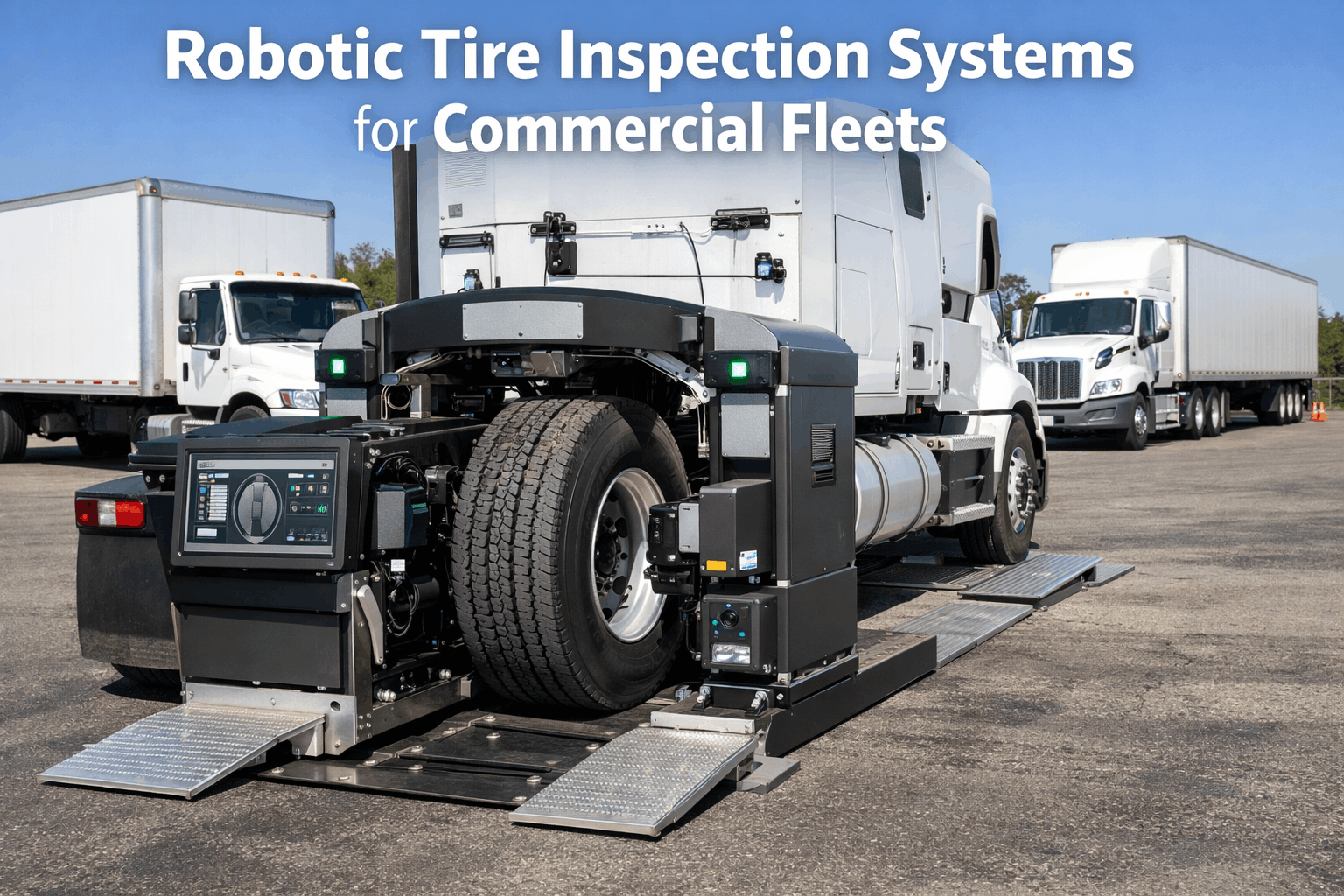

Tire-related breakdowns remain one of the most preventable yet costly disruptions in commercial fleet operations. Every roadside blowout means a stranded driver, a missed delivery window, and an emergency repair bill that can run three to five times higher than a planned replacement. In 2025, with tire costs per mile climbing to $0.047 and the global tire inspection system market reaching $238.6 million, forward-thinking fleet operators are turning to robotic tire inspection systems — AI-powered machines that automatically scan tread depth, measure pressure, detect wear patterns, and flag structural defects in seconds. These systems do not just replace the clipboard and flashlight. They fundamentally change how fleets manage one of their most critical and most neglected assets. If your fleet still relies on manual walkarounds to catch tire problems, this guide will show you exactly what robotic inspection technology delivers, how it works, and why integrating it with a CMMS platform like OxMaint (Sign Up Free) turns raw inspection data into automated maintenance action.

Why Manual Tire Inspections Are Failing Commercial Fleets

The traditional pre-trip and post-trip tire inspection process depends entirely on human consistency. A driver walks around the vehicle, kicks a few tires, maybe uses a tread depth gauge, and checks for obvious damage. This approach has three fundamental problems that robotic systems eliminate completely.

First, manual inspections are inconsistent. Research into AI-powered tire diagnostics shows that visual inspections vary significantly between personnel and environmental conditions — what one driver catches, another misses entirely. Second, they cannot detect internal degradation. Sidewall separations, belt shifts, and slow leaks are invisible to the naked eye but clearly visible to machine vision and sensor arrays. Third, manual inspections generate no actionable data. Even when a driver reports a tire concern, that information rarely flows into a structured maintenance workflow. It sits on paper or gets mentioned verbally to a mechanic who may or may not act on it. Fleet managers ready to close these gaps can Book a Demo to see how OxMaint digitizes every inspection finding into trackable, schedulable maintenance tasks.

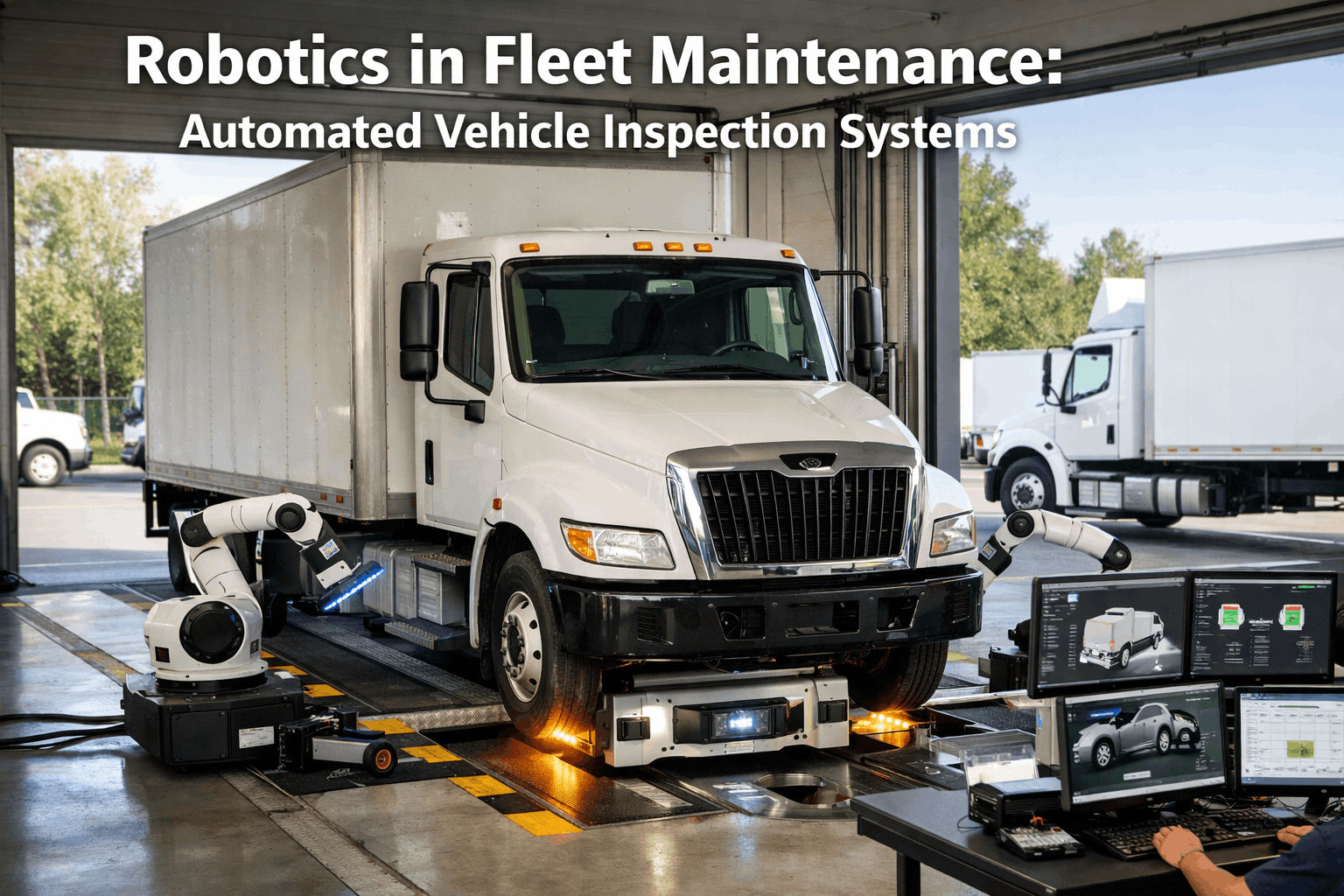

What Robotic Tire Inspection Systems Actually Do

Robotic tire inspection is not a single technology — it is a convergence of machine vision, IoT sensors, AI analytics, and automated reporting that works together to deliver a complete picture of tire health every time a vehicle passes through an inspection point. Here is how each layer of the technology contributes to the overall system.

The Inspection Accuracy Gap: Manual vs. Robotic

Understanding the difference between traditional and robotic inspection is not just about technology — it is about the reliability of every safety decision your fleet makes based on tire condition data.

Turn Every Tire Scan Into a Maintenance Action

OxMaint connects robotic inspection data directly to your maintenance workflow. Automated work orders, scheduled rotations, replacement alerts, and compliance documentation — all from a single platform your team actually uses.

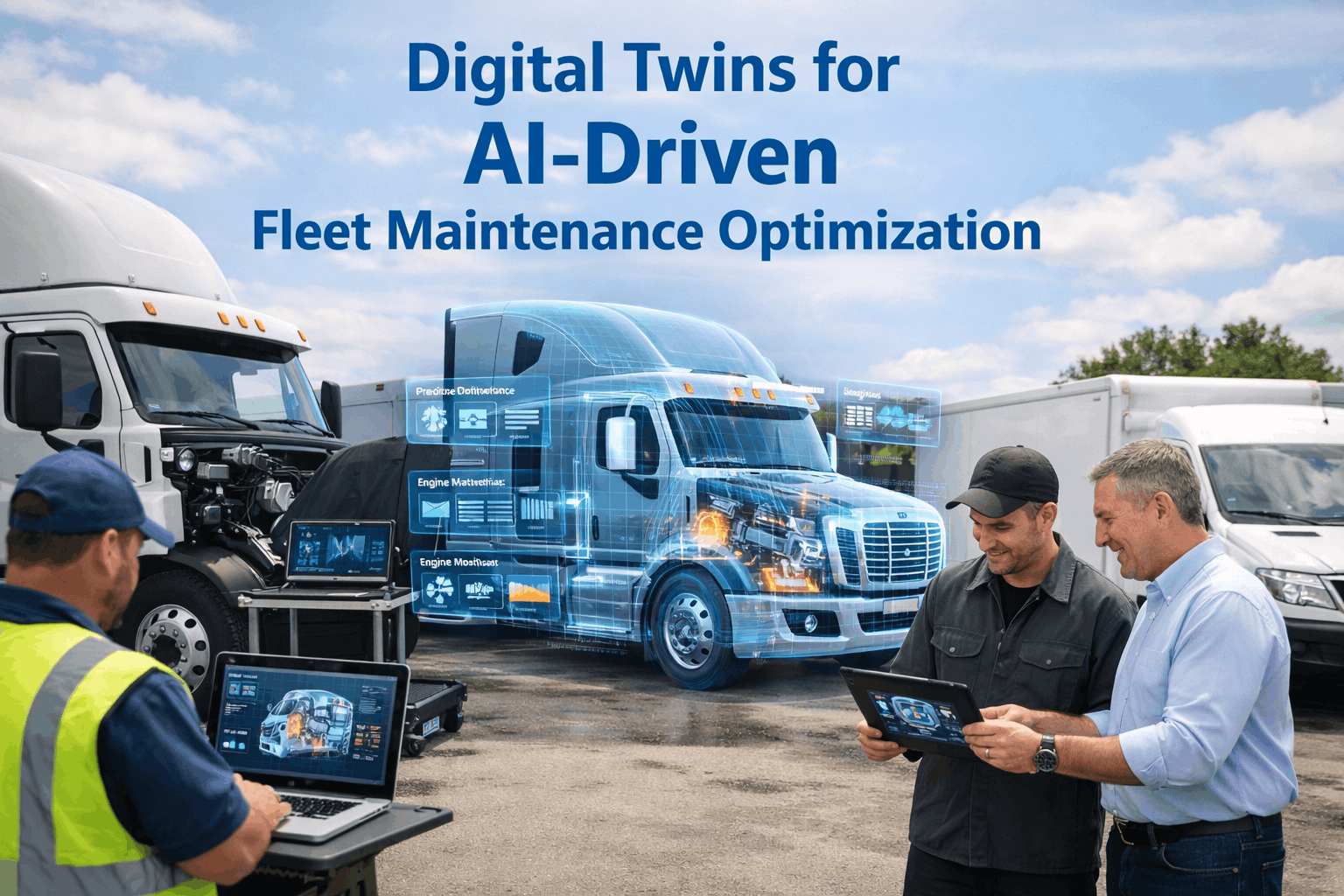

How CMMS Integration Transforms Inspection Data Into Fleet Action

A robotic tire inspection system without CMMS integration is like a diagnostic lab that runs tests but never sends results to the doctor. The real value of automated inspection is realized only when every data point flows into a structured maintenance platform that assigns tasks, tracks completion, and builds historical records for each tire and each vehicle. Here is how OxMaint makes that connection seamless.

When a robotic scanner detects that a steer tire on unit 4782 has worn below the recommended threshold, OxMaint automatically creates a prioritized work order assigned to the next available technician. The work order includes the inspection report, annotated images, tire position, and recommended action. Once the technician completes the replacement, the system updates the vehicle's maintenance history, adjusts the tire inventory count, and recalculates the replacement forecast for that position based on updated wear data. Fleet operators who want to see this workflow in action can Book a Demo and walk through a live integration scenario.

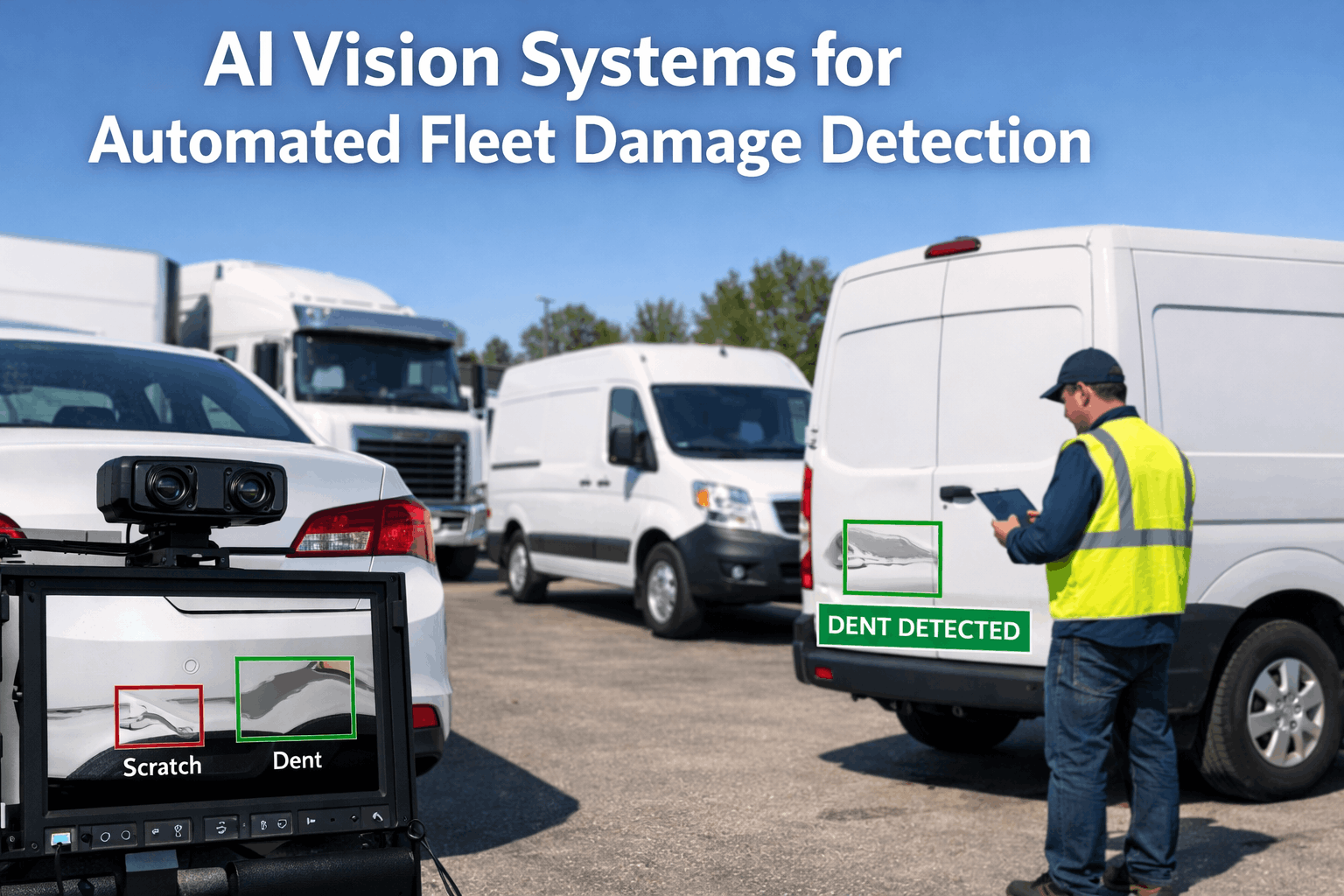

What Robotic Inspection Catches That Drivers Miss

The most dangerous tire failures are the ones that look fine from the outside. Robotic systems detect failure indicators that are physically invisible during a standard walkaround, giving maintenance teams weeks or months of lead time to act before a tire becomes a safety hazard or DOT violation.

AI compares tread depth across the full tire width and flags uneven wear caused by toe, camber, or caster misalignment — catching suspension and steering issues through tire data alone.

Continuous monitoring detects gradual leaks losing as little as 1–2 PSI per week. By the time a driver notices handling changes, the tire has already suffered internal heat damage from prolonged underinflation.

High-resolution cameras identify surface cracking from UV exposure, ozone degradation, and age-related rubber deterioration invisible to the naked eye during a walkaround inspection.

The system flags diameter and tread depth mismatches across dual assemblies and axle positions that cause uneven load distribution, premature wear, and increased fuel consumption.

Machine vision detects embedded nails, screws, glass, and debris in tread grooves that have not yet caused a puncture but will eventually lead to blowouts at highway speed.

Thermal imaging identifies hot spots from internal belt separation, brake drag transferring heat to tires, and bearing failures radiating heat through the wheel assembly.

Each of these detection capabilities feeds directly into a maintenance decision. When connected to OxMaint (Sign Up Free), every finding becomes a trackable work order with full documentation for compliance audits and warranty claims.

The Business Case: ROI of Robotic Tire Inspection

The financial argument for robotic tire inspection is built on four measurable outcomes that fleet finance teams can track directly against their current tire-related costs.

These savings compound across every vehicle in the fleet. For a 200-truck operation spending $0.047 per mile on tires across 80,000 annual miles per truck, even a 20% cost reduction represents over $150,000 in annual savings. Fleet managers evaluating this investment can Book a Demo to calculate projected ROI based on their specific fleet size and operating profile.

Your Tires Are Talking. Your CMMS Should Be Listening.

OxMaint transforms robotic tire inspection data into automated maintenance workflows — from predictive replacement scheduling to compliance-ready documentation. Stop losing trucks to preventable tire failures.

Frequently Asked Questions

What is a robotic tire inspection system and how does it work

A robotic tire inspection system uses a combination of high-speed cameras, laser profilometers, IoT pressure sensors, and AI algorithms to automatically scan every tire on a commercial vehicle as it drives through an inspection station. The system measures tread depth across the full tire surface, checks inflation pressure, detects sidewall damage and foreign objects, and identifies irregular wear patterns caused by alignment or suspension issues. The entire scan takes under 60 seconds and generates a digital report with annotated images that can be sent directly to a CMMS platform like OxMaint for automated maintenance scheduling.

How accurate are AI-powered tire inspection systems compared to manual checks

Deep learning tire inspection models achieve accuracy rates higher than 94% in real-world defect detection, and advanced systems reach 99.5% accuracy for surface defects including cracks, bulges, and foreign object penetration. Manual inspections, by comparison, vary significantly between inspectors and are heavily influenced by lighting conditions, time pressure, and fatigue. AI systems also detect internal degradation indicators through thermal imaging and pressure trending that are completely invisible during a standard visual walkaround.

Can robotic tire inspection integrate with existing fleet maintenance software

Yes. Modern robotic inspection platforms are designed to integrate with CMMS and fleet management systems through APIs and standard data formats. When connected to OxMaint, inspection findings automatically generate prioritized work orders with specific tire positions, measurements, annotated images, and recommended actions. This eliminates the manual handoff between inspection and maintenance that causes findings to get lost or delayed in traditional workflows.

What types of tire defects can robotic systems detect that drivers cannot

Robotic systems detect several categories of defects that are invisible during manual walkarounds. These include internal belt separation identified through thermal imaging, slow pressure leaks losing 1–2 PSI per week, micro-cracking from UV and ozone exposure, mismatched tire diameters across dual assemblies, embedded debris that has not yet caused punctures, and irregular tread wear patterns indicating alignment or suspension problems. Each of these conditions progresses silently until it causes a sudden failure on the road.

What is the return on investment for implementing robotic tire inspection

Fleets implementing automated tire inspection with CMMS integration typically see a 20–30% reduction in overall tire operating costs, a 30% decrease in unplanned tire-related downtime, and a 15–25% extension in average tire service life. For a 200-truck fleet operating 80,000 miles per truck annually at the current industry average of $0.047 per mile in tire costs, a 20% reduction translates to over $150,000 in annual savings. Most fleets report full ROI within 12–18 months of deployment.

How does OxMaint help fleet managers act on tire inspection data

OxMaint receives real-time data from robotic inspection systems and automatically converts findings into structured maintenance workflows. When a scan identifies a tire issue, OxMaint creates a prioritized work order assigned to the appropriate technician, includes all relevant inspection data and images, tracks the repair to completion, updates vehicle maintenance history, adjusts tire inventory counts, and recalculates replacement forecasts based on updated wear trends. This closed-loop process ensures no inspection finding goes unaddressed and builds the compliance documentation fleets need for DOT audits and warranty claims. Sign up for OxMaint to experience this workflow firsthand.