and ensures every prediction translates into tracked maintenance action.

Book a demo to see the integration in action.

Do I need to replace my vehicles to add IoT monitoring

No. Most fleet IoT solutions are retrofit-ready, using OBD-II plug-in telematics devices and aftermarket sensors that can be installed on any vehicle regardless of age or manufacturer. Cloud-based processing means no specialized on-vehicle computers are needed. Implementation can start with basic telematics and expand to advanced sensors over time.

What is the difference between basic telematics and AI-powered monitoring

Basic telematics provides raw data and threshold-based alerts (e.g., "temperature exceeded 220°F"). AI-powered monitoring analyzes patterns, context, and history to provide intelligent predictions (e.g., "temperature trend combined with vibration pattern indicates cooling pump failure within 12 days"). The difference is reactive notification versus proactive prediction.

How quickly can I see ROI from IoT fleet monitoring

Most fleets report measurable fuel savings and reduced emergency repairs within the first 30-60 days of IoT deployment. Predictive maintenance accuracy improves significantly over 3-6 months as AI models learn fleet-specific patterns. Full ROI from reduced downtime, lower maintenance costs, and extended vehicle lifespans typically materializes within 6-12 months.