This guide provides a complete framework for conducting DEF (Diesel Exhaust Fluid) system inspections, documenting findings with standardized report templates, and maintaining SCR (Selective Catalytic Reduction) compliance across your fleet. Oxmaint's inspection management platform streamlines DEF system checks with digital checklists, automated reporting, and compliance tracking that keeps every vehicle running clean and within regulatory standards.

Why Structured DEF Inspections Matter

Critical DEF System Components to Inspect

A thorough DEF system inspection covers every component in the aftertreatment chain. Each element plays a vital role in emissions reduction, and overlooking even one can trigger fault codes, derating events, or costly catalyst damage. Here are the six core areas your inspection must address.

DEF Tank & Level Sensor

Inspect tank for cracks, leaks, and contamination. Verify level sensor accuracy against actual fluid volume and check cap seal integrity.

Supply Lines & Fittings

Examine all hoses, connectors, and heated lines for crystallization buildup, kinks, abrasion damage, and proper heating element function.

DEF Pump & Pressure Module

Test pump operation, verify pressure output within OEM specifications, and check for air leaks that compromise dosing accuracy.

Dosing Injector & Nozzle

Assess injector spray pattern, inspect for crystalline deposits or carbon fouling, and verify mounting integrity at the exhaust pipe.

SCR Catalyst & Housing

Check catalyst substrate for cracking, contamination, or thermal damage. Inspect mounting brackets, gaskets, and exhaust connections for leaks.

NOx Sensors & Controls

Validate upstream and downstream NOx sensor readings, verify DEF quality sensor function, and scan for stored diagnostic trouble codes.

Paper Reports vs Digital Inspection Templates

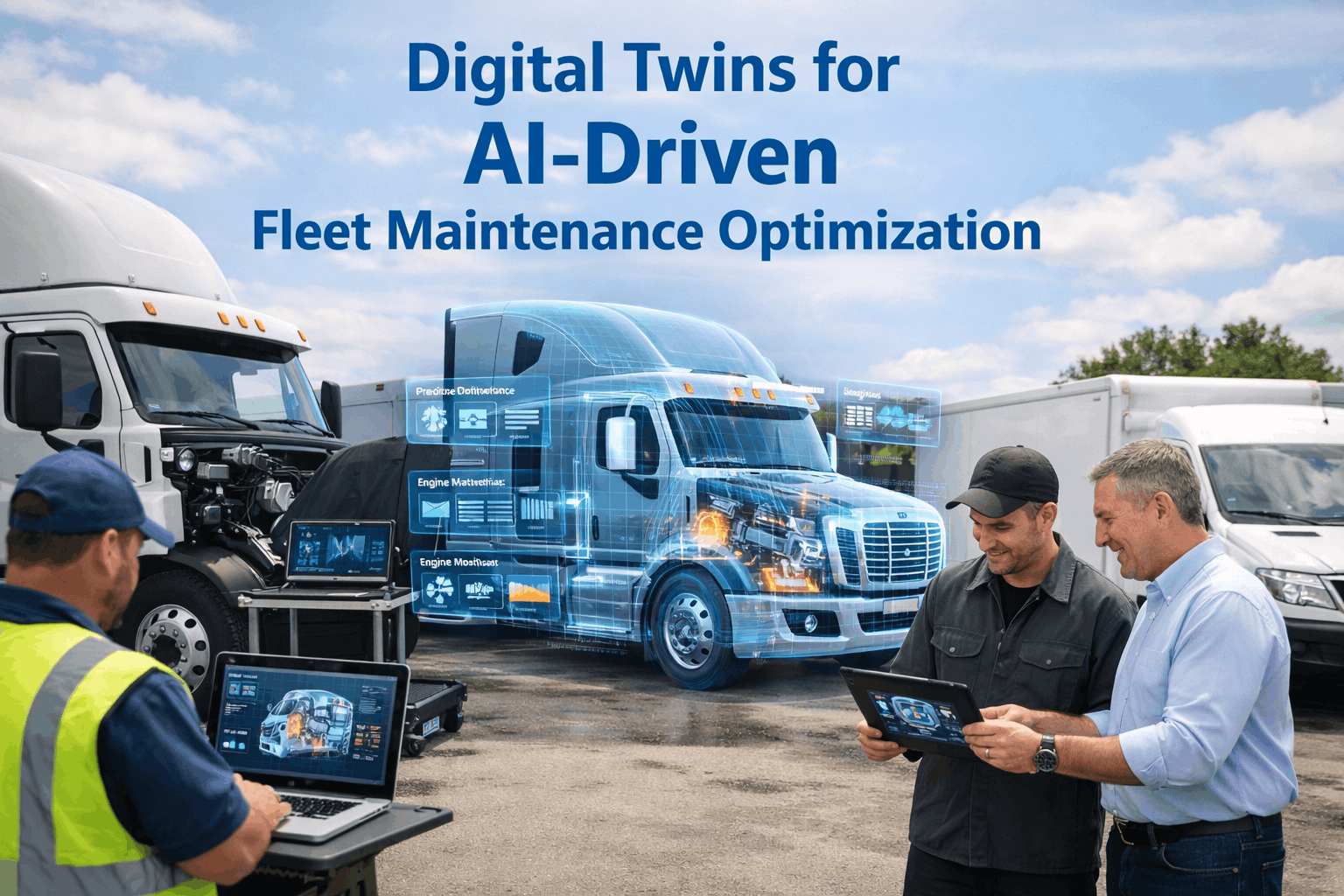

How Oxmaint Streamlines DEF Inspections

Configure Custom Inspection Templates

Build DEF-specific inspection checklists tailored to your fleet's vehicle makes, engine types, and aftertreatment configurations using Oxmaint's drag-and-drop template builder.

Schedule & Assign Inspections

Set recurring DEF system inspections based on mileage intervals, engine hours, or calendar schedules. Assign technicians automatically and send mobile notifications when inspections are due.

Execute with Mobile Checklists

Technicians complete inspections on smartphones or tablets with guided step-by-step workflows, mandatory photo captures, pass/fail scoring, and real-time data validation.

Generate Reports & Track Corrective Actions

Inspection reports are generated automatically with all findings, photos, and recommendations. Failed items trigger work orders instantly. Signup to start building your DEF inspection workflows.

Inspection Coverage by DEF Component

Consistent inspection depth across all DEF subsystems is essential for preventing unplanned failures. The following data reflects coverage benchmarks for fleets that have adopted standardized digital inspection programs.

What Your DEF Inspection Report Should Include

Combining thorough inspection reports with component failure tracking and root cause analysis workflows builds a comprehensive maintenance strategy that addresses both symptoms and underlying system issues.

Frequently Asked Questions

What should be included in a standard DEF system inspection checklist

A comprehensive DEF inspection checklist should cover the DEF tank condition and fluid level, supply line integrity and heating elements, pump pressure and operation, dosing injector spray pattern and deposits, SCR catalyst condition, NOx sensor readings, DEF quality concentration, and a scan for active or stored aftertreatment fault codes. Each item should have pass/fail criteria and space for notes and photo documentation.

How often should DEF system inspections be performed

Most fleet maintenance programs recommend DEF system inspections every 10,000 to 15,000 miles or at each preventive maintenance interval, whichever comes first. Vehicles operating in extreme temperatures, dusty environments, or with high idle times may require more frequent inspections. Oxmaint allows you to set custom intervals based on mileage, engine hours, or calendar schedules.

What are the most common DEF system failures found during inspections

The most frequently identified issues include crystallization buildup in the dosing injector and supply lines, DEF quality degradation from contamination or age, faulty NOx sensors providing inaccurate readings, cracked or leaking supply lines especially at connection points, and DEF pump pressure loss. Early detection through routine inspections prevents these from escalating into derating events or catalyst damage.

How do digital inspection templates improve DEF maintenance compliance

Digital templates enforce consistency by requiring technicians to complete every checklist item before submission, capturing timestamped photo evidence, and automatically flagging failed components for follow-up. Completion rates and compliance metrics are tracked in real-time dashboards, making it easy for fleet managers to verify that all vehicles are inspected on schedule and deficiencies are resolved.

Can Oxmaint generate DEF inspection reports automatically

Oxmaint's platform automatically compiles inspection findings into professional reports that include component status, photos, fault codes, technician notes, and corrective action items. Reports can be exported as PDF, shared with stakeholders, or stored in the vehicle's digital maintenance history for audit readiness and regulatory compliance.

What happens when a DEF inspection reveals a critical deficiency

When a technician marks a component as failed during an Oxmaint inspection, the system immediately generates a work order with the deficiency details, associated photos, and priority level. Fleet managers receive instant notifications, and the vehicle can be flagged as out-of-service until repairs are completed. This closed-loop process ensures no critical finding goes unaddressed.