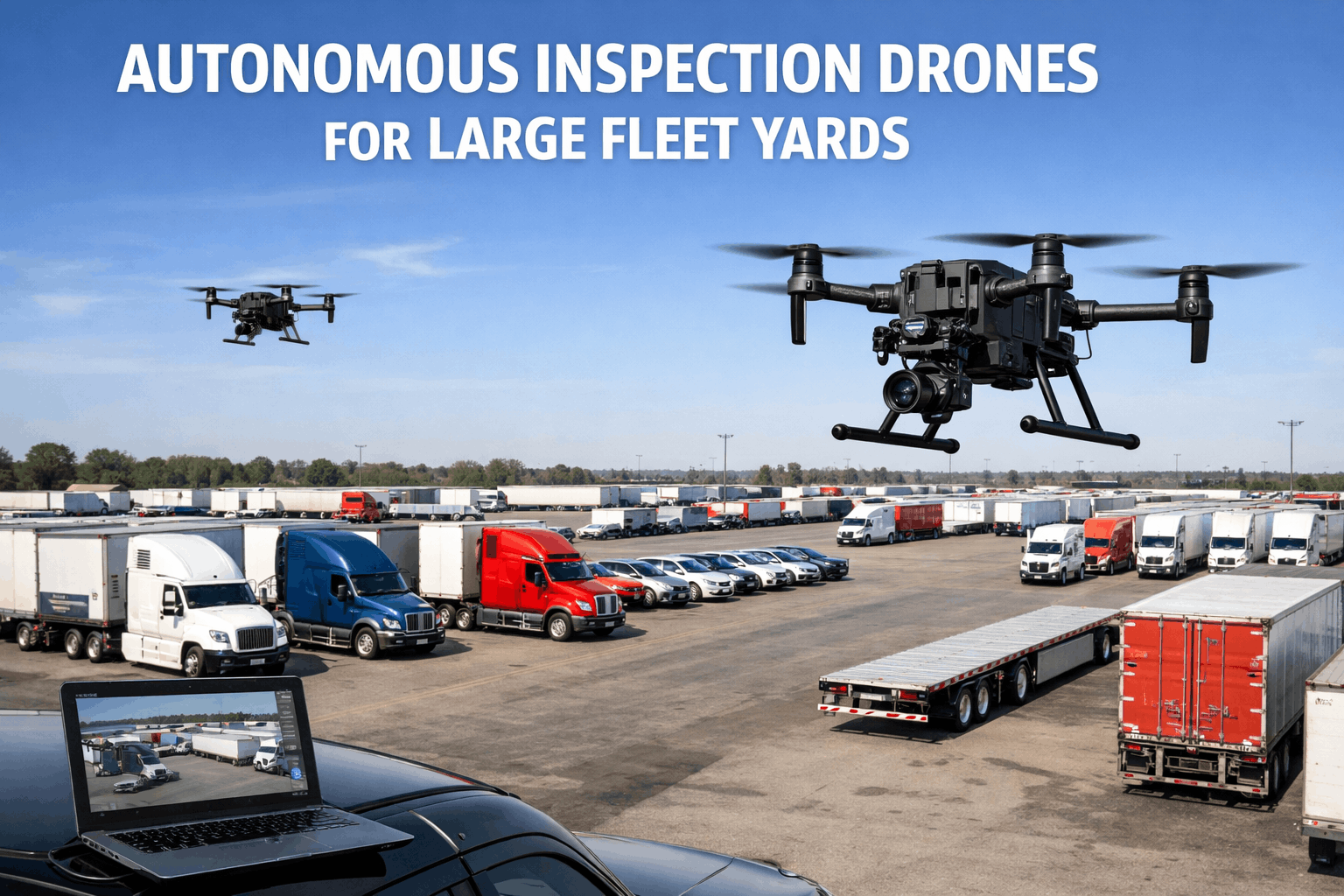

Managing a large fleet yard with hundreds of vehicles spread across acres of open space has always been a logistical headache for maintenance teams. Walking rows of parked trucks, trailers, and heavy equipment with a clipboard takes days, misses hidden damage, and puts inspectors at risk climbing on tall vehicles. Autonomous inspection drones are changing this entirely. Equipped with AI-powered cameras, thermal sensors, and computer vision algorithms, these unmanned aerial vehicles can scan an entire fleet yard in hours — detecting body damage, tire wear, fluid leaks, and rooftop HVAC failures that human eyes routinely miss. When connected to a CMMS platform like OxMaint, every finding becomes an instant, trackable work order. Sign up to see how drone-detected issues flow directly into automated maintenance workflows, or book a demo for a live walkthrough.

Why Traditional Yard Inspections Are Holding Fleets Back

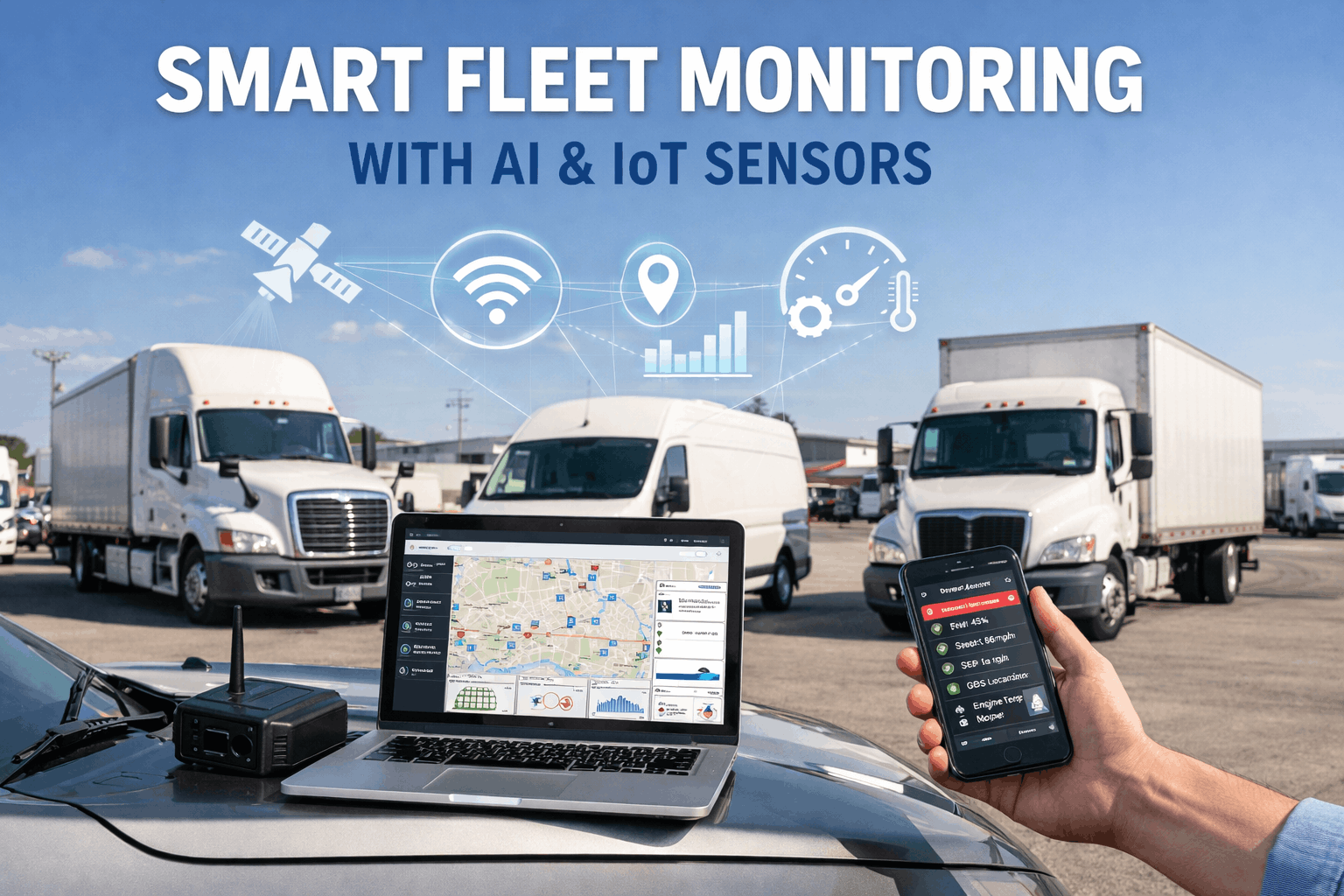

Fleet yards are large, exposed environments where vehicles sit idle between dispatches — accumulating damage from weather, loading operations, and everyday wear that goes unnoticed until the vehicle is already on the road. Traditional inspection methods rely on technicians walking the yard with checklists, visually scanning each vehicle from ground level. This approach has three fundamental problems that drone technology directly solves.

Ground-level inspectors cannot see trailer rooftops, upper cab areas, or the full undercarriage without lifts or crawling underneath. Roof-mounted HVAC units, antenna damage, and upper body corrosion go undetected for weeks or months.

A team of three technicians inspecting a 200-vehicle yard takes three to four full working days. Drones cover the same yard in under two hours with higher accuracy and zero fatigue-related errors.

Paper checklists and manual photo logs create fragmented records that are hard to search, compare, or audit. Drone inspections produce standardized digital reports that feed directly into maintenance platforms.

How Autonomous Inspection Drones Work in Fleet Yards

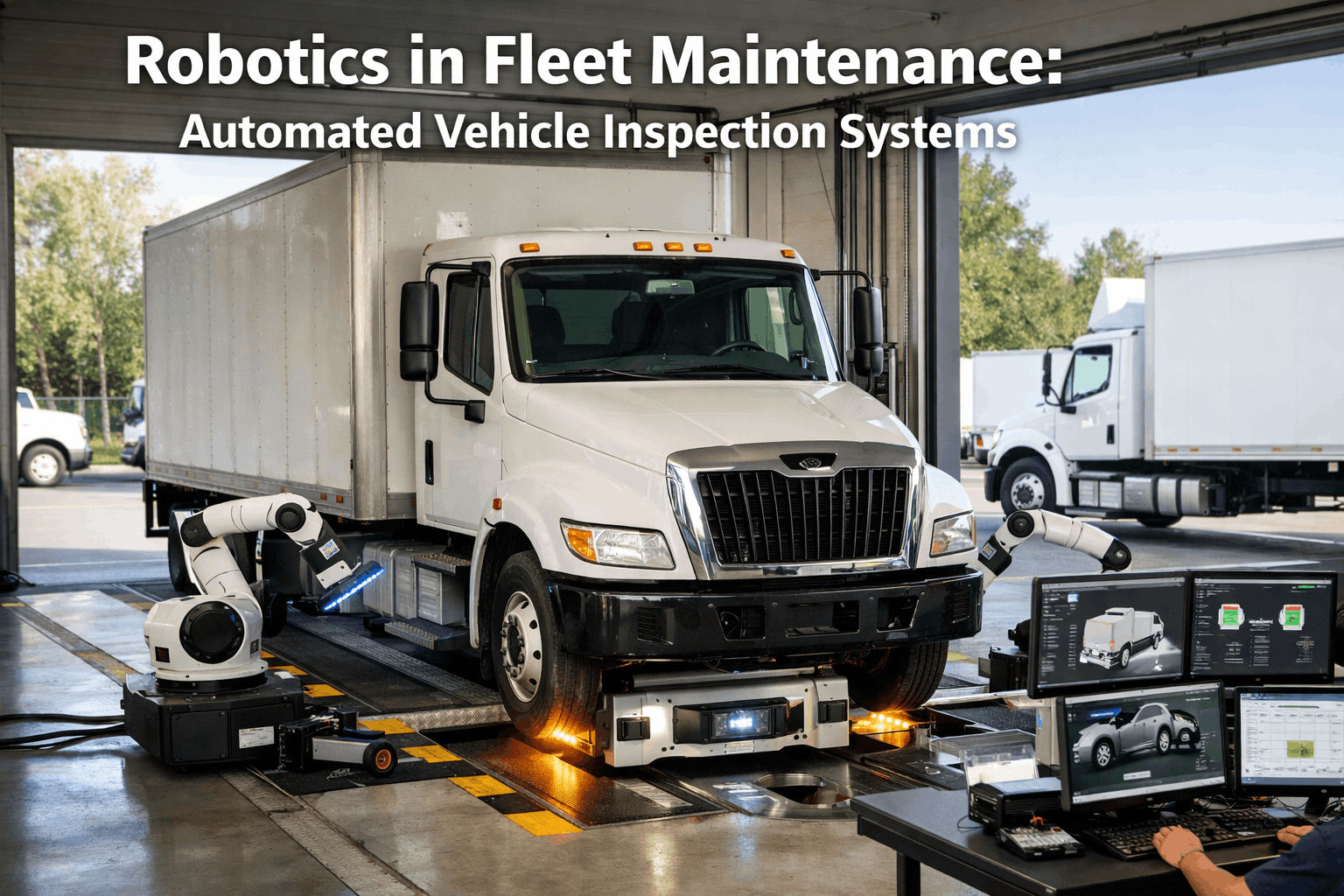

Modern inspection drones are not remote-controlled toys operated by a pilot with a joystick. They are fully autonomous systems that launch from dock stations, follow pre-programmed GPS flight paths across the yard, capture thousands of high-resolution images, and return to base to recharge and upload data — all without human intervention. Here is the complete workflow from takeoff to work order.

This closed-loop system means that a crack detected on a trailer roof at 7:00 AM can have a work order assigned by 7:15 AM and a technician dispatched before the vehicle is scheduled for its next route. Sign up for OxMaint to connect drone inspection data with automated maintenance workflows.

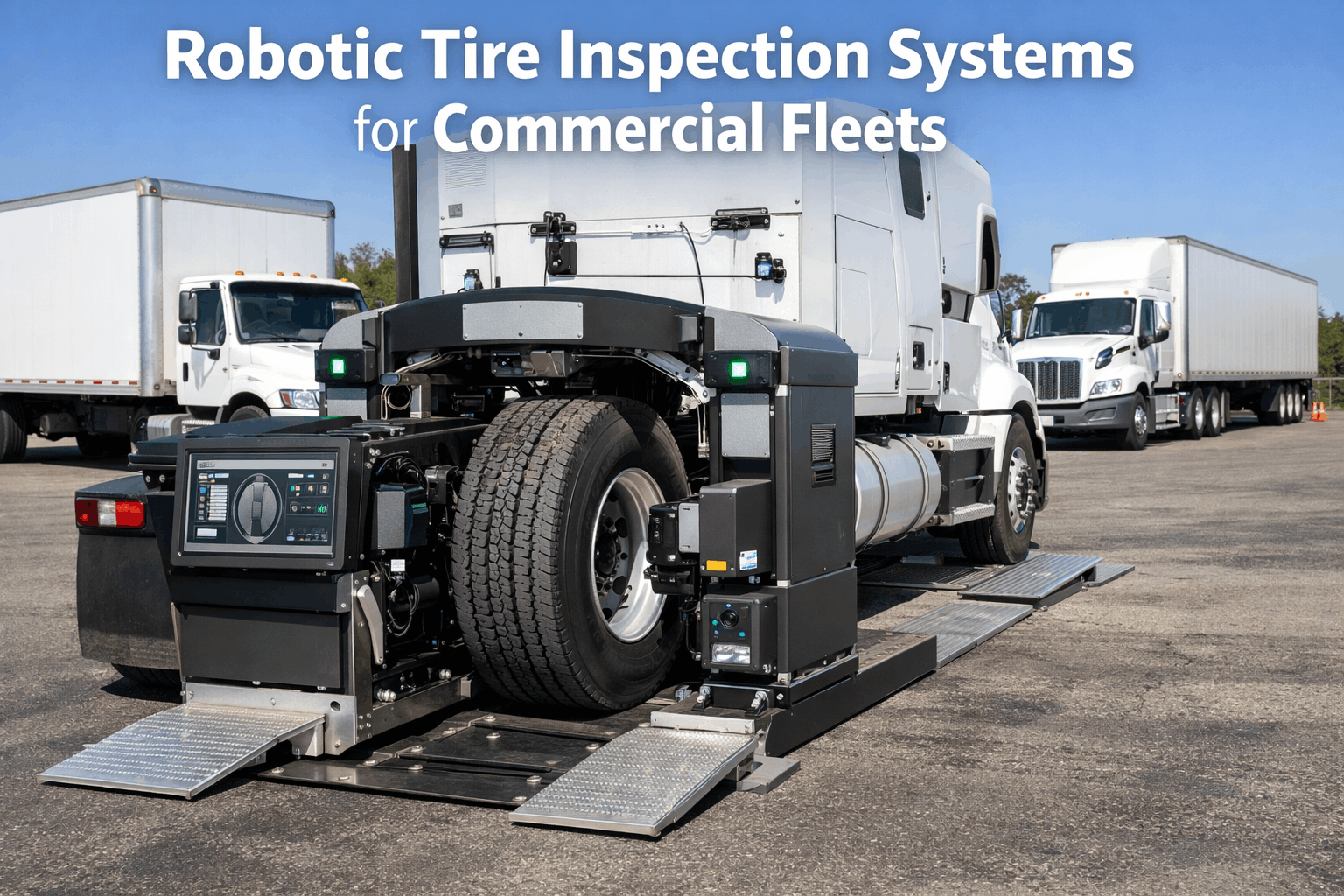

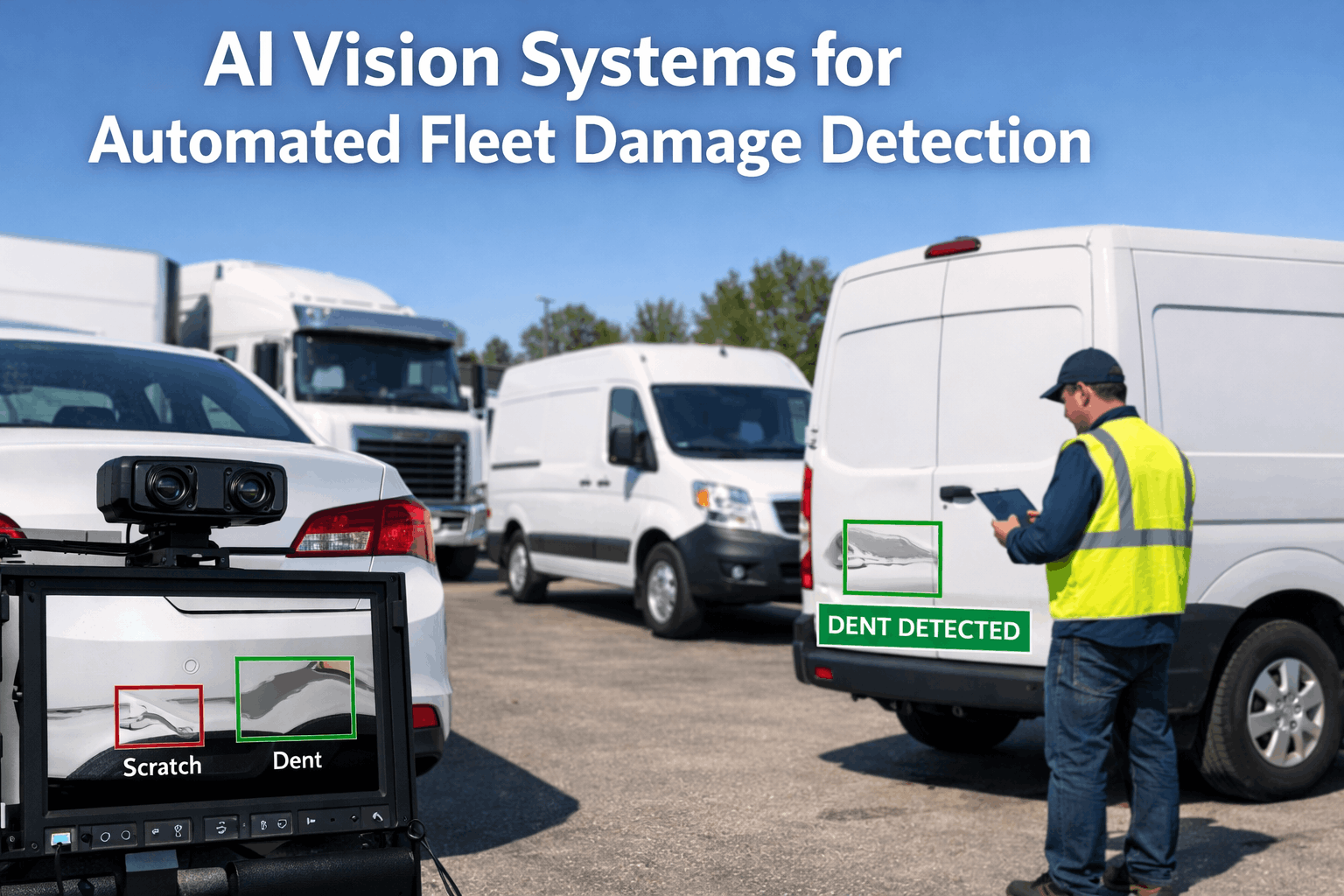

What AI Drone Cameras Actually Detect

The value of drone inspections lies entirely in what the AI vision system can identify. Modern computer vision models trained on fleet vehicle datasets can detect a wide range of issues that affect safety, compliance, and operational readiness. Here are the key detection categories and what they mean for your maintenance planning.

Turn Drone Findings Into Instant Maintenance Action

OxMaint transforms aerial inspection data into prioritized work orders, compliance records, and asset health dashboards — automatically. No manual data entry. No missed defects.

Drone Inspections vs. Manual Inspections: A Direct Comparison

The efficiency gains from drone-based yard inspections are not marginal improvements — they represent a fundamental shift in how fleet maintenance teams allocate time, resources, and attention. Here is how the two approaches compare across the metrics that matter most to fleet operations.

The data makes the case clearly: drone inspections deliver better results in less time with lower risk. The missing piece for most fleet operations is the system that acts on the findings — and that is where OxMaint completes the loop. Book a demo to see how inspection data flows into automated maintenance scheduling.

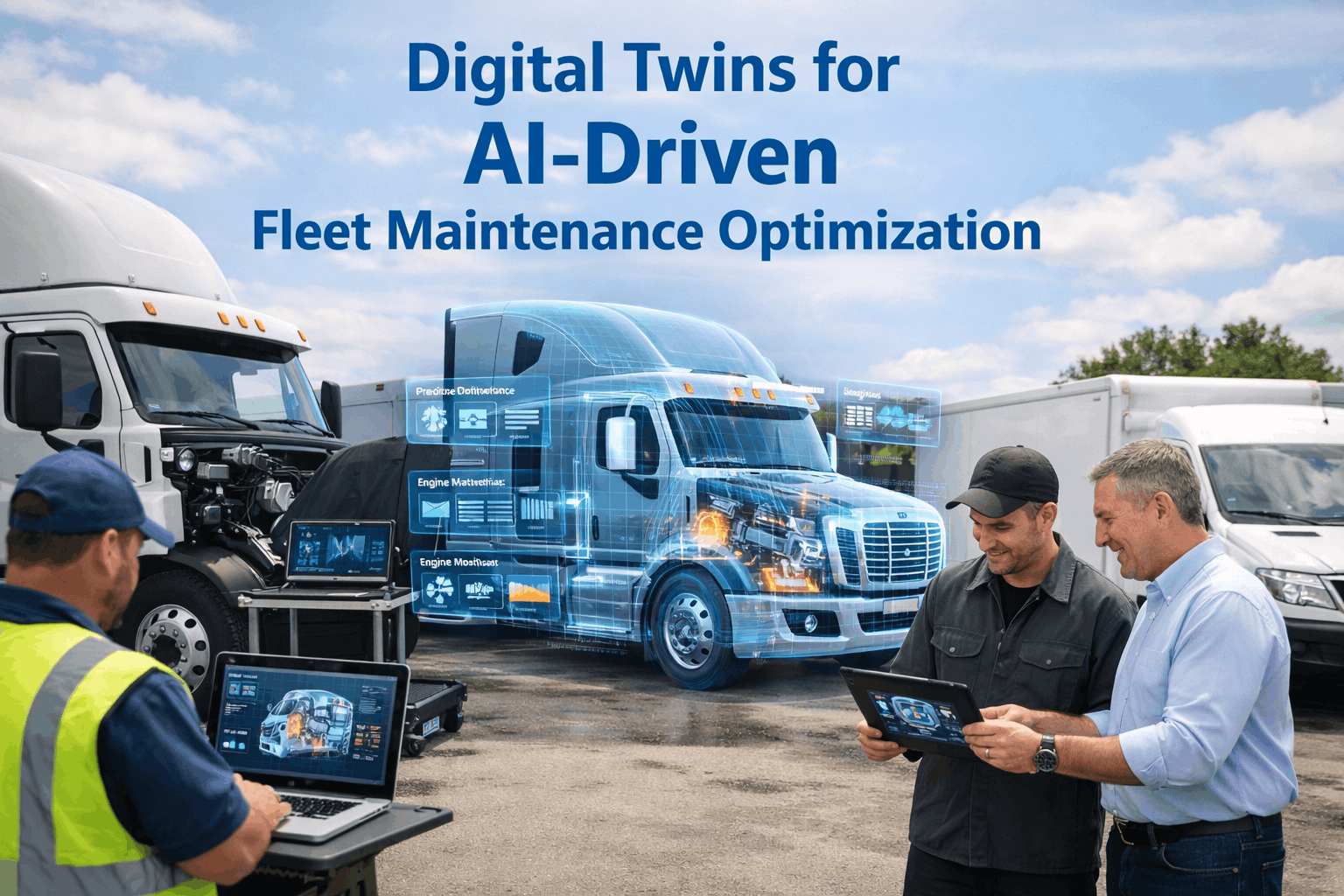

Connecting Drones to Your CMMS: The OxMaint Advantage

An inspection drone without a maintenance management system is like a diagnostic scanner without a repair shop — it identifies problems but cannot fix them. The real value of drone technology is realized when findings are seamlessly connected to work order creation, technician assignment, parts procurement, and compliance tracking. OxMaint provides exactly this bridge.

Drone-detected issues generate prioritized work orders in OxMaint automatically — complete with annotated images, severity levels, vehicle ID, and recommended repair actions.

The system matches repair requirements to available technicians based on skill set, workload, and proximity — minimizing response time between detection and resolution.

When a drone identifies a specific component failure, OxMaint cross-references parts inventory and triggers procurement if stock is low — preventing repair delays.

Every drone inspection and resulting repair is logged with timestamps, photos, and technician sign-offs — building audit-ready compliance records automatically.

This integration creates a closed-loop maintenance system where the time between detecting a problem and resolving it shrinks from days to hours. Sign up for OxMaint and connect your inspection data to intelligent maintenance workflows.

Which Fleet Operations Benefit Most from Drone Inspections

While drone inspection technology can add value to nearly any fleet operation, the return on investment is highest in specific scenarios where scale, vehicle accessibility, or compliance pressure makes traditional methods particularly expensive and slow. Here are the fleet types seeing the strongest results.

Large yards with 100+ trailers benefit from aerial surveys that identify damage on idle units before dispatch. Drones check tire conditions, body integrity, and reflective markings across the entire yard in a single flight session.

Heavy machinery like excavators, cranes, and bulldozers are difficult to inspect manually due to height and size. Thermal drones detect hydraulic leaks, overheating components, and structural fatigue on boom arms without scaffolding.

Municipal bus fleets face strict regulatory inspection schedules. Drones conduct roof inspections for HVAC condition, check for post-service body damage, and create consistent visual records that satisfy audit requirements.

Reefer units require regular monitoring of refrigeration equipment mounted on trailer roofs. Thermal drones verify cooling system performance and detect insulation failures that compromise cargo temperature integrity.

Ready to Automate Your Fleet Yard Inspections

OxMaint gives your maintenance team the platform to receive, organize, and act on drone inspection data — turning aerial findings into completed repairs with full traceability.

Frequently Asked Questions

How do autonomous drones navigate a fleet yard without a pilot

Autonomous inspection drones use pre-programmed GPS flight paths combined with geofencing boundaries to navigate fleet yards independently. The flight manager sets up the route once by defining yard zones, vehicle rows, and altitude parameters. The drone then repeats this mission on a scheduled basis — launching from a dock station, flying the route, capturing imagery, and returning to recharge — all without human control during the flight.

What types of damage can AI drone cameras detect on fleet vehicles

AI-equipped drones can identify body damage such as dents, cracks, and corrosion, along with tire wear patterns, sidewall bulges, fluid leaks beneath vehicles, roof punctures, HVAC unit failures, missing reflective markers, broken lights, and damaged compliance placards. Thermal cameras add the ability to detect heat anomalies indicating internal component failures, overheating brakes, or refrigeration system malfunctions that are invisible to standard cameras.

How do drone inspection findings connect to maintenance work orders

When the drone's AI system identifies an issue, the finding is compiled into a structured report with severity rating, annotated images, and vehicle identification. This report is then pushed directly into a CMMS platform like OxMaint, which automatically generates a prioritized work order, assigns a technician, checks parts availability, and tracks the repair through completion. The entire process from detection to work order takes minutes, not days.

How long does it take a drone to inspect a large fleet yard

A single autonomous drone can survey a yard of 200+ vehicles in approximately two hours, capturing comprehensive imagery from multiple angles including rooftops and upper body areas. By comparison, a manual inspection team of three technicians typically requires three to four full working days to cover the same yard with significantly less coverage of hard-to-reach areas.

Is drone inspection technology practical for smaller fleets

While the ROI is highest for fleets with 100+ vehicles, smaller operations can still benefit — particularly those with tall or hard-to-access equipment like construction machinery, refrigerated trailers, or buses with rooftop HVAC units. The key is pairing drone data with a CMMS like OxMaint that turns findings into actionable maintenance workflows regardless of fleet size. Book a demo to evaluate how drone integration fits your specific operation.

What regulations apply to using inspection drones over fleet yards

In the United States, commercial drone operations fall under FAA Part 107 rules, which cover pilot certification, altitude limits, and airspace restrictions. Fleet yard inspections typically operate well within these parameters since they fly at low altitude over private property. Some operations may require FAA waivers for beyond-visual-line-of-sight flights across very large yards. Many drone inspection providers handle all regulatory compliance as part of their service package.