Fleet managers today face an uncomfortable reality: reactive maintenance is draining budgets, causing unexpected breakdowns, and shortening vehicle lifecycles. The global digital twin market, valued at over $21 billion in 2025, is projected to surpass $149 billion by 2030, and fleet maintenance stands at the center of this transformation. Digital twins — dynamic virtual replicas of your physical fleet vehicles — are rewriting the rules of how maintenance is planned, predicted, and executed. When paired with AI-driven analytics and a robust CMMS platform like OxMaint, these intelligent models turn raw sensor data into actionable foresight, helping you fix problems before they ever happen. Sign up to experience predictive maintenance firsthand, or book a demo to see it in action. Whether you manage 50 trucks or 5,000 mixed assets, understanding digital twin technology is no longer optional — it is the competitive edge that separates thriving fleets from those stuck in costly repair cycles.

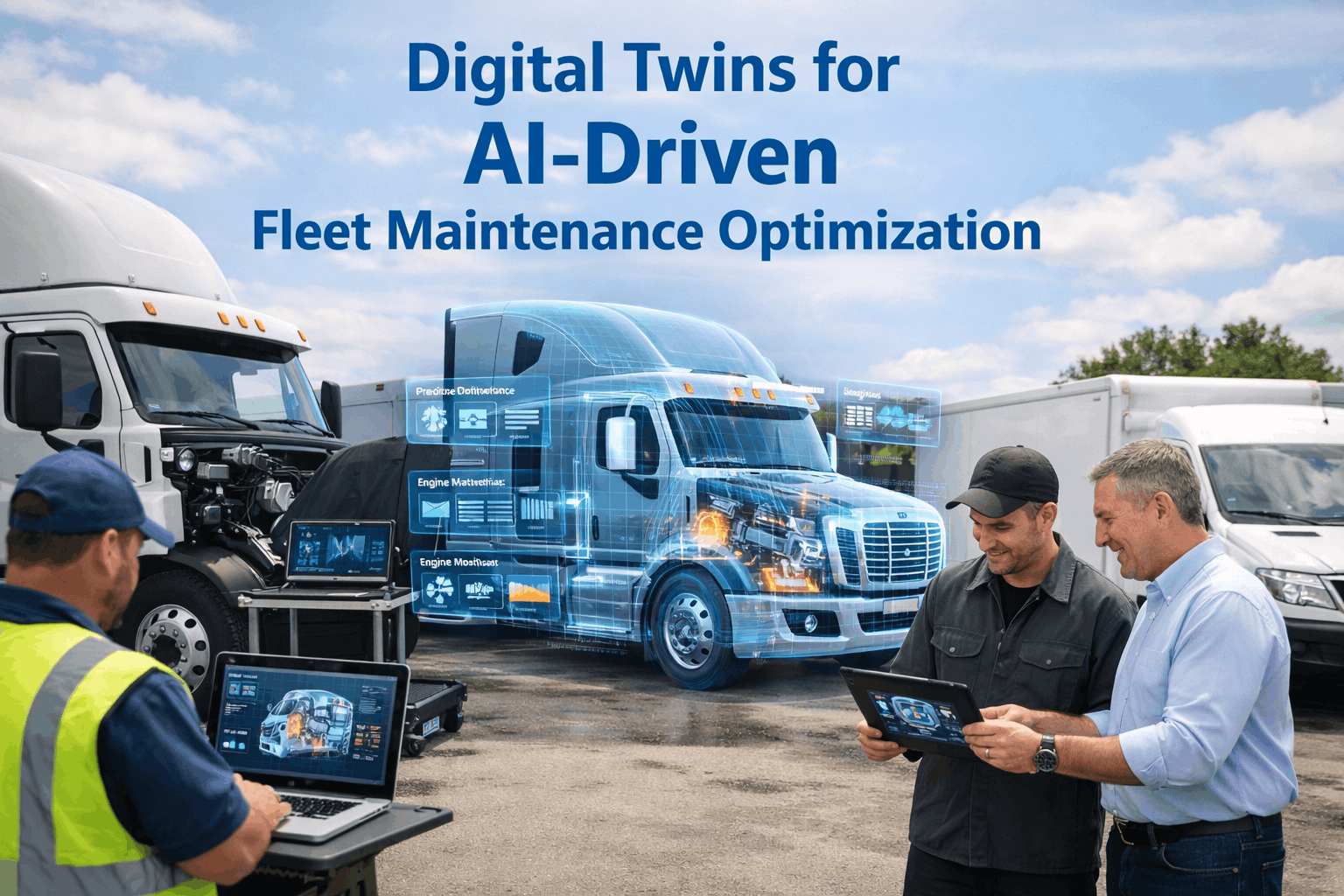

Digital Twins for AI-Driven Fleet Maintenance Optimization

Virtual Vehicle Models. Real-World Savings. Predictive Intelligence at Scale.

What Exactly Is a Digital Twin in Fleet Management?

A digital twin is a continuously updated virtual replica of a physical vehicle — its engine, transmission, brakes, tires, electrical systems, and every critical component. Unlike static 3D models, a fleet digital twin ingests real-time data from IoT sensors, telematics devices, and onboard diagnostics to mirror the exact operating state of each asset in your fleet. Think of it as giving every vehicle a living, breathing digital counterpart that learns, adapts, and predicts.

The real power emerges when this virtual model connects to a CMMS platform. Instead of waiting for a check-engine light or a roadside breakdown, fleet managers receive intelligent alerts weeks in advance — complete with recommended actions, parts requirements, and optimal scheduling windows. Ready to bring this intelligence to your fleet? Sign up for OxMaint and start building smarter maintenance workflows today.

Why Traditional Fleet Maintenance Is Failing

Most fleet operations still rely on calendar-based or mileage-based maintenance schedules. While better than purely reactive approaches, these methods are fundamentally flawed because they treat every vehicle identically — regardless of actual operating conditions, driver behavior, or component health. The result is a costly combination of over-maintenance on healthy vehicles and under-maintenance on stressed ones.

Industry research shows that predictive maintenance powered by digital twins can reduce unplanned downtime by up to 70% and cut maintenance spending by 25-40%. For a fleet averaging $1.78 per mile in operating costs, even a 15% efficiency gain translates to massive annual savings. The question is not whether to adopt this technology — it is how quickly you can implement it. Book a demo to see how OxMaint makes this transition seamless.

Five Core Capabilities of AI-Driven Digital Twins

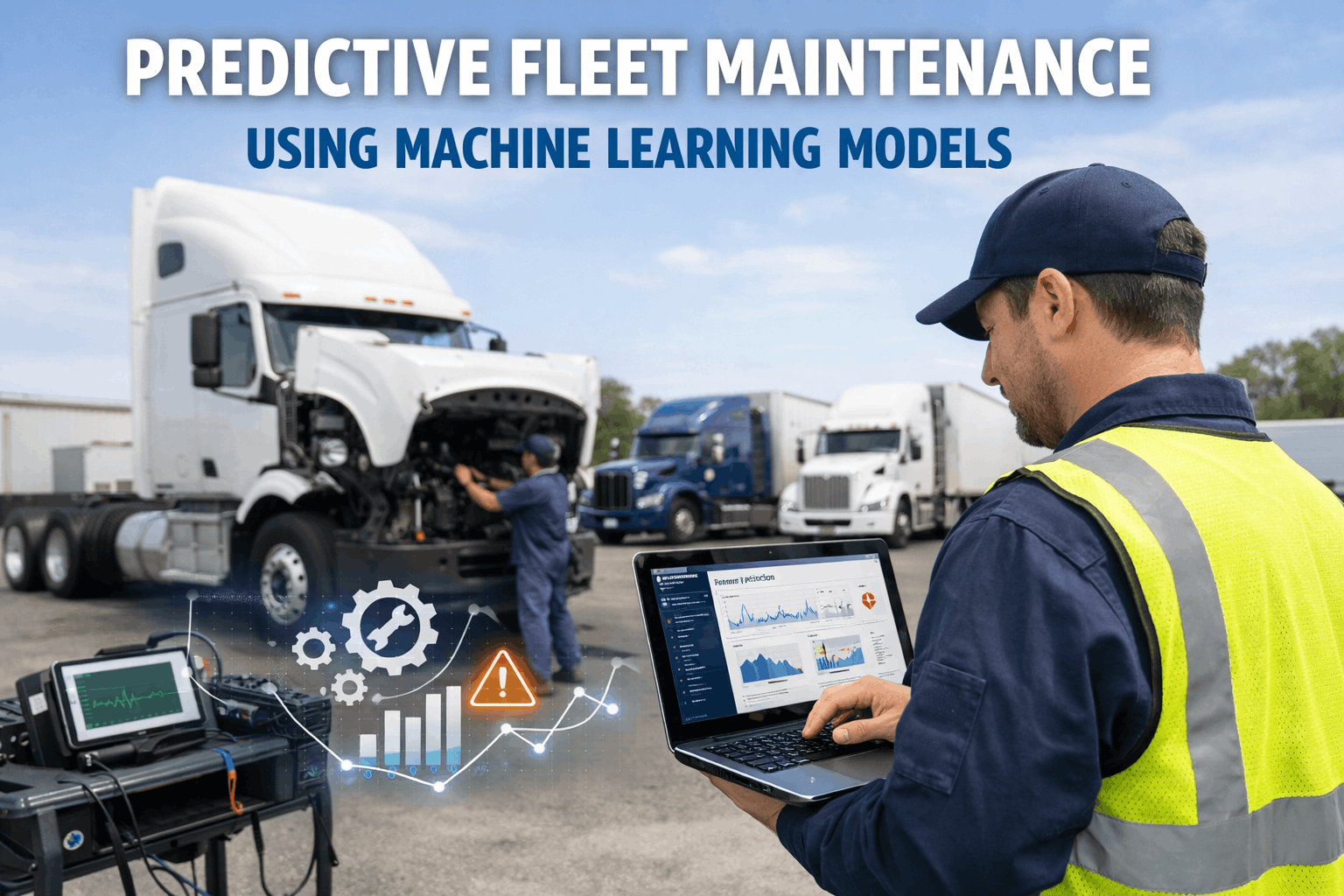

Predictive Failure Detection

AI algorithms analyze vibration patterns, temperature fluctuations, fluid pressures, and electrical signatures to identify component degradation patterns. A turbocharger losing efficiency, a bearing showing early fatigue, or brake pads wearing unevenly — the digital twin catches these signals and translates them into precise maintenance recommendations with timelines and severity ratings.

Virtual Stress Testing

Before subjecting a real vehicle to extreme conditions, the digital twin simulates outcomes. What happens to engine longevity if a truck consistently operates at high altitude? How does seasonal temperature variation affect battery health in your EV fleet? These simulations provide actionable intelligence without risking physical assets.

Lifecycle Cost Optimization

Digital twins track every component from installation through end-of-life. By analyzing replacement intervals, repair costs, and performance degradation curves across your entire fleet, AI models determine the optimal time to replace versus repair — maximizing the value extracted from every asset dollar spent.

Fleet-Wide Benchmarking

When two identical trucks on similar routes show different fuel consumption or component wear patterns, the digital twin reveals why. Is it driver behavior, route characteristics, or a developing mechanical issue? This cross-fleet intelligence helps standardize best practices and isolate problems before they spread.

Automated CMMS Workflows

The most powerful digital twin implementations connect directly to maintenance management systems. When the AI detects an impending issue, it does not just send an alert — it creates a work order, checks parts availability, schedules a technician, and estimates repair duration. OxMaint delivers exactly this level of integration.

Transform Your Fleet Maintenance with Intelligent Digital Twins

OxMaint combines AI-powered analytics with comprehensive CMMS capabilities to bring digital twin intelligence to fleets of every size. Stop reacting. Start predicting.

Real-World Impact: Digital Twins by the Numbers

The business case for digital twin technology in fleet maintenance is backed by compelling data from across the transportation and logistics industry. These are not theoretical projections — they represent documented outcomes from organizations that have made the shift from reactive to predictive maintenance strategies.

The digital twin market itself tells the story of momentum: growing from approximately $21 billion in 2025 to a projected $150 billion by 2030. Fleet operators who adopt now are not just saving money — they are building a compounding data advantage that late adopters will struggle to match. Sign up for OxMaint to start capturing these gains for your fleet.

How OxMaint Integrates Digital Twin Intelligence

A digital twin is only as powerful as the system that acts on its insights. OxMaint serves as the operational brain that translates AI-generated predictions into organized, trackable, and measurable maintenance actions. Here is how the integration works in practice:

Smart Work Order Generation

When the digital twin identifies a developing issue, OxMaint automatically creates a prioritized work order with failure probability scores, recommended parts, and estimated labor hours.

Intelligent Scheduling

The system considers vehicle availability, technician workload, parts inventory, and route schedules to recommend the optimal maintenance window — minimizing disruption to operations.

Asset Lifecycle Dashboards

Every vehicle's digital twin data feeds into comprehensive lifecycle views showing health scores, maintenance history, cost trends, and predicted remaining useful life for critical components.

Compliance Automation

Digital twin data automatically populates compliance records, inspection reports, and regulatory documentation — ensuring your fleet stays audit-ready without manual data entry.

The combination of digital twin intelligence and OxMaint's CMMS capabilities creates a closed-loop system where data drives decisions, decisions drive actions, and actions generate better data. It is the maintenance optimization cycle that fleet managers have been waiting for. Book a demo to experience this integration firsthand.

Getting Started: Your Digital Twin Roadmap

Implementing digital twin technology does not require a complete fleet overhaul overnight. The most successful deployments follow a phased approach that delivers quick wins while building toward full fleet intelligence. Here is a practical roadmap for fleet managers ready to make the transition:

Foundation (Months 1-3)

Deploy OxMaint across your fleet to centralize maintenance data. Install IoT sensors on your 10-20 highest-value or highest-risk assets. Establish baseline metrics for downtime, maintenance costs, and component replacement intervals.

Intelligence (Months 3-6)

Activate AI analytics on your pilot fleet. Begin receiving predictive maintenance alerts and compare digital twin recommendations against traditional scheduling. Measure early wins in downtime reduction and cost savings.

Optimization (Months 6-12)

Scale digital twin coverage to your full fleet. Enable automated work order generation and intelligent scheduling. Implement fleet-wide benchmarking to identify systemic improvement opportunities.

Transformation (12+ Months)

Leverage accumulated data for lifecycle cost optimization, procurement forecasting, and fleet composition planning. Your digital twin platform becomes the strategic decision-making engine for your entire operation.

The key is starting with a strong CMMS foundation — and OxMaint is built exactly for this purpose. Every work order, inspection, and maintenance event you track today becomes the training data that makes your digital twin smarter tomorrow. Sign up now and lay the groundwork for predictive fleet intelligence.

Ready to Build Your Fleet's Digital Twin?

Join thousands of fleet managers who are already using OxMaint to centralize maintenance, predict failures, and optimize every asset in their fleet. Your journey to AI-driven maintenance starts here.

Frequently Asked Questions

What is a digital twin in fleet maintenance

A digital twin is a real-time virtual replica of a physical fleet vehicle that continuously ingests data from IoT sensors, telematics, and onboard diagnostics. It mirrors the exact condition of every critical component — engine, transmission, brakes, tires, and electrical systems — allowing AI algorithms to simulate performance, detect anomalies, and predict failures before they occur. When connected to a CMMS like OxMaint, these predictions become automated maintenance actions.

How much does digital twin technology cost for fleet operations

Implementation costs vary based on fleet size and sensor requirements. Most fleet operators begin with a pilot program on 10-50 vehicles, with sensor costs as low as $0.10-$0.80 per unit. When paired with an affordable CMMS platform like OxMaint, many organizations achieve positive ROI within 6-18 months through reduced downtime and optimized maintenance spending. The key is starting with high-value assets where predictive insights deliver immediate savings.

Can small and mid-sized fleets benefit from digital twins

Absolutely. Cloud computing and affordable IoT sensors have made digital twin technology accessible to fleets of all sizes. A 50-vehicle fleet can see meaningful results by deploying sensors on critical assets and using OxMaint to centralize and act on the data. The percentage-based savings in maintenance costs and downtime reduction are proportionally similar whether you manage 50 vehicles or 5,000.

What types of fleet vehicles work with digital twin technology

Digital twins can be created for virtually any fleet asset — long-haul trucks, delivery vans, construction equipment, buses, refrigerated units, utility vehicles, and even electric vehicle fleets. The technology adapts to diesel, CNG, hybrid, and electric powertrains. Each vehicle type benefits from tailored monitoring parameters, such as refrigeration cycle tracking for cold chain vehicles or battery health modeling for EVs.

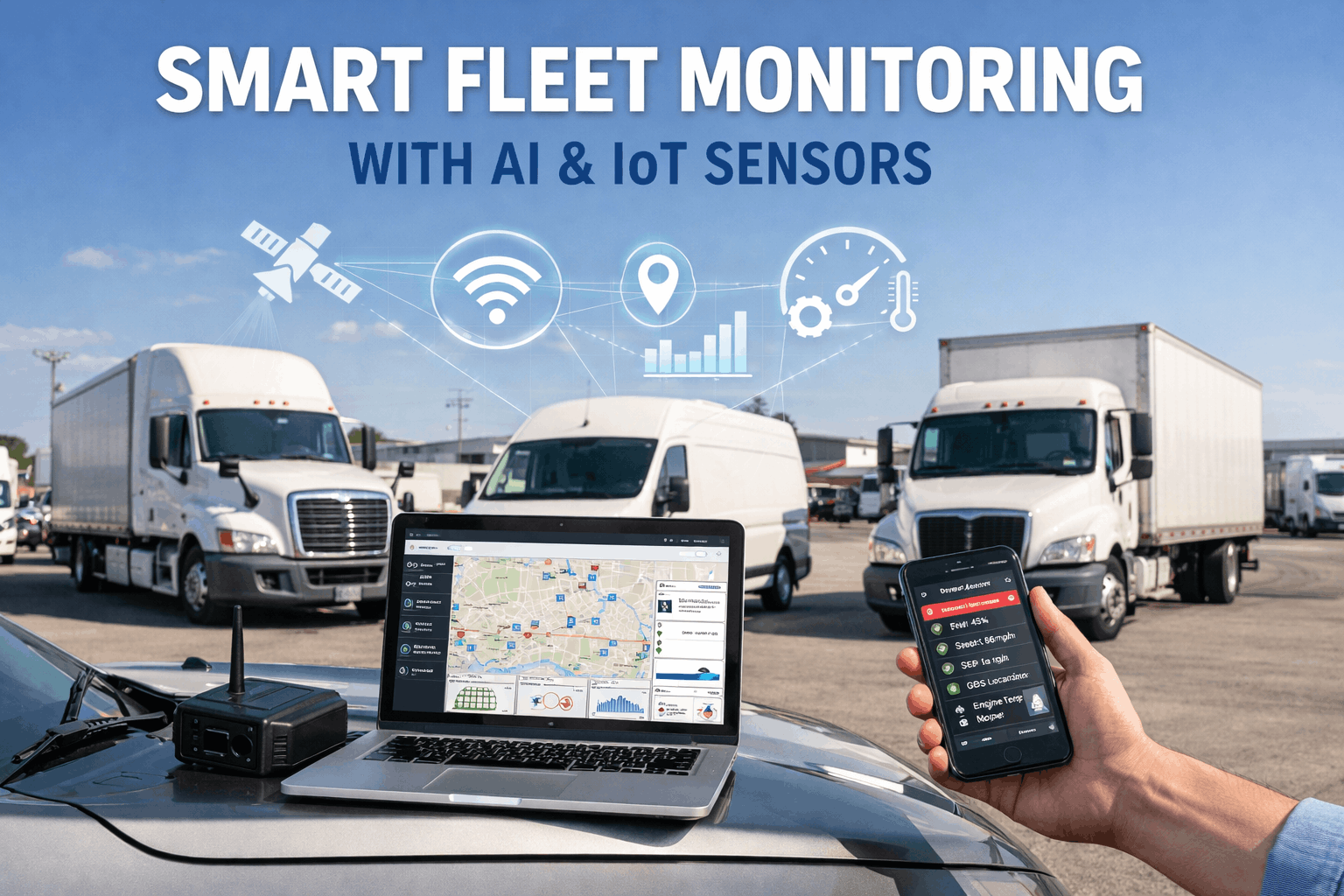

How does a digital twin differ from standard fleet telematics

Traditional telematics tells you what is happening right now — vehicle location, speed, and basic diagnostics. A digital twin goes far beyond this by creating a comprehensive model that processes historical patterns, real-time data, and environmental factors through AI to predict what will happen next. It shifts fleet maintenance from descriptive analytics to prescriptive and predictive intelligence, recommending specific actions before problems materialize.

How does OxMaint support digital twin integration

OxMaint serves as the operational backbone that translates digital twin insights into action. The platform supports automated work order generation from predictive alerts, intelligent maintenance scheduling, asset lifecycle tracking, parts inventory management, and compliance documentation. By centralizing all maintenance data in OxMaint, you create the data foundation that continuously improves your digital twin's accuracy and predictive capabilities. Book a demo to see this integration in action.